Automatic processing and producing system for preserved fresh flowers

An automatic processing and production system technology, applied in flower processing, flower preservation devices, botanical equipment and methods, etc., can solve the problems of inability to realize production automation or automation, increase labor costs, etc., to prevent air pollution and improve automation. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

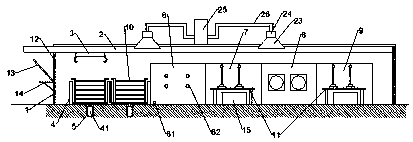

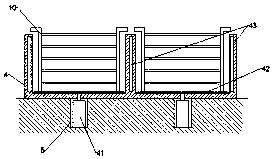

[0034] refer to figure 1 As shown, the present invention provides an automatic processing and production system for preserved flowers, including a processing chamber 1, a handle track 2 is arranged on the top of the processing chamber 1, and a mechanical gripper 3 is slidably arranged on the handle track 2. In the processing room 1, there are dehydration and decolorization pool 4, cleaning room 6, dyeing room 7, drying room 8, and softening and color fixing room 9, respectively, for dehydration and decolorization, cleaning, dyeing, drying, softening and color fixing. and other processes, the top of the processing chamber 1 is provided with a suction hood 23, the suction port of the suction hood 23 leads into the processing chamber 1, and the suction hood 23 is provided with a suction mechanism 24, the suction mechanism 24 includes a motor and a turbine , the air suction mechanism 24 is connected to the gas purifier 25 through the gas delivery pipe 26, and the peculiar smell or...

Embodiment 2

[0039] On the basis of the above embodiments, another embodiment of the present invention is that a feed port 12 is provided on one side of the processing chamber 1, a door body 13 is hinged at the lower edge of the feed port 12, and a The lower edge of the opening 12 is also fixedly provided with a tripod 14 for supporting the door body 13 on a horizontal plane so that when the door body is opened, the door body 13 can be supported by the tripod frame 14 to be in a horizontal state, so that the faceplate placement frame 10 is placed on the door body. 13 is convenient for grabbing of mechanical gripper 3.

Embodiment 3

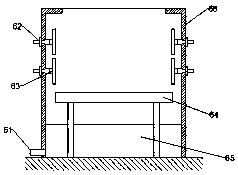

[0041] refer to image 3 As shown, in another embodiment of the present invention, the bottom of the cleaning chamber 6 is provided with a sump 65, and the placing platform 64 is placed in the sump 65, and the water after cleaning can flow into the sump 65, and one side of the cleaning chamber A drainpipe 61 is arranged at the bottom of the wall 66, and the drainpipe 61 communicates with the sump 65. Preferably, the drainpipe 61 can communicate with the water tank, so as to facilitate the collection and recycling of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com