Patents

Literature

73results about How to "Easy to collect and reuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

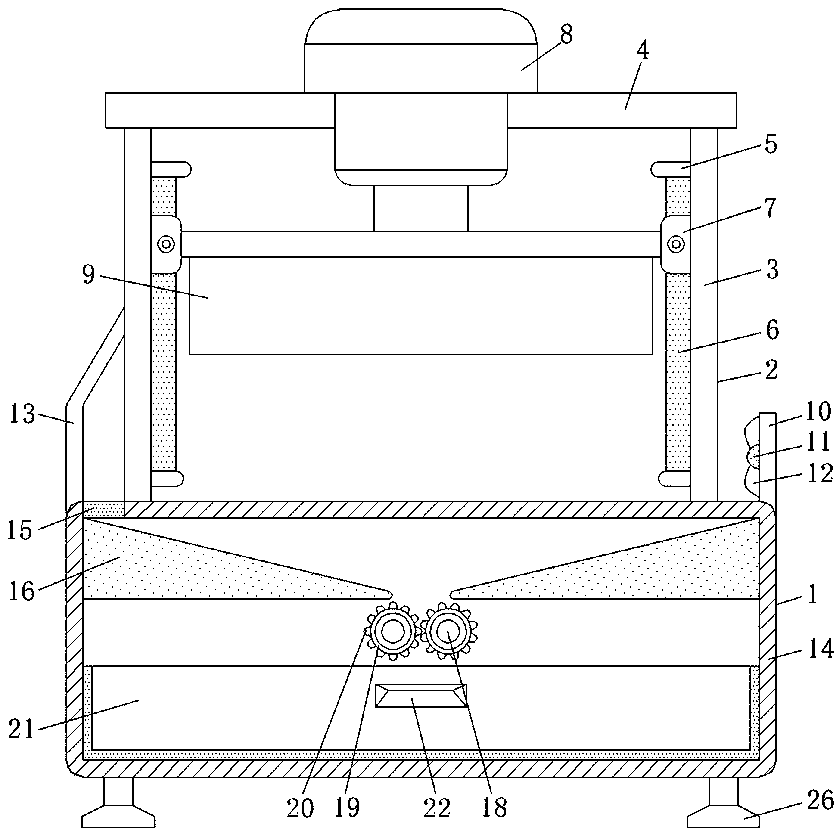

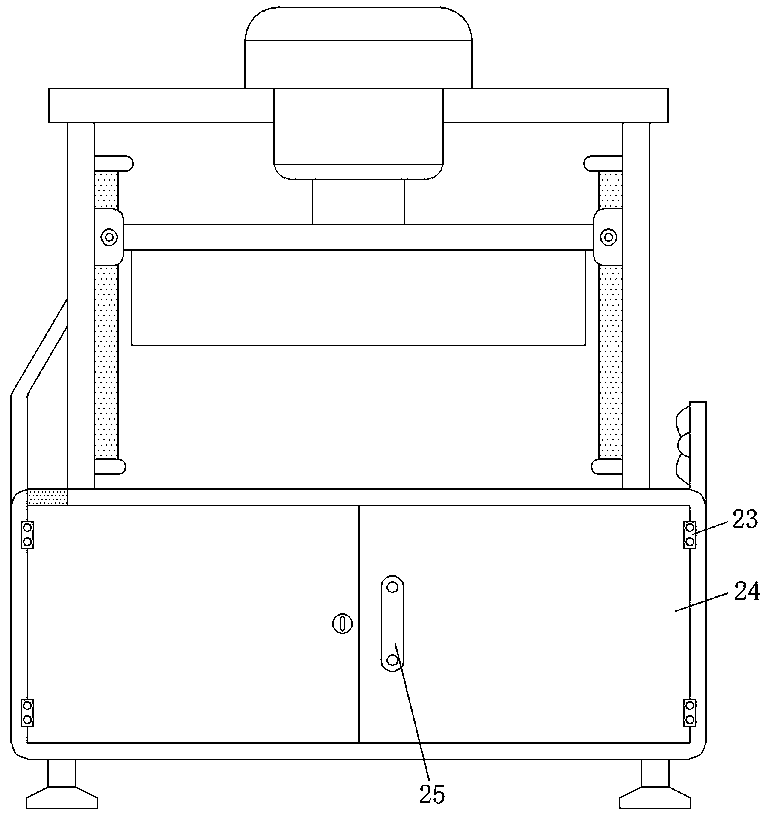

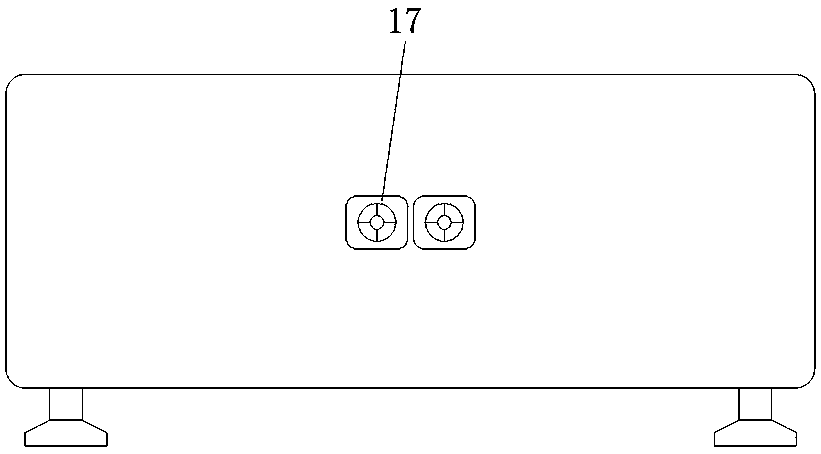

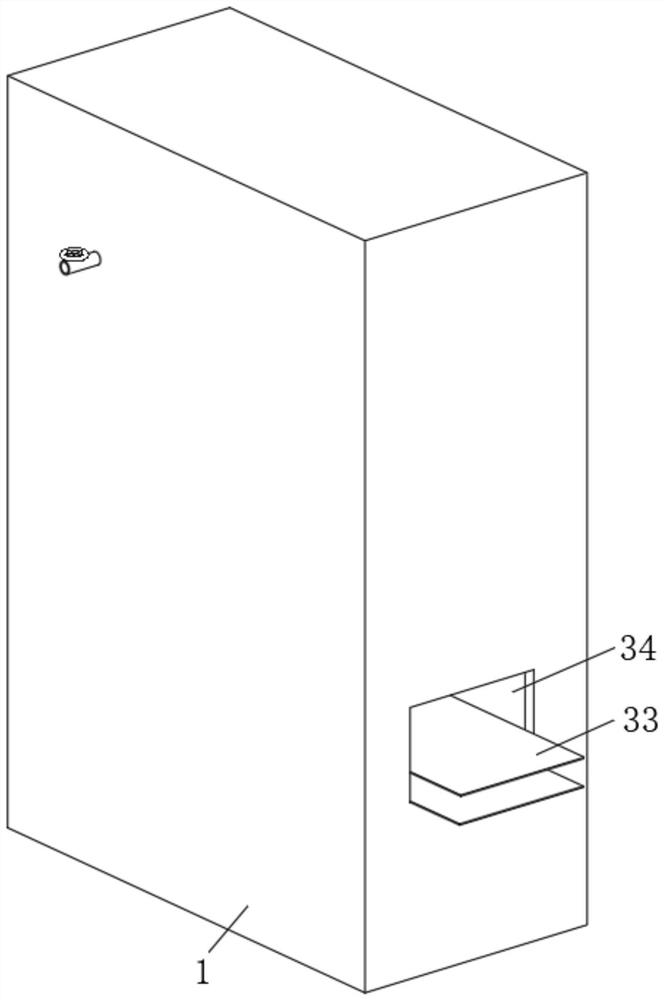

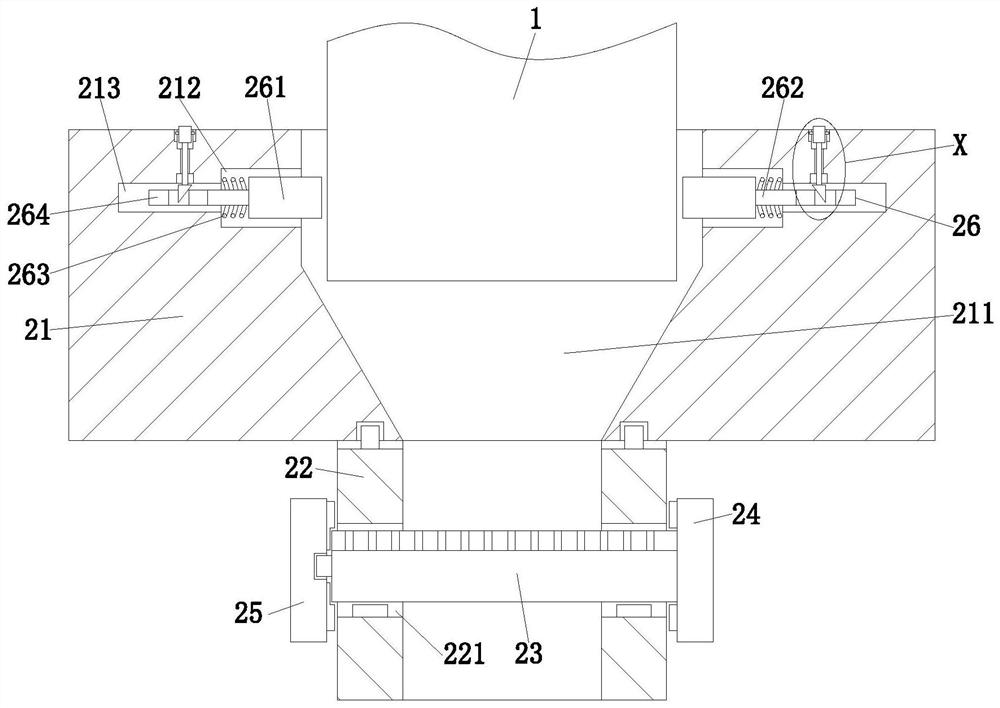

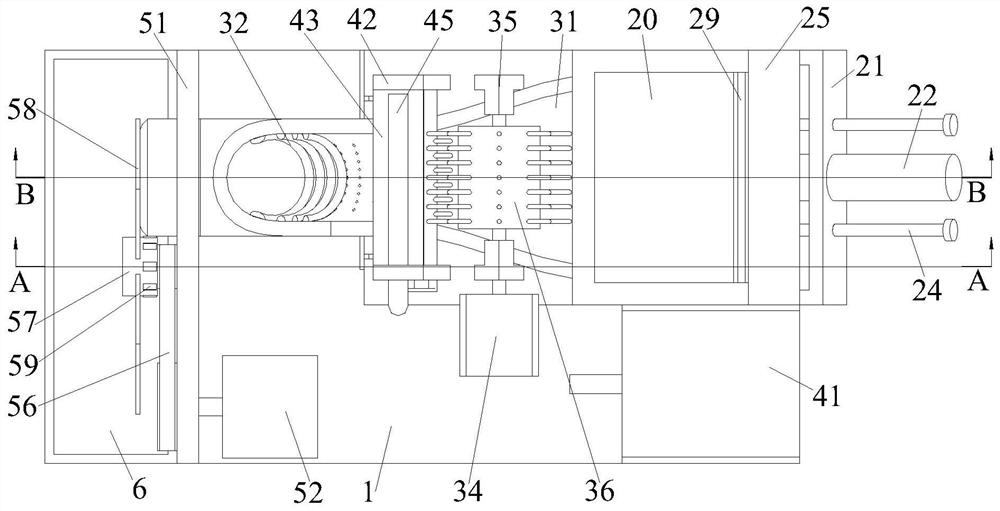

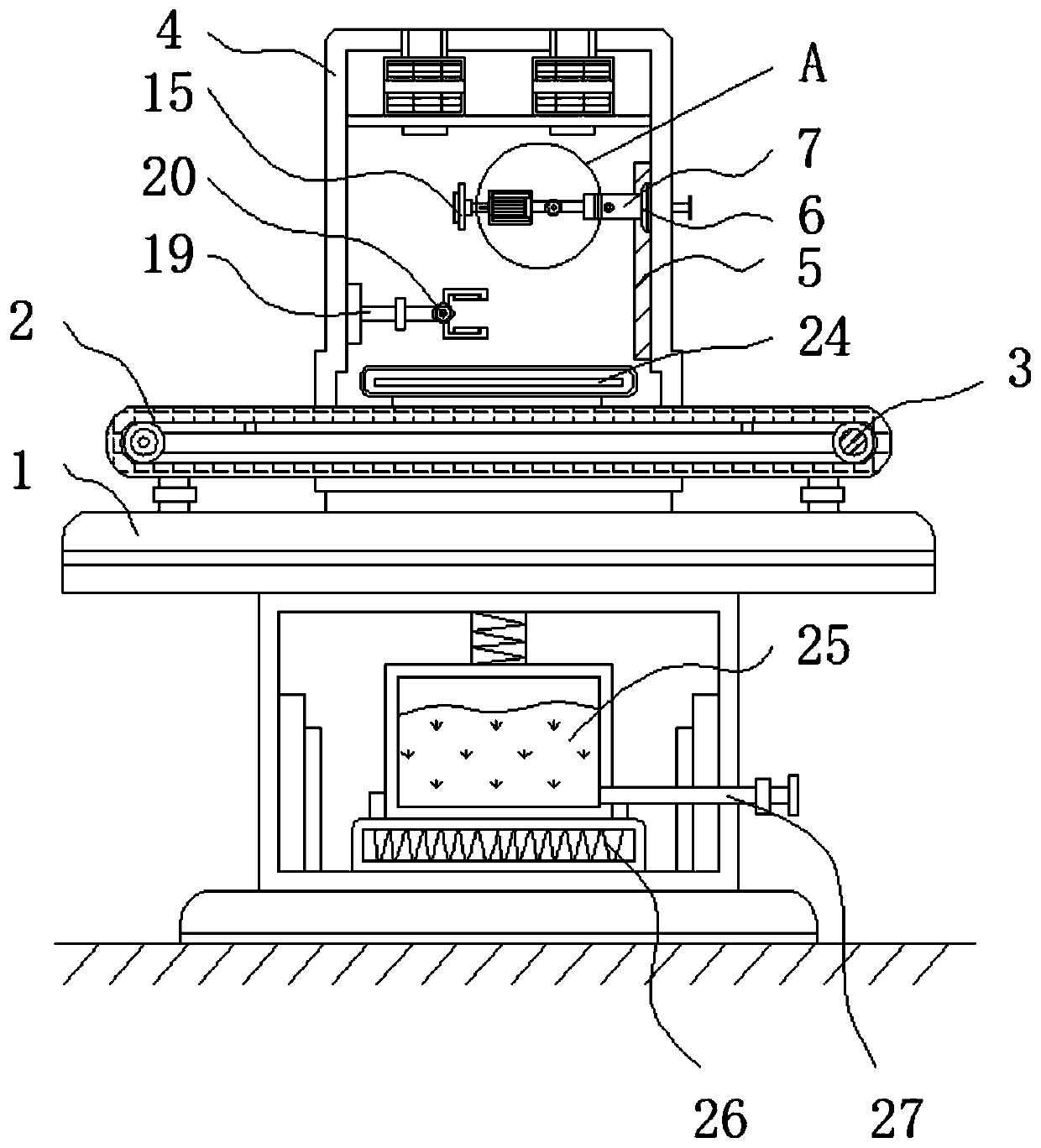

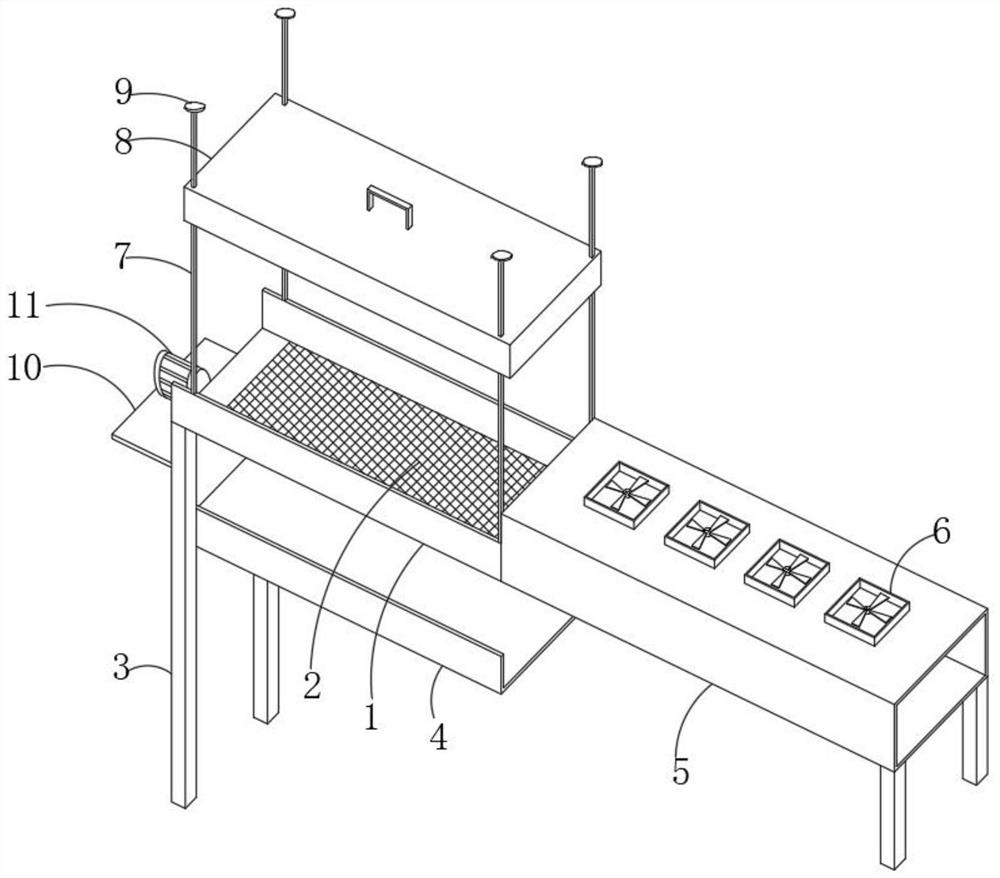

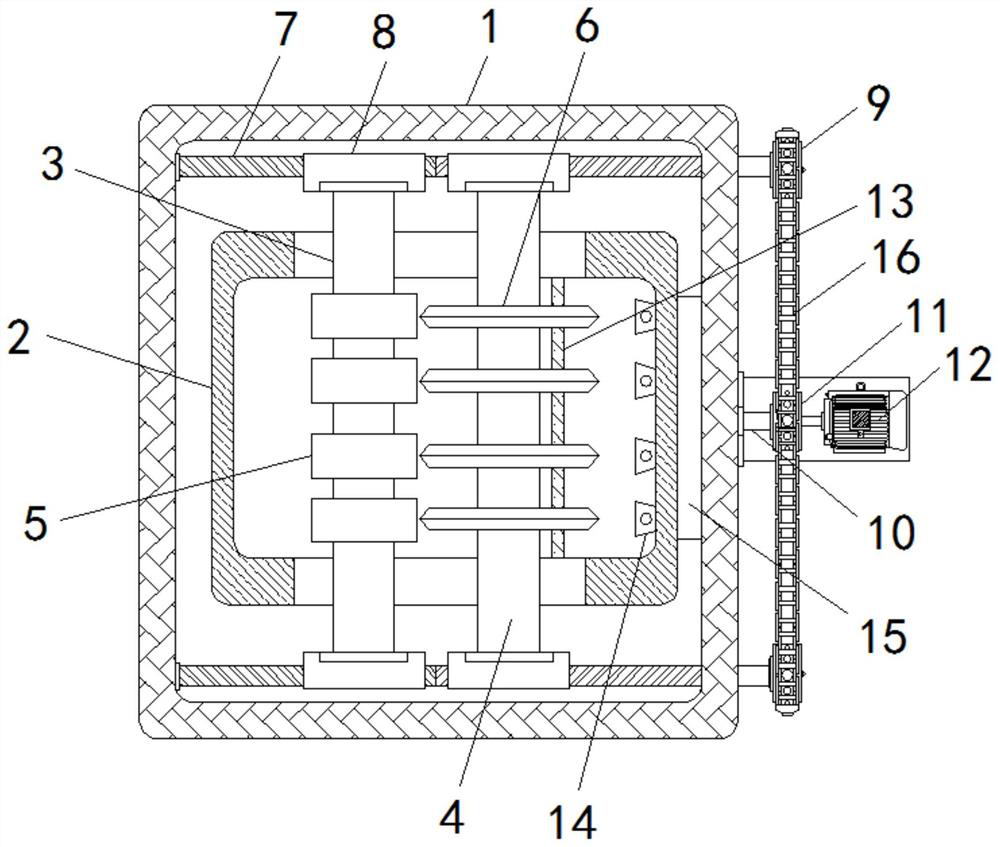

Waste recovery device for paper plate cutting

PendingCN110788914AEasy to collect and reuseAvoid safety hazardsGrain treatmentsMetal working apparatusEngineeringCardboard

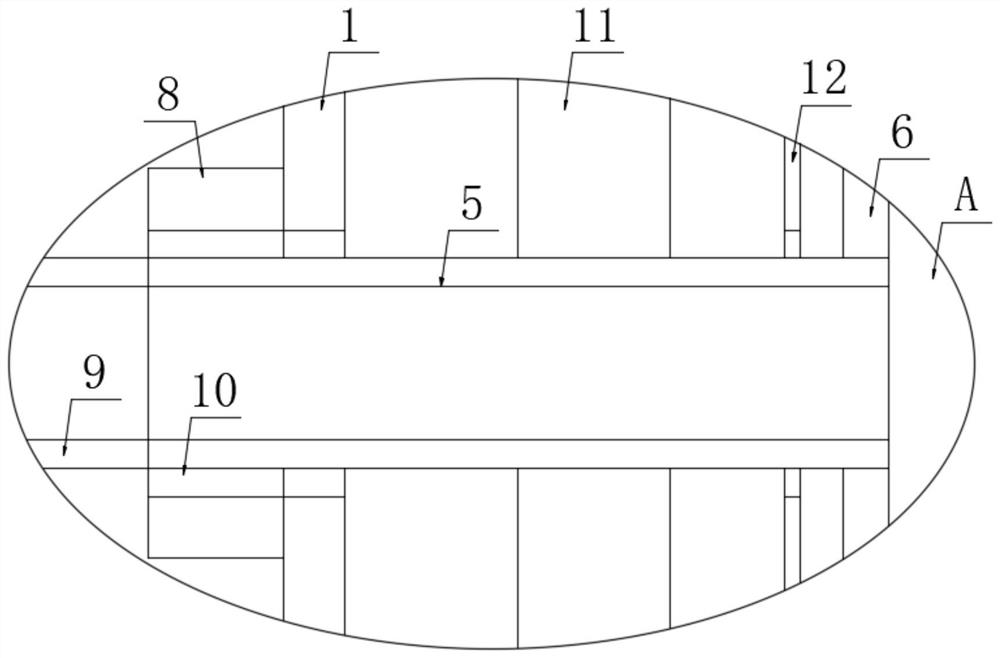

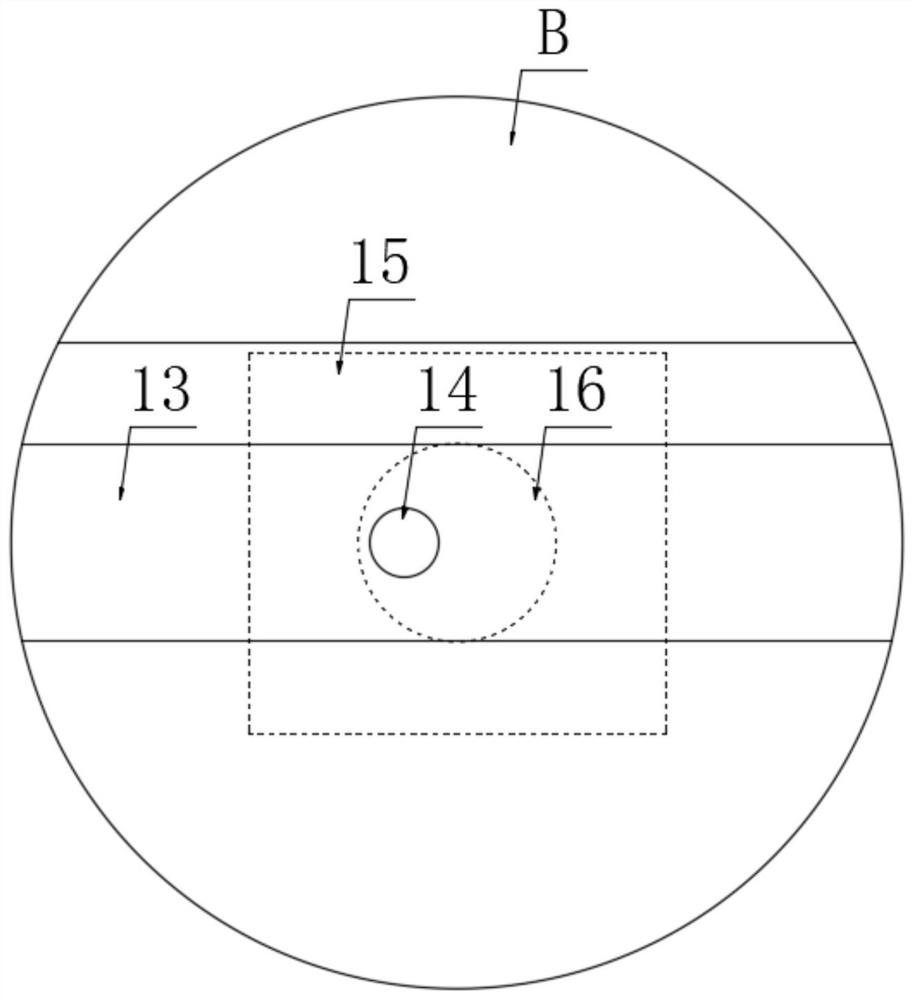

The invention discloses a waste recovery device for paper plate cutting. The waste recovery device for paper plate cutting comprises a treatment device and a cutting device, wherein the cutting deviceis arranged at the top of the treatment device. According to the waste recovery device for paper plate cutting, the arranged treatment device is capable of carrying out effective treatment on the cutleftover materials, collecting the leftover materials after breaking the leftover materials, and effectively reducing lots of space waste, so that collection and reutilization for the leftover materials are facilitated; through the mutual cooperation of a first servo motor, fan blades, a baffle and a collection port, the leftover materials on the surface of a treatment box can be blown into the treatment box, and an operator does not need to manually collect the leftover materials, so that the occurrence of potential safety hazards is avoided; through arrangement for the cutting device with alimit block and a guide rail, a cutting knife can be effectively limited, and the occurrence of the case of a cutting displacement of the cutting knife is avoided; and moreover, the waste recovery device for paper plate cutting is reasonable in structure, and convenient to use.

Owner:安徽本色印刷有限公司

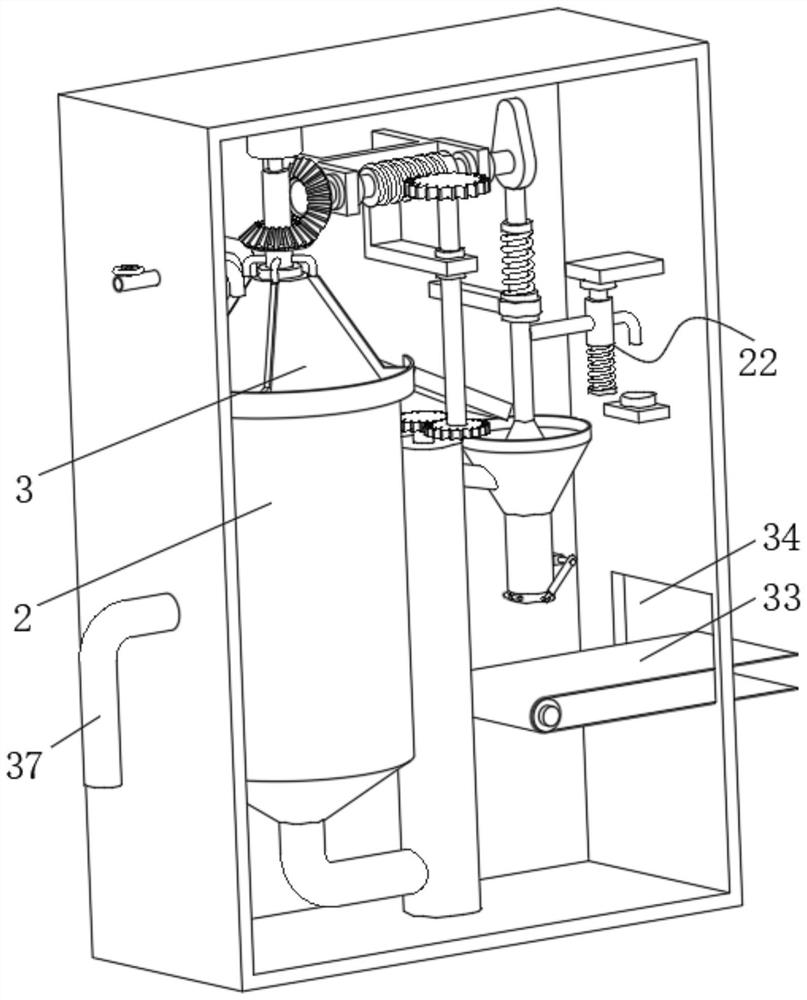

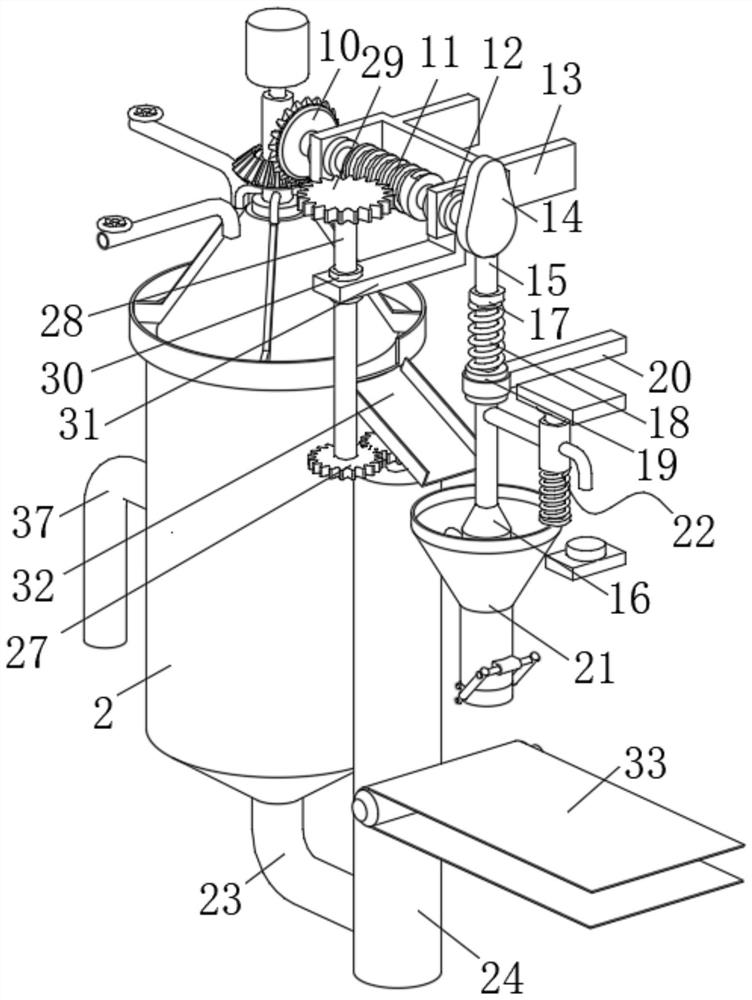

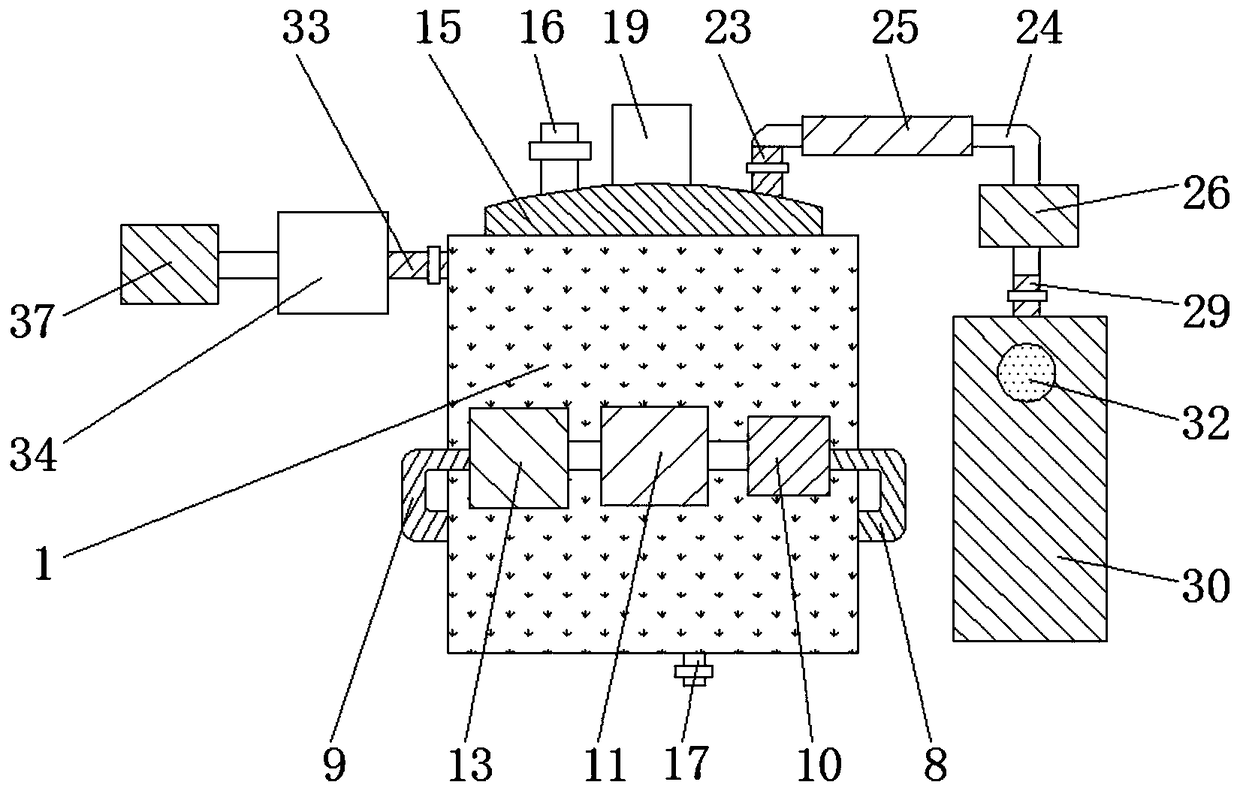

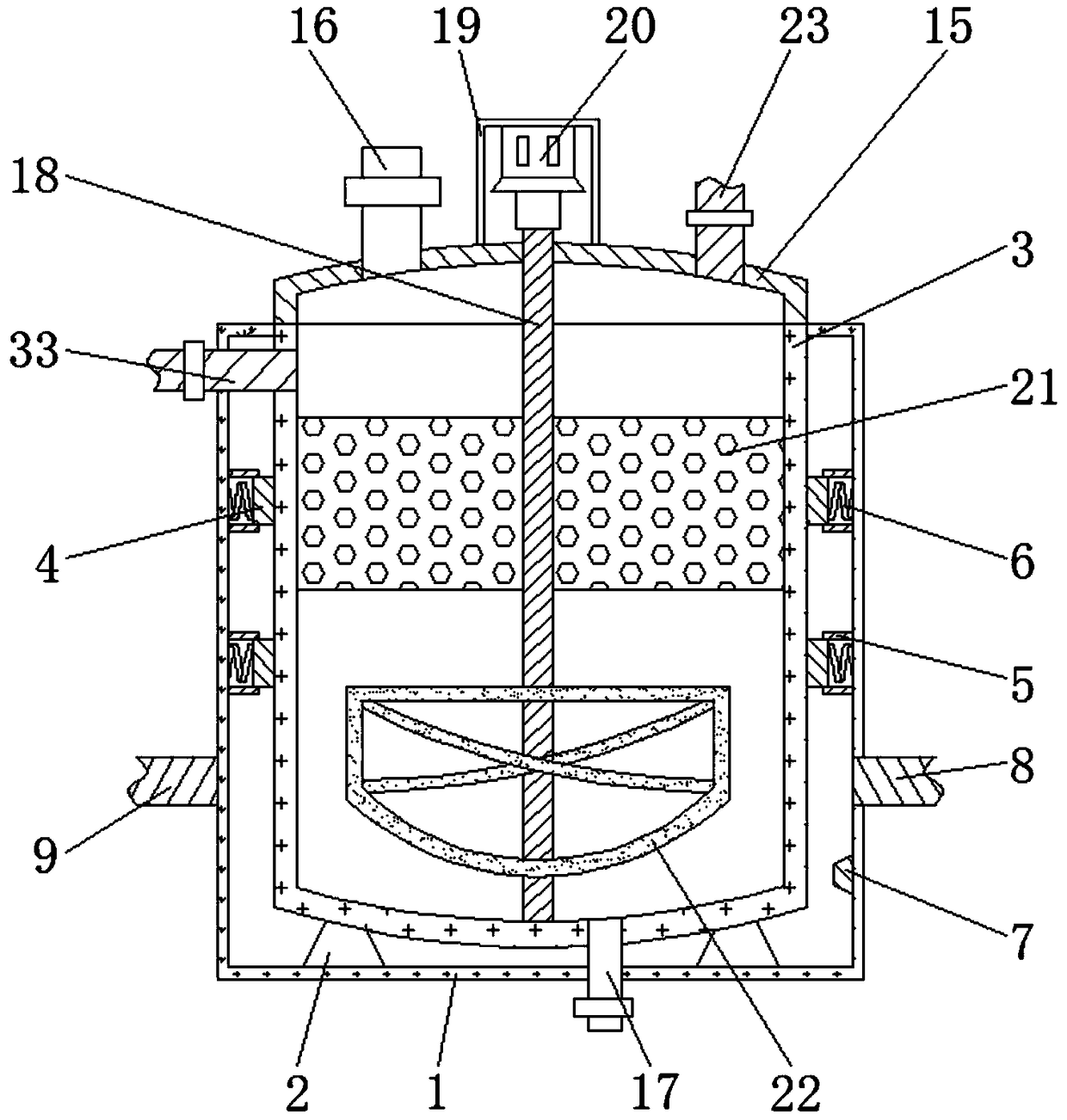

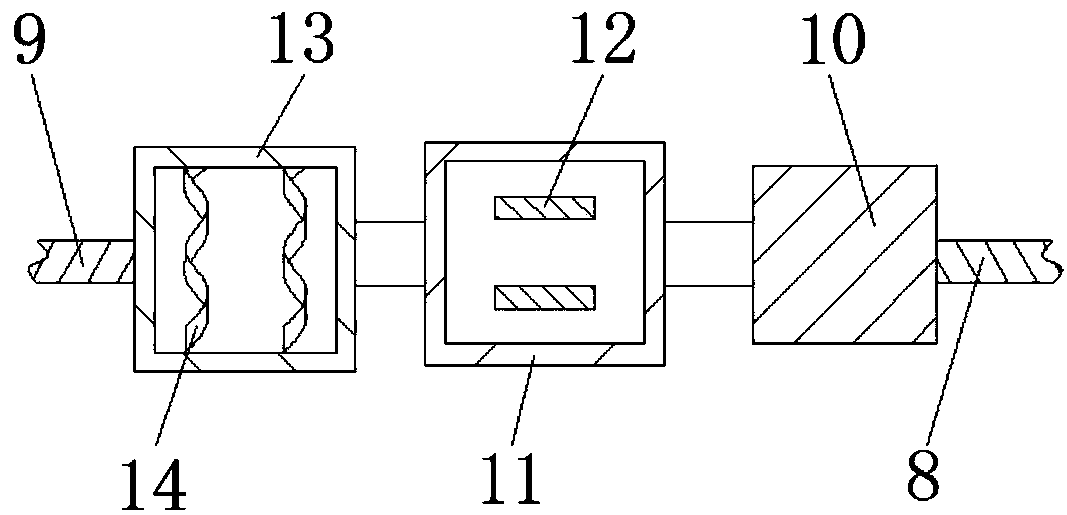

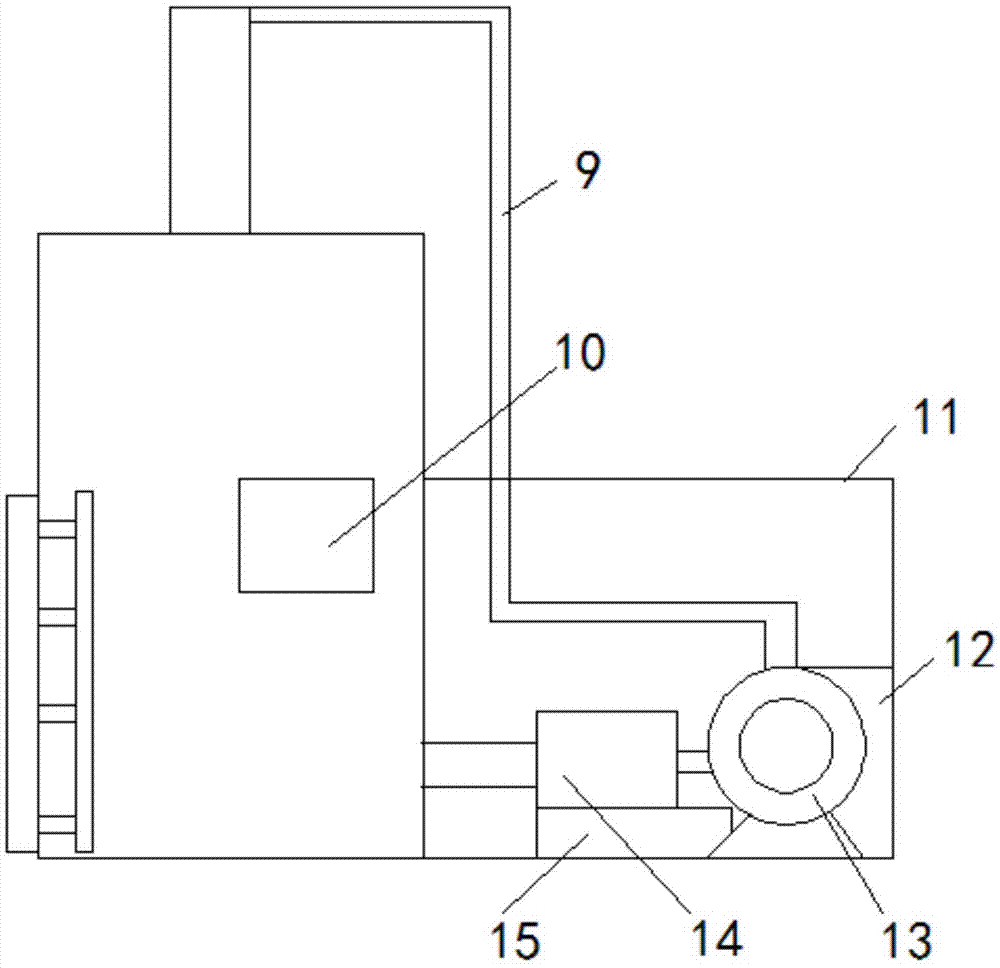

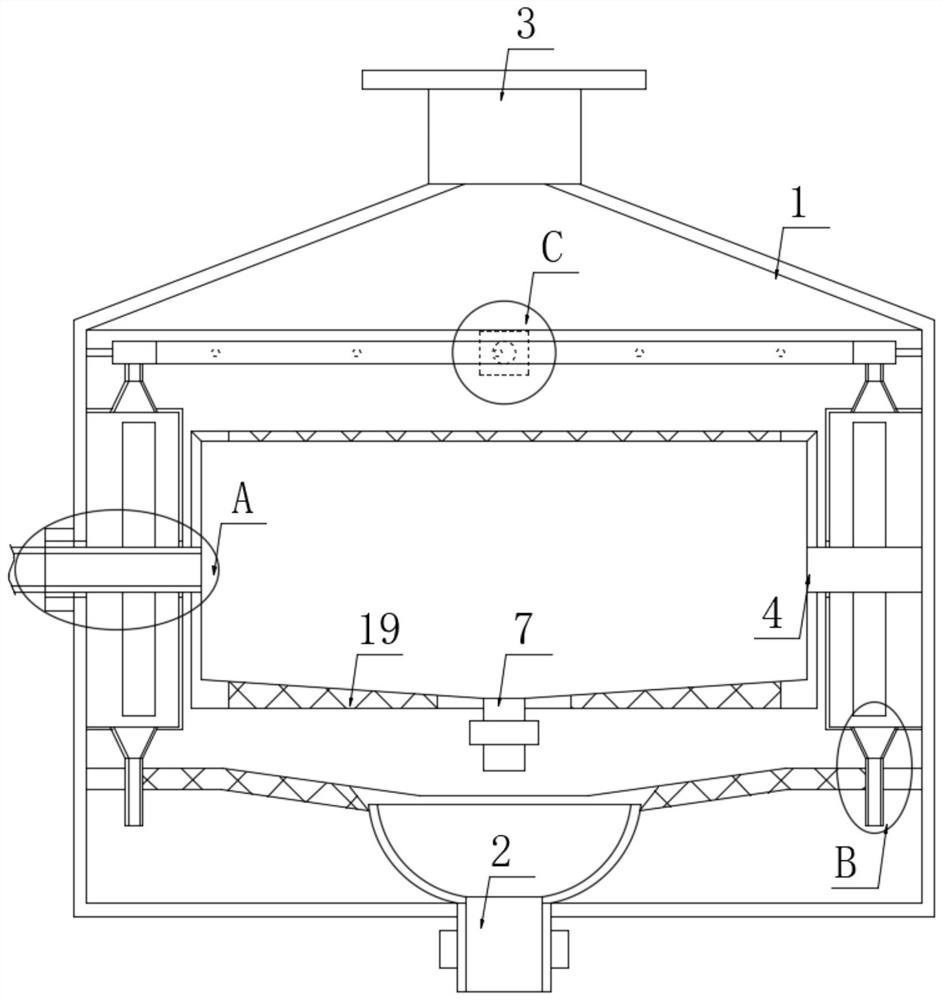

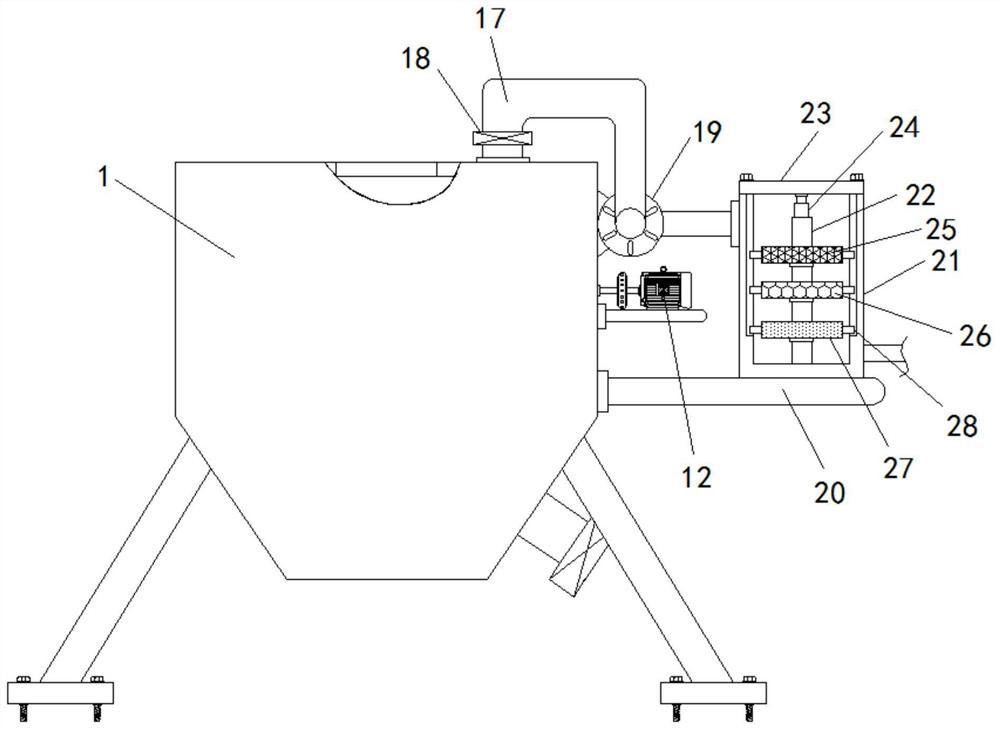

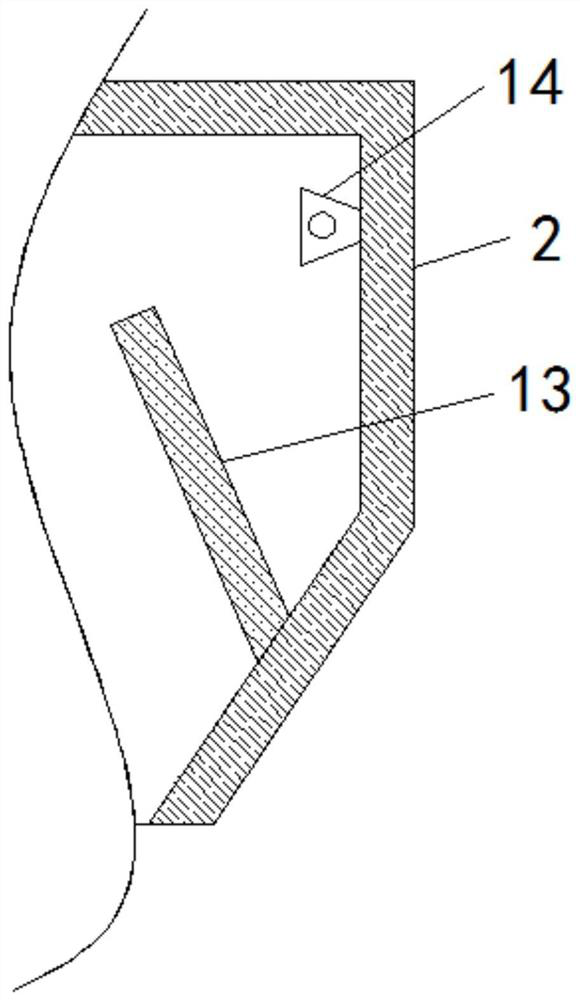

Industrial sewage and waste residue treatment device

InactiveCN111792747ANo cloggingEasy to collectSludge treatmentSpecific water treatment objectivesFiltrationElectric machine

The invention discloses an industrial sewage and waste residue treatment device, and belongs to the technical field of sewage treatment. The device comprises a box body, wherein a precipitation tank is mounted in the box body, the top of the precipitation tank is fixedly connected with a filtering hopper, an annular groove is fixedly connected to the edge of the filtering hopper, a discharging notch is formed in the outer side wall of the annular groove, a bearing a is fixedly connected to the top surface of the filtering hopper in an embedded mode, and is rotatably connected to the bottom endof a rotating shaft, the top end of the rotating shaft is fixedly connected with the output shaft of a driving motor, and the driving motor is installed on the top surface of the interior of the boxbody. According to the invention, all power of the treatment device is provided by one driving motor and two hydraulic rods, so that electric driving components are reduced, the manufacturing cost isreduced, the overall linkage performance is good, and the automation degree is high; and the device has the functions of primary filtration, secondary filtration, automatic compression, discharging, conveying and the like of waste residues, is diversified in function, reduces subsequent waste residue treatment steps, has good practicability, and is worthy of application and popularization.

Owner:陈平

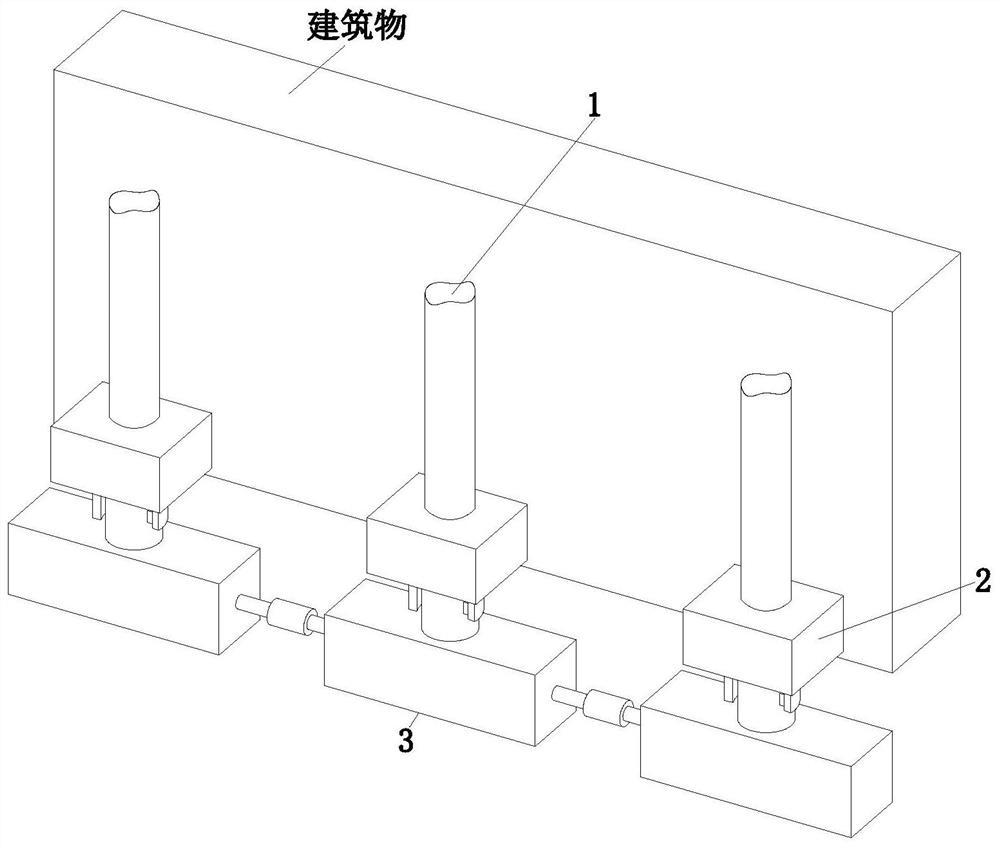

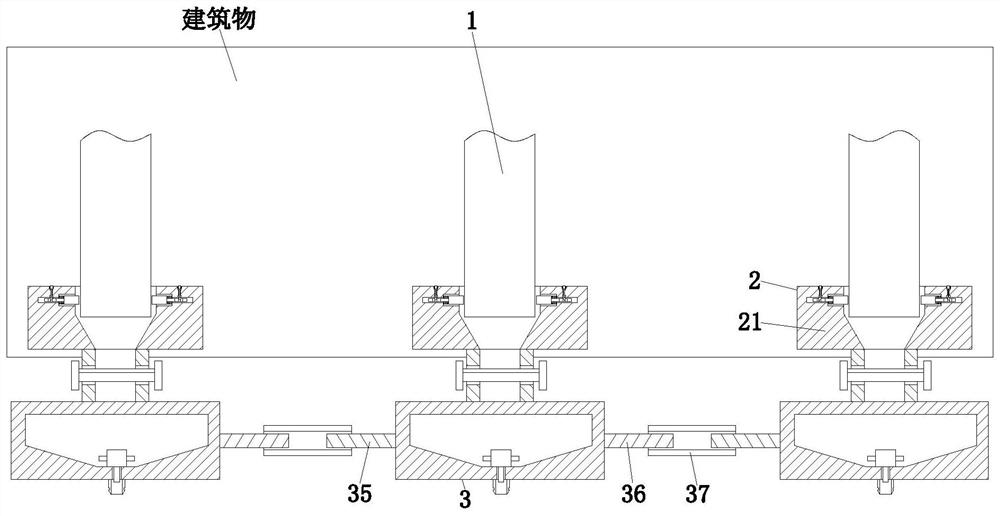

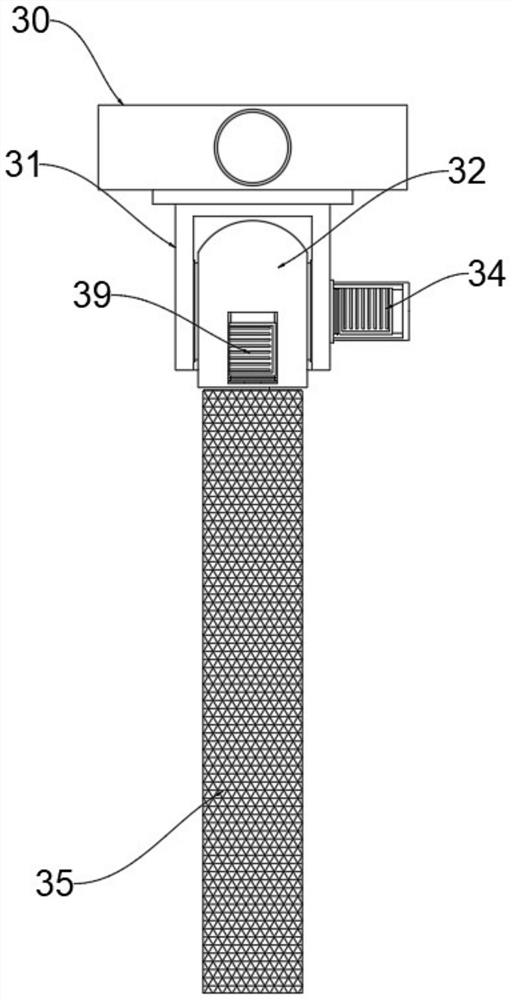

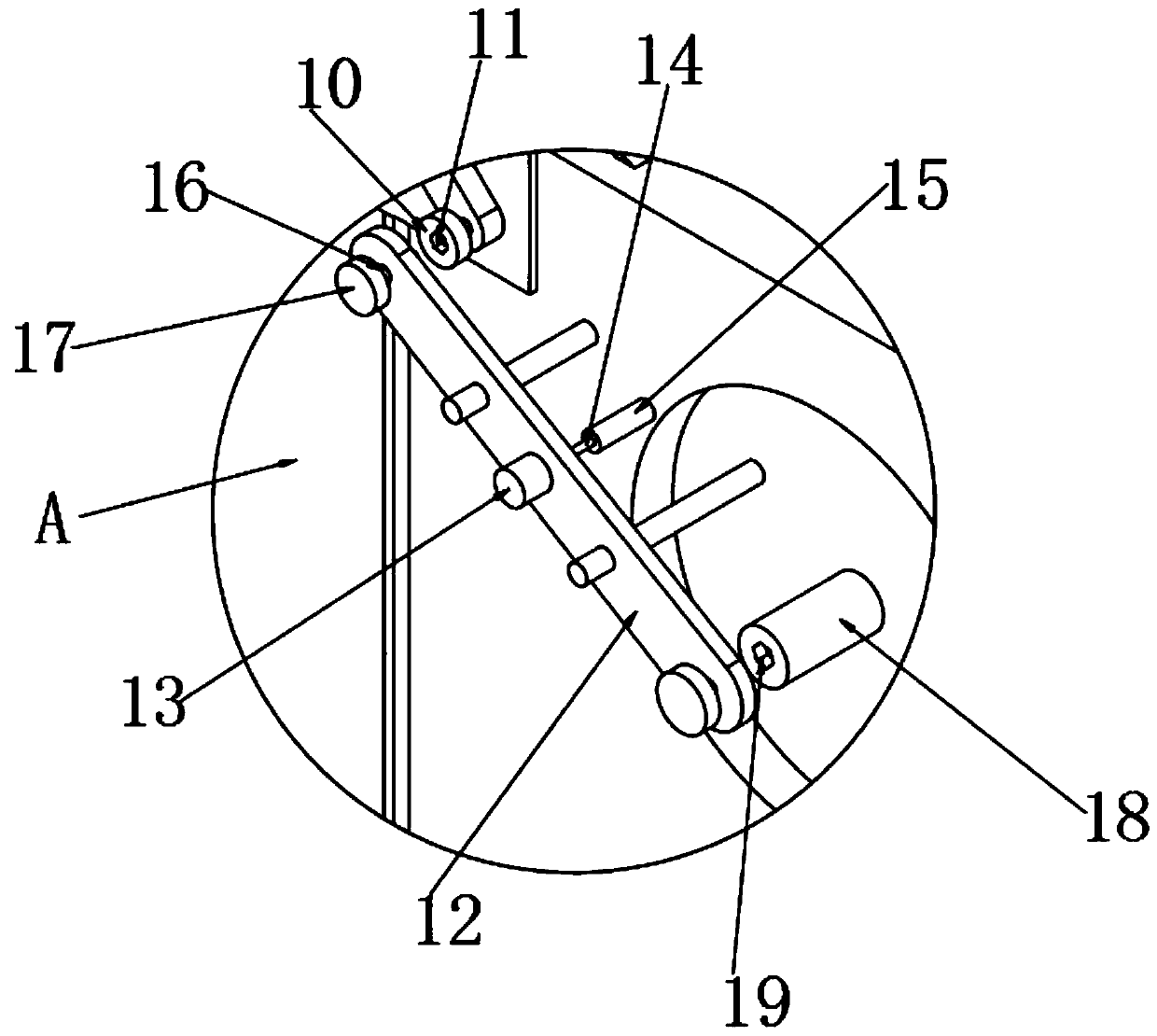

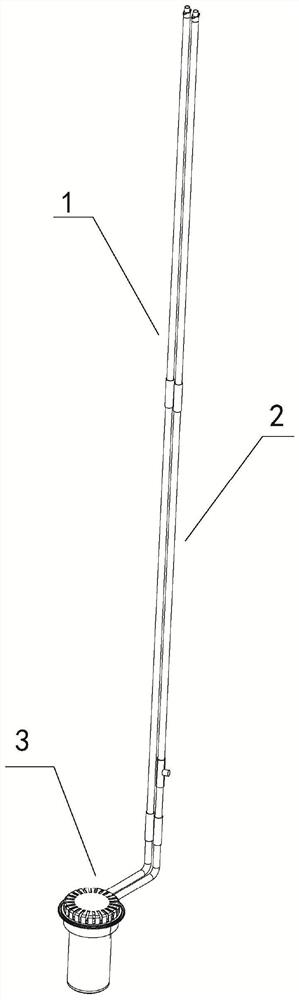

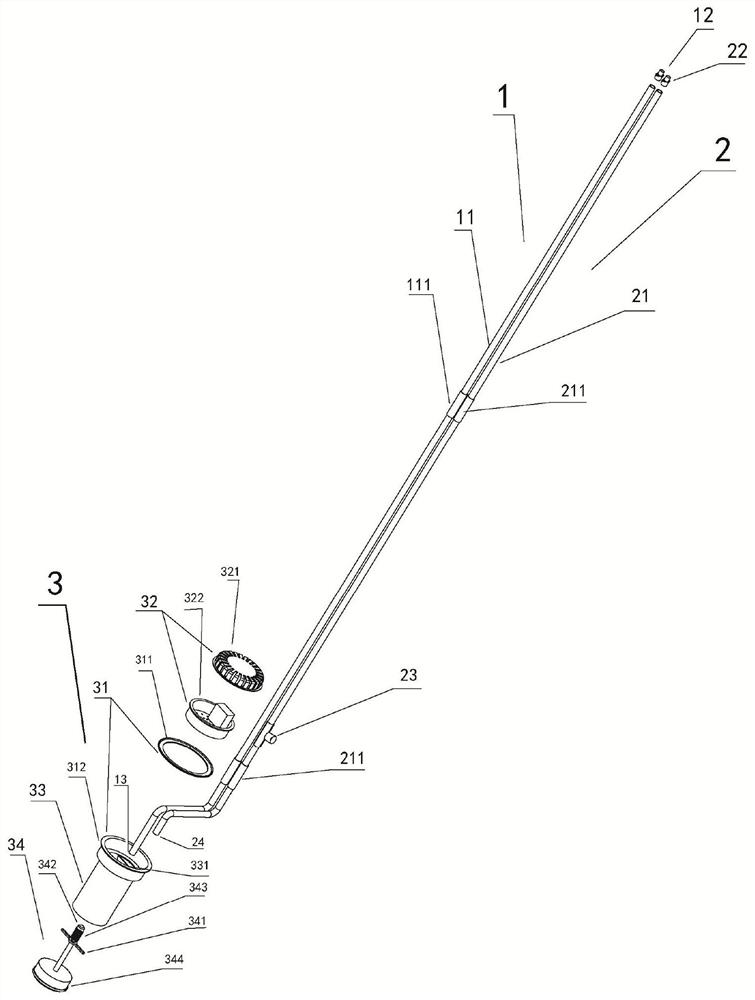

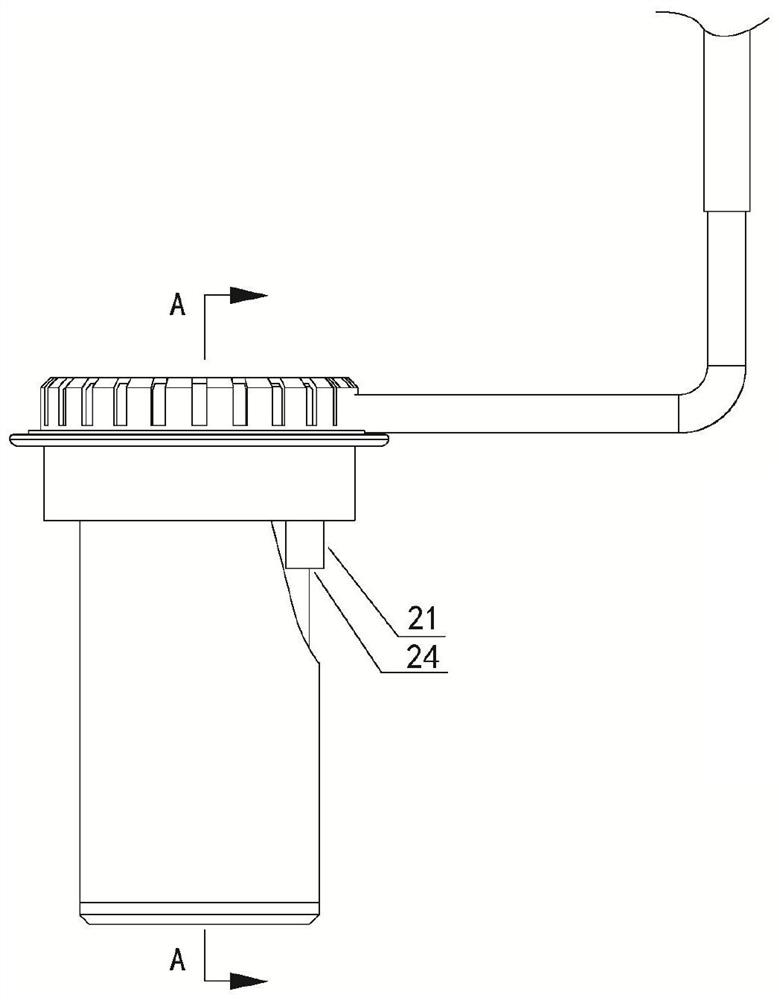

Automatic treatment device for collecting and recycling rainwater

ActiveCN113089770AEasy to collect and storeEasy to reuseFatty/oily/floating substances removal devicesSewerage structuresAgricultural cropsStormwater

The invention provides an automatic treatment device for collecting and recycling rainwater. The automatic treatment device comprises a drainage pipe, a connecting unit and a filtering unit, the drainage pipe is installed at a drainage port of a building, the connecting unit is arranged at the lower end of the drainage pipe, and the filtering unit is arranged along the lower end of the connecting unit. The automatic treatment device can solve the problems that when the rainwater is generally collected, the rainwater mostly flows into a water collection cavity through a drainage pipe, the drainage pipe and the water collection cavity cannot be fixed, so that the rainwater is likely to splash out, the rainwater needs to be manually transferred into a water storage pond, the rainwater in the water collection cavity cannot be completely drained, therefore, the rainwater easily corrodes the inner wall of the water collection cavity, at present, most of the rainwater is not filtered after being collected and is directly put into use, and as the rainwater contains a large number of micro elements and is not suitable for crops, and impurities are easily doped in the rainwater in the collection process, the crops are easily damaged, and the like.

Owner:NANJING FORESTRY UNIV

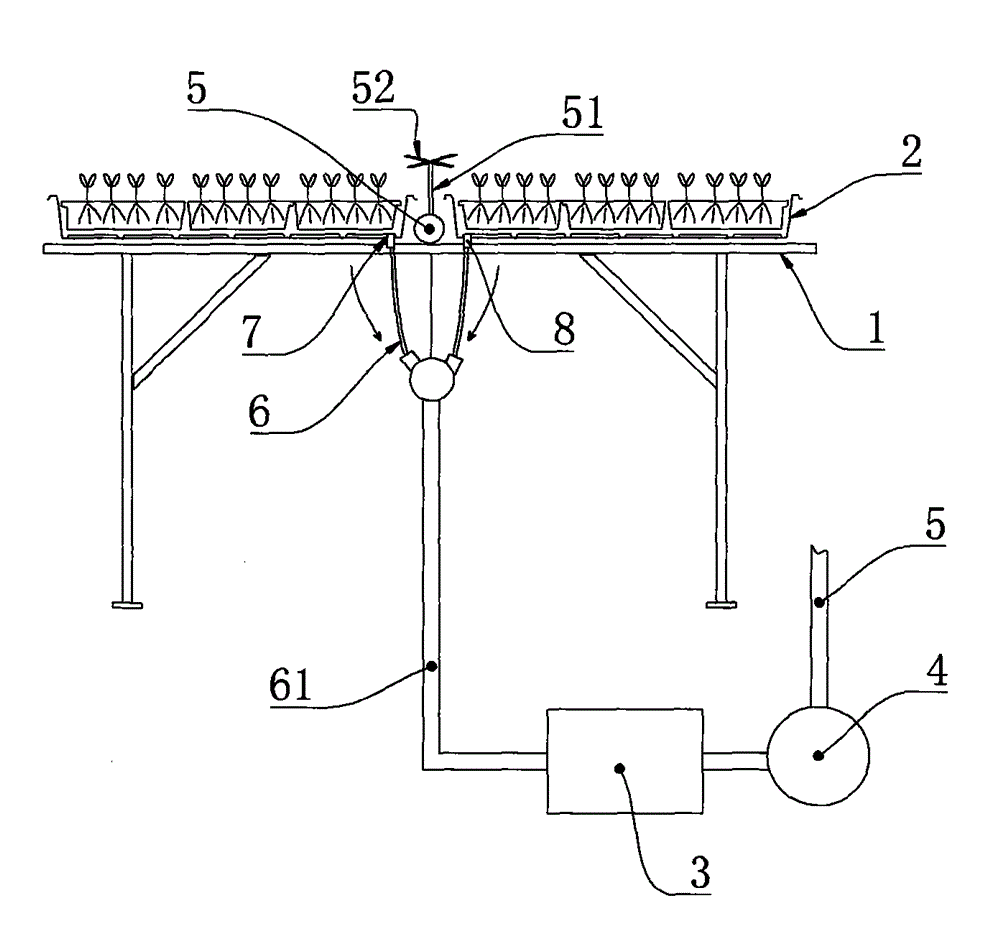

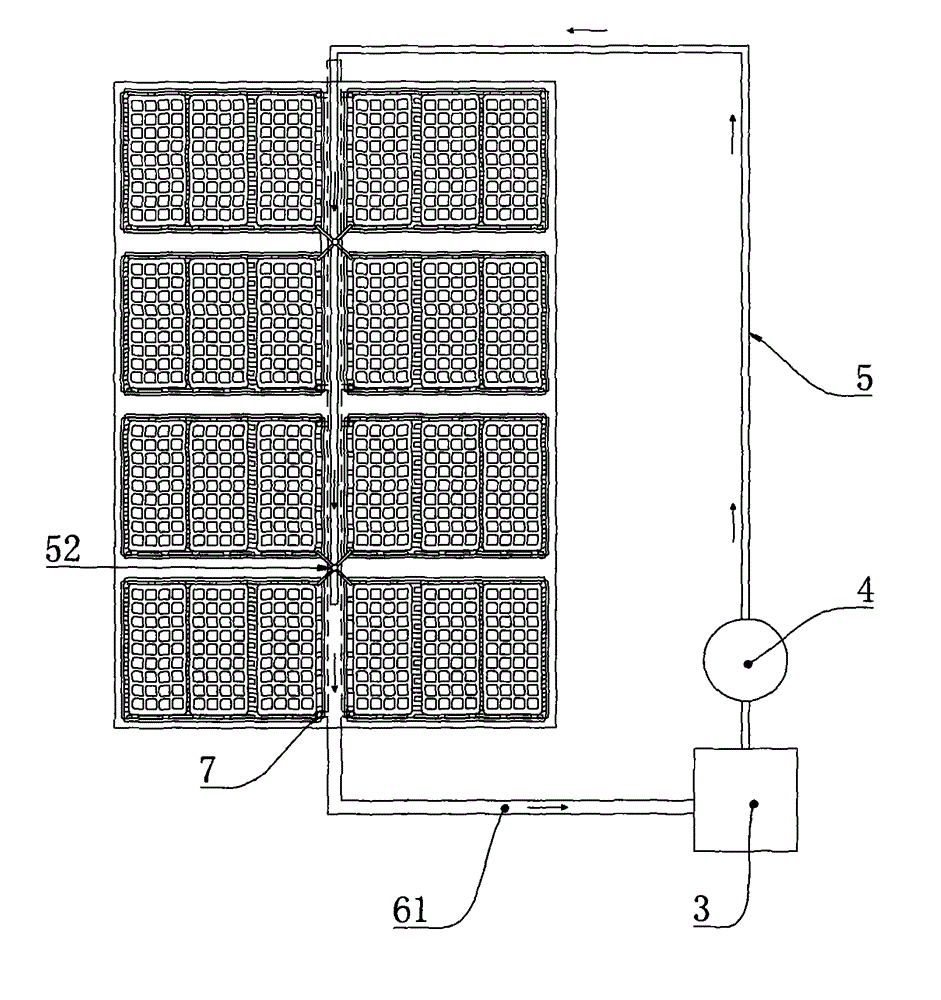

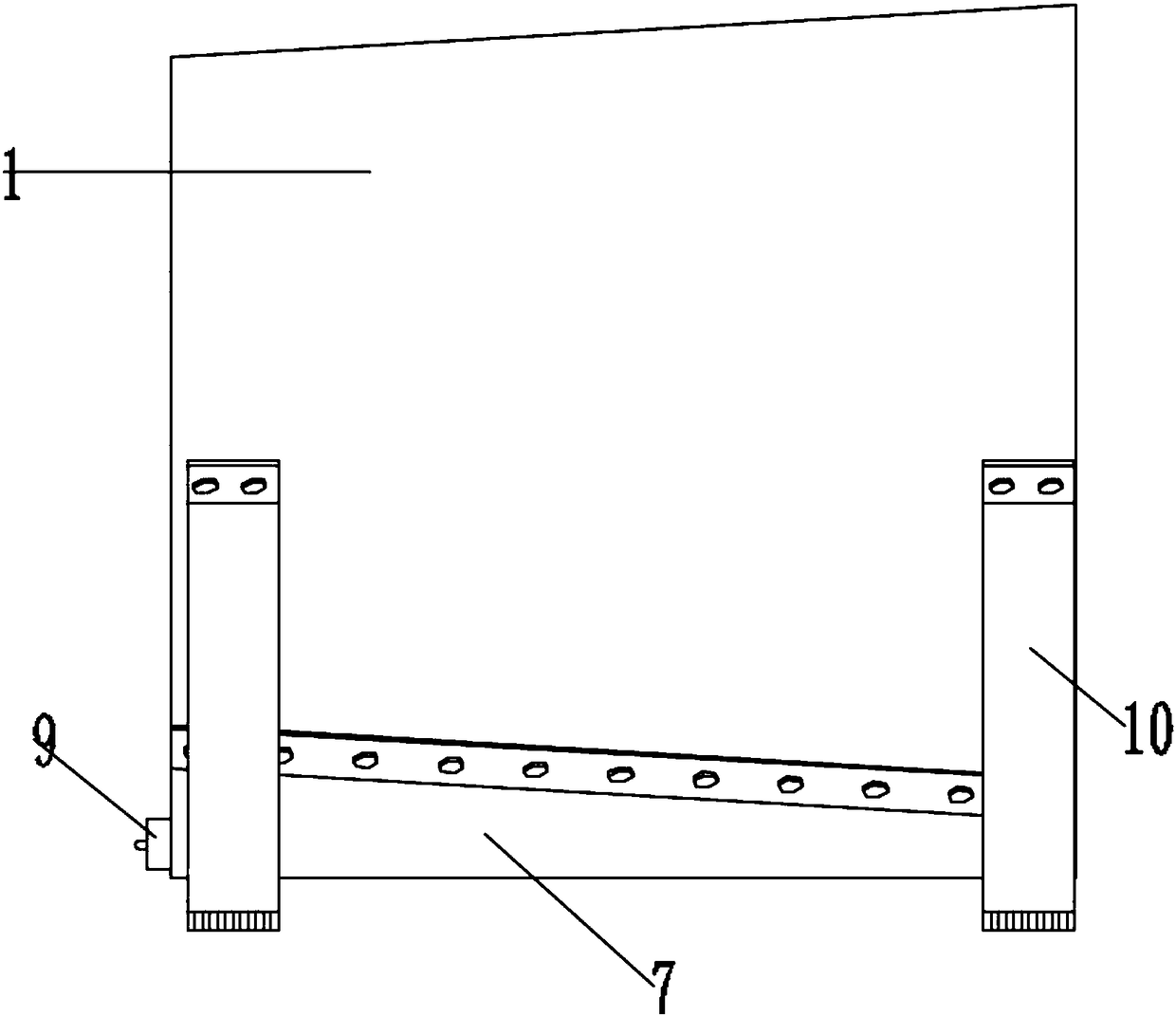

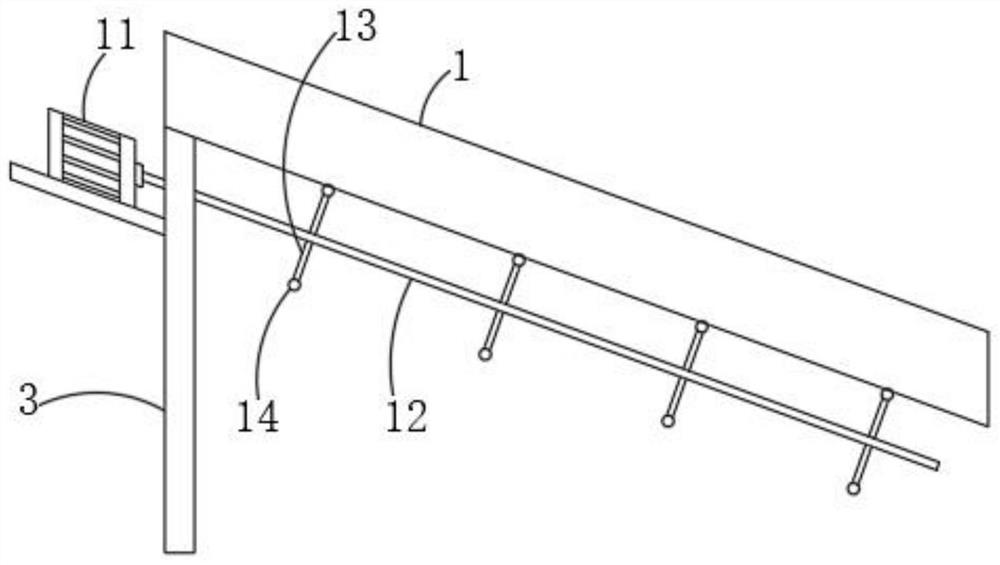

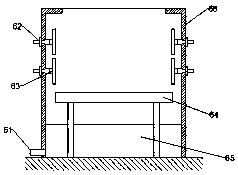

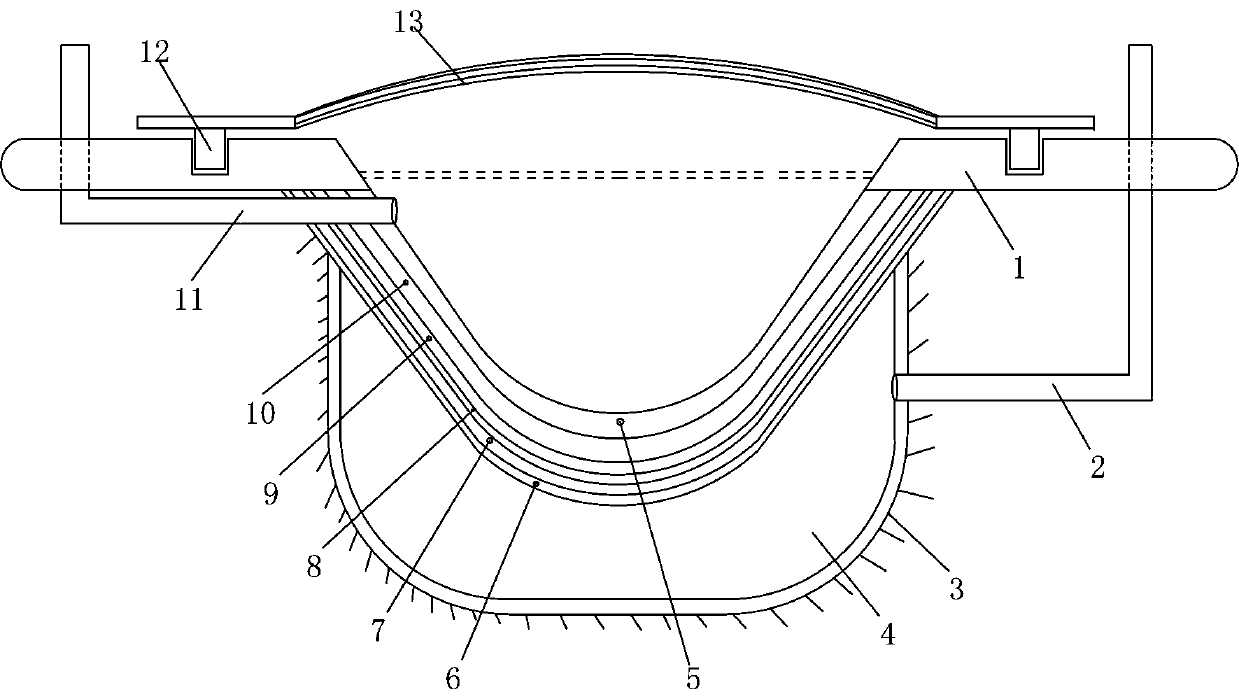

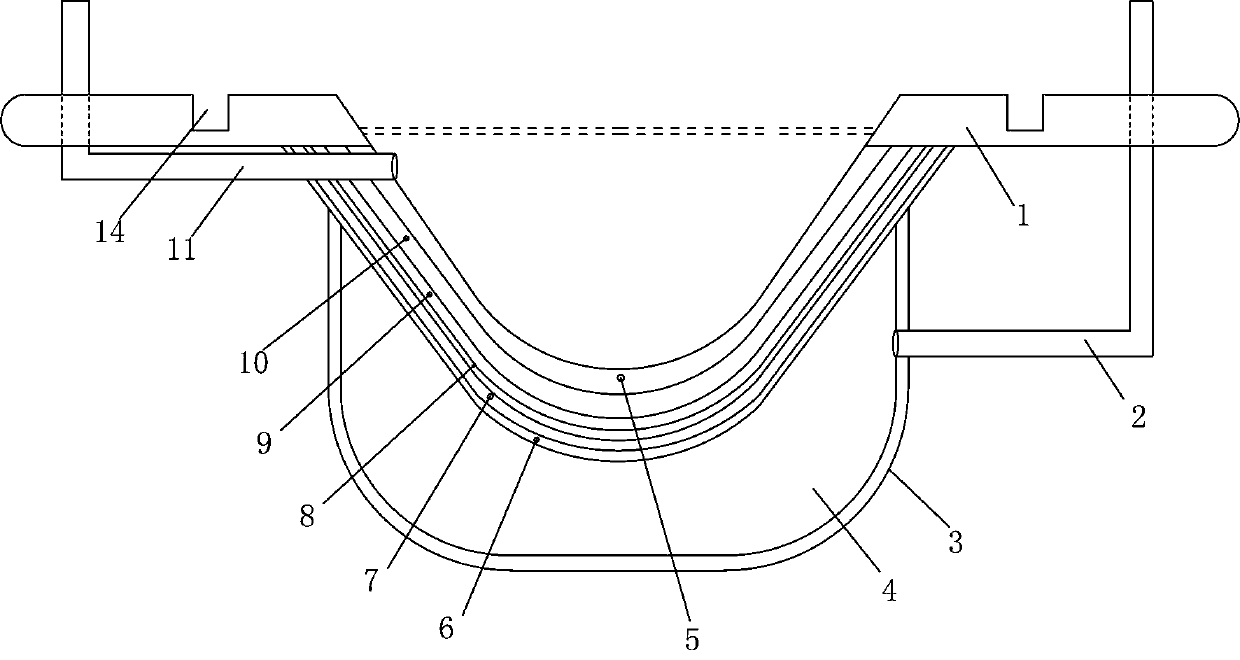

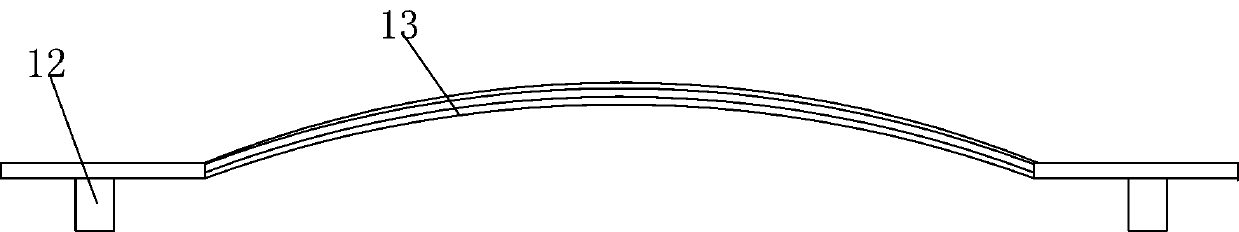

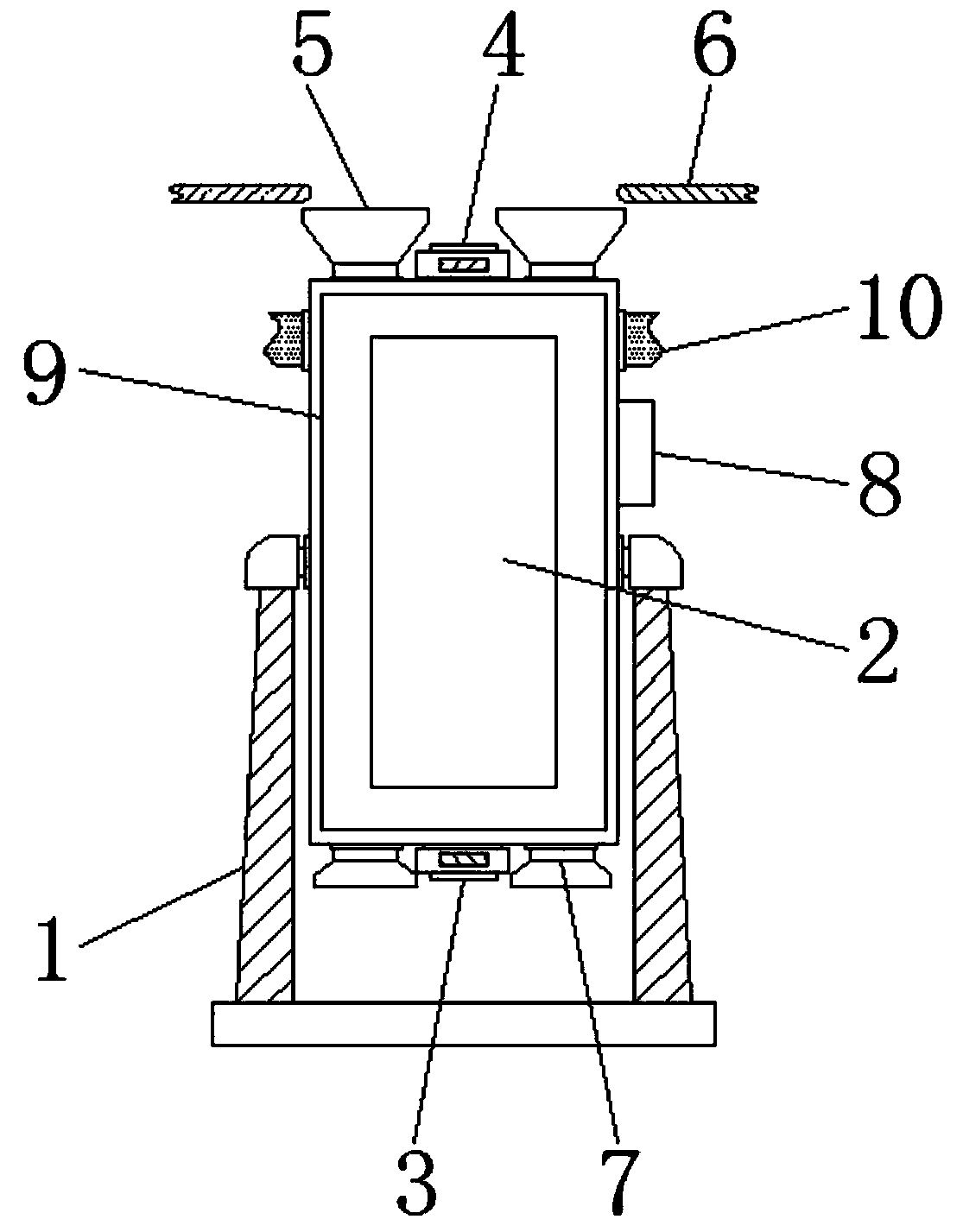

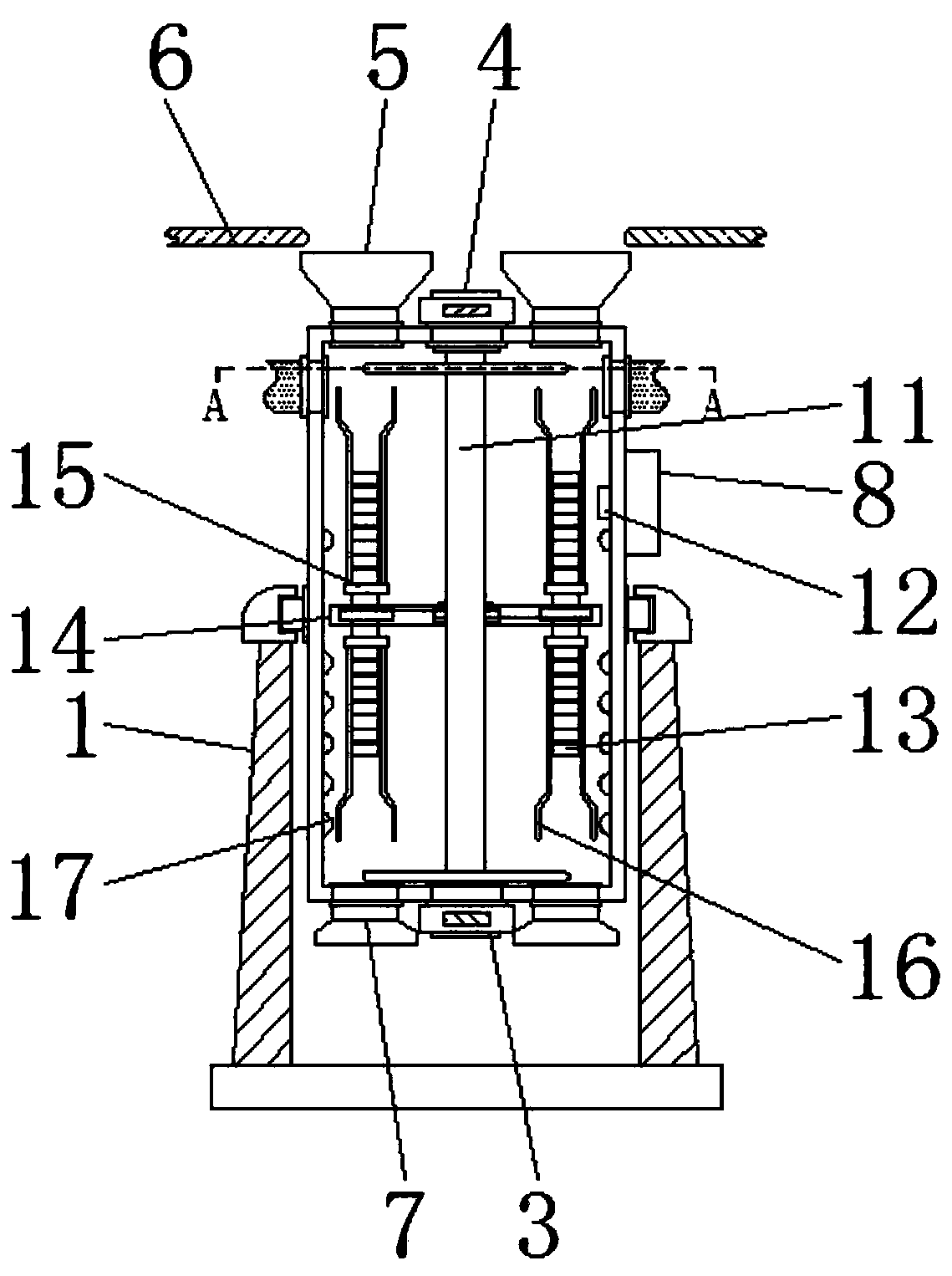

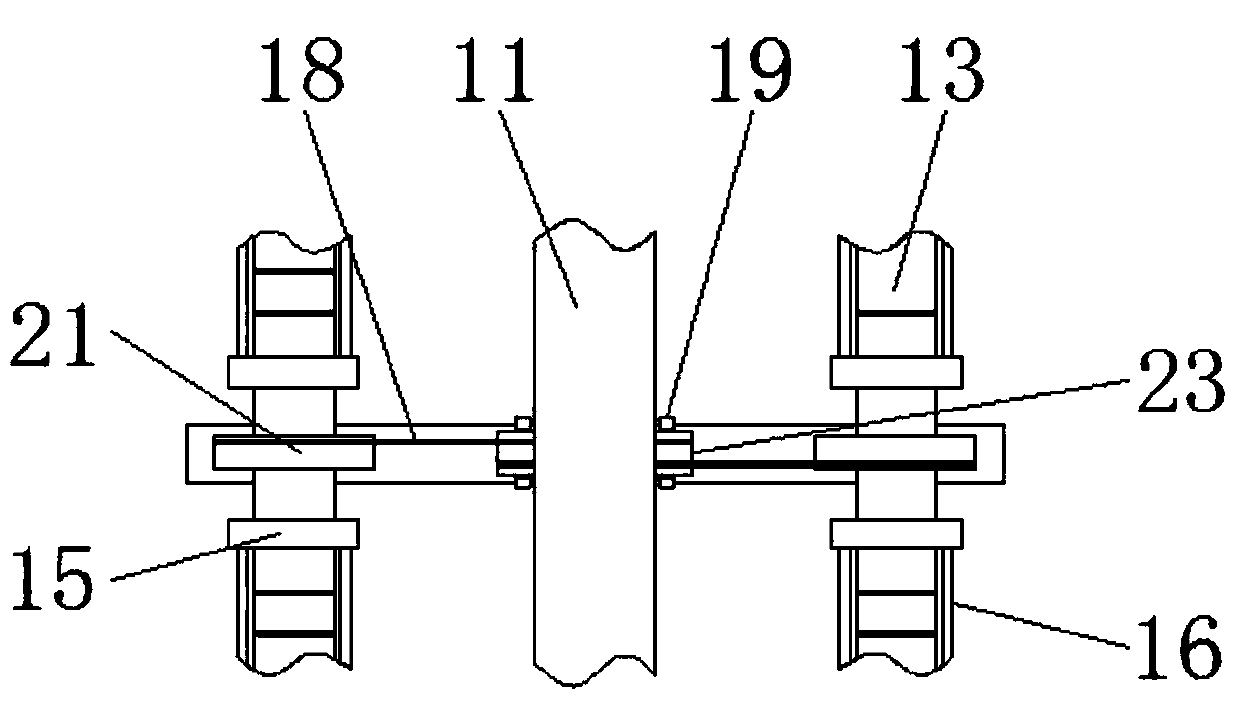

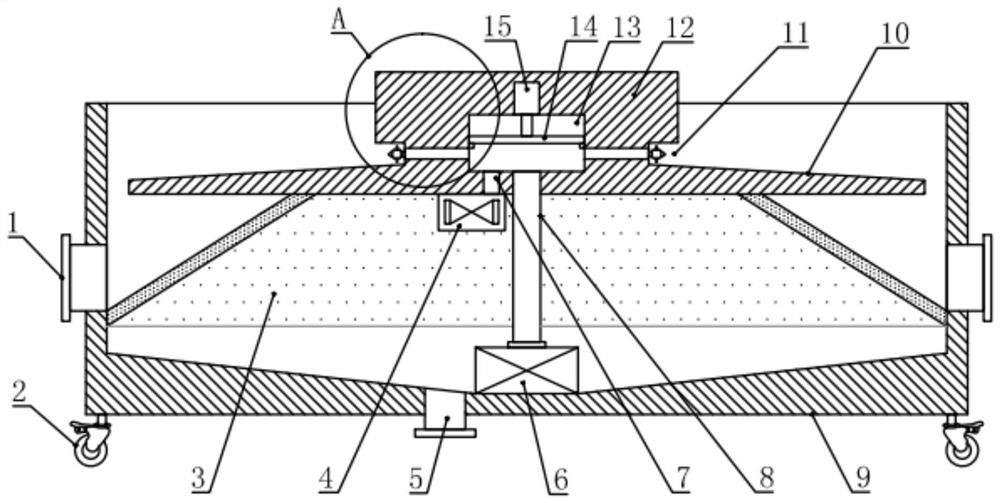

Tidal tray seedling culture water level dynamic management device

InactiveCN104813793AEasy dischargeEasy to collect and reusePressurised distribution of liquid fertiliserEngineeringNutrient solution

The invention relates to a tidal tray seedling culture water level dynamic management device which is characterized by comprising a seedling culture rack, a plurality of horizontally arranged tidal trays arranged on the seedling culture rack, and a nutrient solution circulation device, wherein the nutrient solution circulation device comprises a water inlet assembly used for providing a nutrient solution and water for the tidal trays, and a collecting assembly used for recovering the nutrient solution and water in the tidal trays; a drain hole connected with the collecting assembly is formed in the bottom of each tidal tray; filter parts used for controlling the water level in the tidal trays are respectively arranged on the drain holes. The tidal tray seedling culture water level dynamic management device provided by the invention is low in manufacturing cost, high in efficiency and easy to popularize, and can be used for carrying out dynamic control on the water level in the tidal trays.

Owner:WENZHOU ACADEMY OF AGRI SCI +1

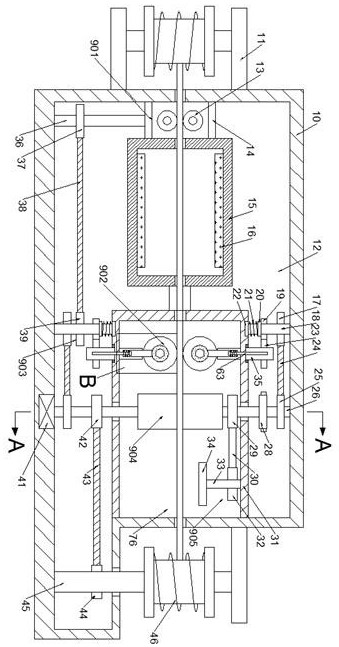

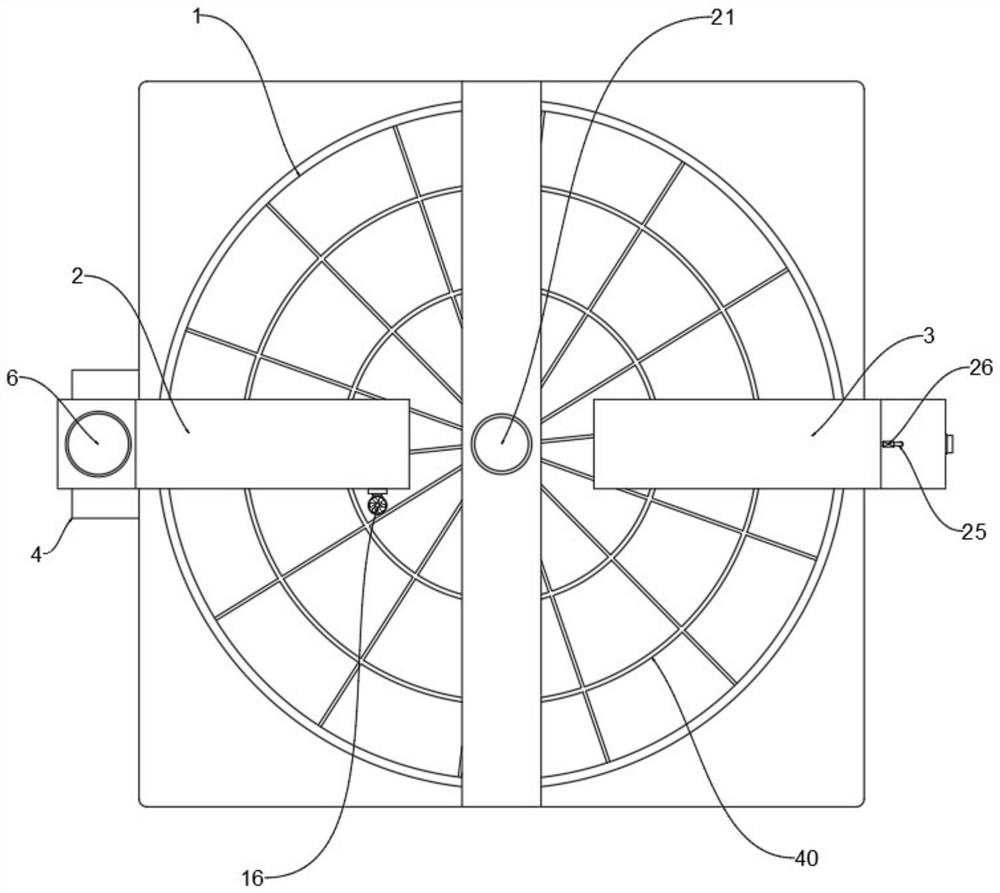

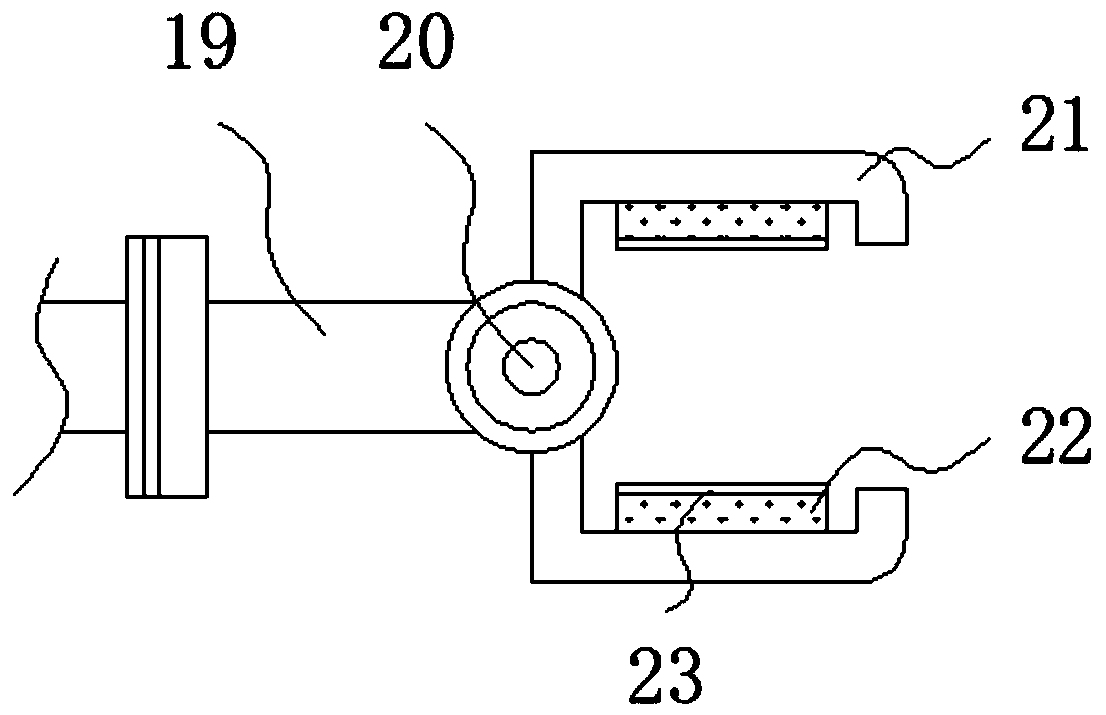

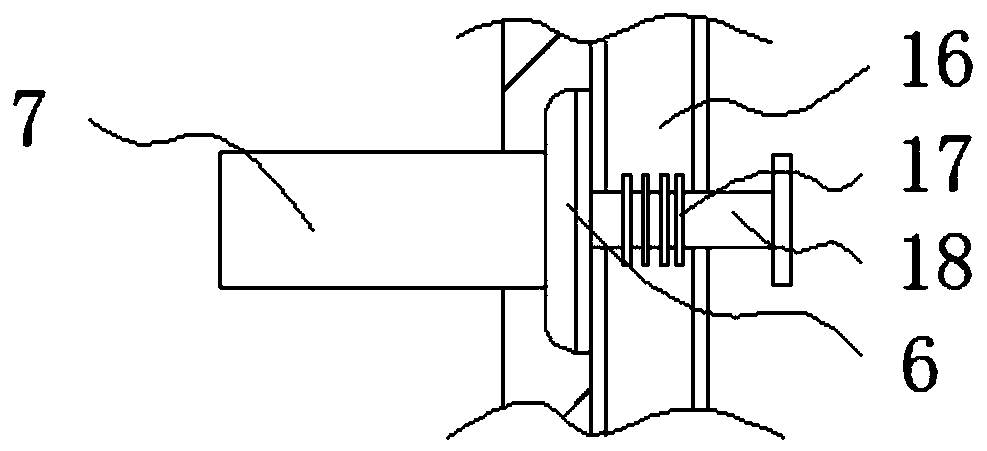

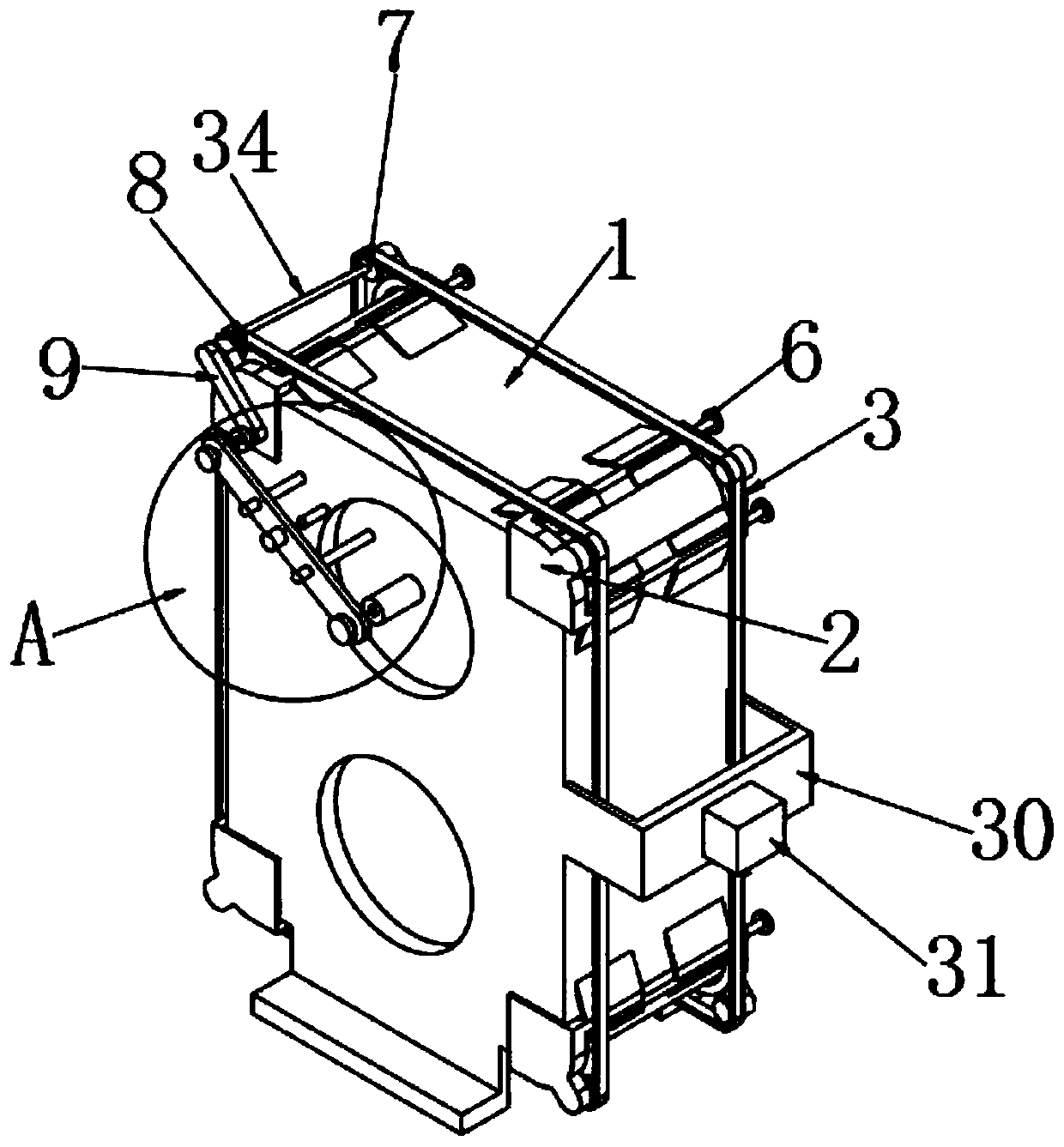

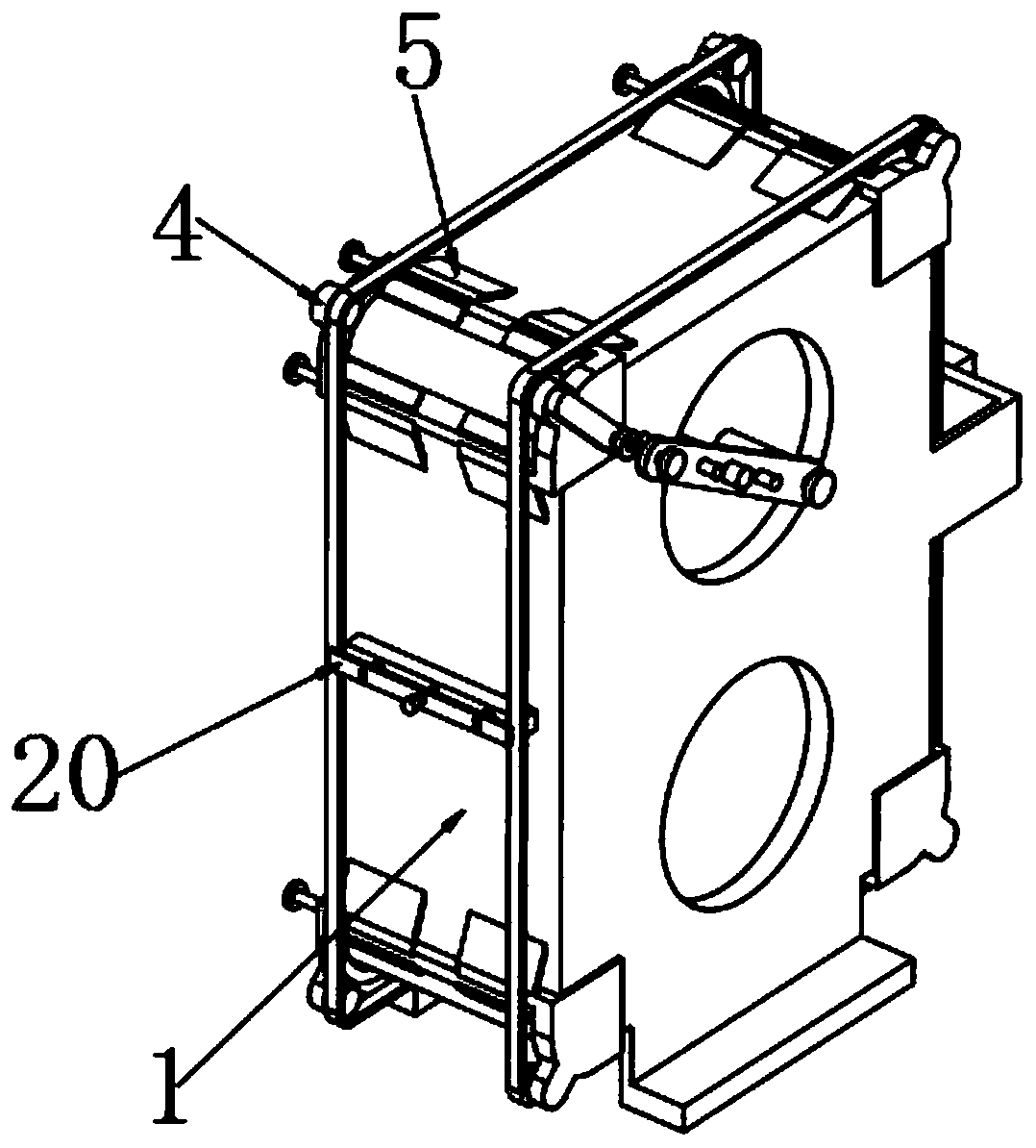

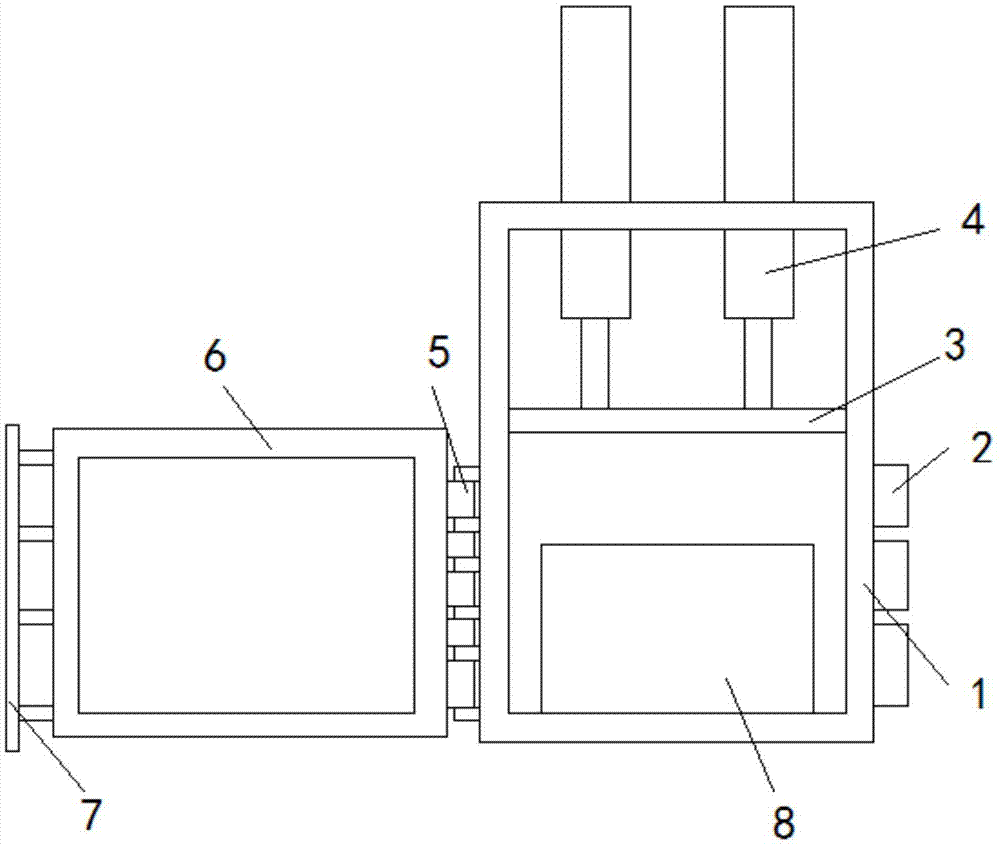

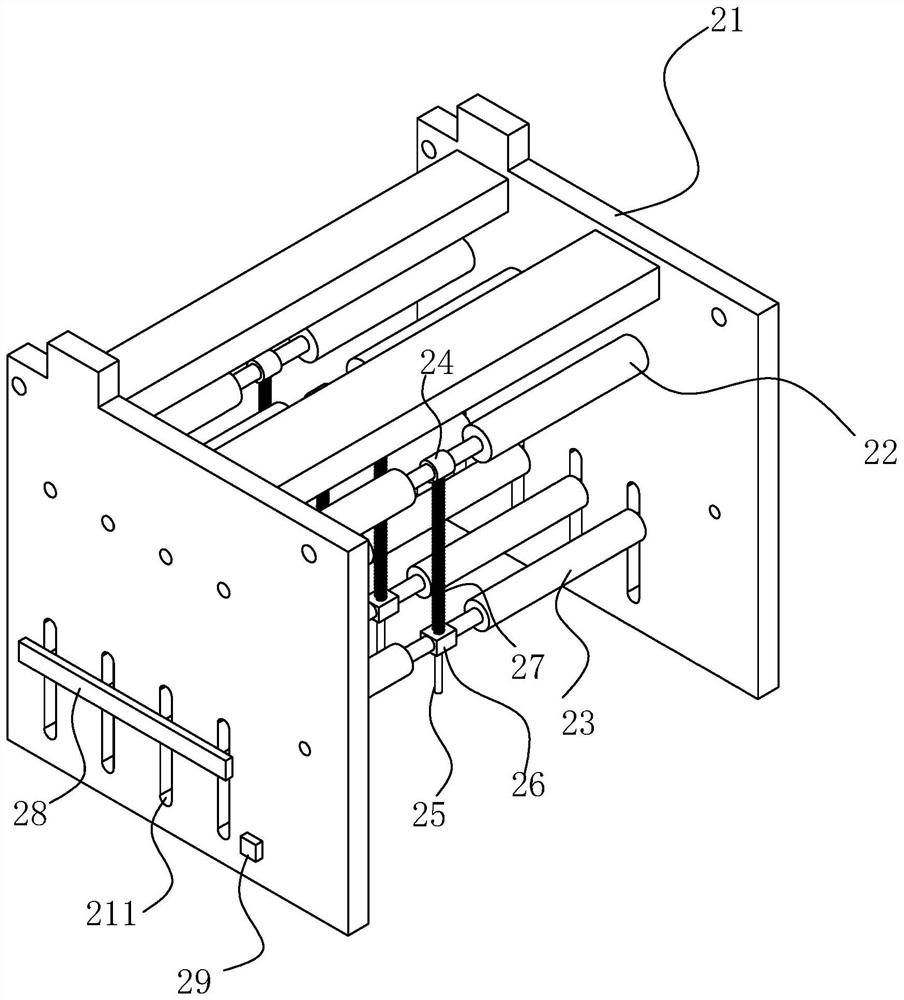

Mechanical equipment for automatically separating waste cable sheath from metal core

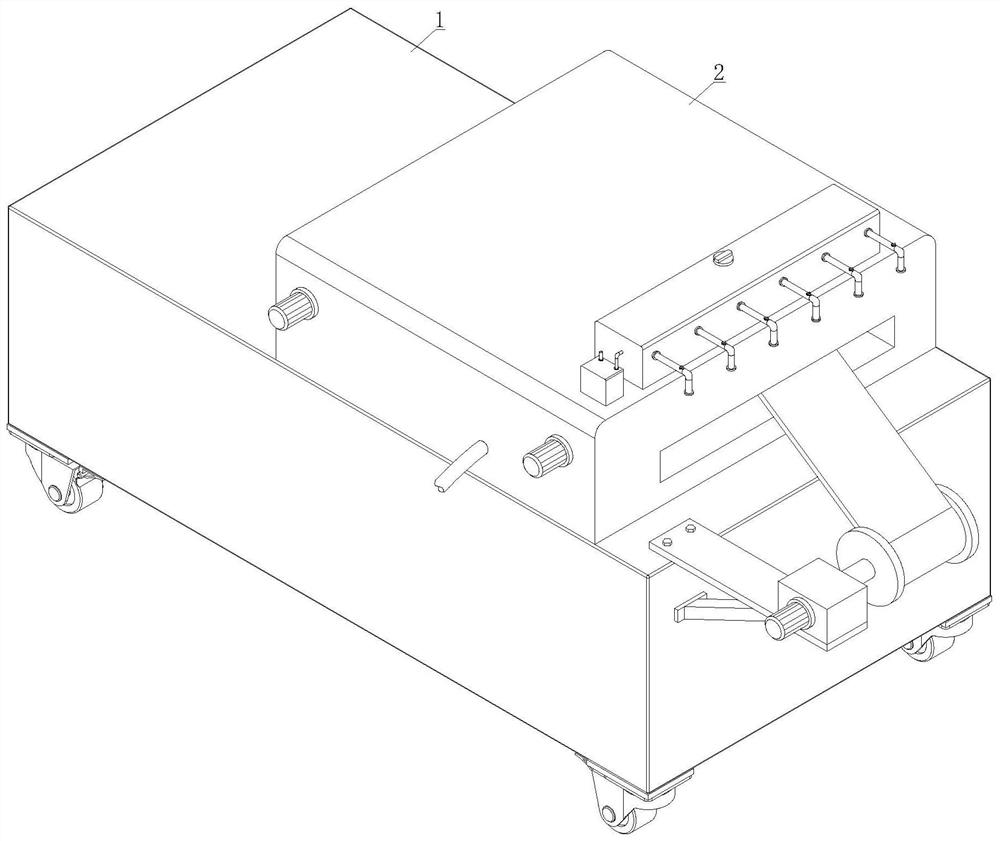

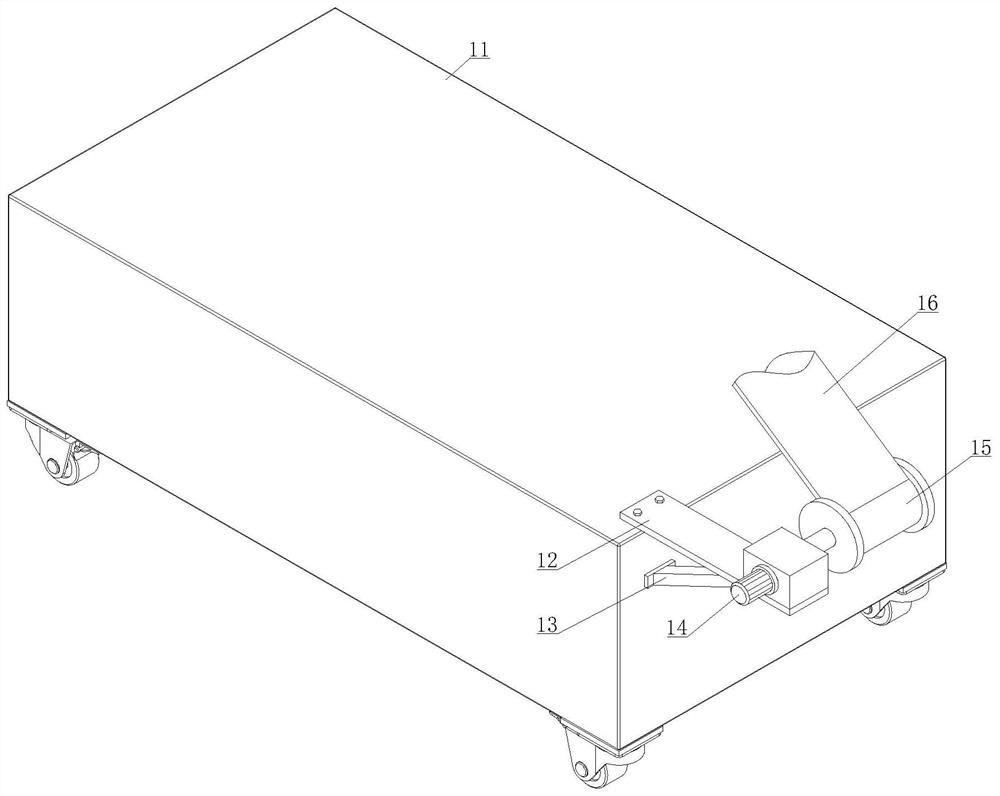

InactiveCN111682461AEasy to collect and reuseBasic electric elementsApparatus for removing/armouring cablesStructural engineeringMechanical equipment

The invention discloses mechanical equipment for automatically separating a waste cable sheath from a metal core. The mechanical equipment comprises a machine body, a cable supply wheel used for providing cables is arranged on the left side wall of the machine body, a first transmission cavity is formed in the machine body, and a transmission box is fixedly arranged on the left side wall of the first transmission cavity. The mechanical equipment is provided with a cutting device, the driving space of a cutting knife is adjusted to cut different cables; a cutting is arranged, and the cutting knife rotates to cut a cable sheath; a sheath winding device is arranged, and first and second sheath winding wheels rotate to recover the cable sheath cut by the cutting knife; and a heat dissipation device is arranged, a fan cools a metal core after the sheath is stripped, and metal core is convenient to collect and reutilize.

Owner:南京溧水高新产业股权投资有限公司

Fillable plant fibre powder for tableware

InactiveCN1752333AGood fillingIncrease filling volumeTable equipmentsVegetal fibresFilling materialsMaleic anhydride

The present invention relates to a plant fibre powder body which can be used as filling material for making tableware and kitchenware. Its composition includes (by wt%) 85-98% of plant fibce, 0.5-5% of surface modifying agent, 1-10% of plasticizing agent and 0-8% of colouring agent. The described surface modifying agent is JL-GO2 type modifying agent or mixture of JL-GO2 type modifying agent and coupling agent and / or maleic anhydride.

Owner:董运达 +2

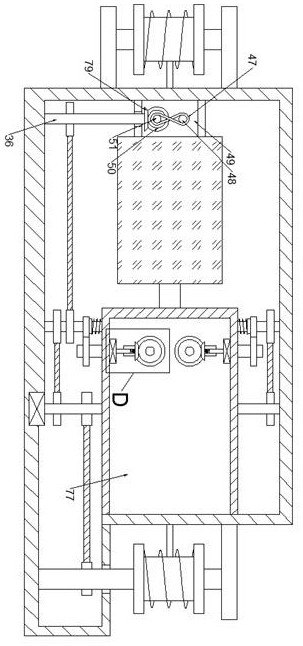

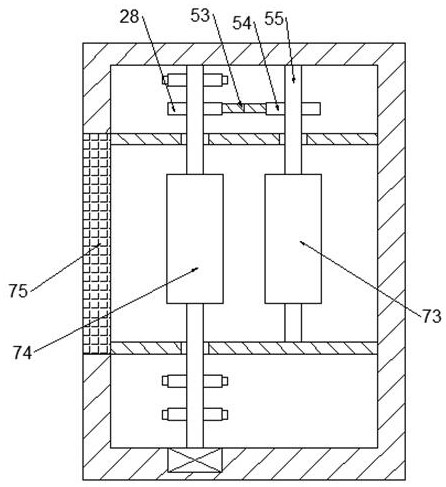

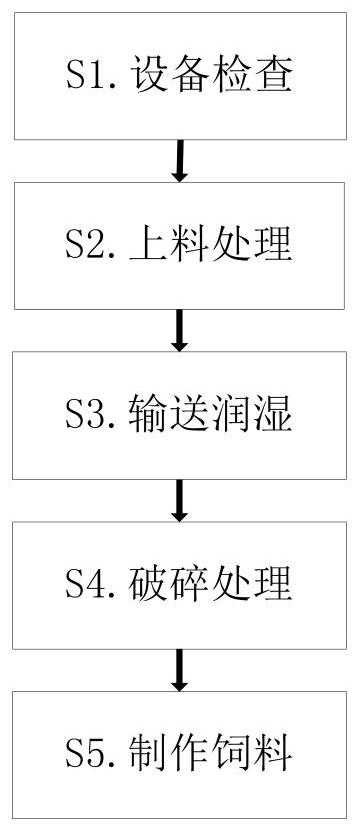

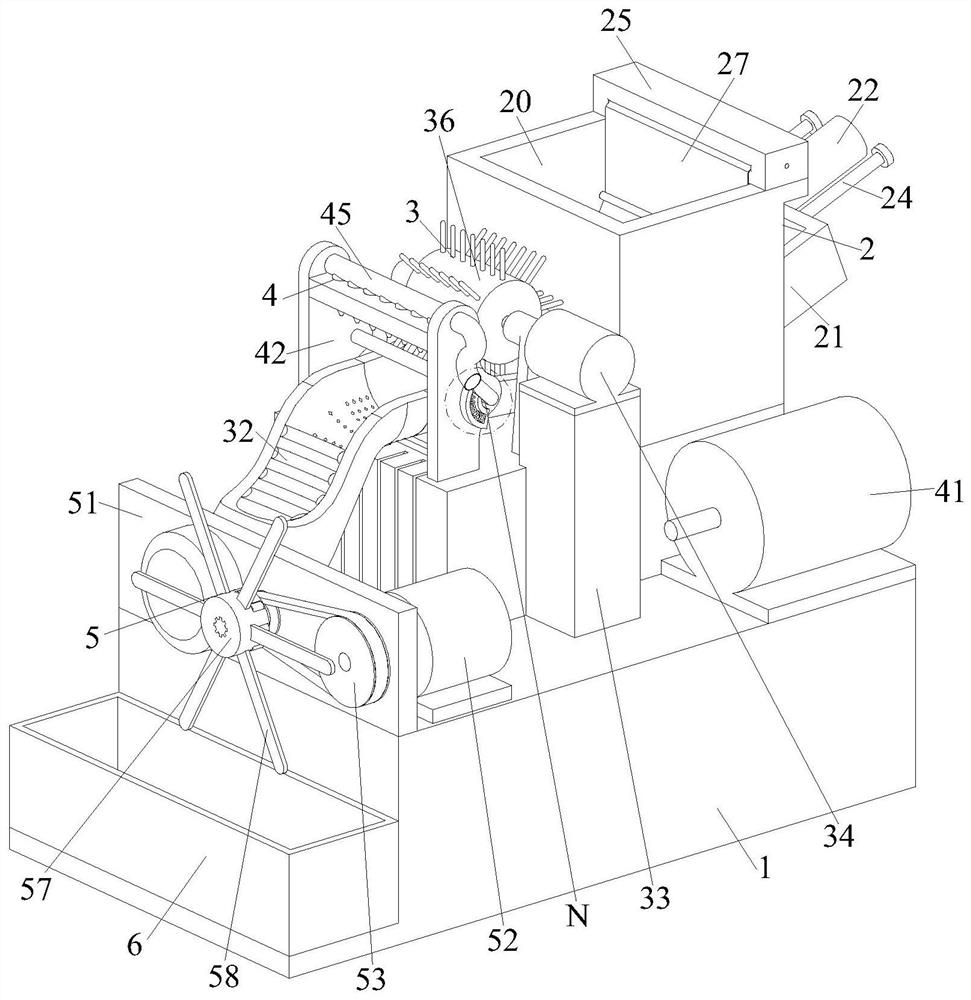

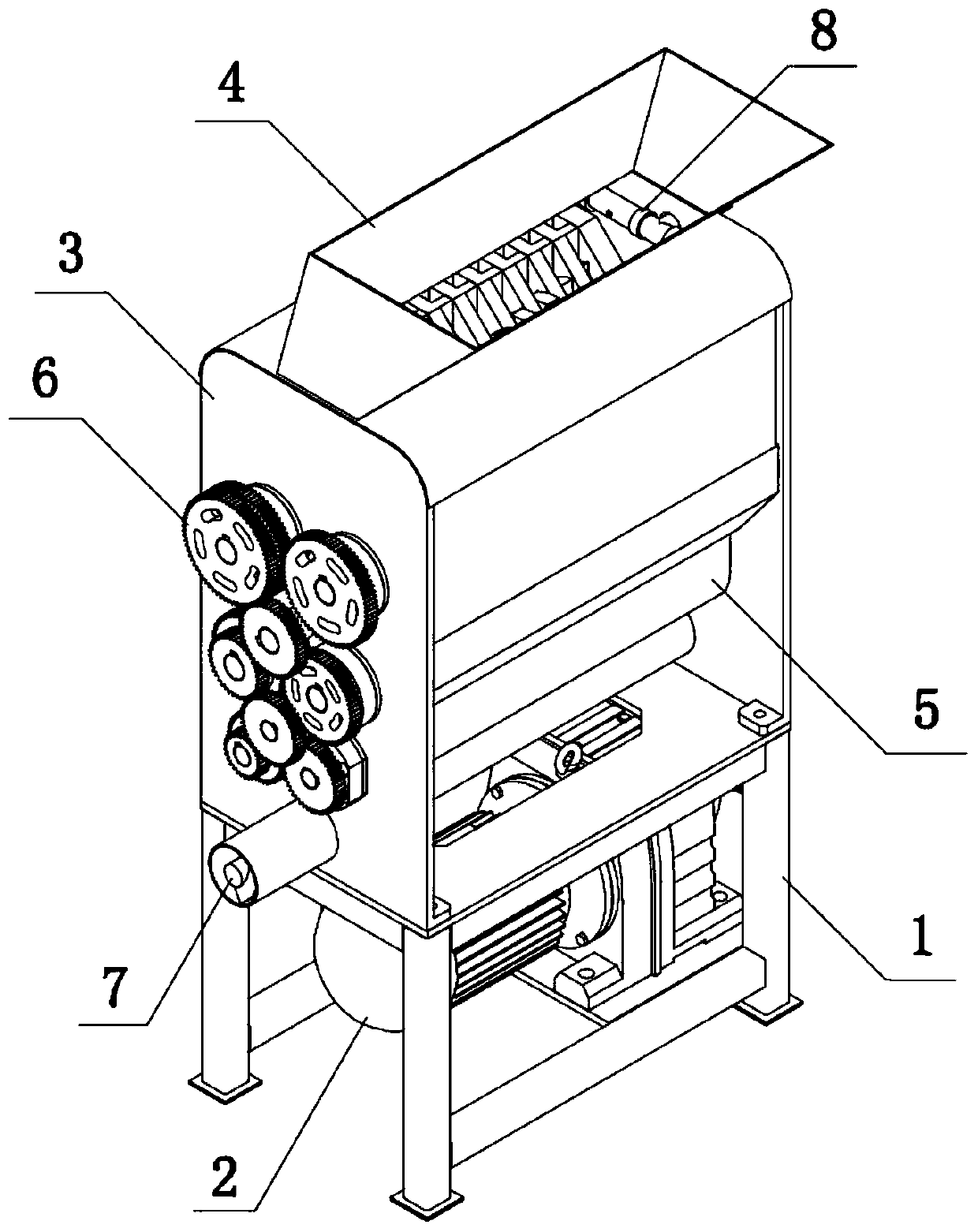

Preparation and processing technology of livestock feed

The invention relates to a preparation and processing technology of livestock feed. According to the technology, a bottom plate, a feeding device, a conveying device, a wetting device, a crushing device and a collecting frame are arranged to cooperatively complete livestock feed preparation. The preparation and processing technology of the livestock feed can solve the problems that when crop straw is crushed manually, the crop straw is generally directly cut and crushed manually, the crop straw is difficult to fully crush manually, so that the crop straw is difficult to fully ferment during feed preparation, and the manual cutting and crushing wastes time and labor and the preparation efficiency of the livestock feed is reduced, and can solve the problems that when existing livestock feed preparation equipment conducts preparation, an existing crushing device conducts crushing treatment on the crop straw, humidifying treatment is not conducted on the surface of the crop straw in the crop straw crushing process, crushed chippings are prone to splashing and the working environment is poor when the livestock feed is prepared.

Owner:祖赛赛

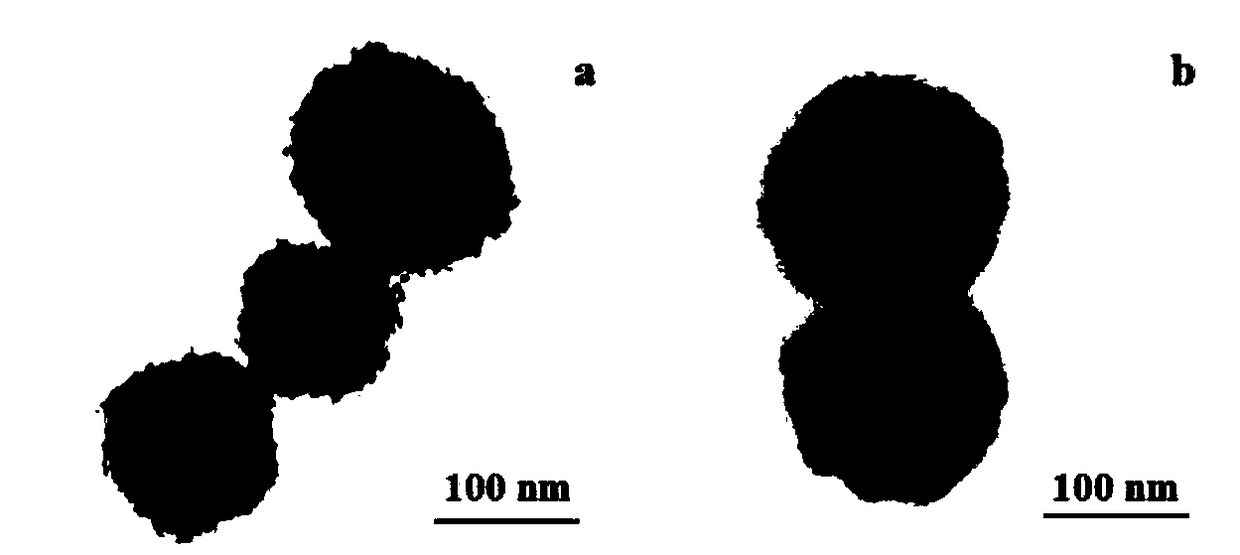

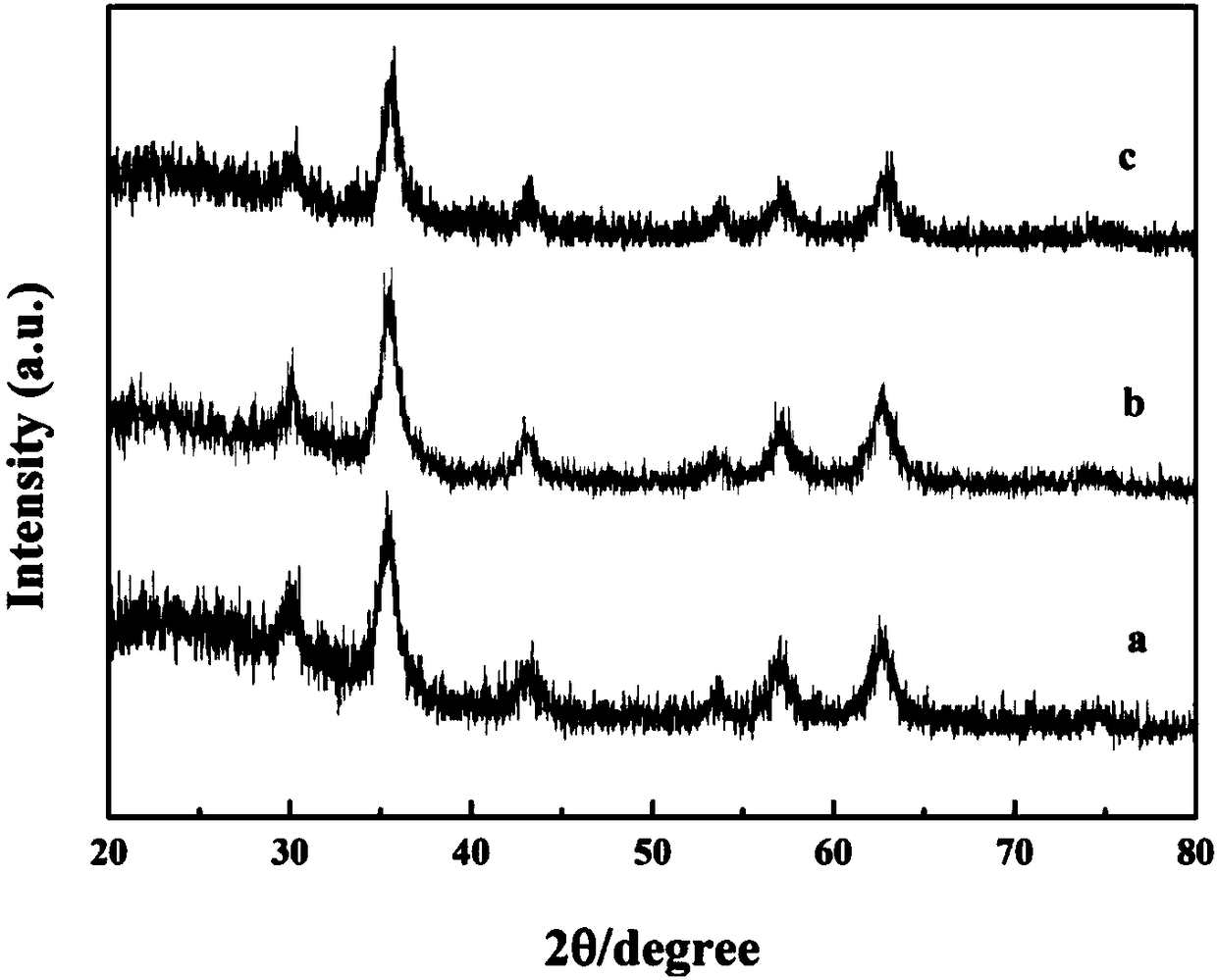

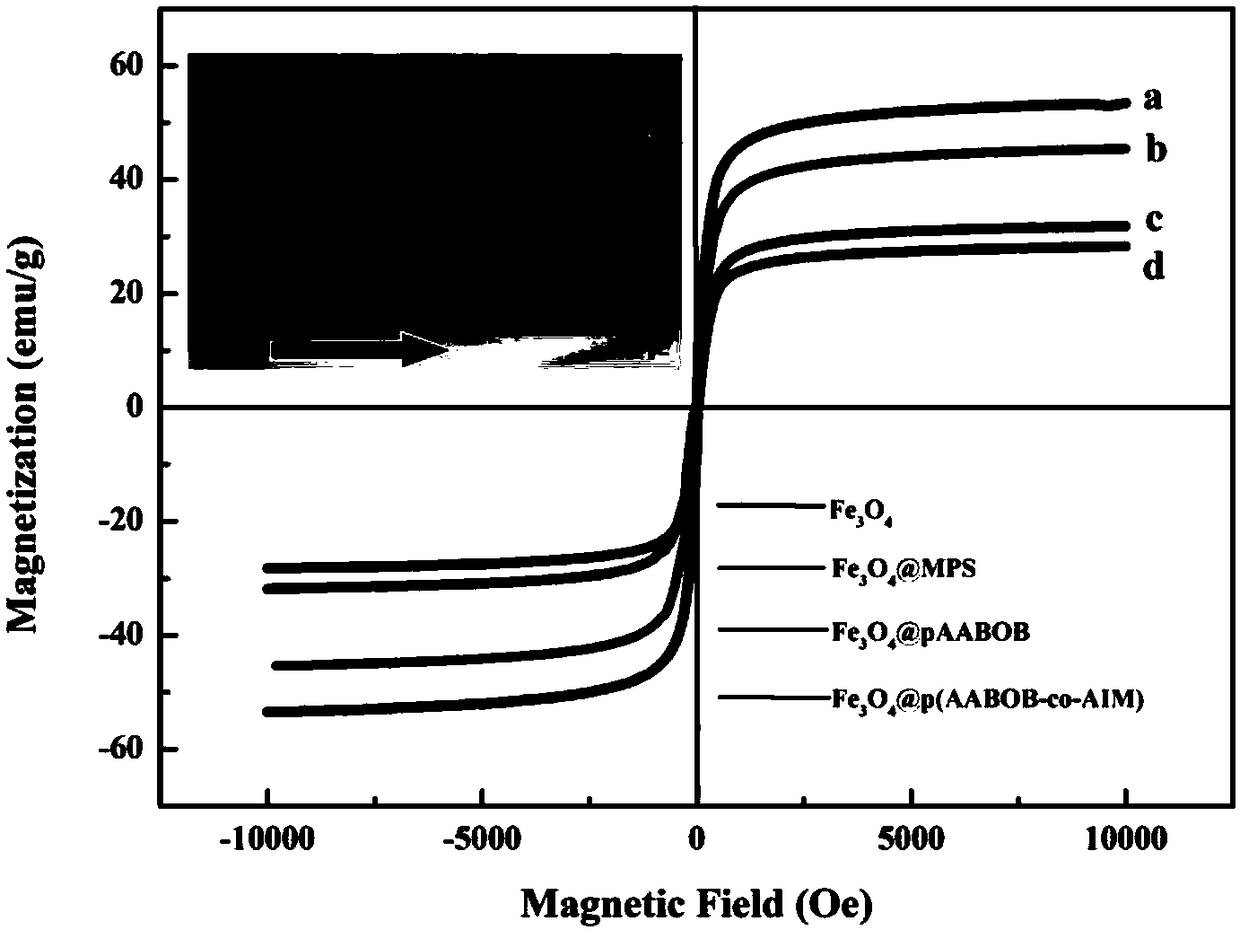

Wulff type phenylboronic acid (AABOB) functionalized magnetic nanometer microspheres and preparation method and applications thereof

InactiveCN108569772AImmobilizationEvenly dispersedMaterial nanotechnologyWater contaminantsMicrosphereNickel ions

The invention belongs to the technical field of inorganic materials and analysis, and relates to Wulff-type phenylboronic acid (AABOB) functionalized magnetic nanometer microspheres and a preparationmethod and applications thereof. Firstly, Fe3O4@MPS microspheres and acetonitrile are mixed and ultrasonically dispersed; then AABOB, N-allyl imidazole, a crosslinking agent MBAA and an initiator thatis azobisisobutyronitrile are added; the mixture is heated to initiate polymerization; a product obtained is washed repeatedly and dried in vacuum; then the product is subjected to synergistic actionof nickel ions and is used for horseradish peroxidase immobilization; and the obtained immobilized enzyme is used for degradation of phenolic pollutants. The immobilized enzyme synthesized from the magnetic nanometer microspheres has good recyclability, the relative enzyme activity can still be 83% after five times of reutilization, which is far higher than that reported in present literatures, and the immobilized enzyme has pH stability, temperature stability and storage stability which are significantly improved that those of materials not immobilized.

Owner:JIANGSU UNIV

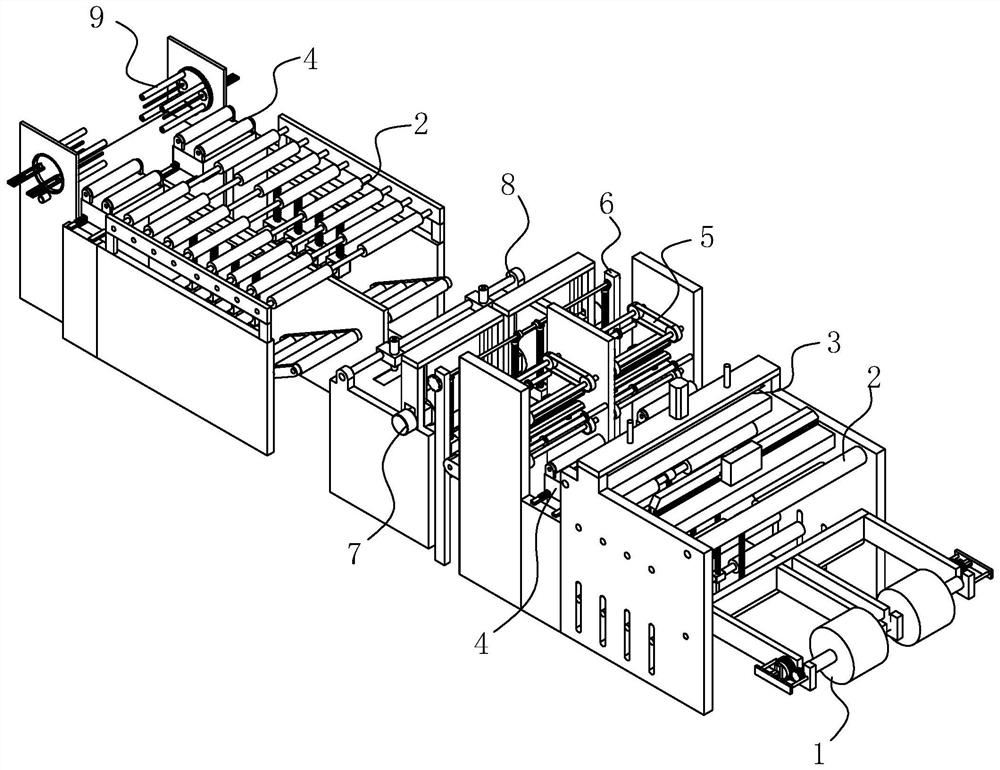

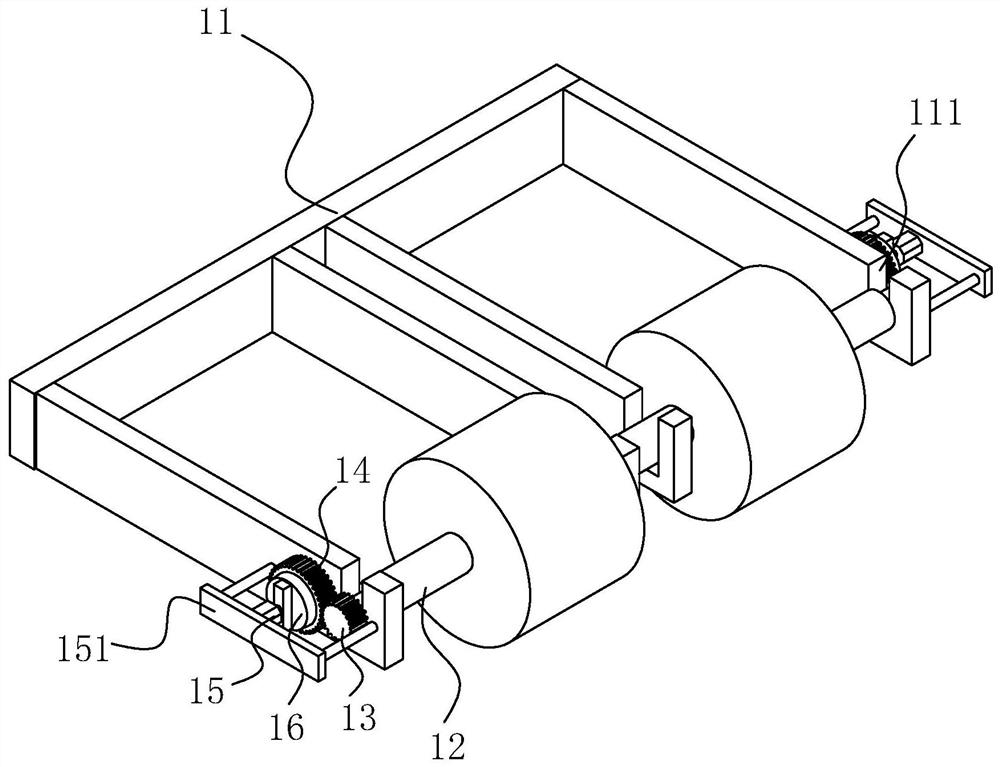

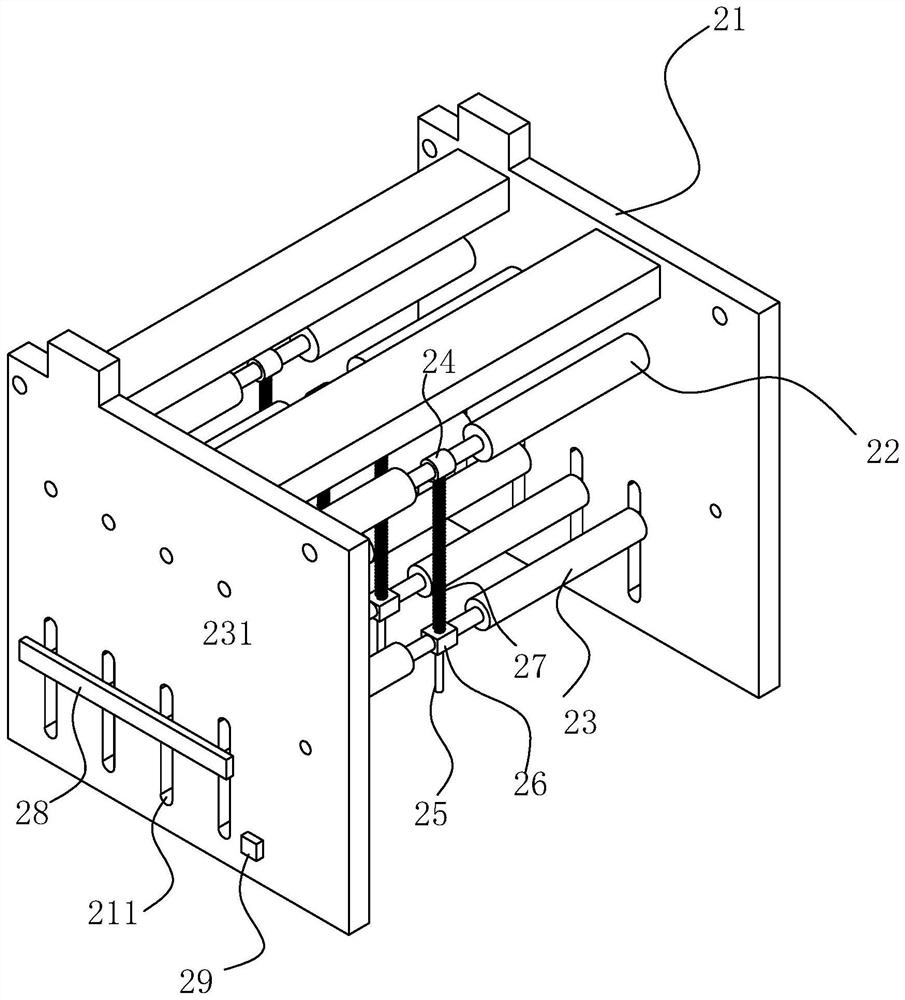

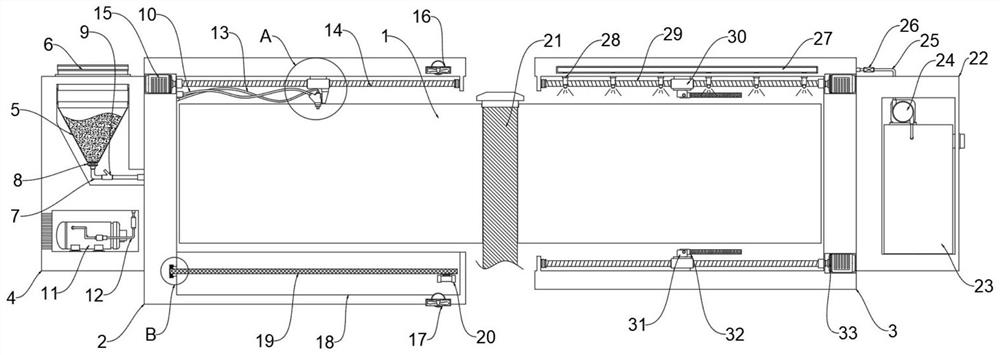

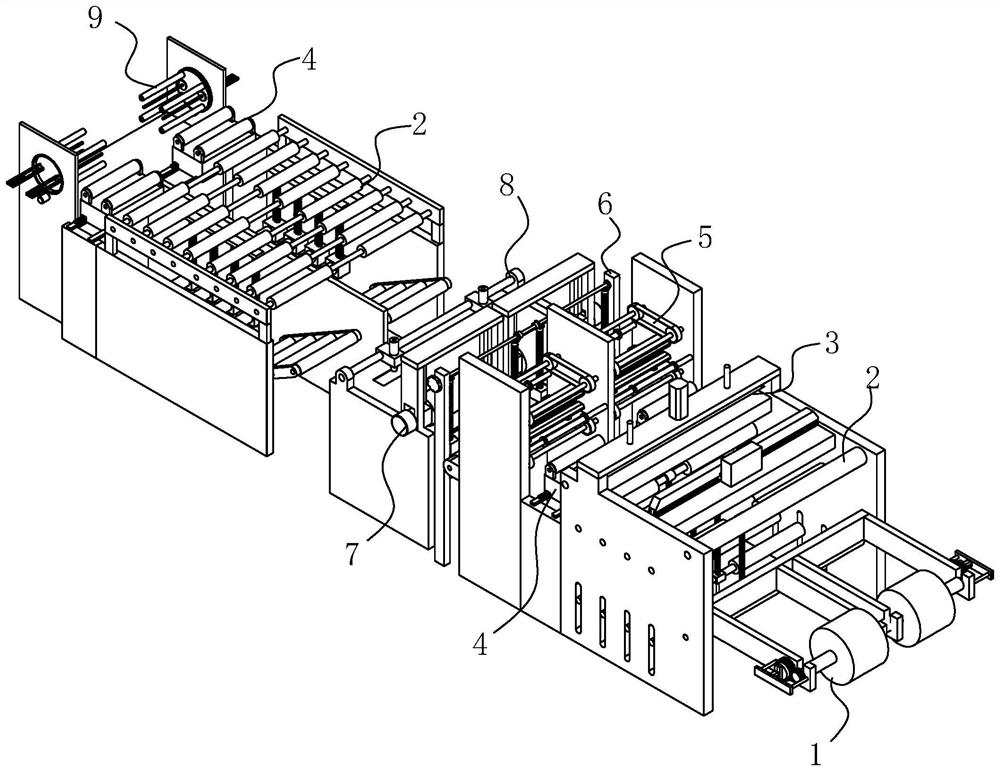

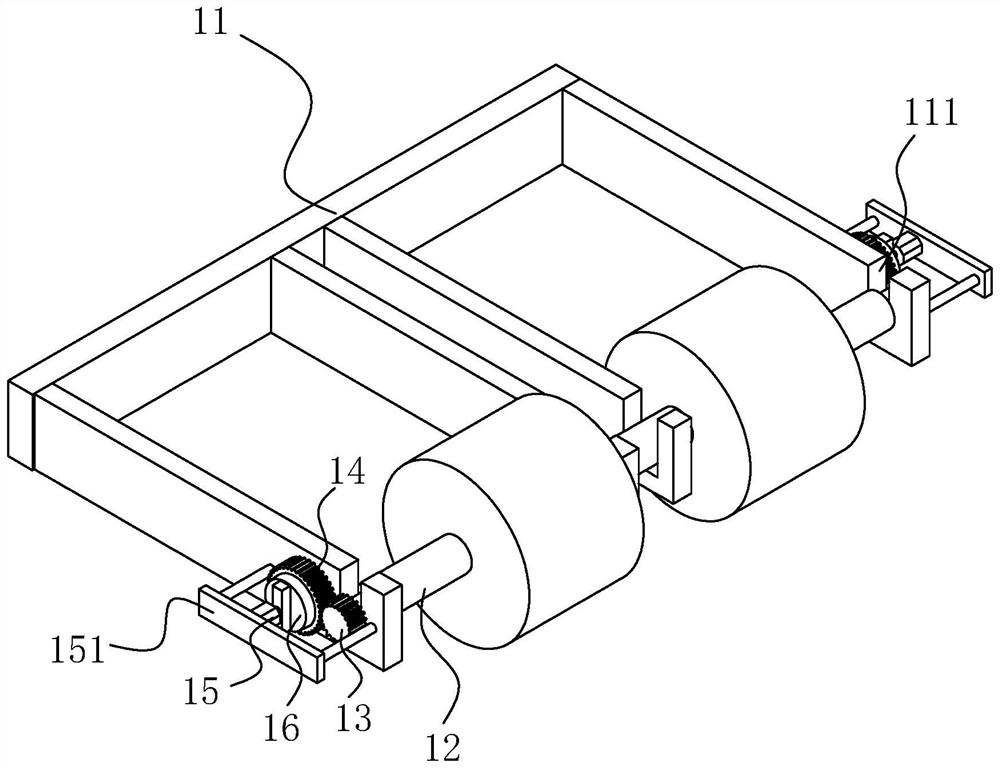

Vest bag production equipment and technology

ActiveCN112373123AReduce uneven croppingReduce stackingBag making operationsPaper-makingWorkbenchIndustrial engineering

The invention discloses vest bag production equipment and a vest bag production technology, and relates to the technical field of bag making. According to the technical scheme, the vest bag productionequipment is characterized by comprising a rack, a loading device arranged on the rack, a heat seal device arranged at one side of the loading device, and a discharging device arranged at a discharging end of the rack, and further comprising a die cutting device arranged between the heat seal device and the discharging device; and the die cutting device comprises a die cutting support, a workbench arranged at the top end of the die cutting support, supporting frames fixed to the top end of the workbench, die cutting blocks connected with the supporting frames, die cutting rollers rotatably connected with the die cutting blocks, and die cutting molds arranged on the die cutting rollers. The vest bag production equipment and the vest bag production technology have the effects that a production technology is optimized, and the situations of uneven trimming of bag bodies are reduced.

Owner:QINGDAO ZHOUSHI PLASTIC PACKAGE

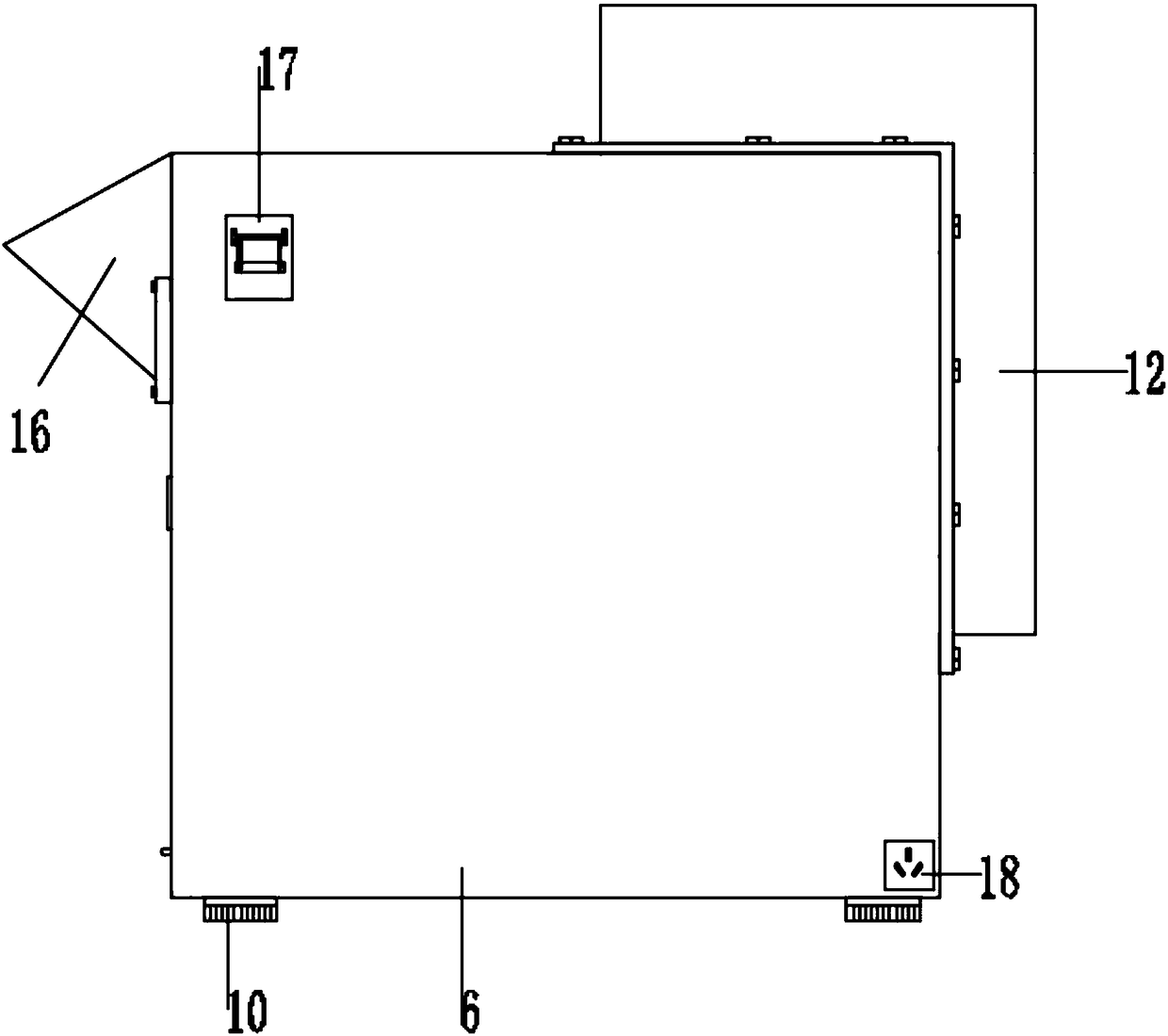

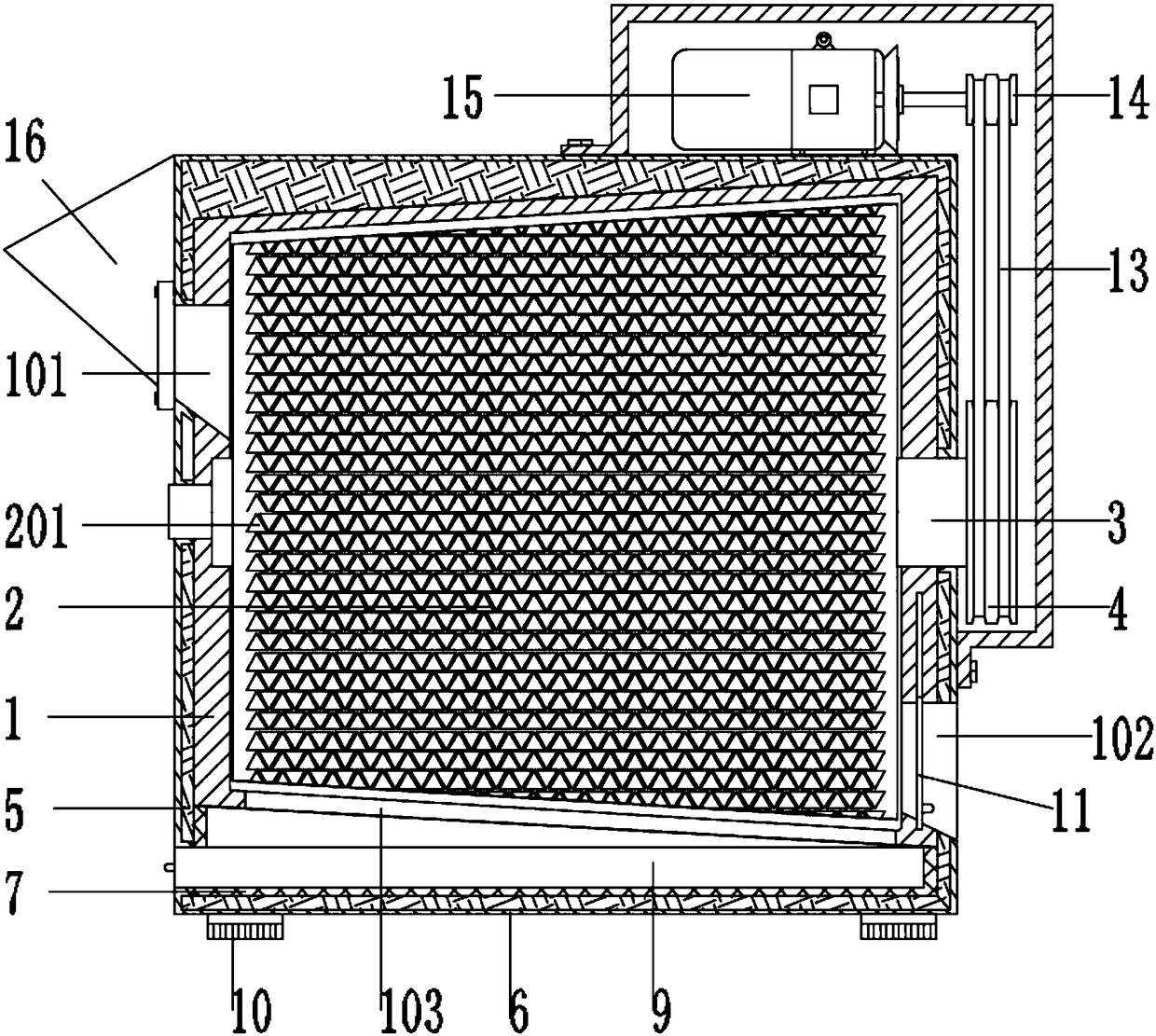

Blockage clearing device for multi-air-preheater system and blockage clearing method of blockage clearing device

PendingCN112682814AClean up comprehensivelyPrevent adhesionCombustion processIndirect carbon-dioxide mitigationAir preheaterStructural engineering

The invention discloses a blockage clearing device for a multi-air-preheater system and a blockage clearing method of the blockage clearing device, relates to the technical field of air preheater cleaning, and aims to solve the problem that heat exchange fins in existing air preheaters are prone to soot impurity adhesion and difficult to clear along with long-time use. A first anti-blocking device is installed on one side of a heat exchange rotor, a first lead screw is rotationally installed at the upper end of the interior of the first anti-blocking device, a sand-containing spray head is fixedly installed below a first sliding block, and a sand storage barrel and an air compressor are arranged in a first fixing box. A recovery groove is formed in the lower end of the interior of the first anti-blocking device, a second anti-blocking device is installed on the other side of the heat exchange rotor, second lead screws are rotationally installed at the upper end and the lower end of the interior of the second anti-blocking device, a rotating base is fixedly installed at one end of a second sliding block, a cleaning head is rotationally installed in the rotating base, and a second fixing box is fixedly arranged on one side of the second anti-blocking device.

Owner:南京市利澜电力节能科技有限公司

Rust removing equipment for machining

ActiveCN108527137AEasy to assemble and useReduce physical laborEdge grinding machinesPolishing machinesEngineeringControl switch

The invention provides rust removing equipment for machining. The rust removing equipment comprises a master control switch and a power plug. Four supporting columns are mounted on the outer wall of arust removing inner cylinder, and a feeding hole is formed in the top of the left side end face of the rust removing inner cylinder and communicates with the bottom of a feeding funnel; a discharginghole is formed in the bottom of the right side end face of the rust removing inner cylinder, a gate plate is mounted at the discharging hole, and one end of the gate plate is slidablyconnected with the interior of the rust removing inner cylinder; and a rust leaking hole is formed in the bottom of the rust removing inner cylinder and located in the top of a rust residue collecting drawer. Grinding balls and the outer walls of mechanical parts makes mutual friction advantageouslythrough rotating of a rust removing rotating cylinder, and rust contained in the exteriors of the mechanical parts is removed, so that the exteriors of the mechanical parts are smoother and cleaner, and the mechanical parts can conveniently assembled and used by people; the rust removing rotating cylinder is arranged obliquely so thatpeople can discharge the mechanical parts convenientlythrough rotating of the rust removing rotating cylinder, physical labor of people is reduced, and the working efficiency is promoted.

Owner:扬州君杰金属制品有限公司

Energy-saving boiler

PendingCN113803702AIncrease profitNot easy to influenceSteam generation heating methodsSteam boilersThermodynamicsEngineering

The invention discloses an energy-saving boiler. The boiler comprises a bottom plate, a heating device is fixedly connected to the right side of the top of the bottom plate, a heating box is fixedly connected to the position, located at the bottom of the outer wall of the left side of the heating device, of the top of the bottom plate, a heat insulation plate is fixedly connected to the right side of the top of the heating box, a control panel is arranged at the top of the outer wall of the left side of the heat insulation plate, and a ventilation opening is formed in the middle of the bottom of the outer wall of the left side of the heating box. The invention relates to the technical field of boilers. According to the energy-saving boiler, heat generated by electrifying of the heating box can be transferred through connection with a preheating mechanism, meanwhile, the heat insulation plate can insulate the influence of the heat, dust generated by traditional heating can be conveniently reduced, the situation that water is scattered in the water adding process is avoided, then the utilization rate of the heat generated by heating can be improved, the boiler has good stability during working, the boiler can be uniformly heated, and the service life of the boilder is effectively prolonged.

Owner:黄涌凯

Battery processing and production device with function of waste recovery treatment

InactiveCN110370151AHigh precisionImprove the quality of the finishFinal product manufactureSecondary cells manufactureElectrical batteryEngineering

The invention relates to a battery processing and production device with the function of waste recovery treatment. The battery processing and production device comprises a workbench, an extending rodand a motor protection case. A conveying belt is fixed to the upper end of the workbench, and a conveying motor is mounted in the conveying belt. A device body is arranged on the outer portion of theconveying motor, and a sliding groove is formed in the device body. A sliding block is in sliding connection in the sliding groove. A telescopic rod is arranged on the left side of the sliding block.The extending rod is mounted on the left side of the telescopic rod. A first rotary shaft is mounted on the left side of the extending rod. According to the battery processing and production device with the function of waste recovery treatment, a sliding structure is formed by the sliding groove and the sliding block; according to the height of a raw material, the sliding block and the sliding groove can slide, so that a tool bit is attached to the raw material needing to be ground, and therefore the device is suitable for raw materials of different heights better; and a telescopic structure is formed by the telescopic rod and the extending rod, and the extending rod is pulled out from the interior of the telescopic rod according to the position of the raw material.

Owner:颜锦程

Environment-friendly chemical reaction kettle device with tail gas collection function

InactiveCN108889256AAvoid polluting the environmentIncrease reaction rateGas treatmentDispersed particle filtrationExhaust gasActivated carbon

The invention belongs to the technical field of chemical production and particularly relates to an environment-friendly chemical reaction kettle device with a tail gas collection function. Aiming at the problem of environmental pollution caused by waste gas produced by a chemical production reaction kettle, the invention discloses the following scheme: the environment-friendly chemical reaction kettle device comprises a protecting shell, wherein support seats are arranged at two ends and two sides of the inner wall of the bottom of the protecting shell through bolts, a vertically arranged reaction cylinder is mounted on the outer walls of the tops of the four support seats through bolts, four limiting blocks distributed in an annular array manner are welded to the top and bottom of the outer wall of the periphery of the reaction cylinder, and fixed blocks are welded to the tops and bottoms of the inner walls of two ends and two sides of the protecting shell. According to the environment-friendly chemical reaction kettle device, waste gas produced in the chemical production process enters a collection tank through an exhausting pipe and a connecting pipe and can be conveniently collected and recycled; and the waste gas is cooled by virtue of a cooling pipe, is filtered by virtue of a filtering net plate and is adsorbed through an activated carbon adsorption block.

Owner:刘艳

Central air conditioner outdoor unit heat dissipation and cooling treatment system and treatment method

ActiveCN111486517AEasy to clamp and fixAchieve stretchMechanical apparatusLighting and heating apparatusEngineeringSprocket

The invention discloses a central air conditioner outdoor unit heat dissipation and cooling treatment system. The system comprises an outdoor unit, a translation connecting plate and a supporting seat, wherein fixed clamping seats are mounted at four corners of one side of the outdoor unit. According to the system, temperature rising of the outdoor unit is sensed by a temperature sensor, a fan inthe outdoor unit works to drive a connecting column to rotate, a rotating wheel is driven to rotate through transmission of a first pulley and a first belt, then a sprocket wheel is driven to rotate through transmission of a second pulley and a second belt in a transmission case, then a chain is driven to rotate on the sprocket wheel, the translation connecting plate moves along with rotation of the sprocket wheel, a spring in an inner side cylinder is elastically deformed to drive a sliding rod to move, a first telescopic pipe stretches until a sponge block at a supporting rod is tightly attached to the outer side of the outdoor unit, the sponge block moves along an outer shell of the outdoor unit to wipe condensed water on the surface of the outdoor unit for heat dissipation and cooling,resources can be recycled, and rapid heat dissipation and cooling on the outdoor unit are facilitated.

Owner:中建国发(厦门)集团股份有限公司

Shower waste water collecting device

PendingCN111677059AReduce volumeLow costFatty/oily/floating substances removal devicesSewerage structuresWater collectionSewage

The invention discloses a shower waste water collecting device. The shower waste water collecting device comprises a water suction pipe, a water discharge pipe and a water collecting floor drain plug,wherein the water suction pipe is provided with a water suction port, the water suction port extends into the water collecting floor drain plug, the water discharge pipe is provided with a water discharge port, the water discharge port extends out of the water collecting floor drain plug, the water collecting floor drain plug is provided with a water sealing structure, the water sealing structurecomprises an interchangeable water sealing piece, the water suction pipe comprises a water suction pipeline and a water suction pipe connecting port, the water discharge pipe comprises a water discharge pipeline, a water discharge connecting port and a throttling three-way valve, and the water collection floor drain plug comprise a hair filter, a sewage draining device and a cleaning device. Theshower waste water collecting device is small in size, is plugged in an original floor drain, is simple and convenient to install, is high in universal interchangeability, is applied to a hot water system with a shower waste water recycling function, replaces a waste water collector of the hot water system, can conveniently collect and recycle shower waste water without the need for changing bathroom decoration and original waterway channels, and solves the problems that a common waste water collector is large in size, unsightly in installation and low in waste water collecting and recycling efficiency.

Owner:甘秀坚

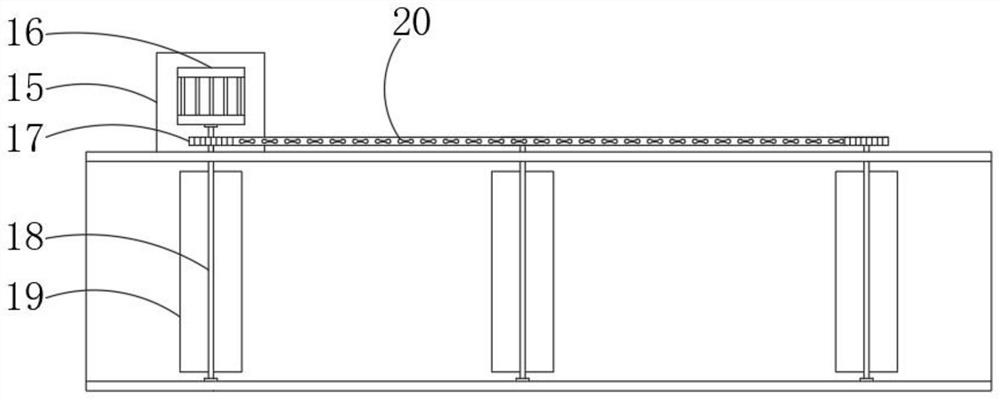

Cooling device for straw particle manufacturing and cooling method of cooling device

InactiveCN112197502AAvoid damageImprove yield rateSievingLighting and heating apparatusPhysicsEngineering

The invention discloses a cooling device for straw particle manufacturing and a cooling method of the cooling device, and relates to the technical field of straw particle manufacturing. The cooling device comprises a material receiving frame, a screening net is installed on the inner bottom face of the material receiving frame, the material receiving frame is obliquely arranged, the lower end of the material receiving frame is fixedly connected with one end of a cooling frame, and the cooling frame and the material receiving frame are the same in inclination degree. Multiple cooling fans are fixedly installed on the upper surface of the cooling frame, through grooves allowing the cooling fans to discharge air are formed in the upper surface of the cooling frame, the upper side of the lowersurface of the material receiving frame and the lower side of the lower surface of the cooling frame are each fixedly connected with two supporting columns, and a rolling mechanism is fixedly installed on one side face of the cooling frame. According to the cooling device for straw particle manufacturing and the cooling method of the cooling device, straw particles which are just produced can becooled, so that the straw particles are rapidly cooled down, the straw particles are conveniently bagged, and damage of the overheated straw particles to packaging bags is avoided.

Owner:和县宇阳秸秆颗粒有限公司

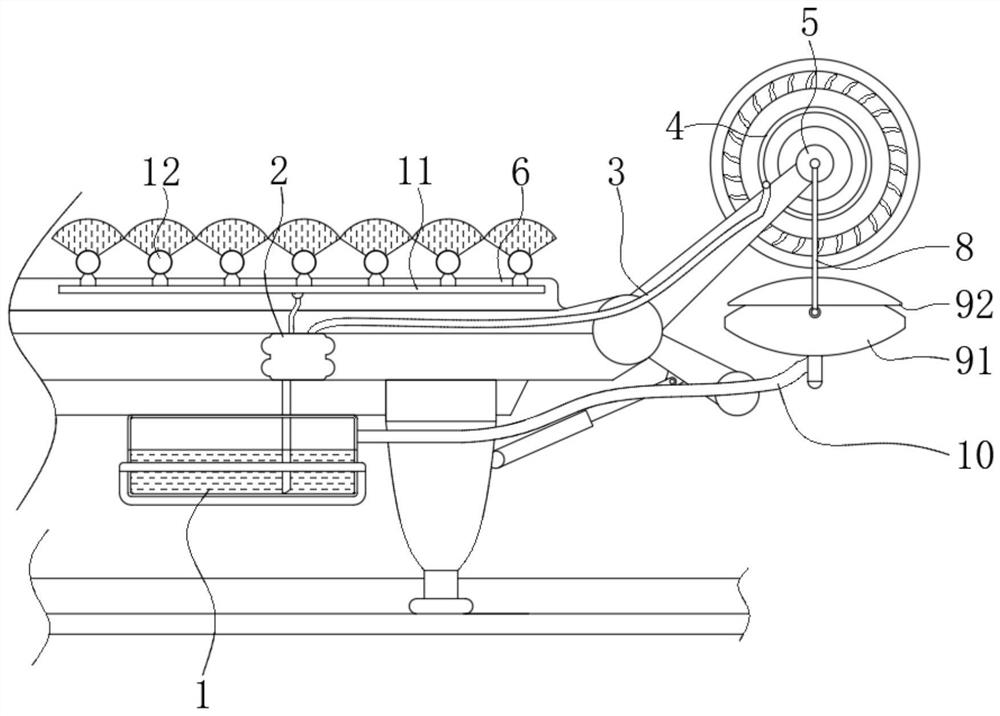

Coal mining machine dust removal device for coal mining and dust removal method thereof

ActiveCN111852471AImprove atomization effectIncrease the chance of agglomerationCombination devicesSpraying apparatusCoal miningMining engineering

The invention relates to the technical field of coal mining machine dust removal, and discloses a coal mining machine dust removal device for coal mining. The device comprises a water tank, wherein arack is arranged at the top of the water tank, the bottom of the rack is fixedly connected with the top of the water tank, a water pump is fixedly connected to the middle of the front surface of the rack, a fixing column is fixedly installed on the right side of the rack, and an air collection device is fixedly installed in the middle of the fixing column. According to the coal mining machine dustremoval device and a dust removal method thereof, through the cooperation of a rocker arm nozzle device and the air collection device, fan blades are used to absorb air out of a water curtain formedby the rocker arm nozzle device, the moisture entering a conical body is extruded, the moisture can be conveniently formed into fine water beads, and the atomization effect of nozzles of the coal mining machine dust removal device for coal mining is improved; and after the water beads are atomized, the weights of the condensed dust beads are increased, and the dust removal effect of the coal mining machine dust removal device for coal mining is improved.

Owner:内蒙古利民煤焦有限责任公司

Automatic processing and producing system for preserved fresh flowers

ActiveCN110558088AAvoid pollutionHigh degree of automationFlower preserving apparatusPulp and paper industryAutomatic testing

The invention discloses an automatic processing and producing system for preserved fresh flowers. The automatic processing and producing system is characterized by comprising a processing room, a gripper track is arranged at the top inside the processing room, a mechanical gripper is slidingly arranged on the gripper track, a dewatering and decoloring pool, a cleaning room, a dyeing room, a dryingroom and a softening and color fixing room are sequentially formed inside the processing room from left to right, a bottom plate is arranged on the bottom face inside a groove of the dewatering and color fixing pool, a flower disc placing frame is placed on the bottom plate, a trough is formed in the ground of the bottom of the dewatering and decoloring pool, an air cylinder is arranged in the trough, and the push-out end of the air cylinder penetrates through the bottom face of the dewatering and decoloring pool and is fixedly connected with the bottom plate. The aim is to provide the automatic processing and producing system for preserved fresh flowers. In this way, the automation is improved when the preserved fresh flowers are produced, and the sum of labor and labor costs are reduced.

Owner:石林华莱永生花卉有限公司

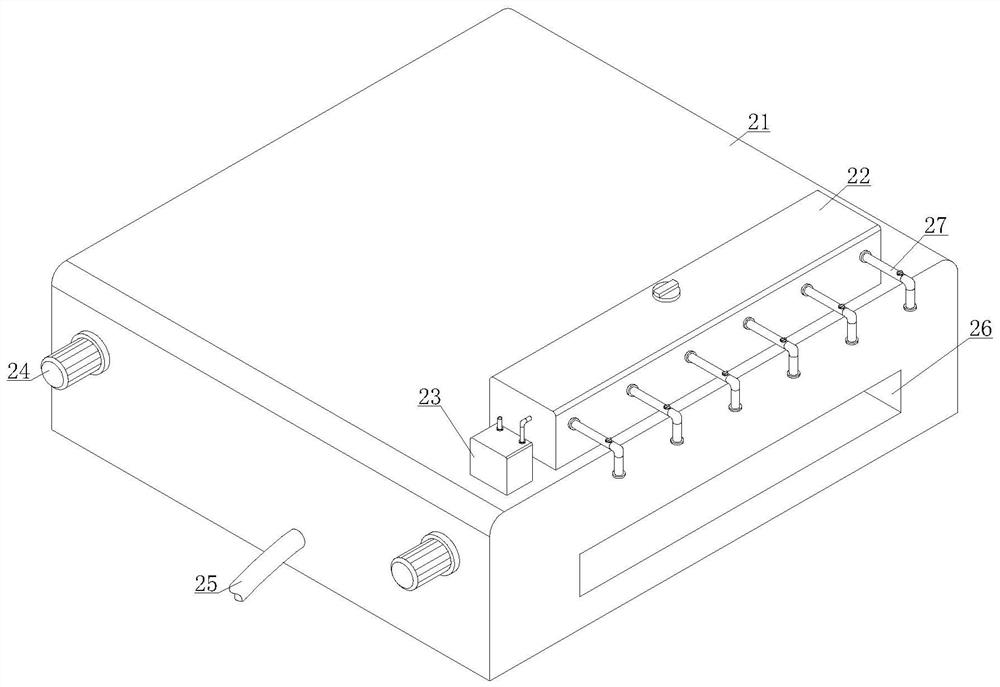

Stamping die waste compression equipment

The invention discloses a stamping die waste compression equipment, which comprises a box body and a rear shell located at the rear side of the box body. The right side of the box body is provided with buckle ears and a control panel, and the upper part of the box body is provided with a hydraulic column. The hydraulic column is located at the inner end of the box with a pressure plate, the box is connected to the box door through a pivot pin, a door lever is provided on one side of the box door, a push plate is provided at the lower part of the rear side of the box, and the rear side of the box is provided with a push plate. The bottom of the inner cavity of the shell is provided with a fixed seat, a hydraulic tank and a hydraulic pump. The fixed seat is provided with a hydraulic push rod, and one end of the hydraulic push rod is connected to a push plate. connect. This kind of stamping die waste compression equipment puts the waste into the box, and the control panel controls the hydraulic pump to drive the hydraulic column to push the pressure plate to squeeze the waste. After extrusion, open the box door, and the control panel controls the hydraulic push rod. The compressed waste is pushed out of the box, and the device has a simple structure, is easy to operate, and does not take up space.

Owner:重庆新源模具有限公司

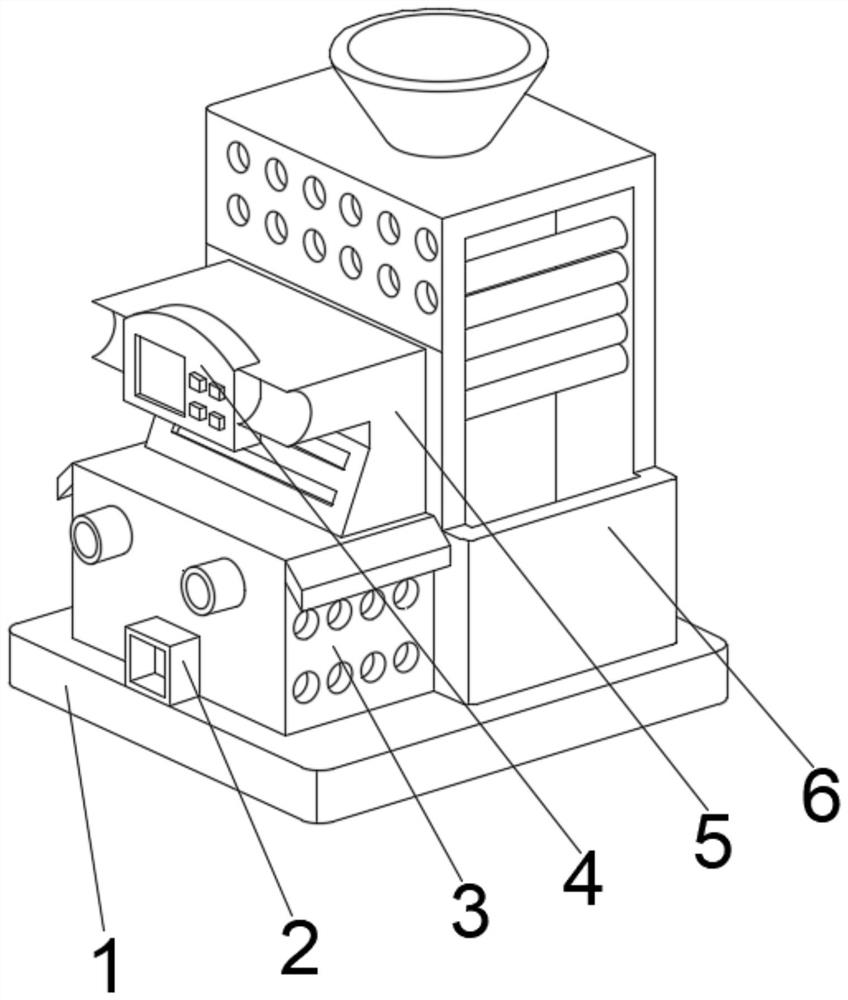

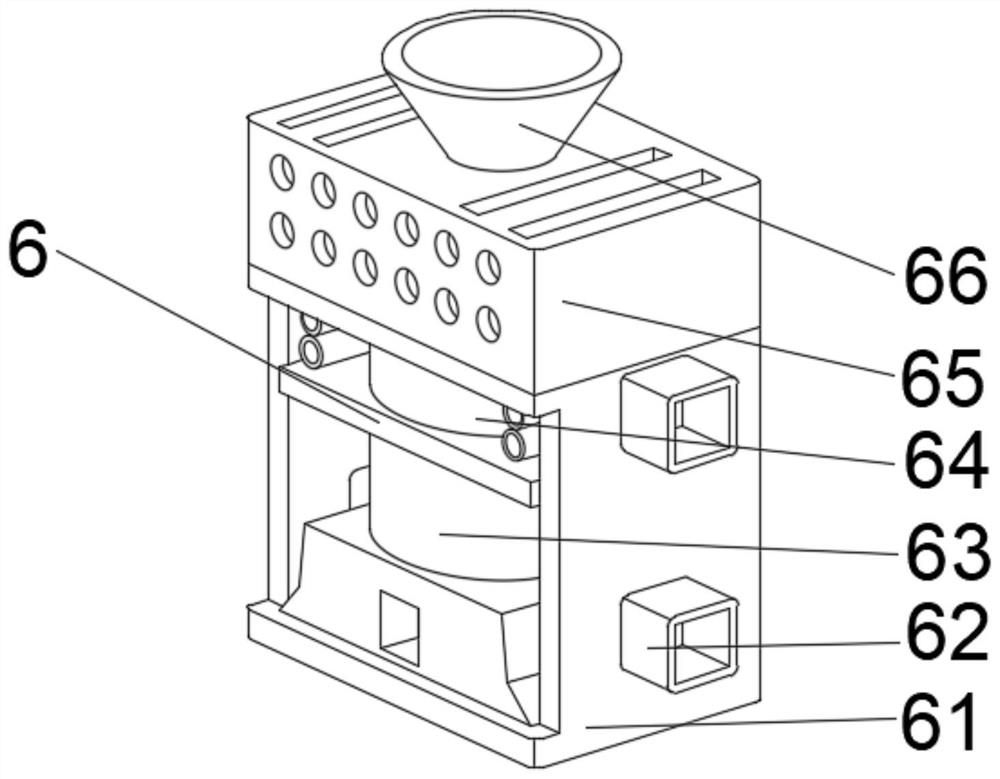

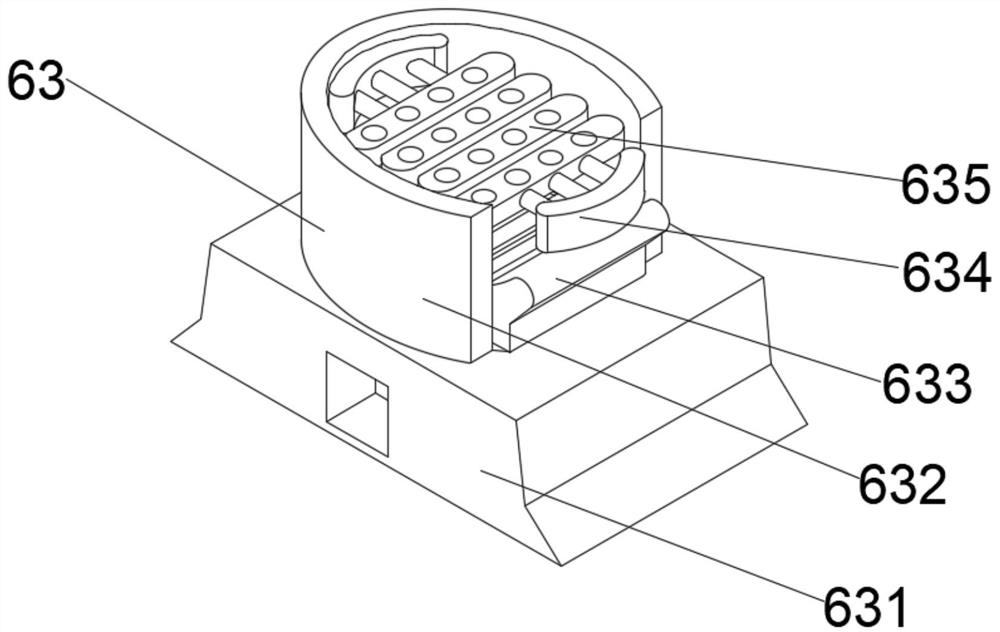

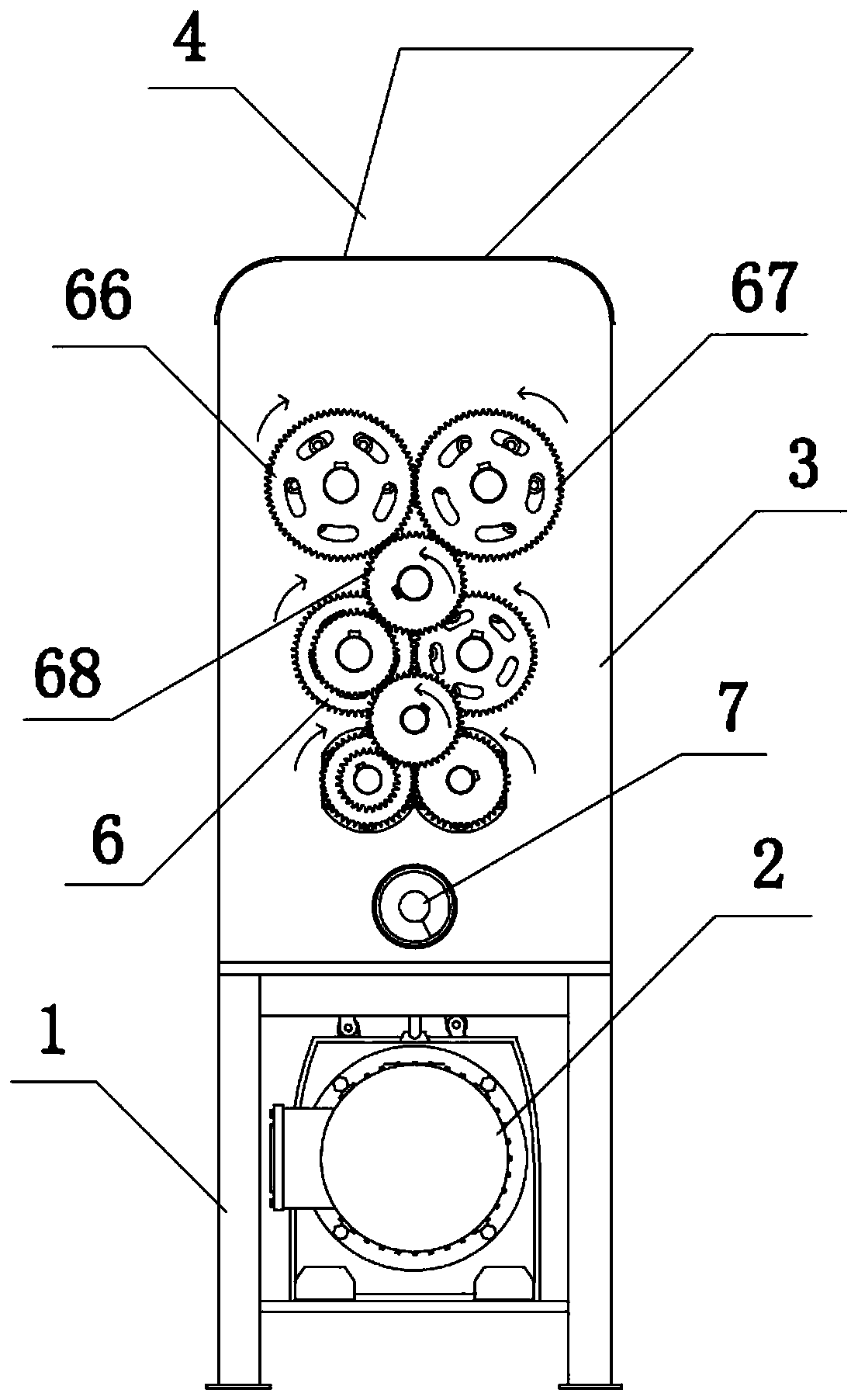

Funnel type permutation and combination kitchen waste processing device and processing method thereof

The invention provides a funnel type permutation and combination kitchen waste processing device. The funnel type permutation and combination kitchen waste processing device comprises a support seat,a power device, an outer housing, a feed hopper, an inner housing, a multistage crushing device, a discharge spiral push rod device and a water delivery device. The funnel type permutation and combination kitchen waste processing device has the beneficial effects of 1, using a decelerator structure, thereby being low in rotation speed and large in torque, and not only reducing influence to surrounding environment, but also effectively crushing block hard materials of bone and the like; 2, using the multistage crushing device, thereby being flexible in structure, and capable of controlling thequantity of roll shaft groups and the size of intervals among roll shafts in each group according to demands in the production process; 3, using the multiple roll shaft groups for continuously feedingfrom the top down, increasing rotation speed of the roll shafts step by step from the top down through transmission among gears, and being capable of effectively preventing the materials from depositing among the multistage roll shaft groups; 4, installing a scraper group, thereby being capable of continuously and effectively clearing material deposits in roll grooves; 5, being capable of selecting if water needs to be used or selecting the water delivery amount according to the demands; and 6, being capable of effectively controlling the size of the discharged materials.

Owner:胡金祥

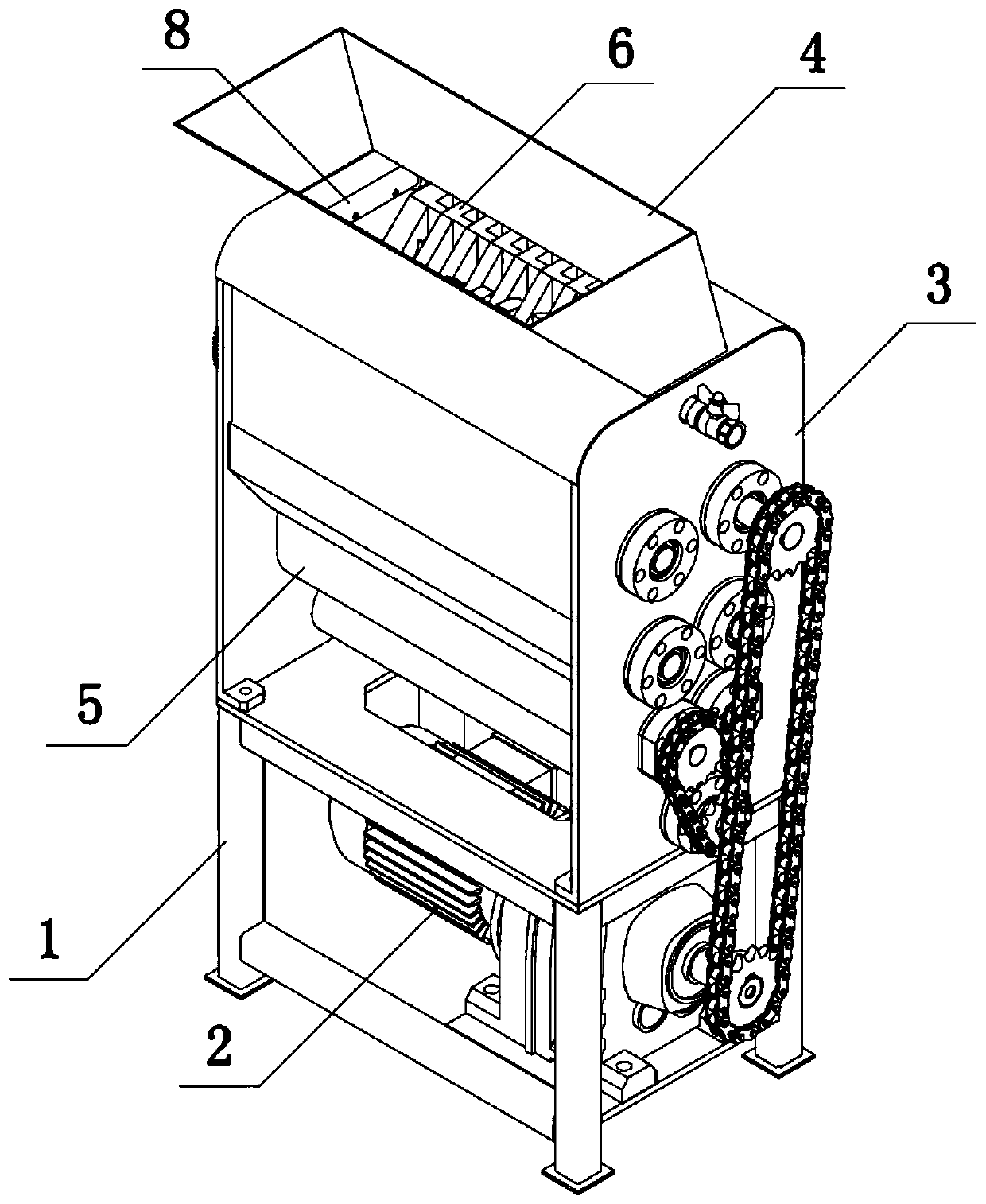

Dust-filtering-type wood processing equipment

ActiveCN111633749AEasy to collect and reuseIssues Affecting the Work EnvironmentGas current separationProfiling/shaping machinesStructural engineeringWood machining

The invention provides dust-filtering-type wood processing equipment. The equipment comprises a bottom plate, a cutting wheel and a servo motor, a n-shaped plate is fixedly connected with the center of the top of the bottom plate, baffles are fixedly connected with the front and rear sides of the bottom of a first supporting plate and the top of the bottom plate perpendicularly and fixedly, a second supporting plate is fixedly connected with the position, located at the lower end of the first supporting plate, of the interior of the n-shaped plate, a driving shaft is transversely connected with the inner center of the first supporting plate in a transferred mode, a track assembly is fixedly connected with the top of a guiding plate, rotating plates are movably connected with the positions,located at the upper end of the track assembly, of a second connecting shaft and a first driven shaft, a sliding assembly is movably connected with the center of the bottom of each rotating plate, supporting feet are vertically and fixedly connected with the periphery of the bottom of the bottom plate correspondingly, a drawer bracket is fixedly connected with the bottom of the bottom plate, a first drawer is in clamped connection with the center of the drawer bracket, and second drawers are in clamped connection with the positions, located on the left and right sides of the first drawer, ofthe drawer bracket correspondingly. The dust-filtering-type wood processing equipment solves the problems of operator health affecting due to wood processing dust and sawdust waste.

Owner:周翔

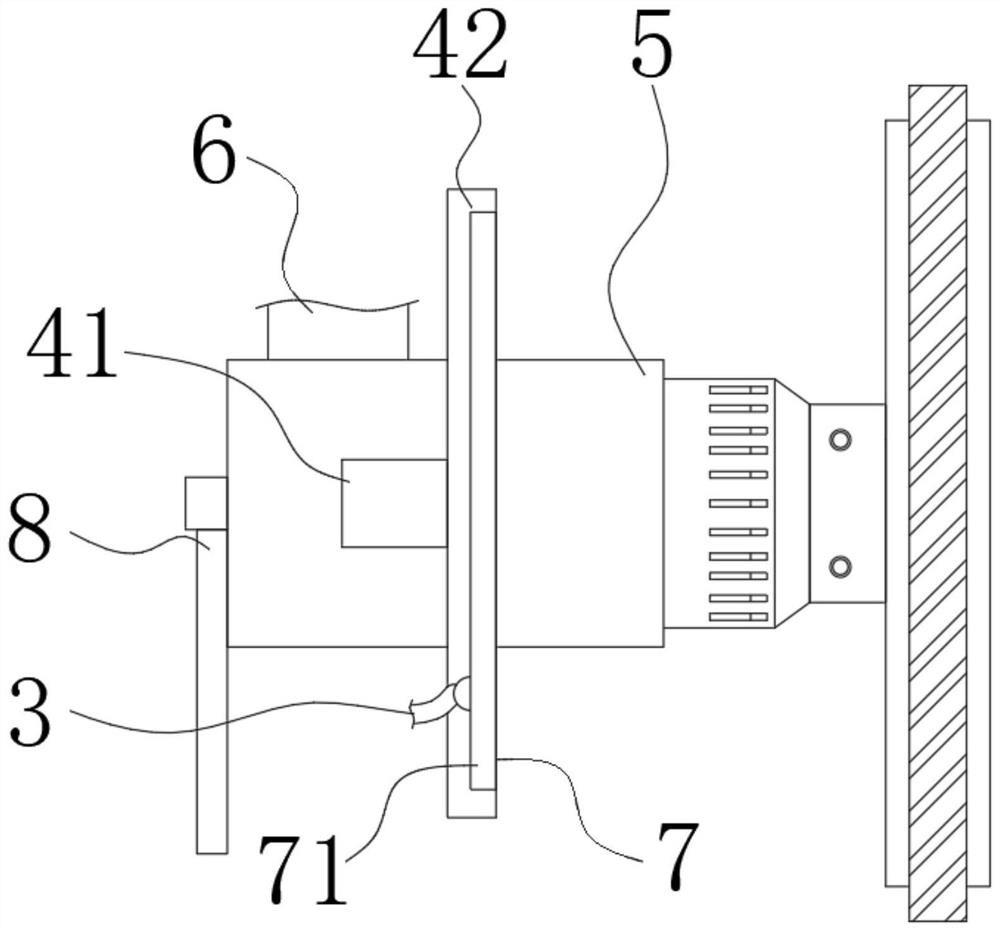

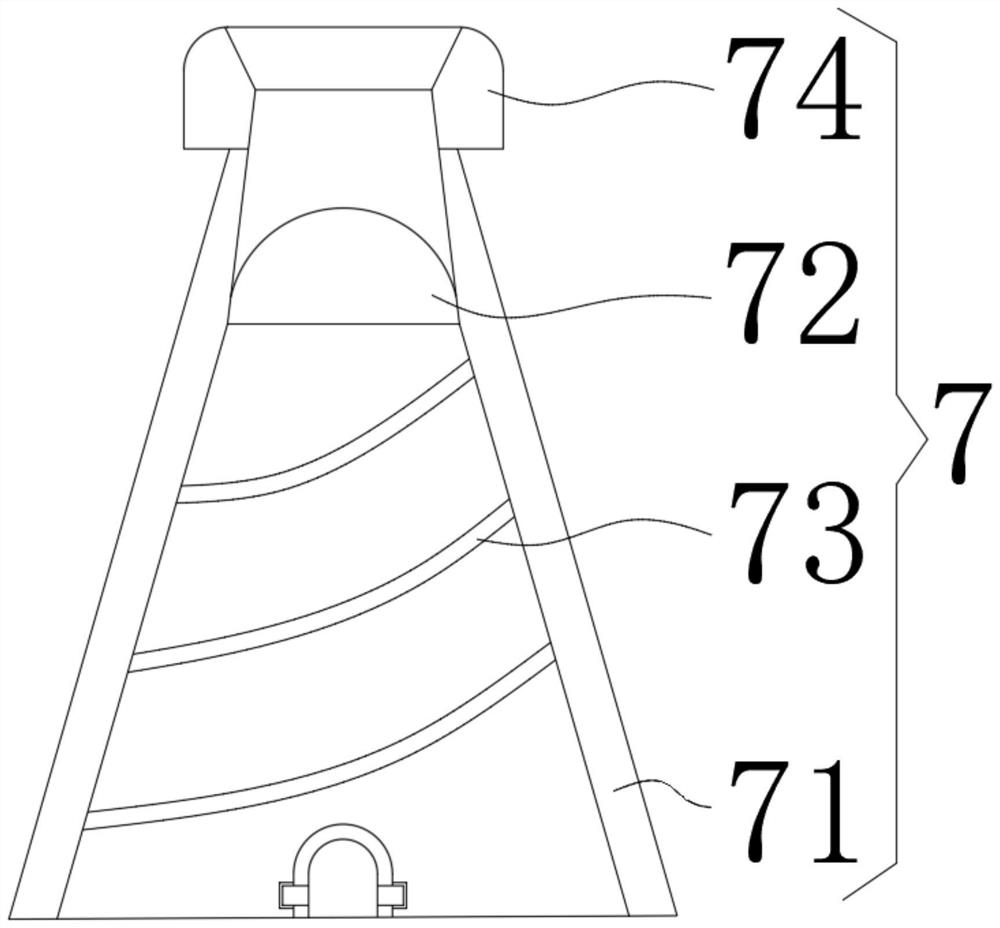

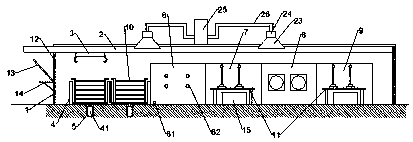

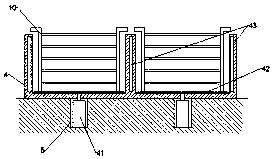

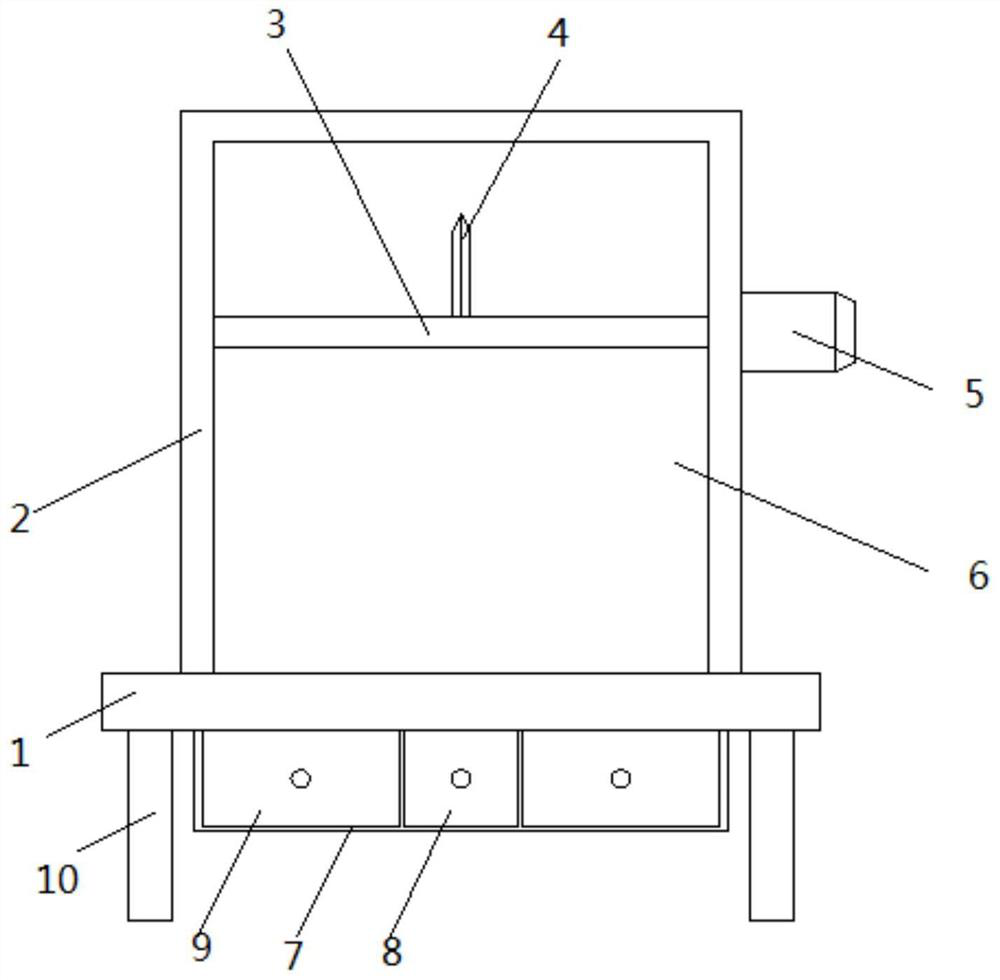

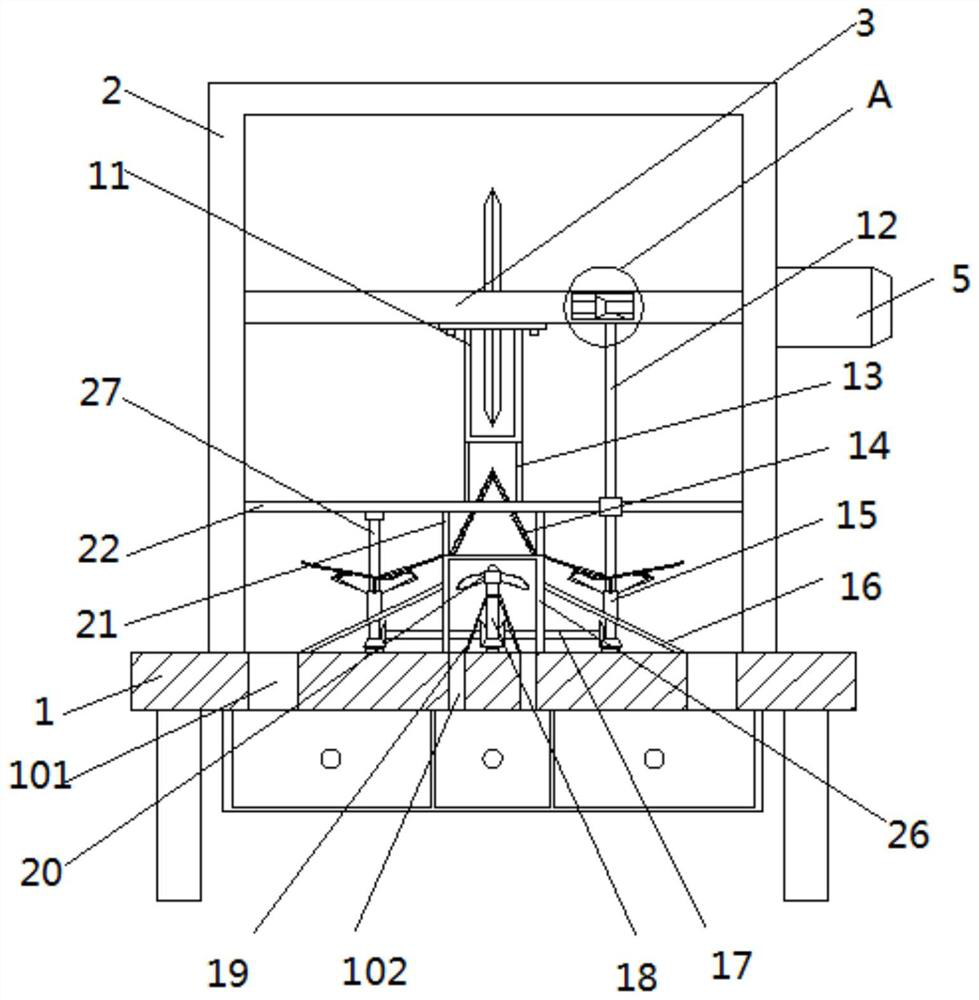

Wood board drilling equipment

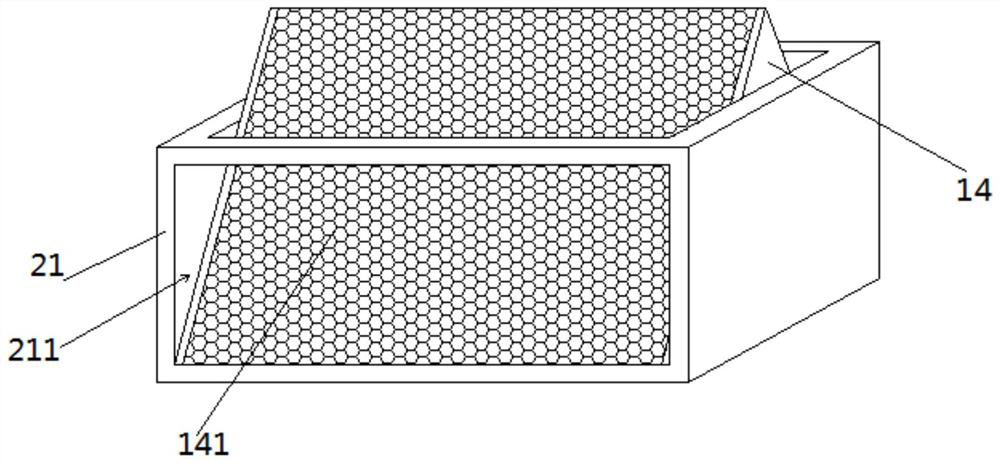

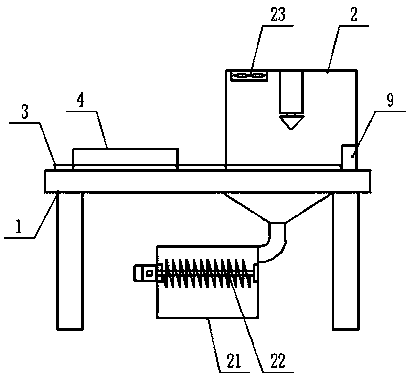

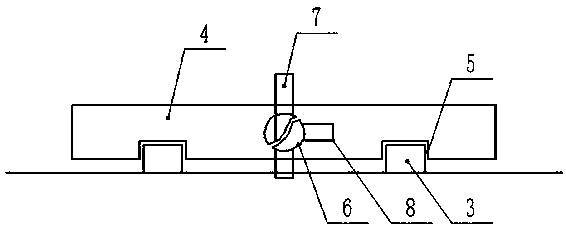

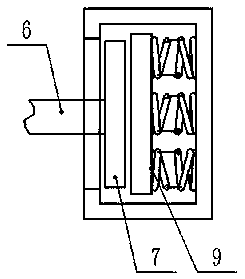

InactiveCN109159214AEasy to collect and reuseGuaranteed cleanlinessStationary drilling machinesBark-zones/chip/dust/waste removalWood plankIndustrial engineering

The invention discloses wood board drilling equipment. The wood board drilling equipment comprises a table body and a processing box, wherein a guide rail and a working table are arranged at the upperend of the table body; the middle part of the inner cavity of the working table is movably provided with a rotating shaft in a penetrated manner; the end, along the length of the rotating shaft, of the rotating shaft is provided with a rectangular clamping block, and the other end of the rotating shaft is provided with a first manual frame; the inner bottom of the processing box is provided witha fastening piece; the upper end of the working table is provided with a clamping mechanism; two ends, along the width direction of the working table, of the working table are provided with supportingmechanisms respectively; and each supporting mechanism consists of a rectangular groove, a lead screw, a sliding seat, a supporting seat, a connecting frame, a screw hole, a screw, a supporting blockand a second manual frame.

Owner:南京途酷信息科技有限公司

Town domestic waste centralized landfill pit and landfill method thereof

ActiveCN110280561AEfficient separationSolve random stackingSolid waste disposalSludgeActivated carbon filtration

The invention discloses a town domestic waste centralized landfill pit and a landfill method thereof. The town domestic waste centralized landfill pit comprises a pit body, wherein anti-seepage layers are arranged on the side part and the bottom of the pit body, and the inner part of the pit body is sequentially provided with a filter screen, an activated carbon filter layer, a sandy soil layer, a deinked sludge layer and a sandy soil layer from bottom to top. The invention further discloses a landfill method of the town domestic waste centralized landfill pit. The town domestic waste centralized landfill pit can be used for controlling the odor emission phenomenon during landfill, reduces the processing difficulty and the cost of garbage leachate, shortens the garbage landfill period, and is beneficial to collecting and reusing the landfill garbage.

Owner:CHINA THREE GORGES UNIV

Winnowing device for removing fine particle dust of lime kiln and control method thereof

ActiveCN111992500AAvoid floating aroundEasy to collect and reuseHuman health protectionGas current separationFiberLime kiln

The invention discloses a winnowing device for removing fine particle dust of a lime kiln and a control method thereof. The winnowing device comprises a feeding pipe and a winnowing box, wherein the winnowing box communicates with a discharging seat and a dust collecting pipe; and the tail end of the dust collecting pipe communicates with a fiber filter bag. The control method comprises the following steps of S1, starting an air pump firstly to convey generated airflow into an annular pipe through an air inlet pipe; and S2, and directly introducing the gas entering the annular pipe into a cover body through two connecting pipes above the annular pipe. The winnowing device has the advantages that air blown out from bottom to top can carry out winnowing dust removal on materials located in the screening box, meanwhile dust can be collected through cooperation of the fiber filter bag, so that the dust is prevented from drifting around along with movement of the materials, and meanwhile the part of resources (dust) can be conveniently collected and reutilized; and meanwhile, the materials placed in the screening box can be driven to turn over through airflow flowing, so that the dust can be subjected to winnowing removal more sufficiently.

Owner:中琉科技有限公司

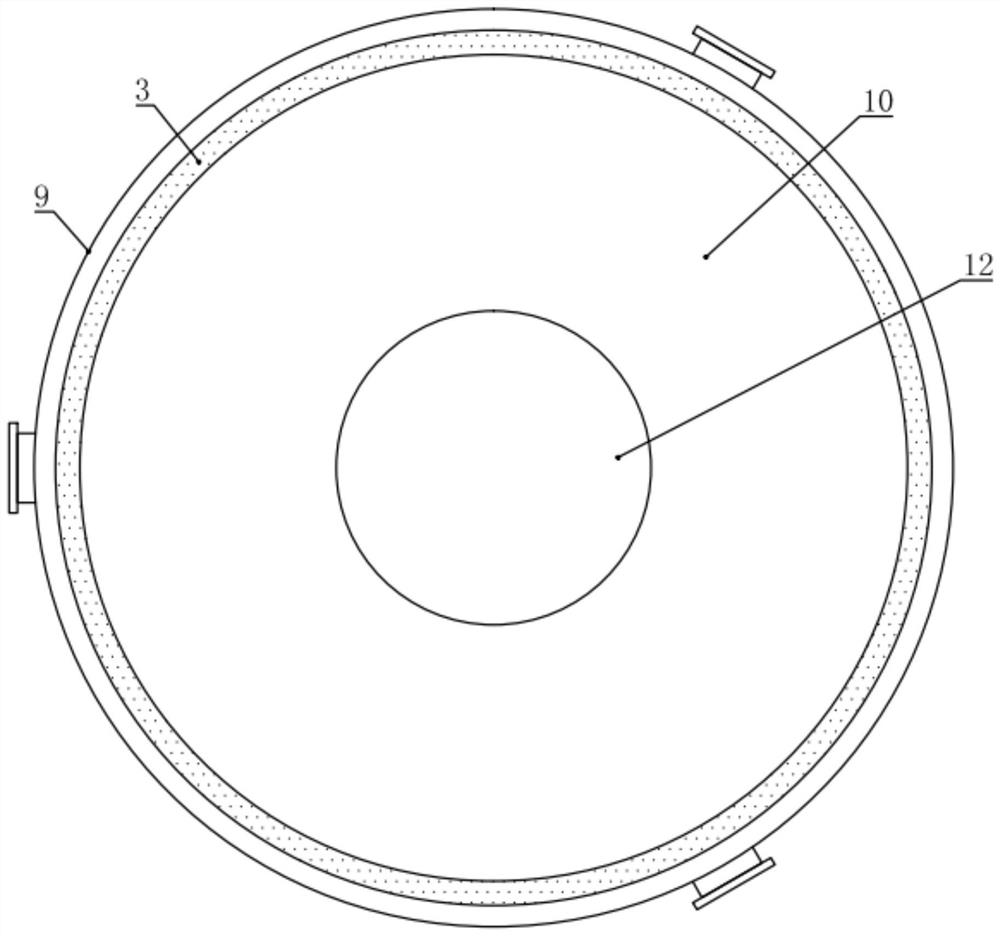

Movable gluing and drying device for aluminum substrate production

InactiveCN112974155AGood removal effectAvoid affecting the effect of gluingPretreated surfacesDrying solid materialsGear driveGear wheel

The invention discloses a movable gluing and drying device for aluminum substrate production. The movable gluing and drying device comprises a feeding device and drying equipment. When copper foil needs to be processed, a second driving motor rotates to drive a second roller shaft to rotate, the copper foil is fed after the second roller shaft rotates, meanwhile, the second driving motor drives a first gear to rotate when rotating, the first gear drives a second gear to rotate through a first chain, a third gear is driven to rotate after the second gear rotates, a rotating wheel installed on the back face is driven to rotate after the third gear rotates, after the rotating wheel rotates, a rotating rod can rotate, after the rotating rod rotates, air pressure in an inner cavity of a pressurizing chamber is compressed, then an air valve is ejected open upwards by the air pressure, after the air valve is ejected open, air enters an inner cavity of a water tank from an exhaust pipe, after the air pressure of the inner cavity of the water tank is increased, an aqueous solution is sprayed out from a spray head, and therefore spray can be sprayed on the surface of the copper foil, and dust on the surface of the copper foil can be conveniently removed.

Owner:赣州逸豪新材料股份有限公司

Rolling-kneading coating device for processing spicy salted duck

The invention discloses a rolling-kneading coating device for processing a spicy salted duck. The rolling-kneading coating device comprises a support base, an observing window, a conveying belt, discharging ports, a vacuum pump, a device body, water inlets and an air suction pipe; the middle of the support base is provided with the device body; the external surface of the device body is provided with the observing window; the upper top end and the lower bottom end of the device body are respectively provided with a second motor and a first motor; the discharging ports are arranged at positionsat two sides of the first motor, and the discharging ports are arranged at the bottom of the device body; meanwhile, the vacuum pump is arranged at the exterior of the right side of the device body;a second rotating disk and a first rotating disk arranged inside a connecting plate are connected through a belt; and the middle of the first rotating disk is provided with a screw rod in a penetrating way. During a using process, the rolling-kneading coating device for processing the spicy salted duck can not only guarantee continuous discharging in feeding and discharging processes of the spicysalted duck, but also guarantee stability in the whole feeding and discharging processes.

Owner:HUNAN UNIV OF ARTS & SCI

Four-segmentation material dividing, guiding and guarding device

PendingCN111774423AImprove efficiencyAvoid deformationDispersed particle filtrationGuiding/positioning/aligning arrangementsEngineeringScrew thread

The invention relates to the technical field of steel rolling equipment, and discloses a four-segmentation material dividing, guiding and guarding device which comprises an outer box body. An inner box body is fixedly connected to the interior of the outer box body, a first rotating shaft and a second rotating shaft are slidably connected to the left end and the right end of the inner wall of theinner box body correspondingly, four guide wheels are fixedly connected to the outer surface of the first rotating shaft, four splitting wheels are fixedly connected to the outer surface of the secondrotating shaft, screw rods are movably connected to the upper end and the lower end of the left side of an inner cavity of the outer box body correspondingly, and sliding blocks are in threaded connection with the left ends and the right ends of the outer surfaces of the screw rods correspondingly. According to the four-segmentation material dividing, guiding and guarding device, the rotating force of a servo motor is converted into the left-right moving force of the first rotating shaft and the second rotating shaft, so that the purpose of adjusting the distance between the splitting wheelsand the guide wheels is achieved, materials with different thicknesses are conveniently split, the application range of the four-segmentation material dividing, guiding and guarding device is widened,the production efficiency is improved, and the four-segmentation material dividing, guiding and guarding device is convenient to use and applicable to various situations.

Owner:靖江精益冶金科技有限公司

Machining equipment with cleaning function

InactiveCN111889431AAvoid influenceKeep dryDrying gas arrangementsCleaning using liquidsTemperature controlEngineering

The invention relates to the field of machining equipment, in particular to machining equipment with a cleaning function. The equipment comprises a machining box body, an annular bottom plate is arranged on the inner side of the machining box body, a machining table is fixed on the upper side of the annular bottom plate, an annular groove is formed in the outer ring of the lower side of the machining table, and a plurality of flushing exhaust heads are mounted in the annular groove; a pressure relief cavity is further formed in the inner side of the machining table, the multiple flushing exhaust heads communicate with the lower portion of the pressure relief cavity through branch pipes correspondingly, a pressure relief device used for relieving pressure of the pressure relief cavity is further installed in the machining table, a flushing pump is installed at the inner bottom of the machining box and communicates with the bottom of the pressure relief cavity through a water conveying pipe, a temperature control draught fan is further installed on the lower side of the annular bottom plate and communicates with the bottom of the pressure relief cavity through an air conveying pipe,an impurity blocking net barrel is further installed on the lower side of the annular bottom plate, and the lower end of the impurity blocking net barrel is fixed to the inner side wall of the machining box body. The device is novel in structure, machining impurities can be conveniently and rapidly removed, and popularization is facilitated.

Owner:SUZHOU KAIENAO AUTOMATION CO LTD

Production equipment and technology of even-back vest bag

ActiveCN112373123BReduce uneven croppingReduce stackingBag making operationsPaper-makingIndustrial engineeringSupport plane

The present application discloses a production equipment and a process for an even-back vest bag, which relates to the technical field of bag making. The discharging device arranged at the discharging end of the frame also includes a die-cutting device arranged between the heat-sealing device and the discharging device; the die-cutting device includes a die-cutting bracket, a workbench arranged at the top of the die-cutting bracket, and a die-cutting device fixed on the die-cutting bracket. A support frame at the top of the workbench, a die-cutting block connected to the support frame, a die-cutting roller rotatably connected with the die-cutting block, and a die-cutting die set on the die-cutting roller. The present application has the effect of optimizing the production process and reducing the occurrence of irregular cutting of the bag body.

Owner:QINGDAO ZHOUSHI PLASTIC PACKAGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com