Movable gluing and drying device for aluminum substrate production

A drying device and a mobile technology, which are applied in the field of mobile gluing drying devices for aluminum substrate production, can solve the problems that the surface of copper foil cannot be cleaned, the surface of copper foil is easily contaminated with dust, and the copper foil is prone to defective products. , to achieve the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

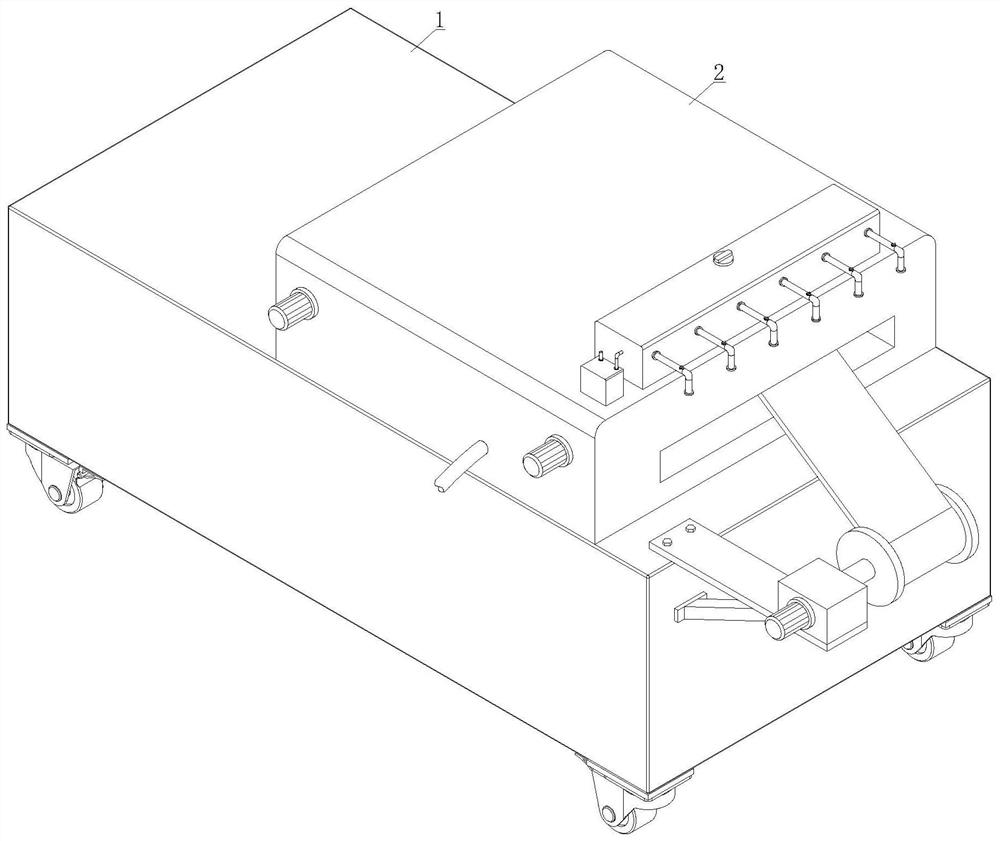

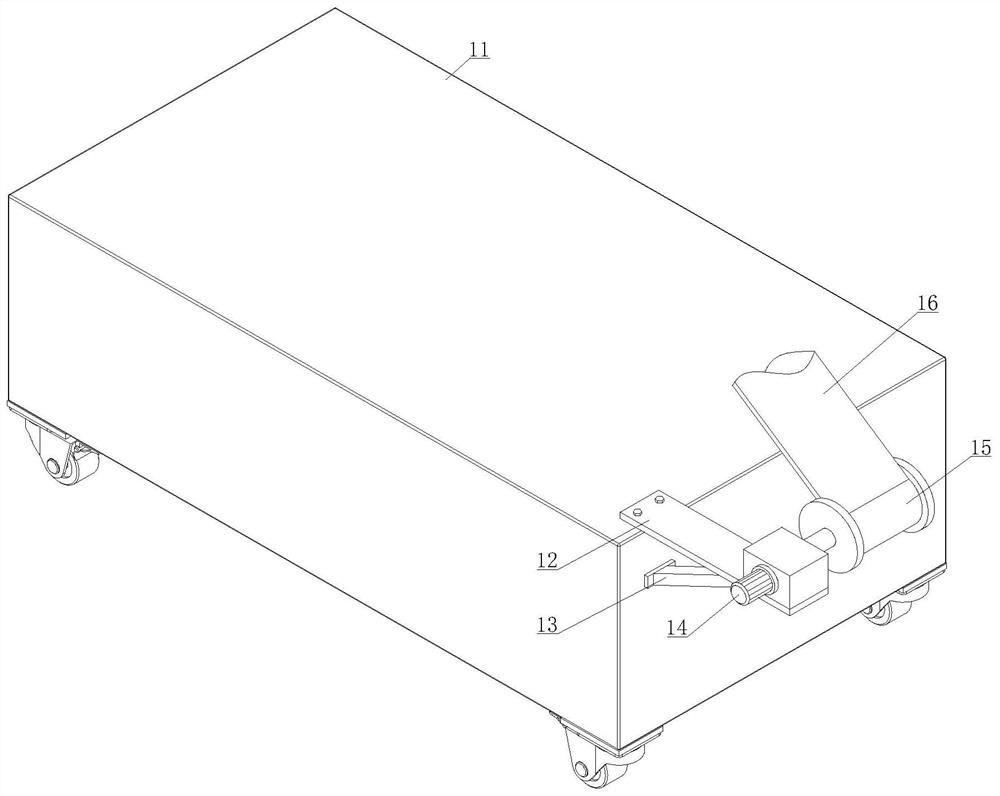

[0030] see Figure 1-2 , a mobile glue drying device for the production of aluminum substrates, comprising a feeding device 1 and a drying device 2, the drying device 2 is installed on one side of the upper end of the feeding device 1, and the feeding device 1 includes a base 11, a second One horizontal plate 12, support 13, first driving motor 14, feeding roller 15 and copper foil 16, the first horizontal plate 12 is installed on one side of the upper end of base 11, and support 13 is installed on one side of base 11, and the support 13 A first driving motor 14 is installed on one side of the upper end, and a feeding roller 15 is installed on the output shaft end of the first driving motor 14. Copper foil 16 is wound on the outer surface of the feeding roller 15, and a drying machine is installed on the upper side of the base 11. device2.

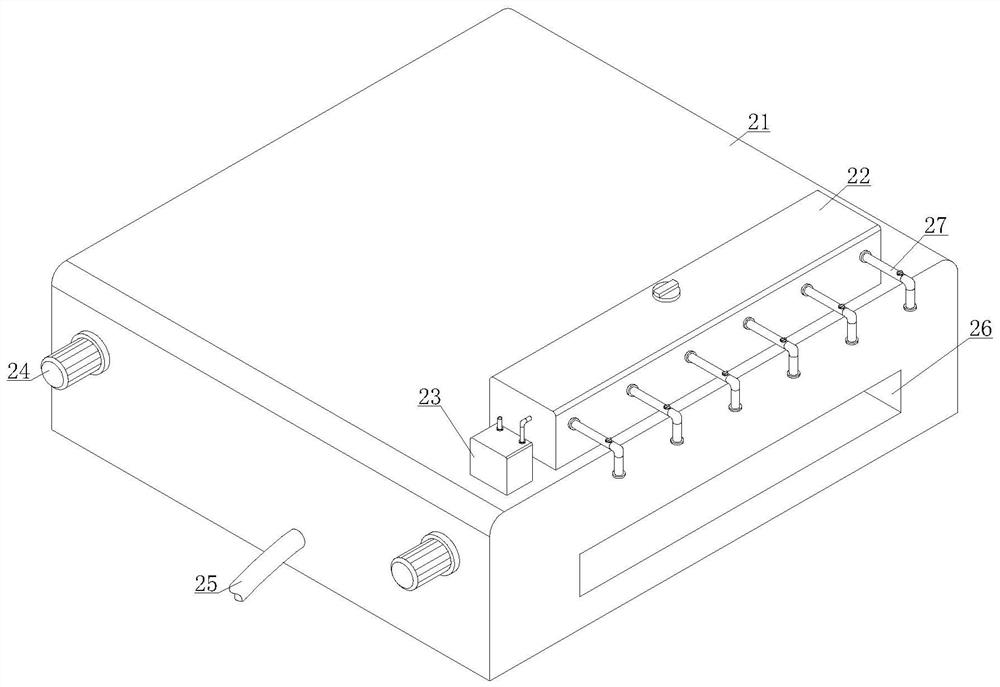

[0031] see image 3, the drying equipment 2 includes a drying box 21, a water tank 22, and a cabinet assembly 23. The cabinet assembly ...

Embodiment 2

[0035] see Figure 1-2 , a mobile glue drying device for the production of aluminum substrates, comprising a feeding device 1 and a drying device 2, the drying device 2 is installed on one side of the upper end of the feeding device 1, and the feeding device 1 includes a base 11, a second One horizontal plate 12, support 13, first driving motor 14, feeding roller 15 and copper foil 16, the first horizontal plate 12 is installed on one side of the upper end of base 11, and support 13 is installed on one side of base 11, and the support 13 A first driving motor 14 is installed on one side of the upper end, and a feeding roller 15 is installed on the output shaft end of the first driving motor 14. Copper foil 16 is wound on the outer surface of the feeding roller 15, and a drying machine is installed on the upper side of the base 11. device2.

[0036] see image 3 , the drying equipment 2 includes a drying box 21, a water tank 22, and a cabinet assembly 23. The cabinet assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com