Wood board drilling equipment

A technology for punching equipment and wood boards, which is applied in wood processing equipment, fixed drilling machines, bark areas/debris/dust/waste removal, etc. It can solve the problems of inconvenient collection and treatment of wood chips, harsh operating environment, and insufficient support. , to achieve the effect of easy collection and reuse, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

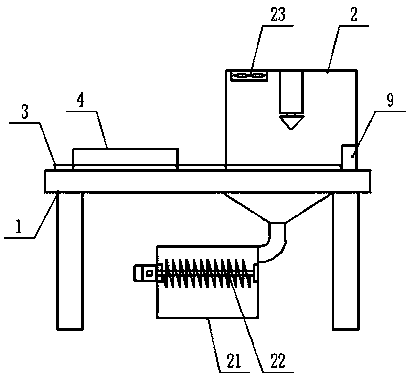

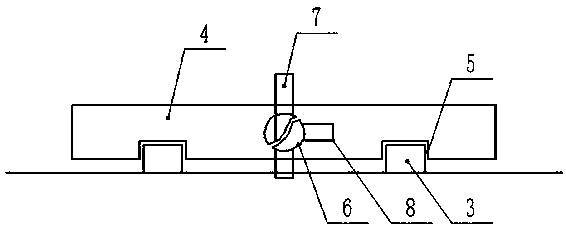

[0021] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Now, a kind of plank punching equipment provided by the present invention is described, which includes a table body 1 and a processing box 2 provided on one side of the upper end of the table body 1 in the length direction, and the upper end of the table body 1 is arranged in parallel at intervals along its width direction. There is a guide rail 3, a workbench 4 is arranged on the top of the table body 1, and guide grooves 5 are respectively opened at the bottom end of the workbench 4 corresponding to the position of the guide rail 3, and the middle part of the inner cavity of the workbench 4 runs through along its moving direction A rotating shaft 6 is movable, and the rotating shaft 6 is provided with a rectangular block 7 along one end of its length direction and corresponding to the position of the processing box 2, and a first manual frame is arranged at the other end of the rotating shaft...

Embodiment 2

[0022] Example 2: see figure 1 , figure 2 Now, a kind of wood punching equipment provided by the present invention will be described. The table body 1 includes the table board and the legs respectively provided at the four corners of the bottom end of the table board. The length direction of the table board is arranged, and one end of the guide rail 3 extends into the processing box 2 respectively, and the lower part of the outer end of the side corresponding to the position where the guide rail 3 protrudes into the processing box 2 is provided with a manual door body. The top in the processing box 2 is provided with an intelligent punching mechanism.

Embodiment 3

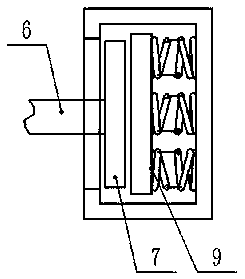

[0023] Embodiment 3: see figure 1 , figure 2 , image 3 Now, a kind of plank punching equipment provided by the present invention will be described. The fastener 9 includes a fastening seat, a hollow groove, a rectangular bayonet, a movable plate and a return spring. The inner bottom of the processing box 2 and the corresponding The middle part of the other end of the manual door body position is provided with the fastening seat, and the inner cavity of the fastening seat is provided with a hollow groove. The fastening seat corresponds to one side end of the manual door body position and corresponds to the rectangular card Block 7 is provided with a rectangular bayonet connected to the inner cavity of the hollow groove, the movable plate is provided in the hollow groove, and the movable plate and the hollow groove correspond to the other side of the rectangular bayonet position The return spring is provided between the ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com