Production equipment and technology of even-back vest bag

A production equipment and vest bag technology, which is applied in the field of back vest vest production equipment and technology, can solve problems such as many process steps, affecting product quality, and uneven stacking, so as to reduce irregular cutting, optimize production processes, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

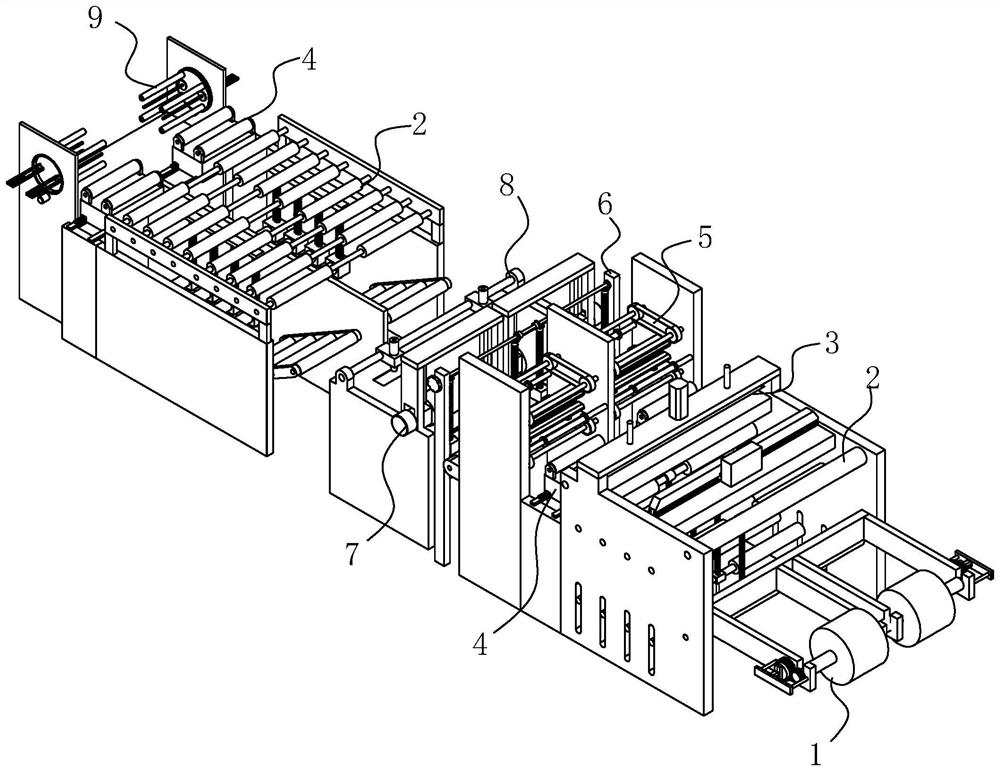

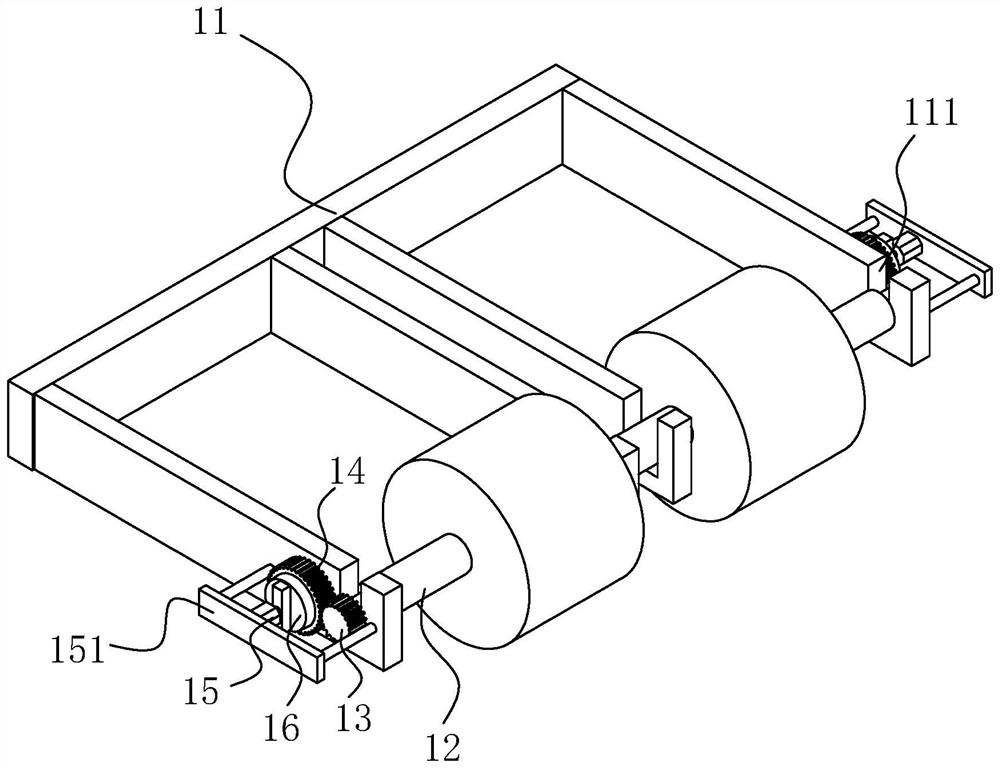

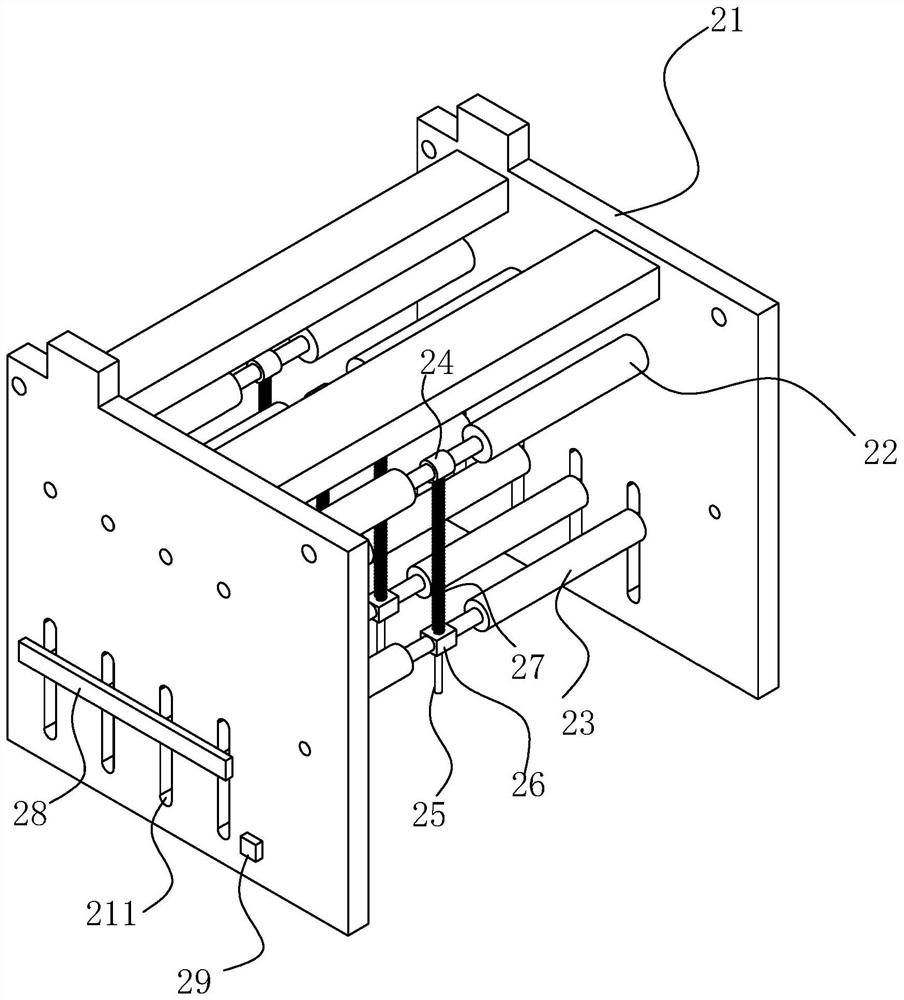

[0045] Example: a production equipment for a vest bag with a back, see figure 1, including the frame, the feeding device 1 arranged on the frame, the tensioning device 2 arranged on one side of the feeding device 1, the connecting device 3 arranged on the frame, and the connecting device 3 is arranged away from the feeding device 1-1 The adjustment device 4 on the side, the heat sealing device 5 arranged on the side of the adjustment device 4 away from the feeding device 1, the adjustment component 6 arranged on the side of the heat sealing device 5 away from the feeding device 1, the adjustment component 6 arranged on the side away from the feeding device 1 The die-cutting device 7 on one side, the scrapping device 8 arranged on the side of the die-cutting device 7 away from the feeding device 1 , and the discharging device 9 arranged on the side of the scrapping device 8 away from the feeding device 1 .

[0046] There are two sets of tensioning devices 2 and adjusting device...

Embodiment 2

[0074] Embodiment 2: a kind of production process of even-back vest bag, comprising the following steps:

[0075] Step 1: Loading. Place the double-layer plastic film roll folded inward on both sides on the feeding device 1, and connect the head end of the new plastic film roll with the tail end of the old plastic film roll through the connecting device 3 to maintain the plastic film. Continuity of feed.

[0076] Step 2: Tension and temporary storage. During the processing of the plastic film, the plastic film is tensioned by the tensioning device 2 to reduce wrinkles and stacking of the plastic bag. And the plastic film is temporarily stored to balance the uneven feeding problem caused by the fast and slow operation of the equipment.

[0077] Step 3: Adjust. Due to the existence of tension, the trajectory of the movement of the plastic film is greatly increased, and a small change will cause the position of the feed to be offset. stability.

[0078] Step 4: Heat sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com