Patents

Literature

34results about How to "Reduce cutting steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

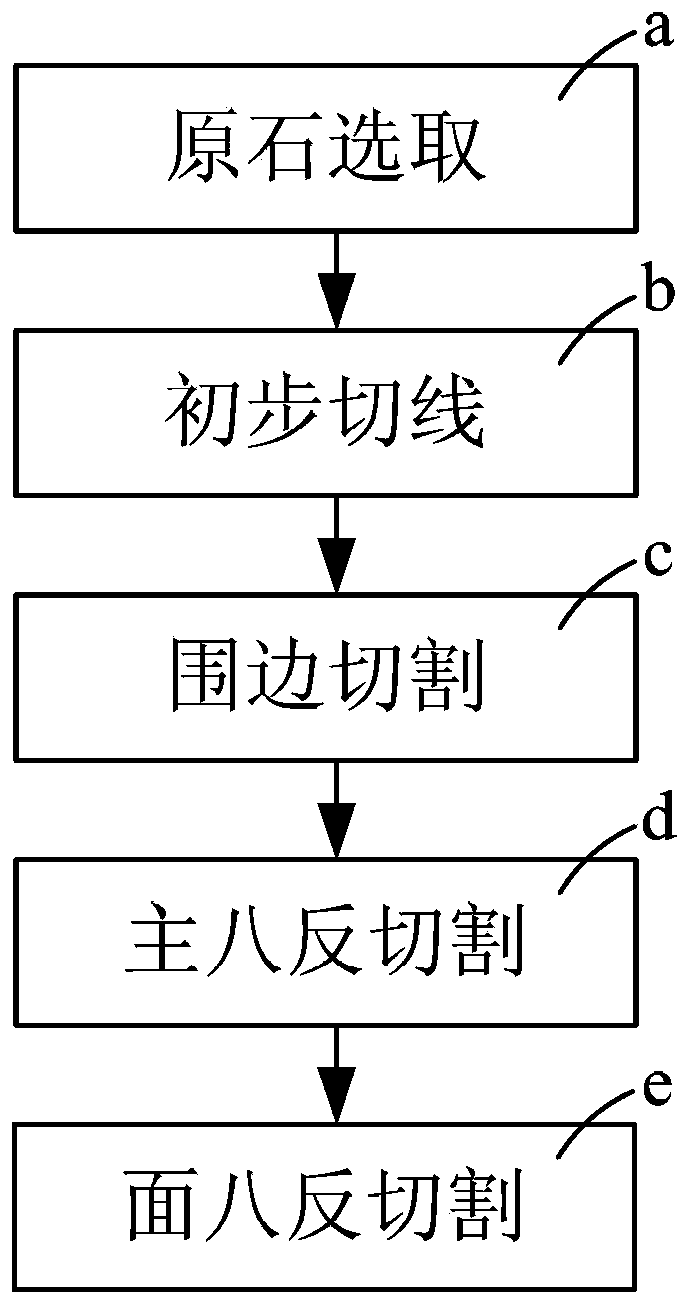

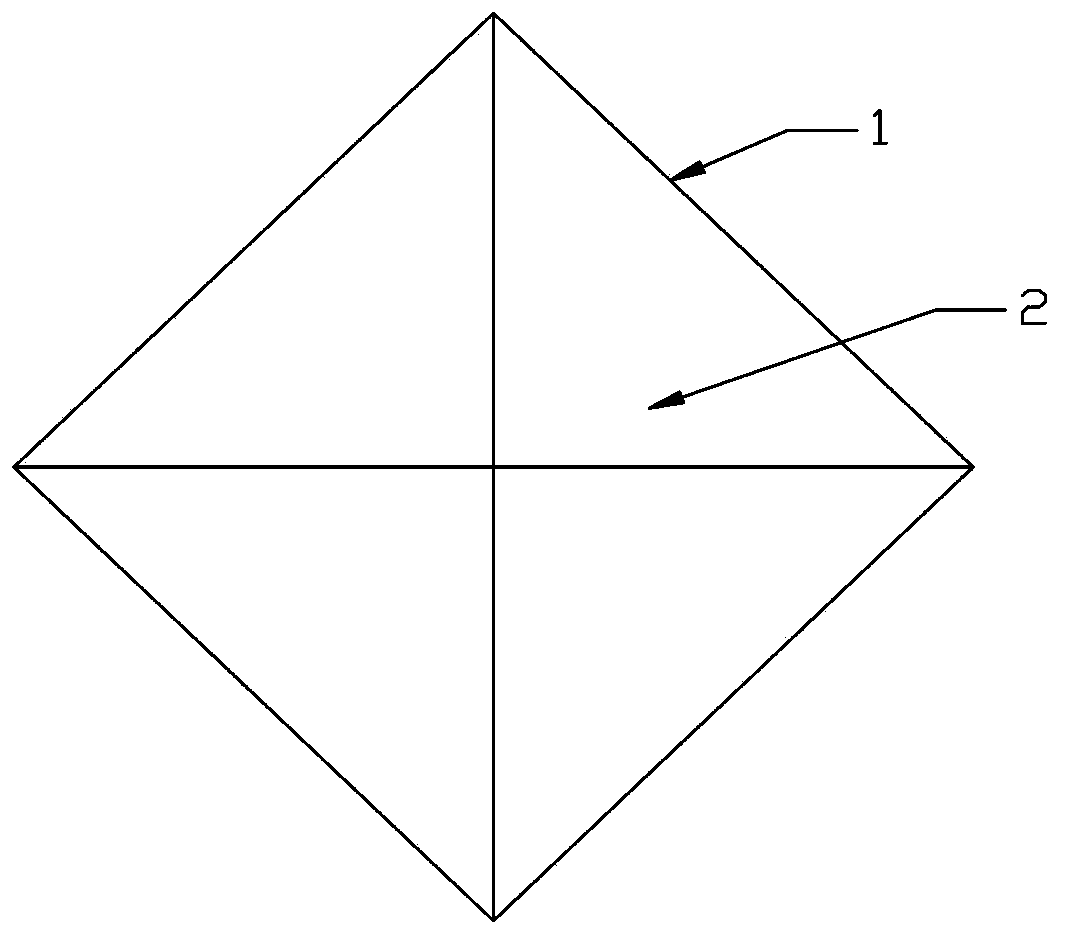

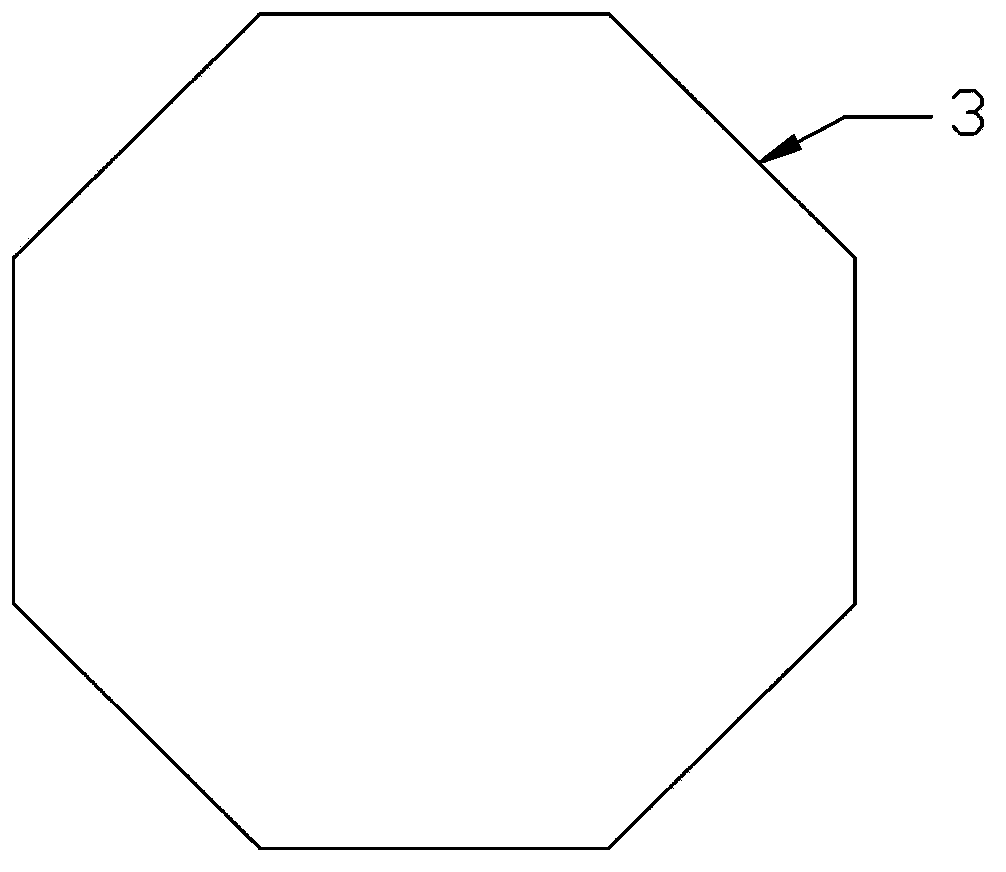

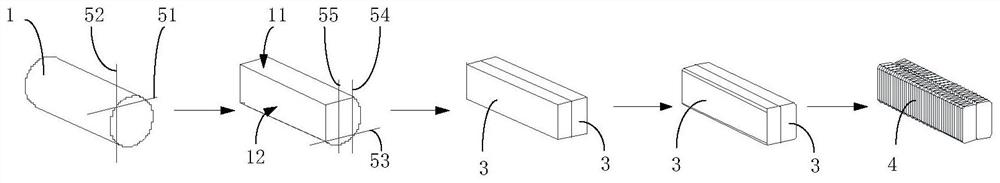

Manufacturing method of octagonal diamond with eight hearts and eight arrows inside

InactiveCN103504734AReduce lossReduce cutting stepsFine working devicesJewelleryMaterials scienceA diamond

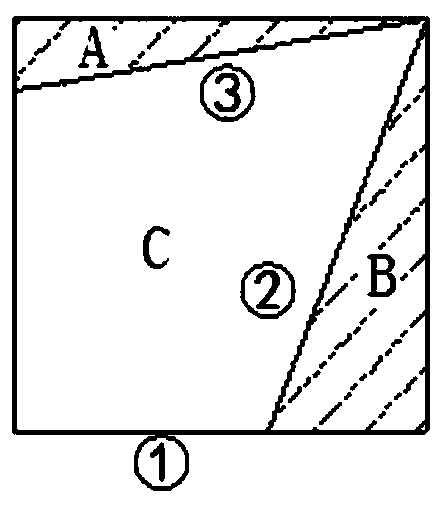

The invention relates to a diamond cutting process, in particular to a manufacturing method of an octagonal diamond with eight hearts and eight arrows inside. The manufacturing method comprises the steps of raw diamond selecting, primary cutting, surrounding edge cutting, main octahedral cone anti-cutting, and surface octahedral cone anti-cutting. By the manufacturing method disclosed by the invention, the steps from raw diamond selecting to each surface cutting are realized by simple steps, so that the loss of the diamond in a cutting process is reduced, the cutting steps of the whole process are reduced, the cutting process of the diamond with eight hearts and eight arrows is simplified, and the product cost is reduced.

Owner:GUANGDONG SHINING HOUSE INT JEWELRY

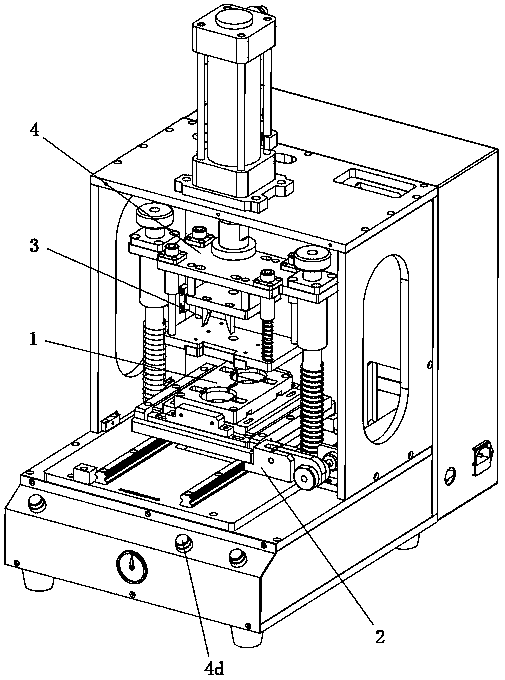

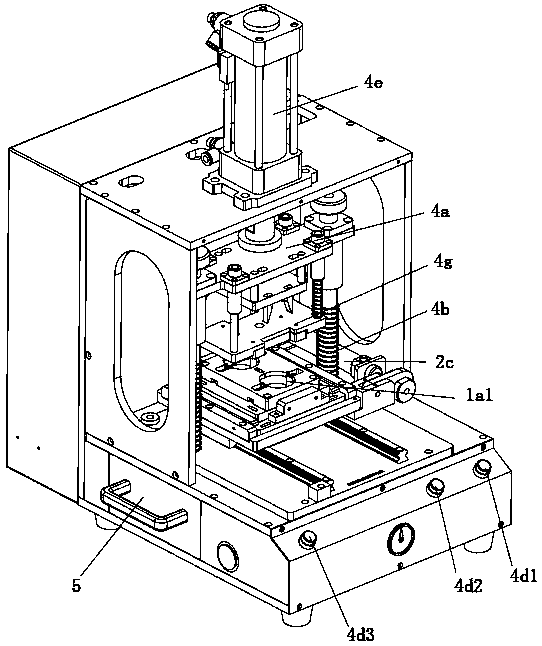

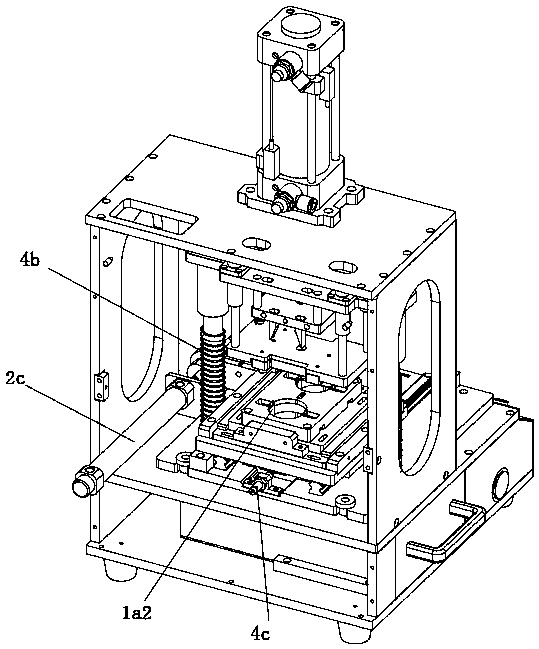

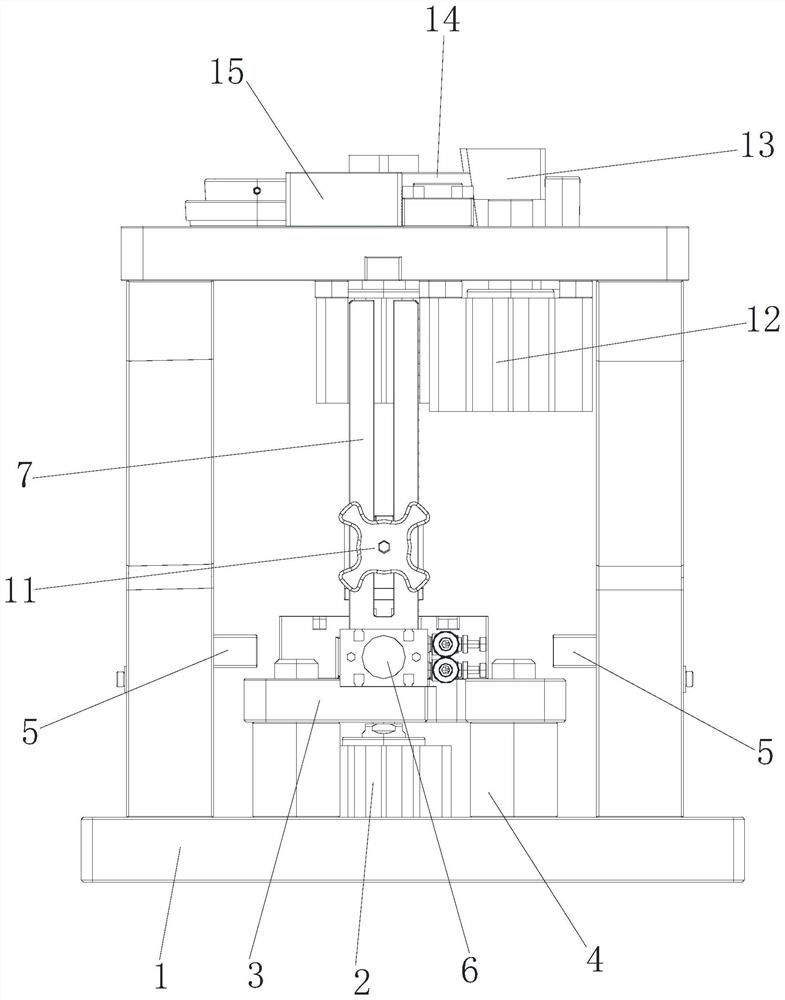

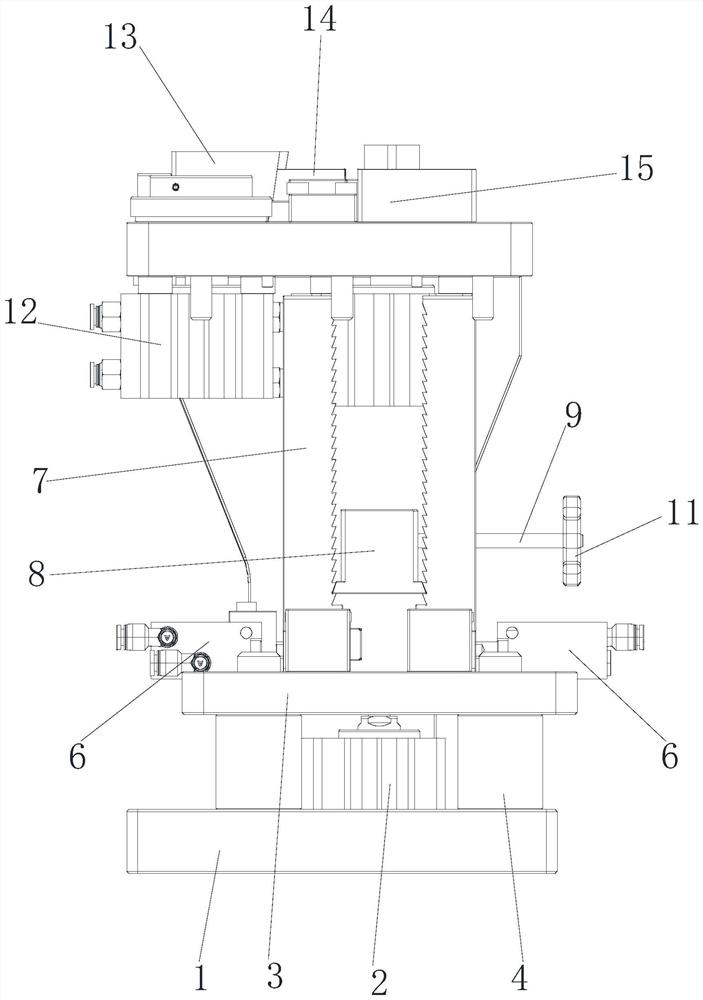

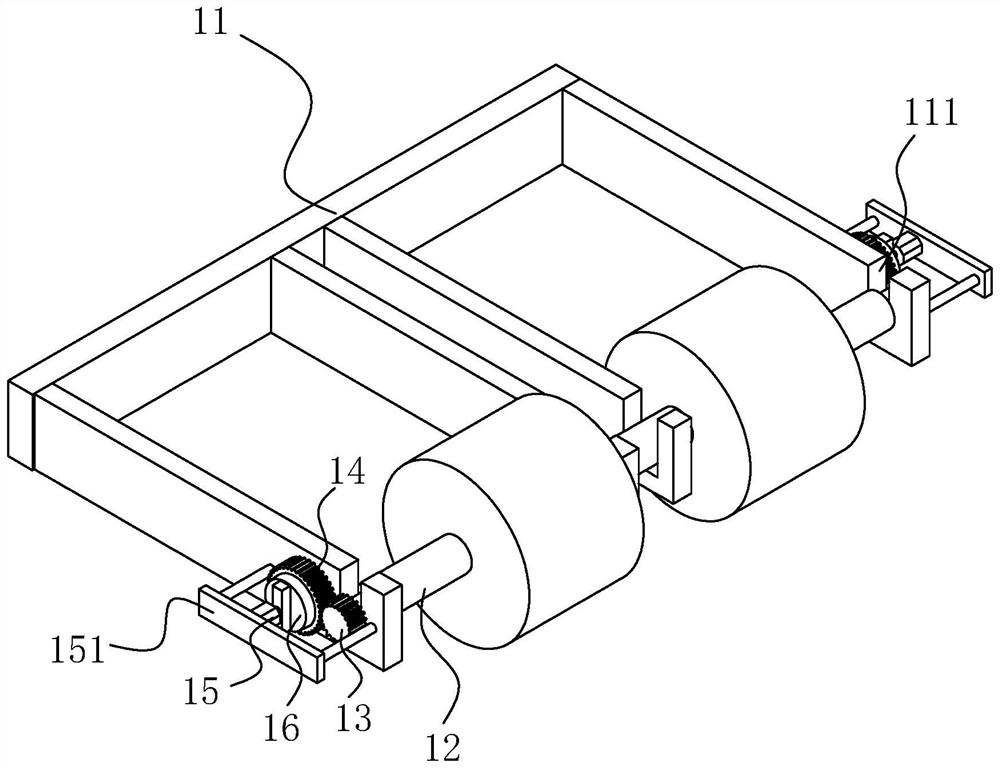

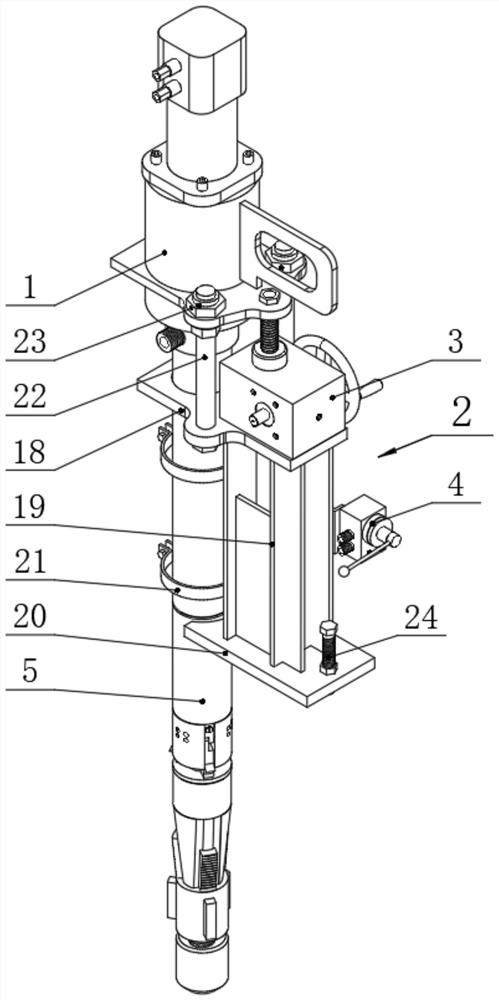

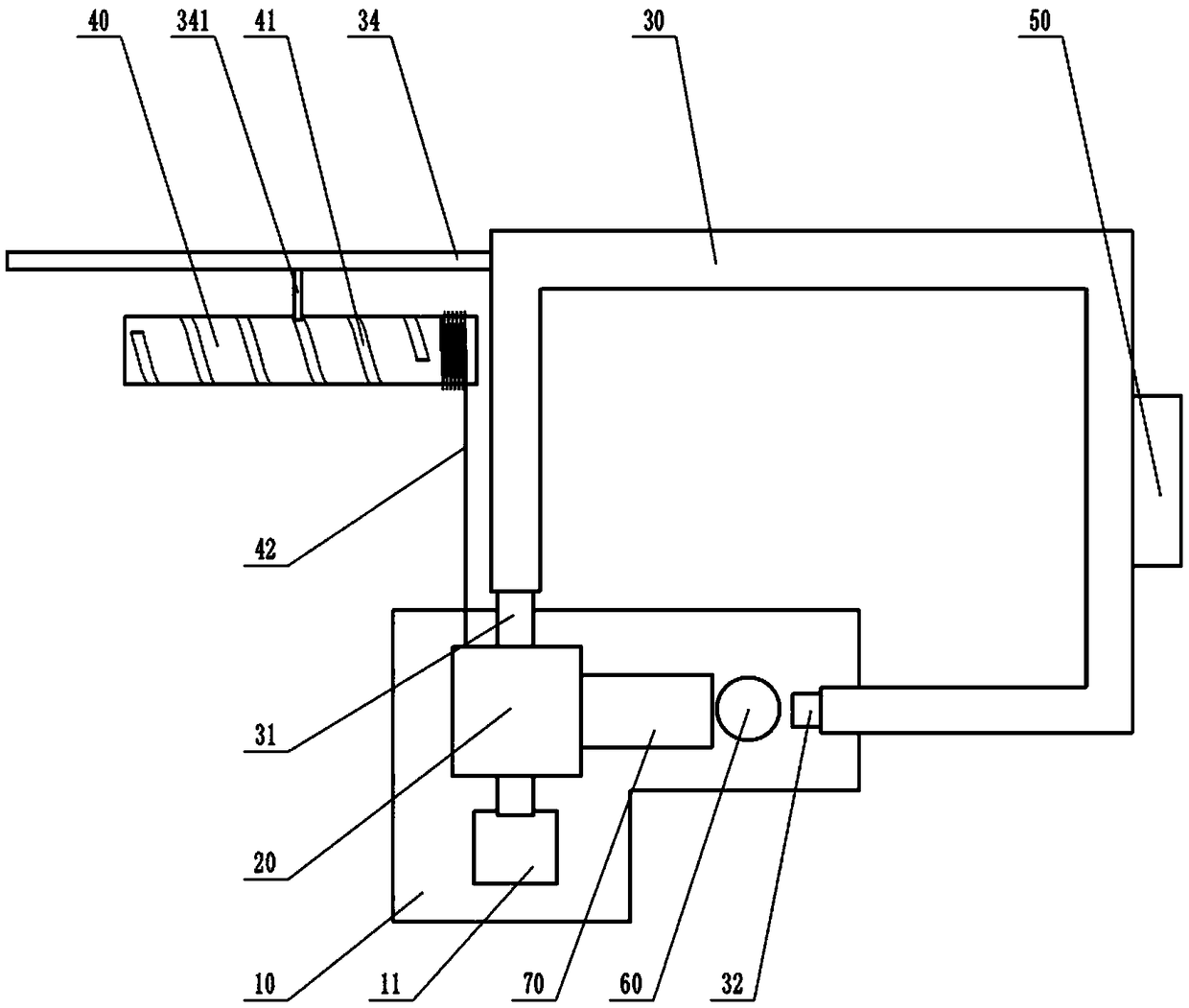

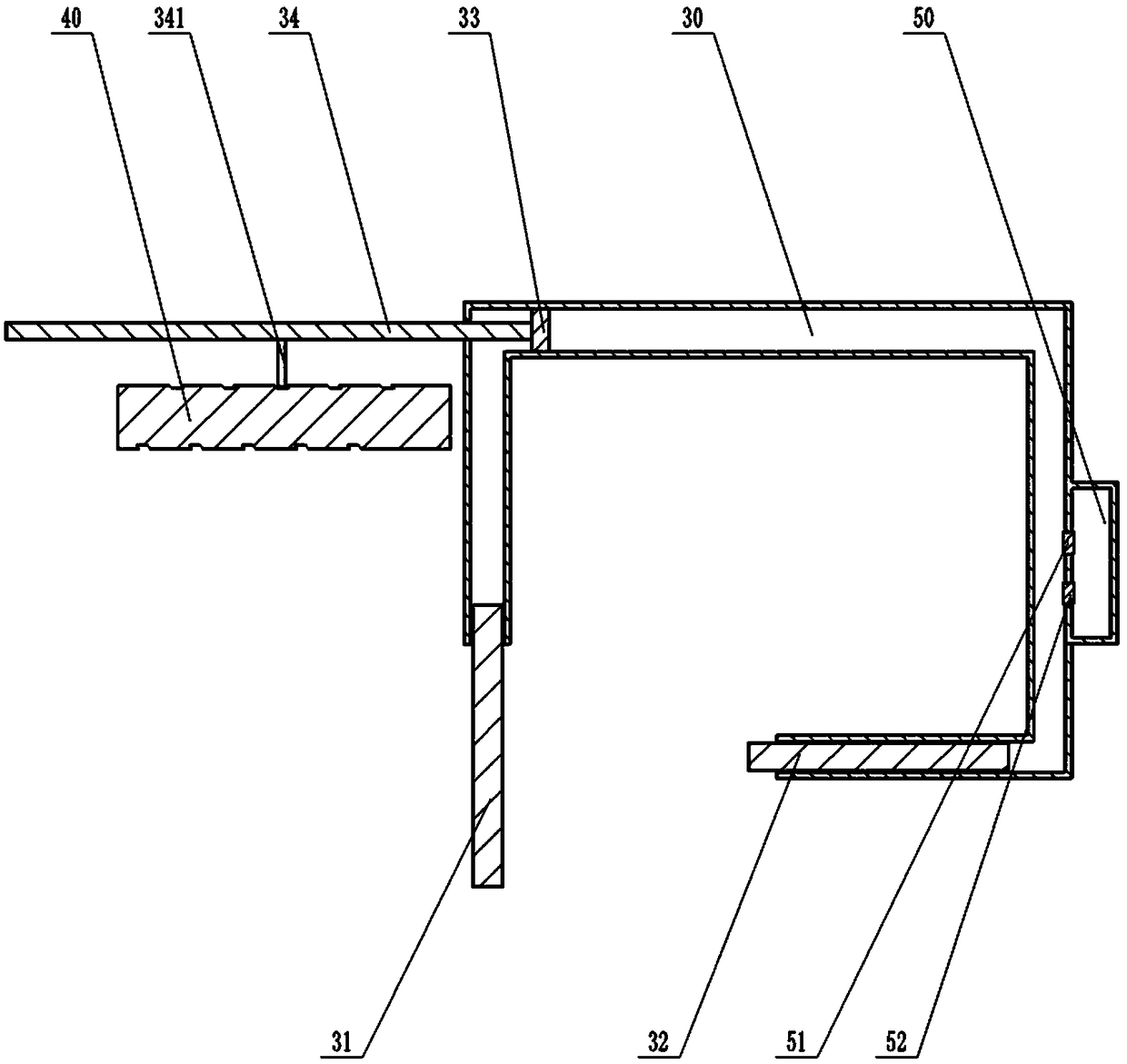

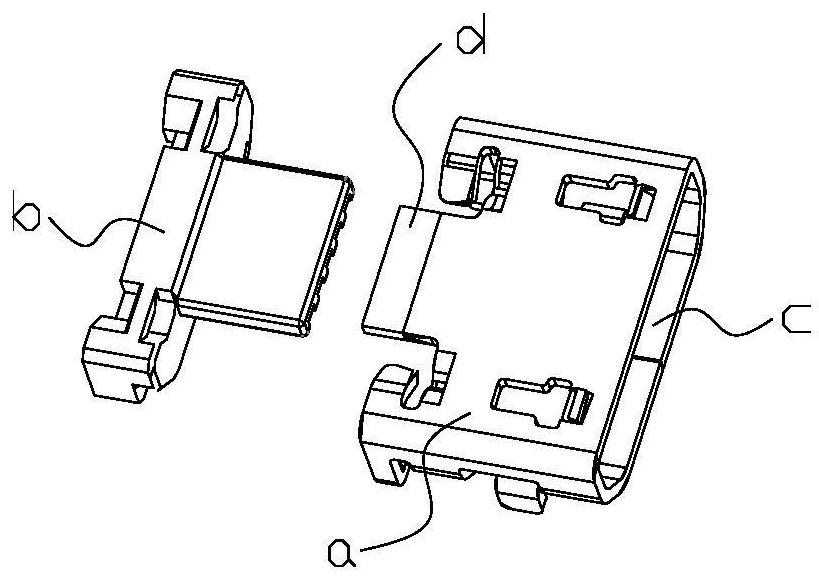

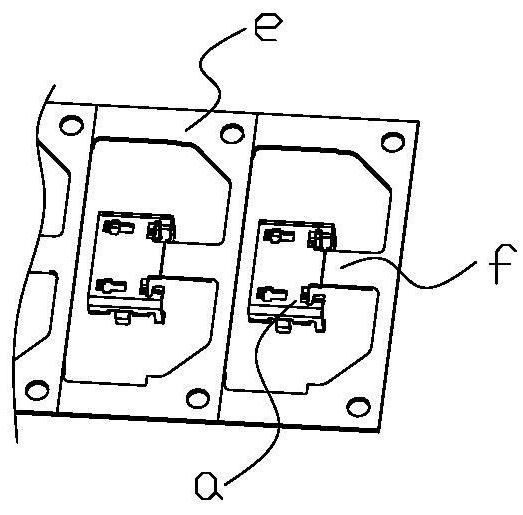

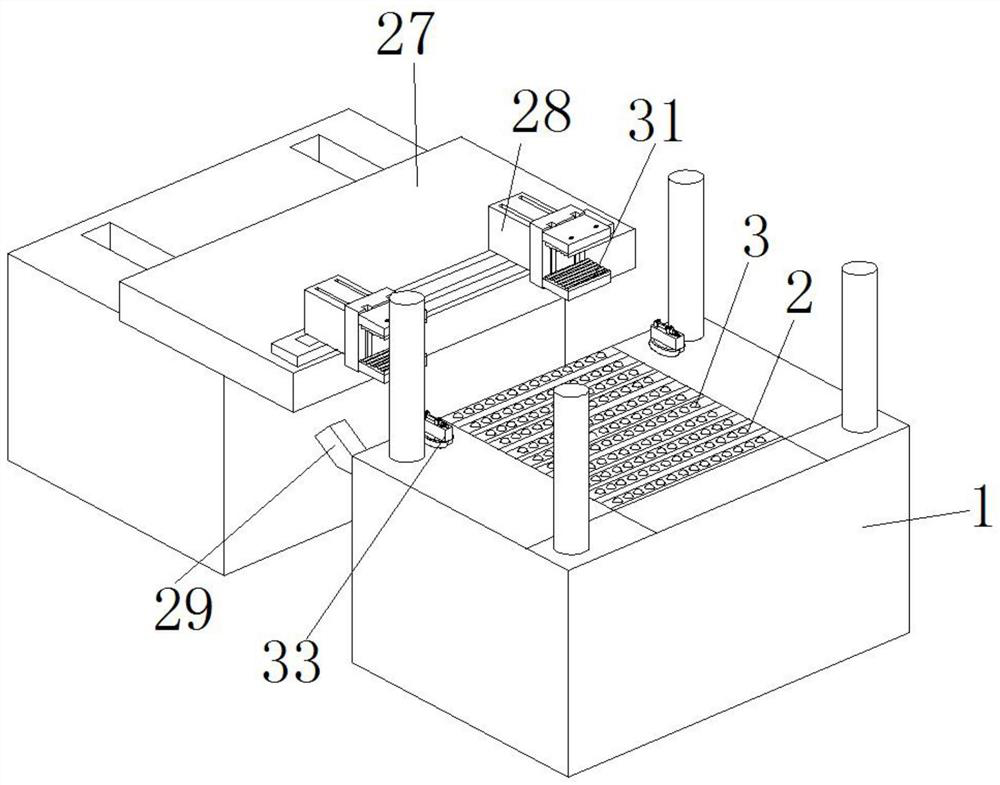

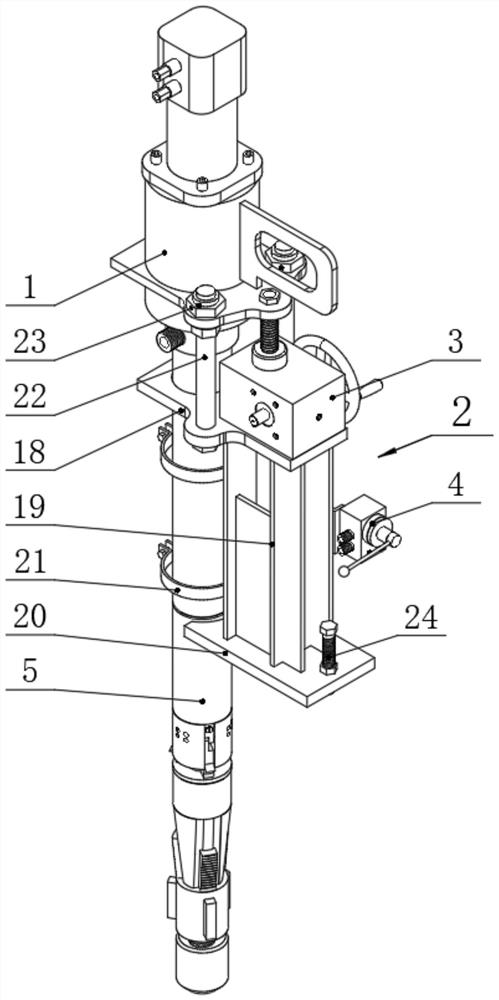

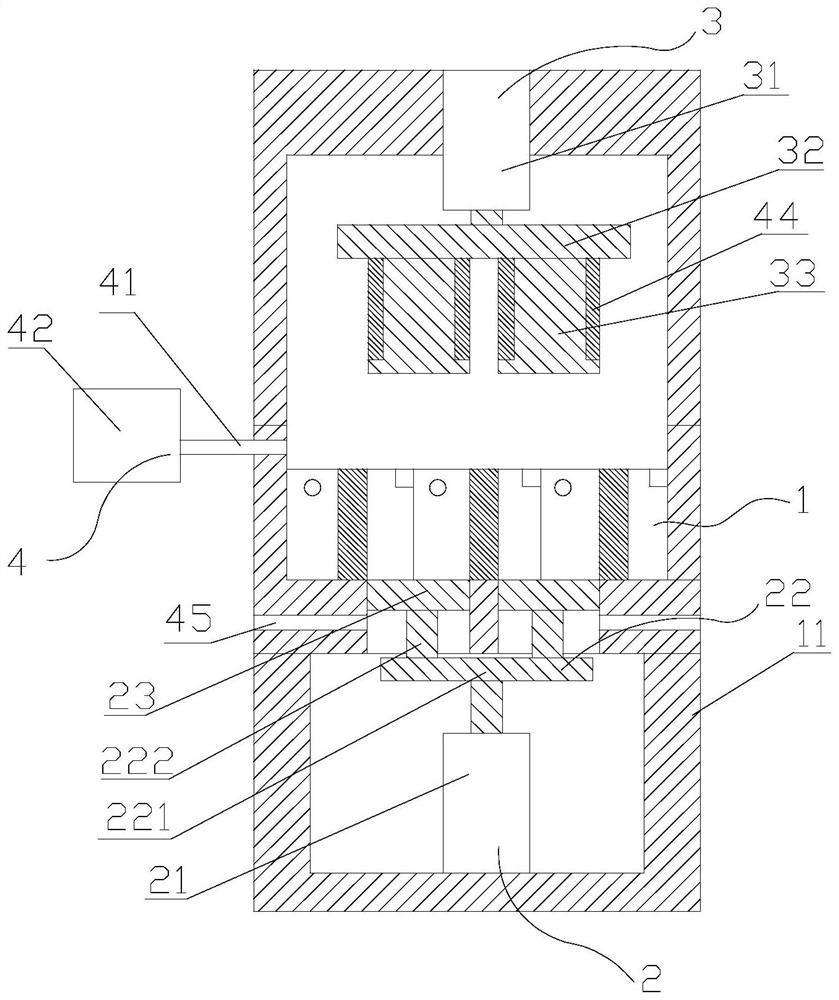

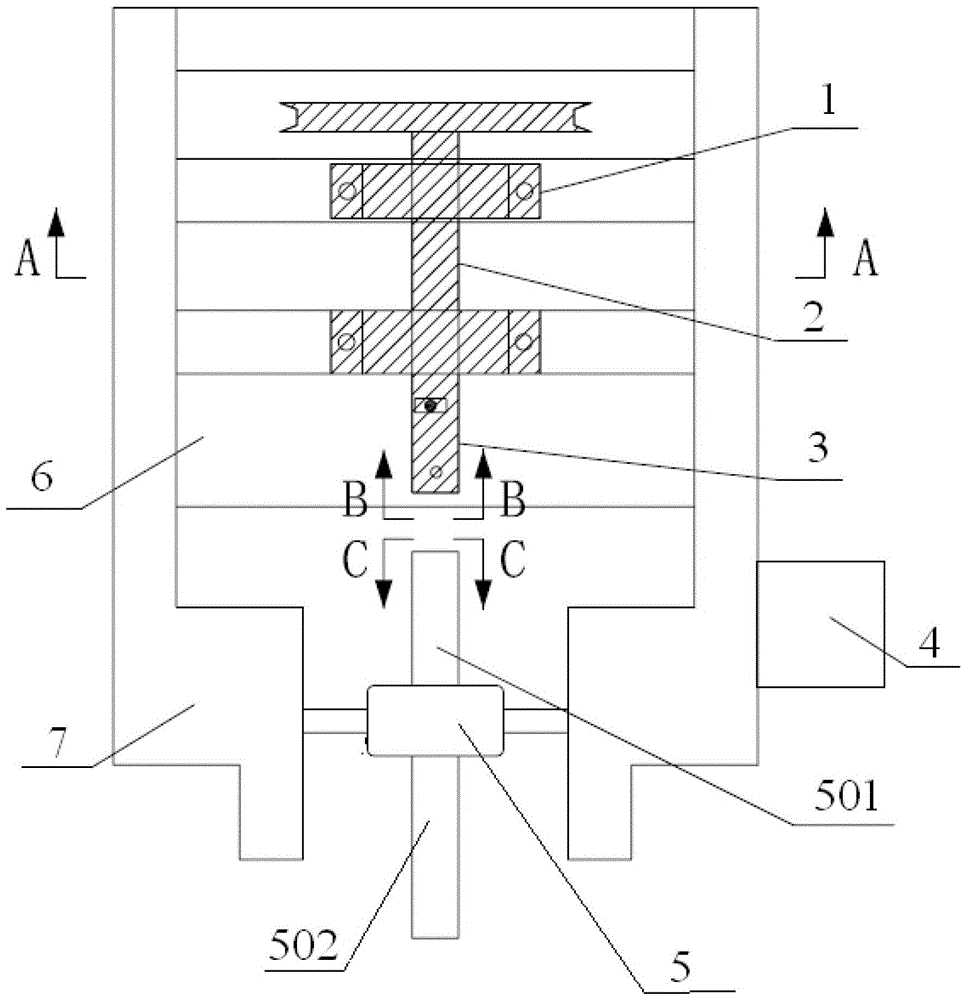

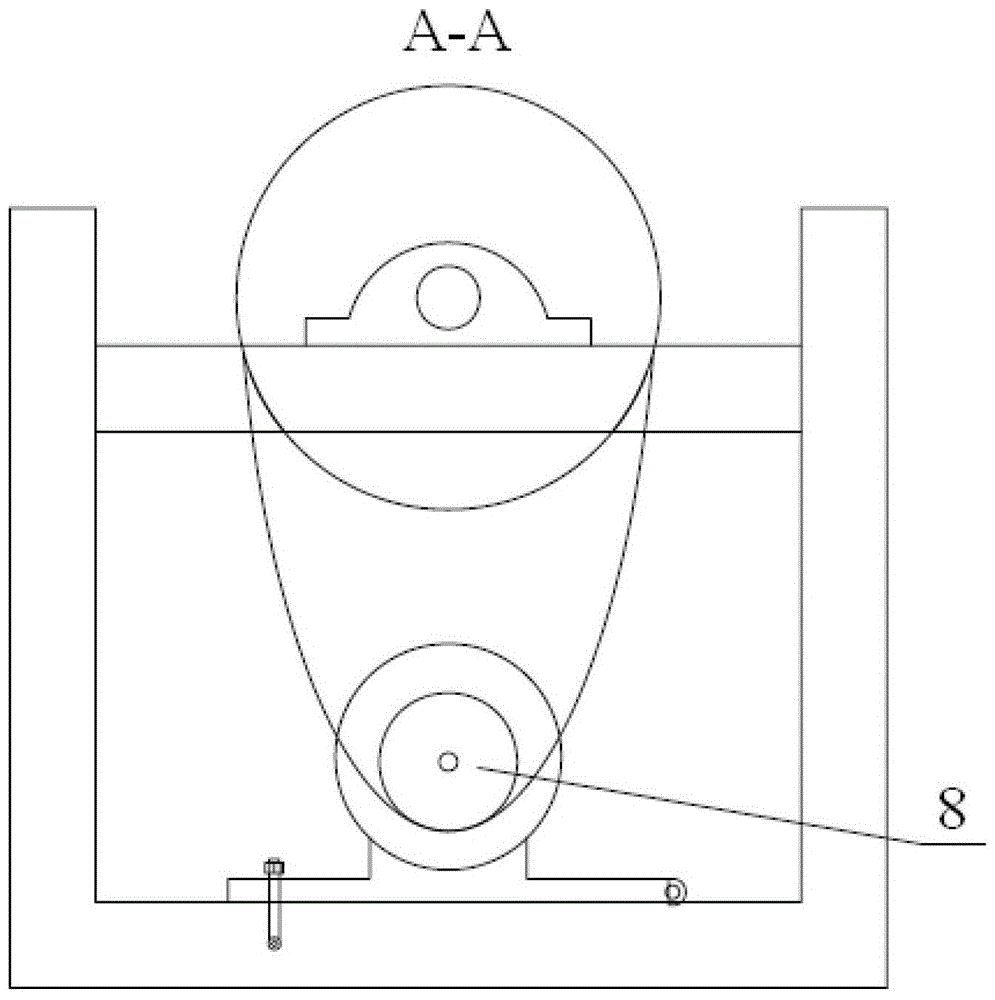

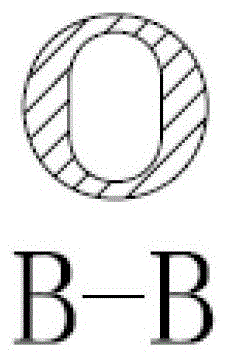

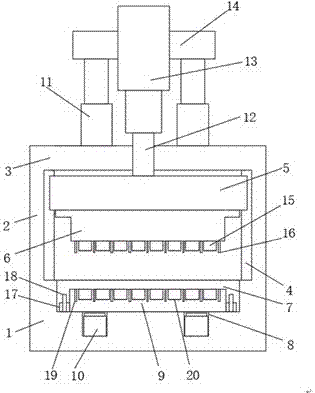

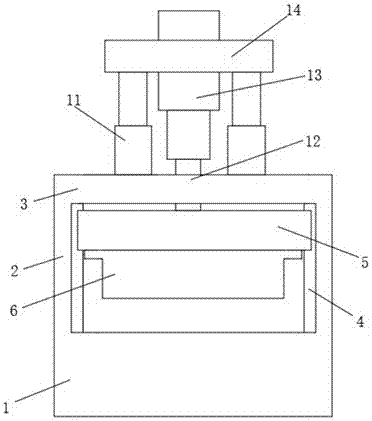

Injection part cutting machine

InactiveCN107825671AReduce error rateReduce cutting stepsMetal working apparatusEngineeringInjection device

The invention relates to the field of cutting equipment, in particular to a cutting machine for injection molded parts, which includes a positioning fixture, a moving mechanism, a cutting assembly and a lifting assembly. A clamping component for an injection molded part, the moving mechanism includes a sliding component for sliding and matching a positioning fixture and a driving component for driving the positioning fixture to slide on the sliding component, and the lifting component includes a lifting platform and a buffer component, It also includes a control device, the control device includes a sensor assembly, a manual control button and a controller, and the sensor assembly and the manual control button are both electrically connected with the controller. The nozzle is cut, and the cutting is completed at one time, which reduces the cutting steps, improves the cutting efficiency, reduces unnecessary labor costs, reduces the error rate of work, and reduces unnecessary production costs.

Owner:王云龙

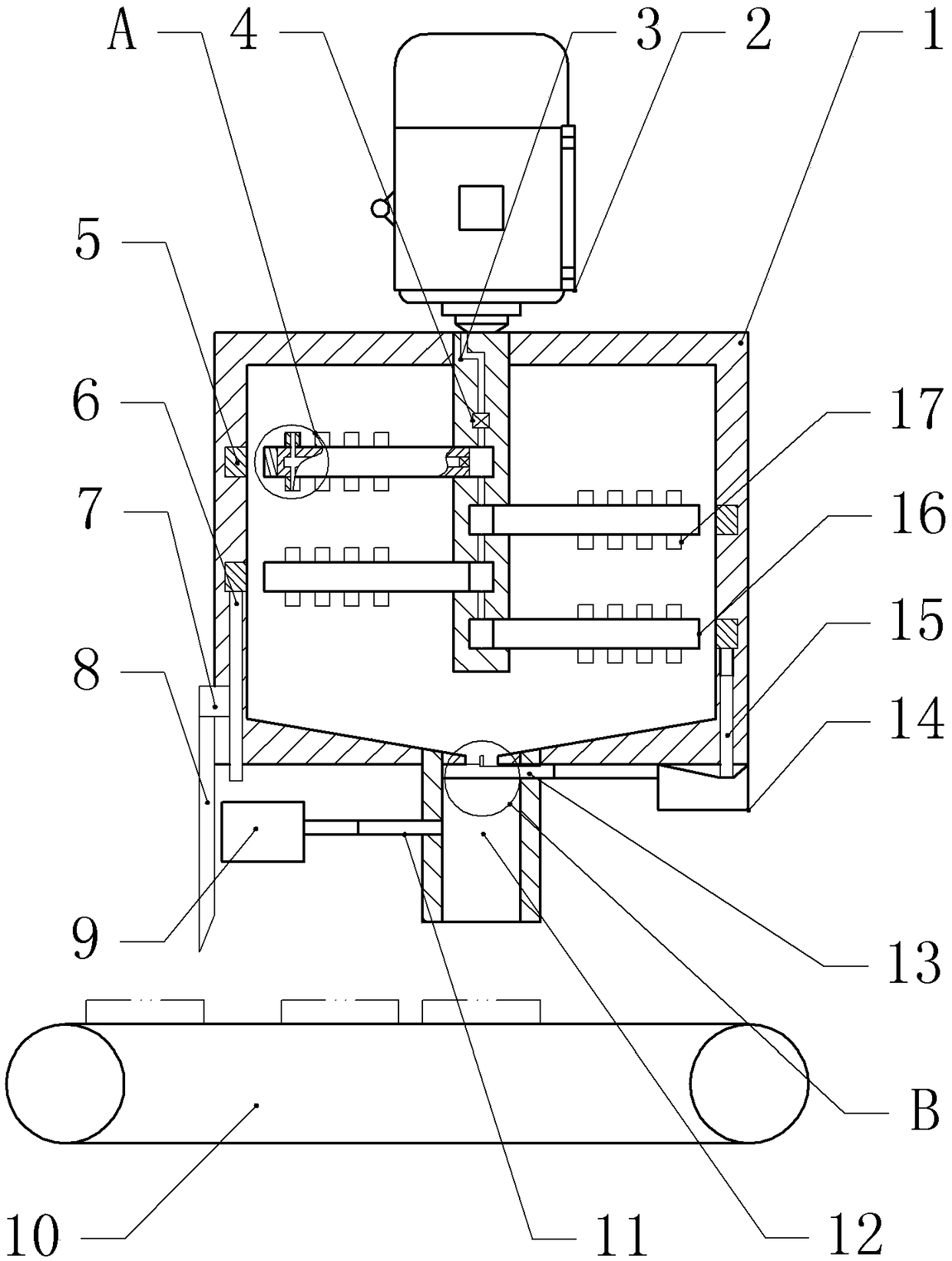

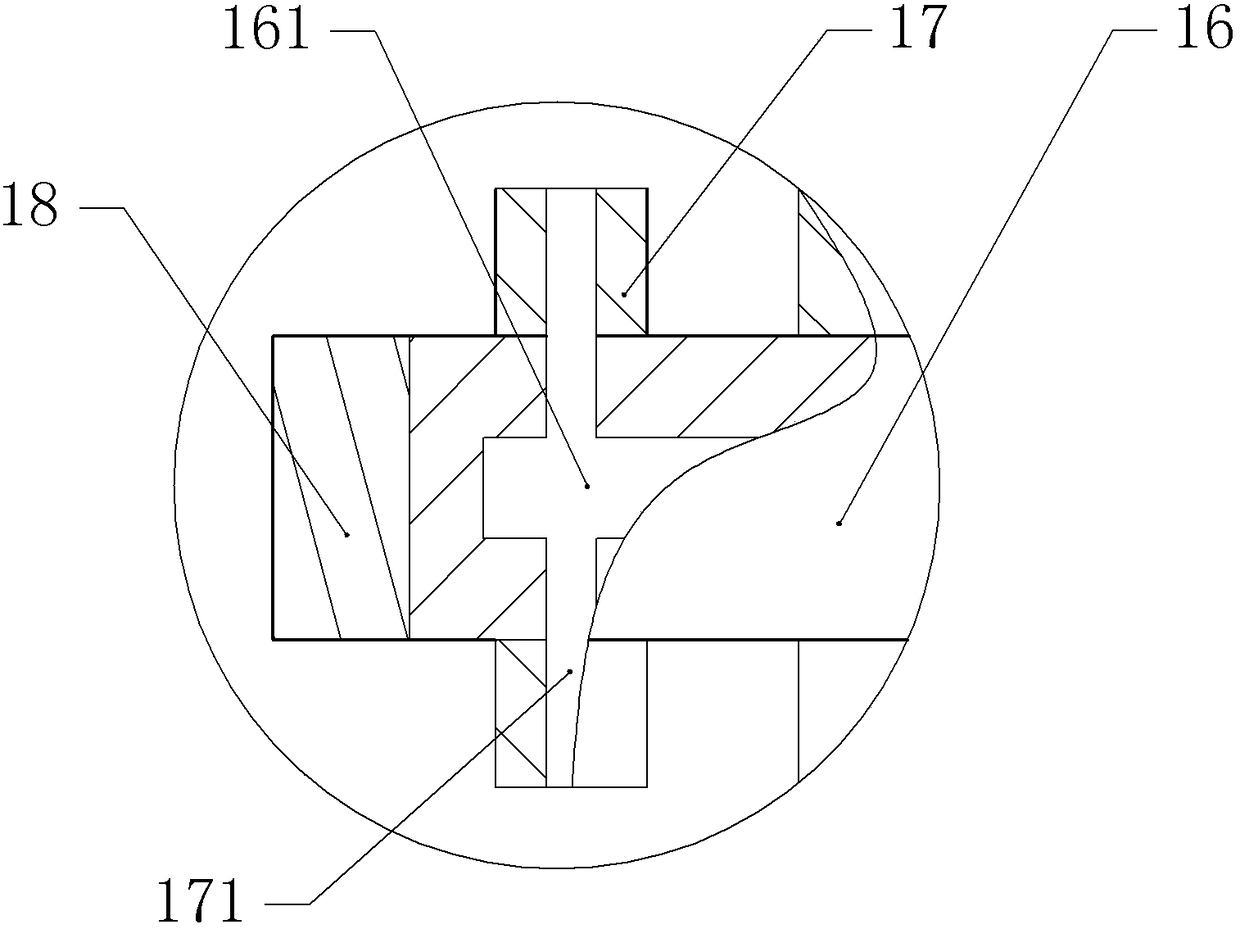

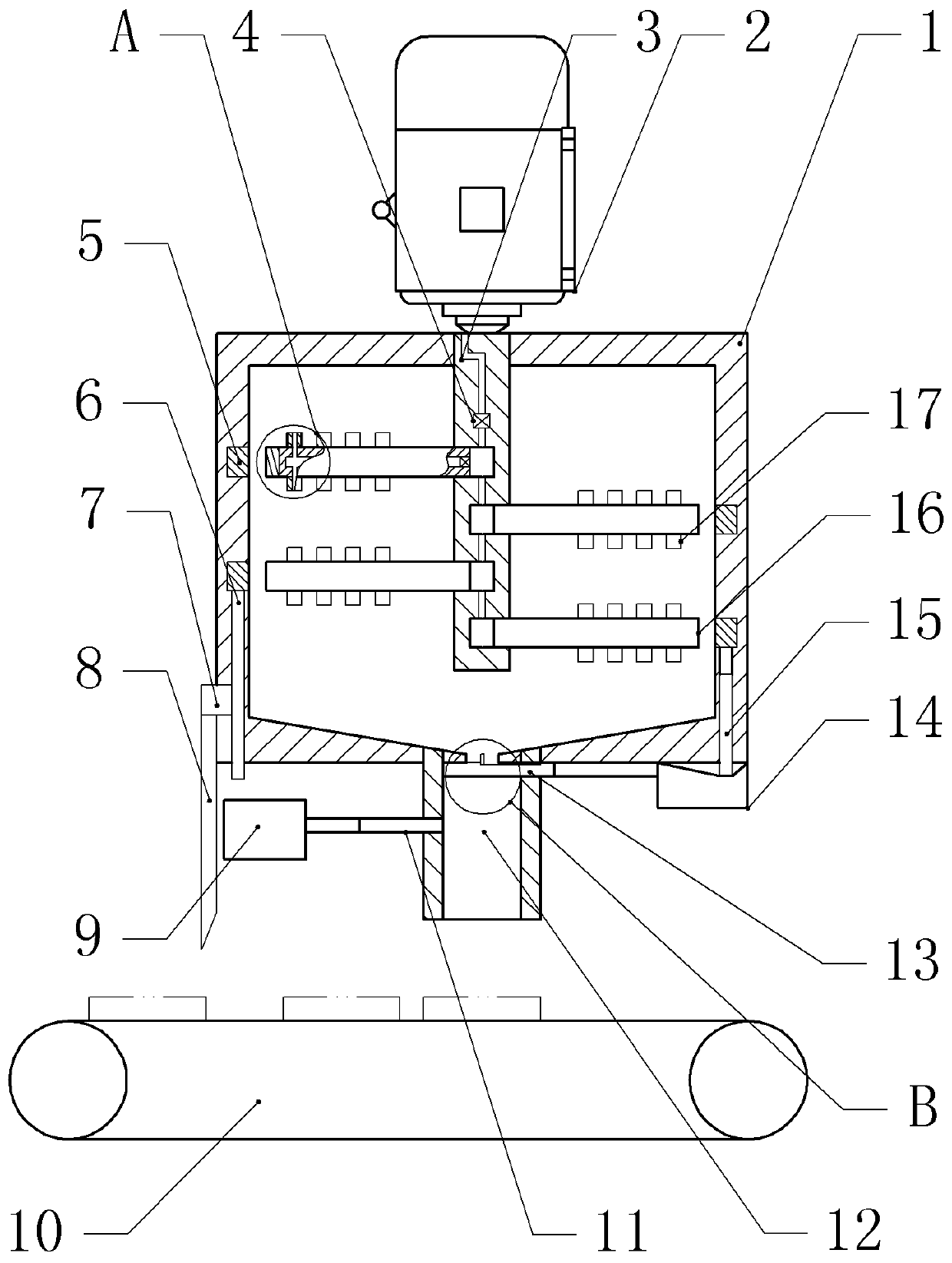

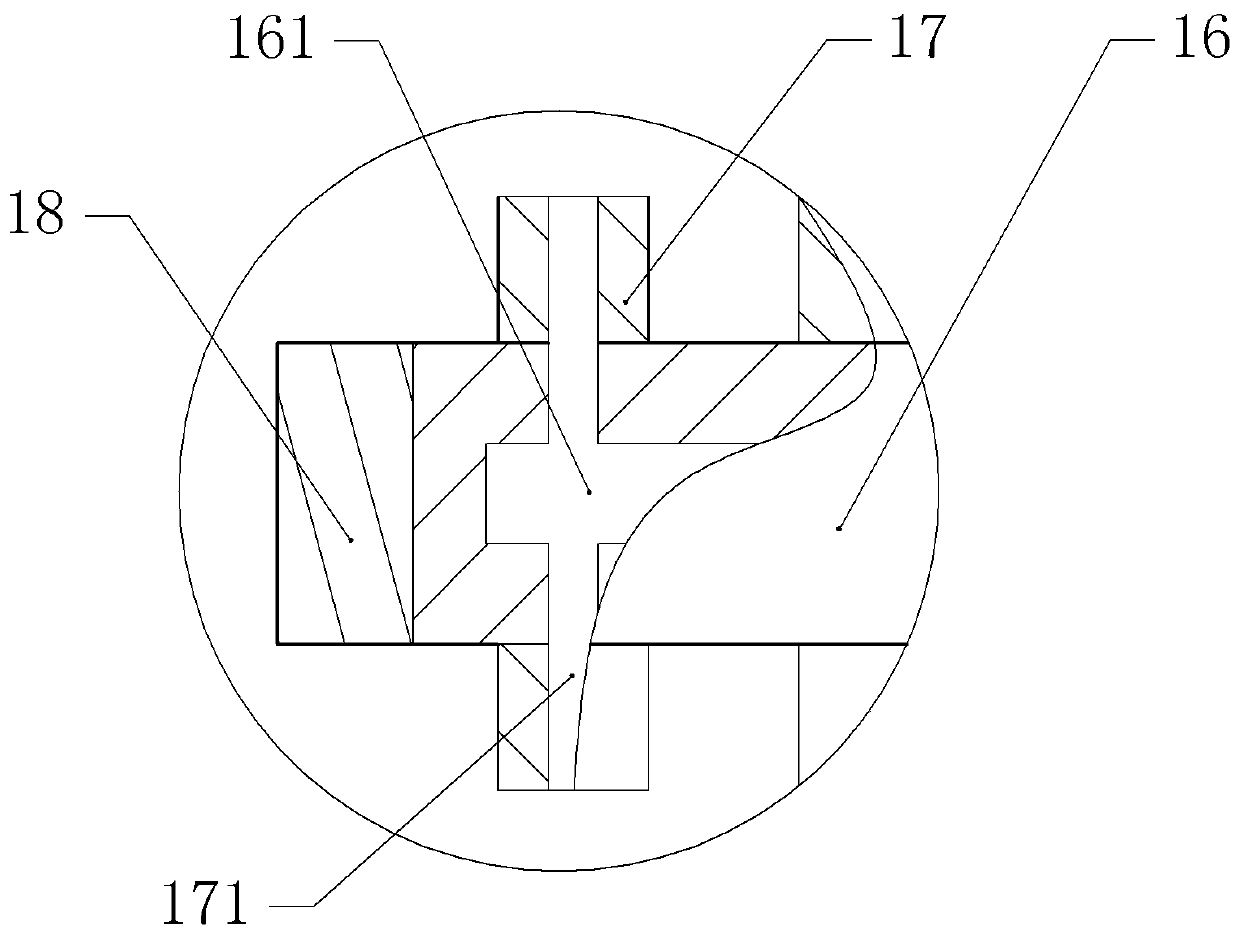

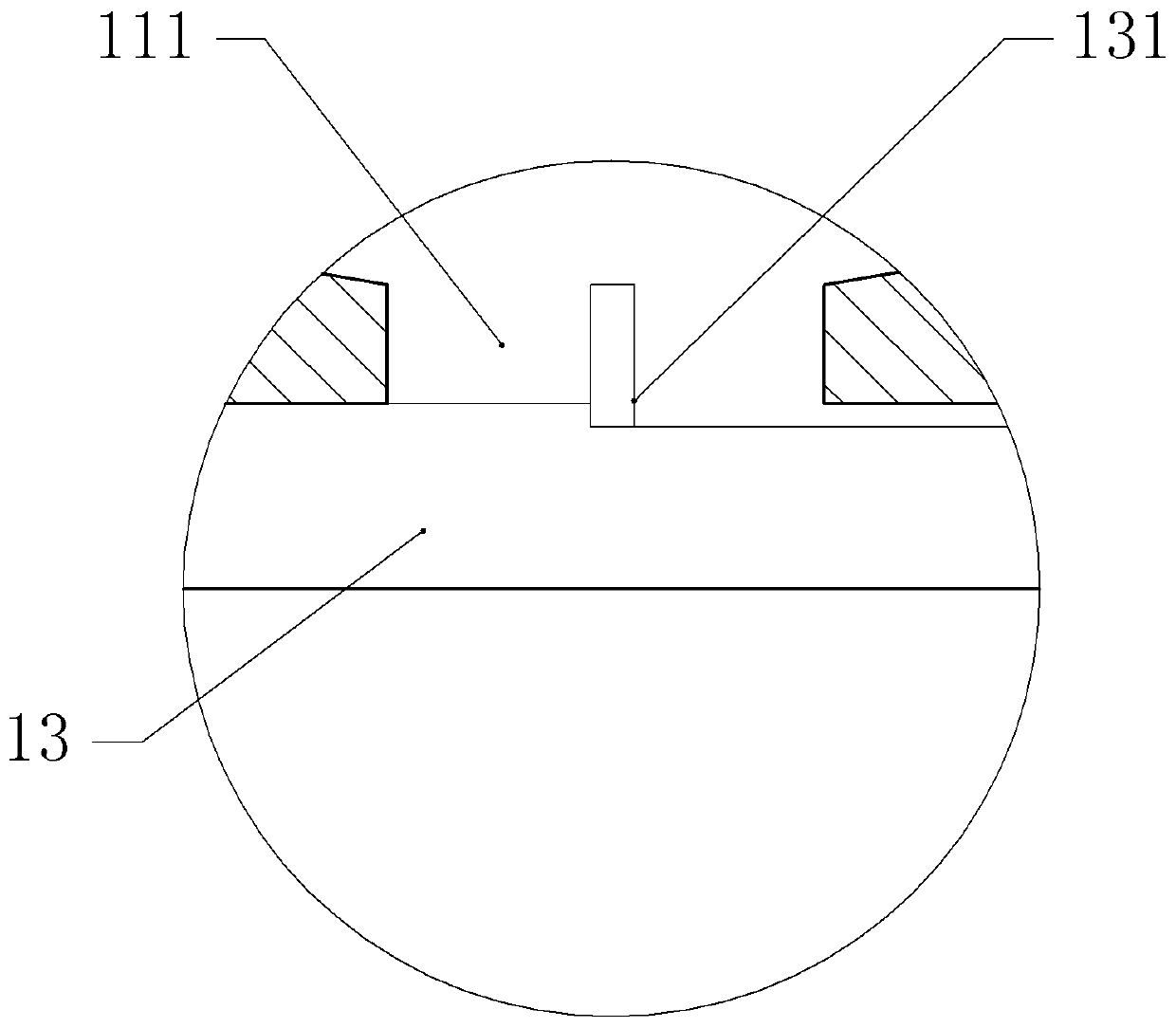

Food packing equipment

The invention relates to the technical field of food packing, and discloses food packing equipment. The food packing equipment comprises a rack, a conveying belt and a quantifying mechanism, wherein the quantifying mechanism comprises a stirring box and a motor; a rotating shaft is arranged in the stirring box and is provided with slide ways; a stirring shaft is arranged in each slide way; a permanent magnet is fixed on each stirring shaft; electromagnets are fixed on two side walls of the stirring box; a long iron rod is arranged on a side wall of the stirring box; a short iron rod is arranged on another side wall of the stirring box; a first air bag is arranged below the long iron rod; a second air bag is arranged below the short iron rod; the bottom of the stirring box communicates witha discharging tube; the upper portion of the discharging tube is slidably connected with a second closing plate; the lower portion of the discharging tube is slidably connected with a first closing plate; the conveying belt is positioned below the discharging tube and is mounted on the rack; and the conveying belt is in intermittent transmission through a geneva mechanism. The food packing equipment is simple in structure, and can quantify food required to be packed, and the conveying belt intermittently conveys packing bags.

Owner:重庆新滋味食品有限公司

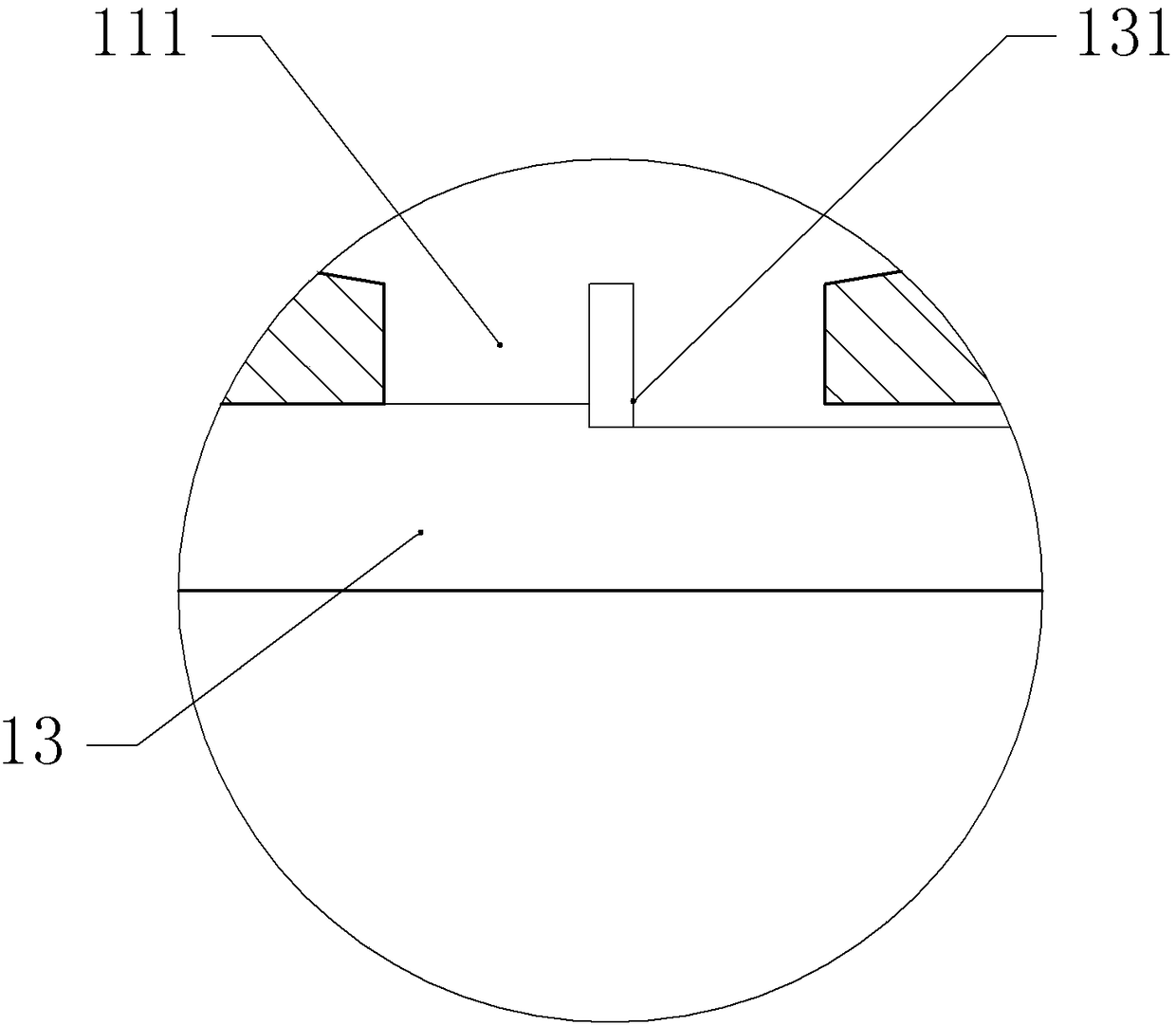

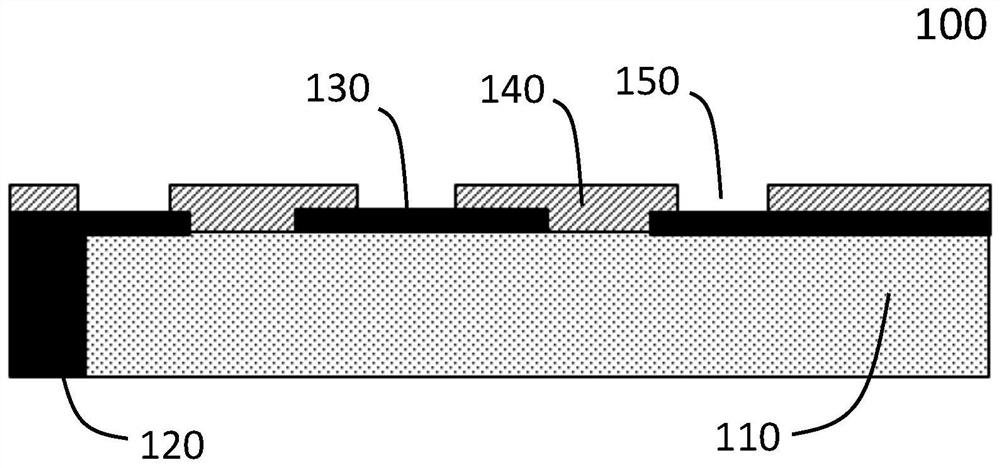

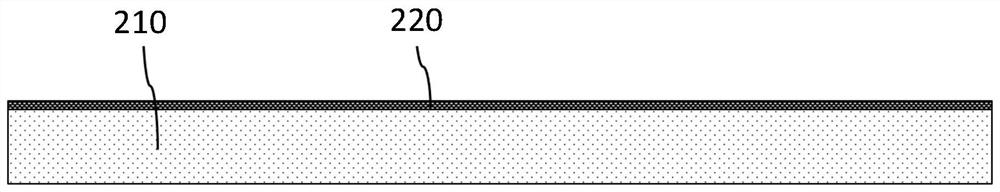

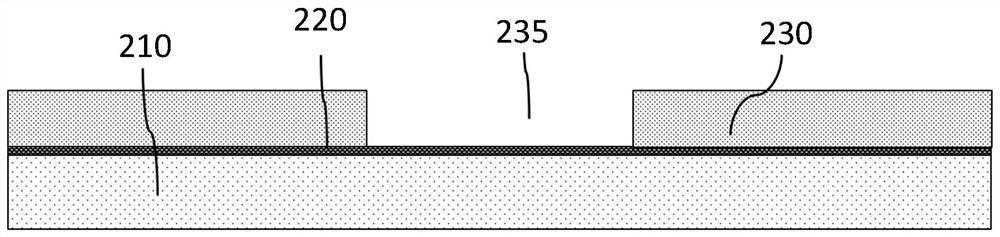

Slide glass structure with side wall bonding pad, and manufacturing method thereof

ActiveCN112702836AAvoid etchingAvoid damageCoupling light guidesElectrical connection printed elementsDielectric substrateEngineering

The invention discloses a slide glass structure with a side wall bonding pad. The structure comprises: a dielectric substrate which is a substrate of the slide glass structure of the side wall bonding pad; a sidewall pad, wherein the side wall bonding pad is arranged on the side wall of the dielectric substrate and extends from the bottom surface to the top surface along the side wall of the dielectric substrate; a surface metal wiring layer, arranged on the top surface of the dielectric substrate and electrically connected to the side wall bonding pad; a surface dielectric layer arranged on the top surface of the dielectric substrate and above part of the surface metal wiring layer; and a surface dielectric layer window, wherein a part of the surface metal wiring layer is exposed from the surface dielectric layer window.

Owner:NAT CENT FOR ADVANCED PACKAGING

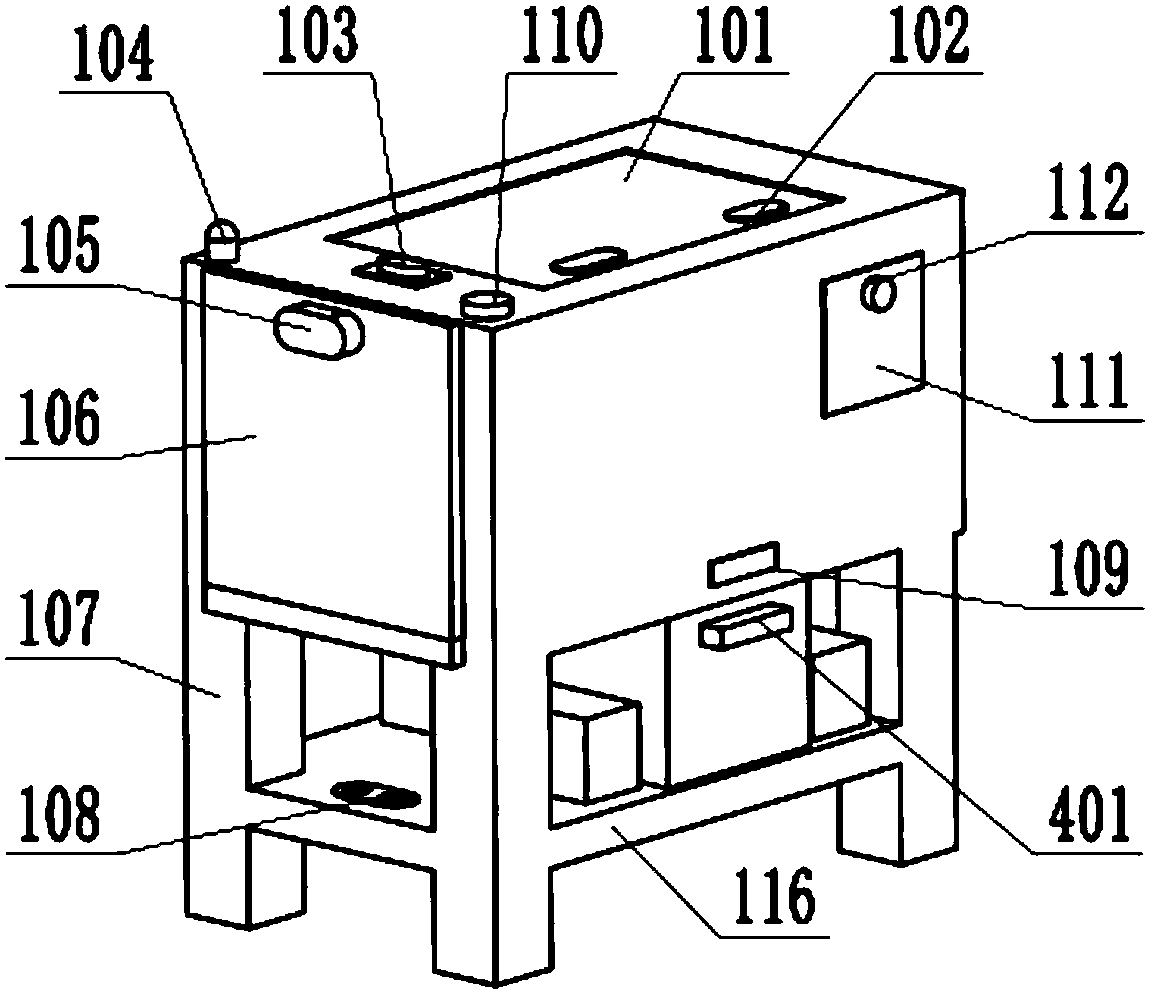

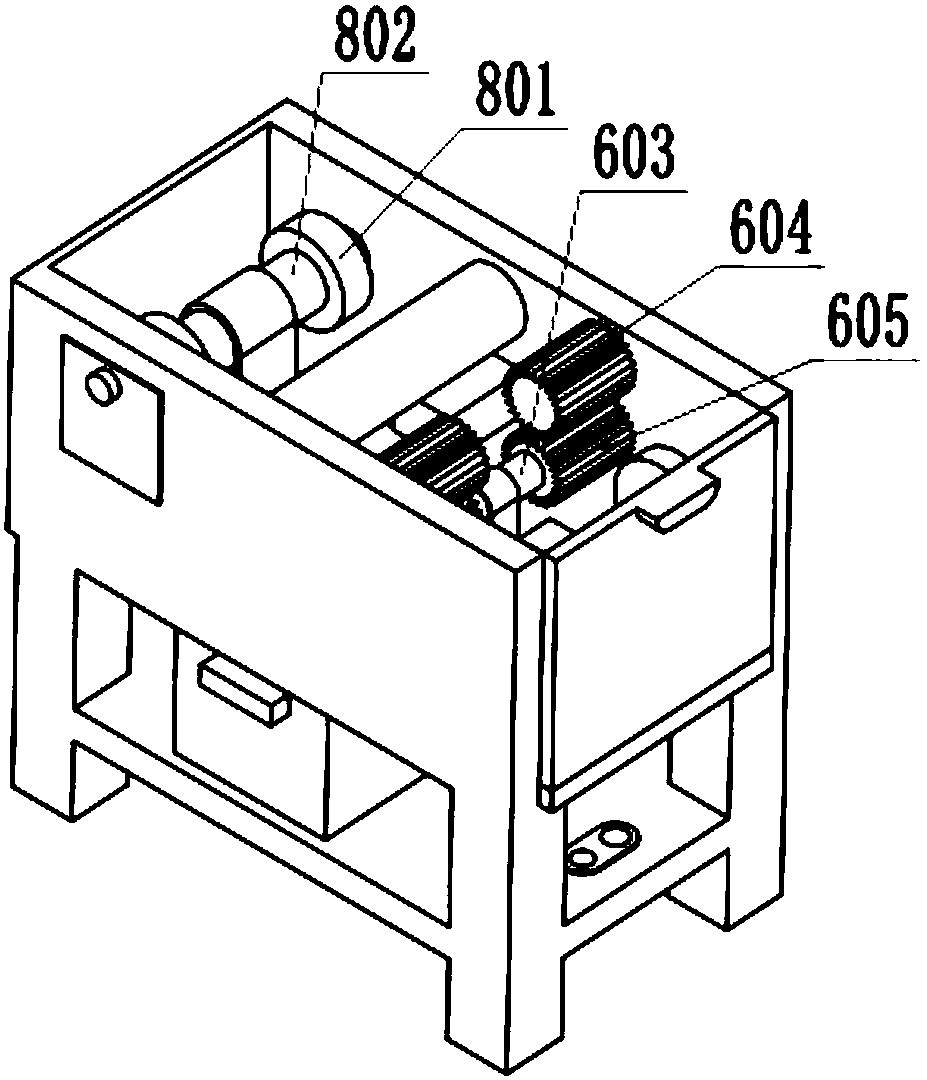

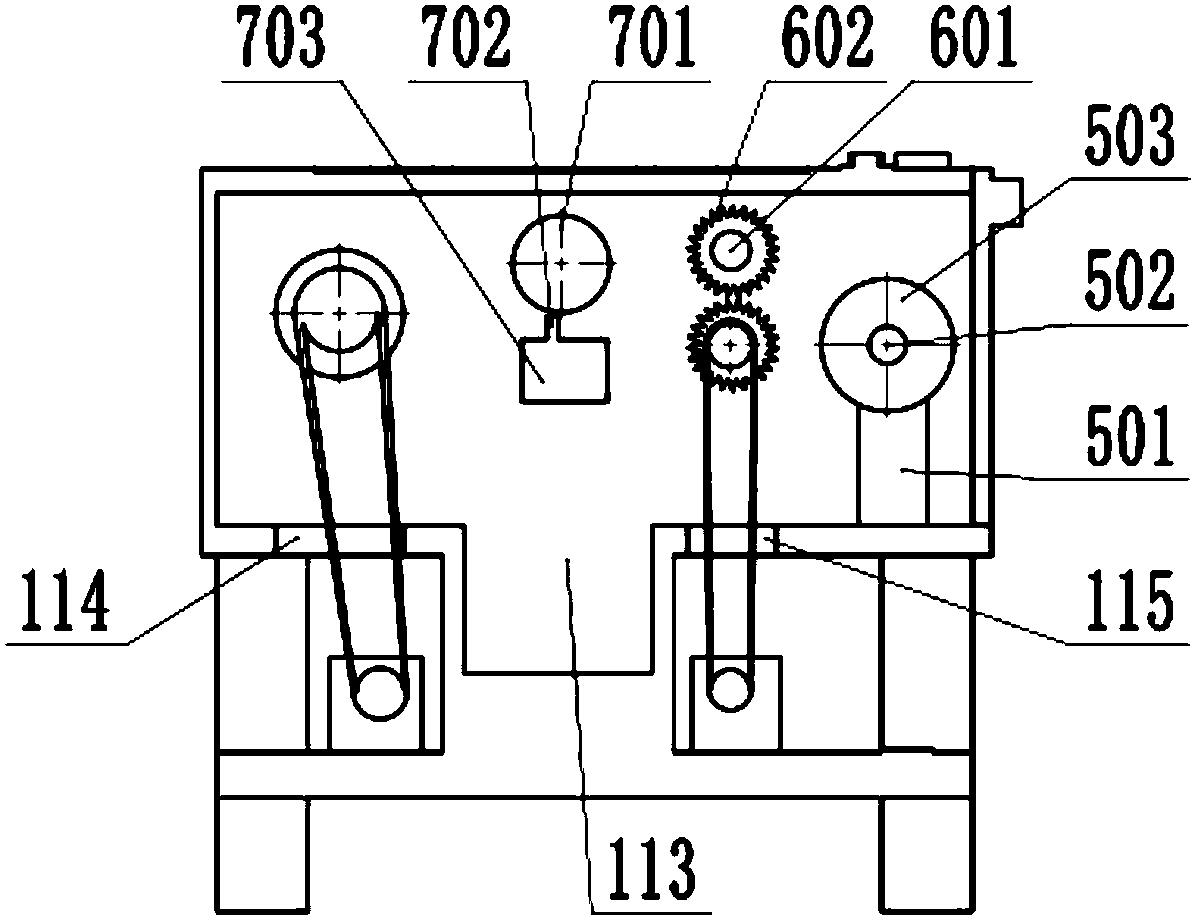

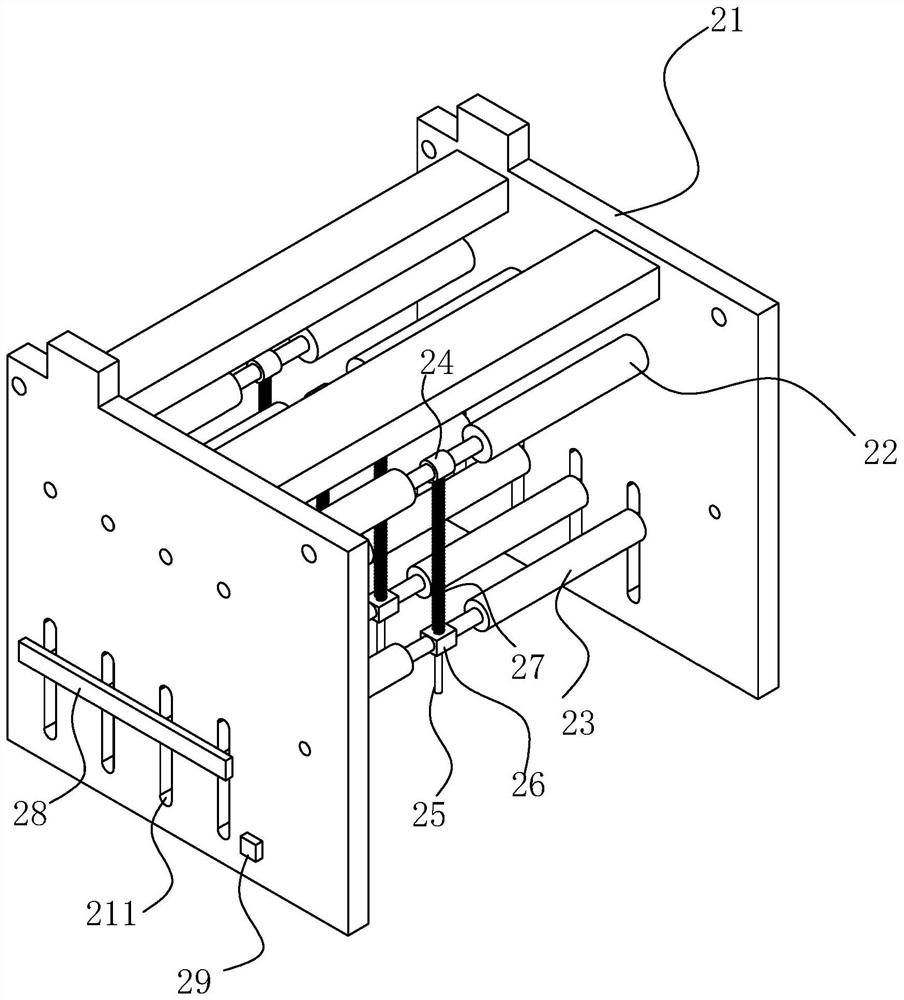

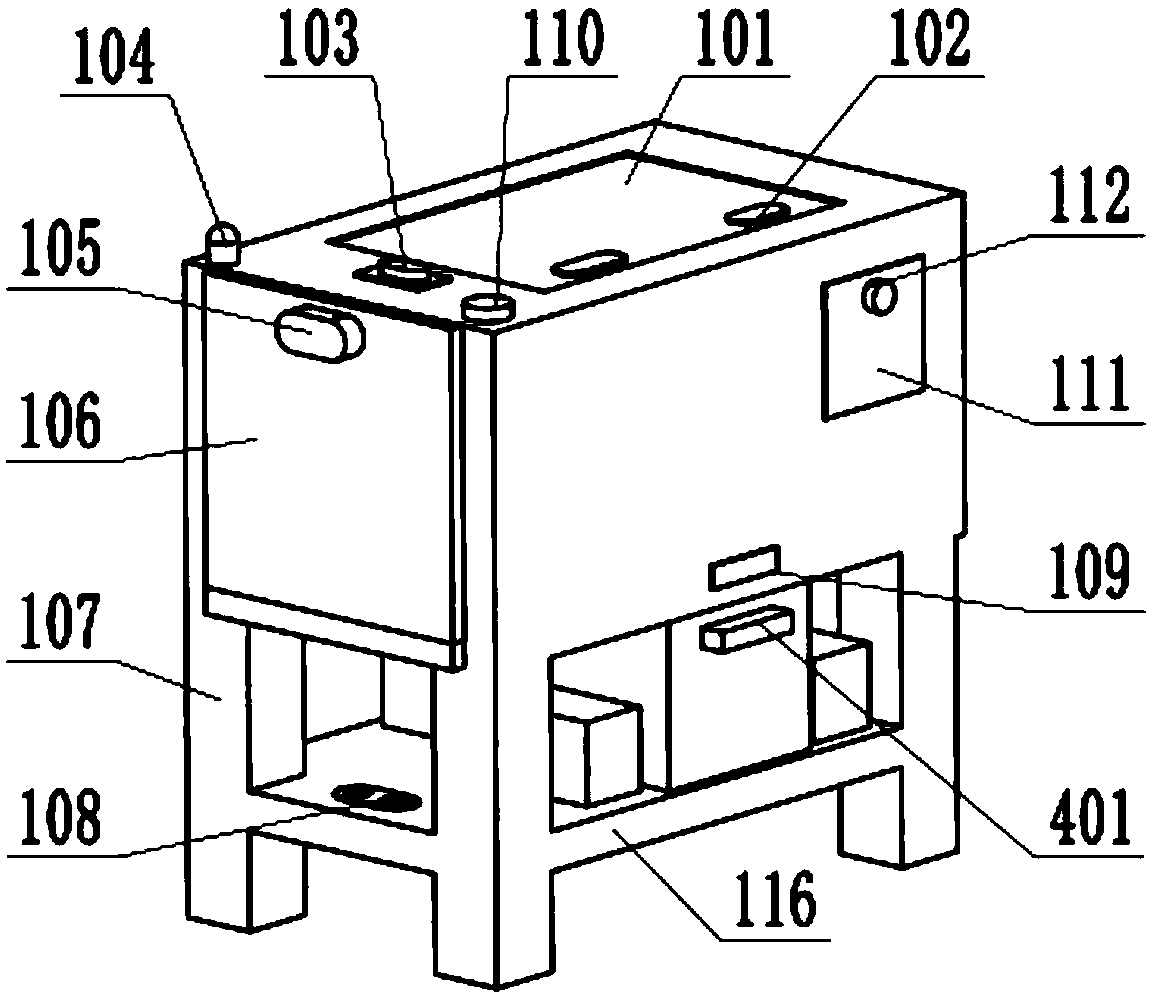

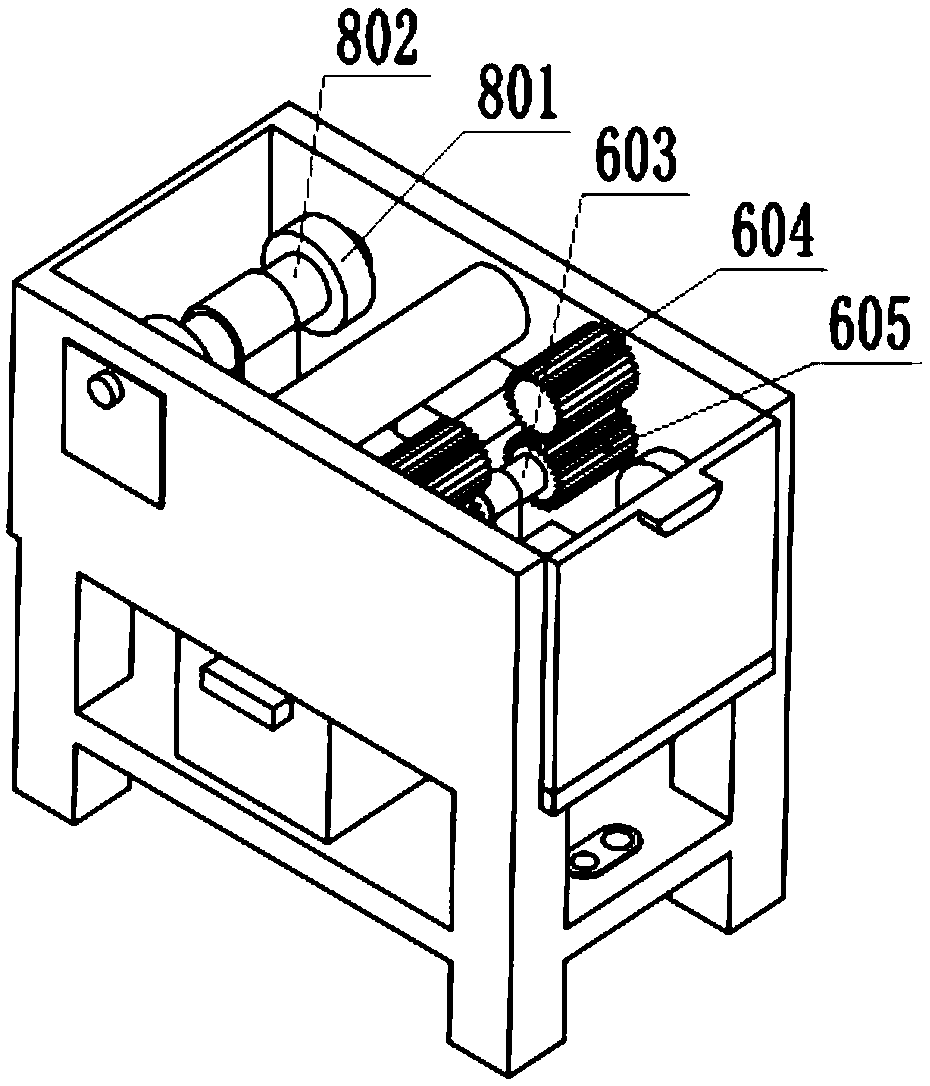

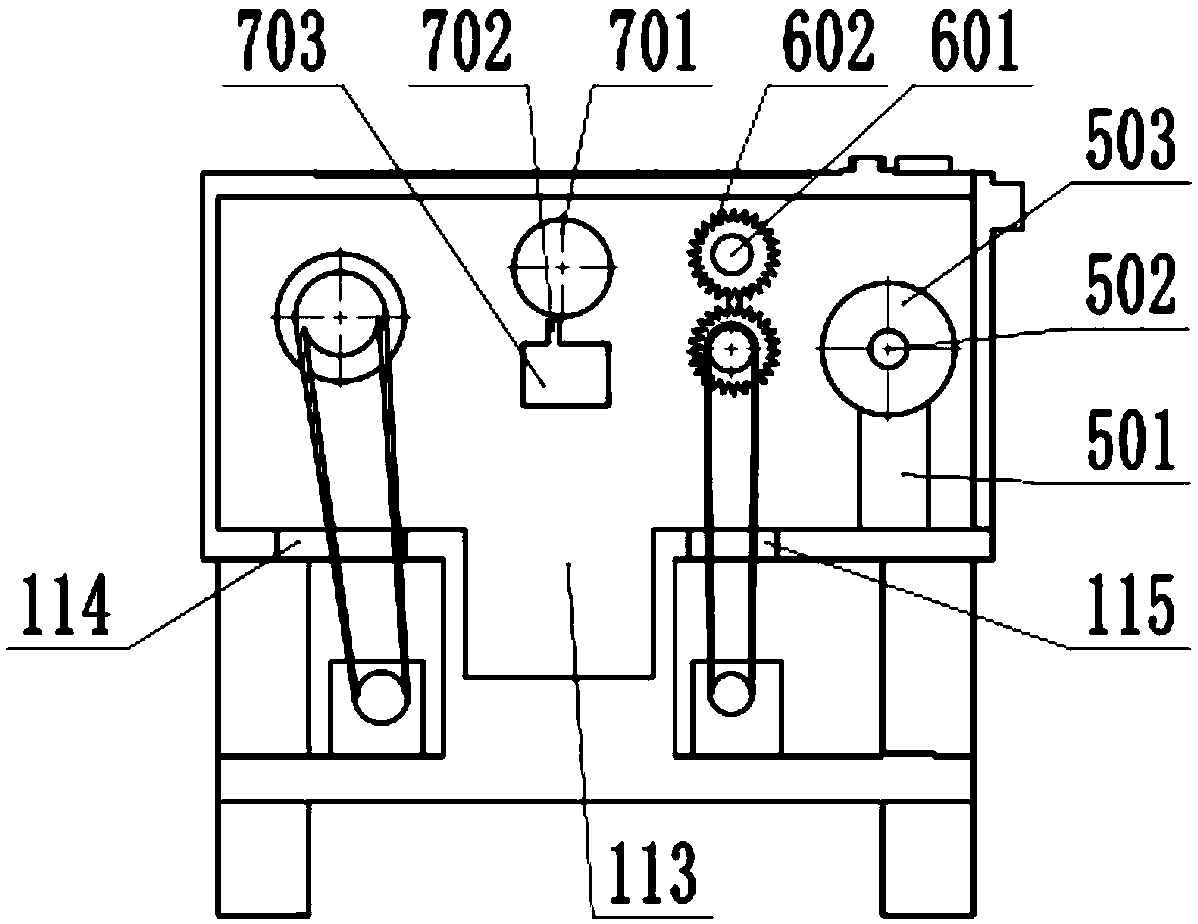

Recycling device of wire and cable dedicated for power distribution cabinet

InactiveCN107845454ASave pay-off speedImprove securityBasic electric elementsApparatus for removing/armouring cablesEngineeringElectric power

The invention discloses a recycling device of a wire and cable dedicated for a power distribution cabinet. The recycling device is composed of a chassis, a pay-off unit, a crushing unit, a separatingunit, a take-up unit and first and second motors arranged at the lower end of the chassis. Support legs are arranged at the lower end of the chassis. A baffle is arranged among the support legs. A front reel change door is arranged at one side of the chassis. A door handle is arranged on the front reel change door. The pay-off unit is arranged in the front reel change door. The crushing unit is arranged at one side of the pay-off unit. The separating unit is arranged at one side of the crushing unit. The take-up unit is arranged at one side of the separating unit. Rear reel change doors are arranged on chassis walls on the two sides of the take-up unit. The recycling device not only realizes the separation of a wire core from a wire sheath, but also realizes automation in the entire process. The separation devices are all located inside the chassis and the safety is improved.

Owner:佛山市欧能电气设备有限公司

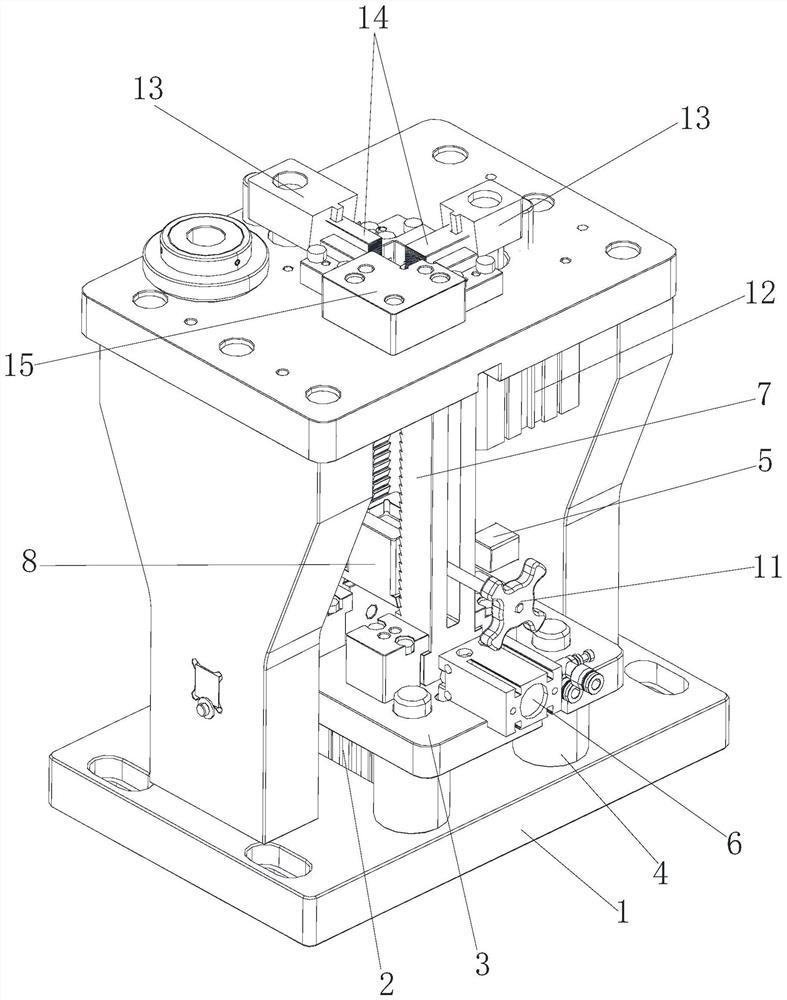

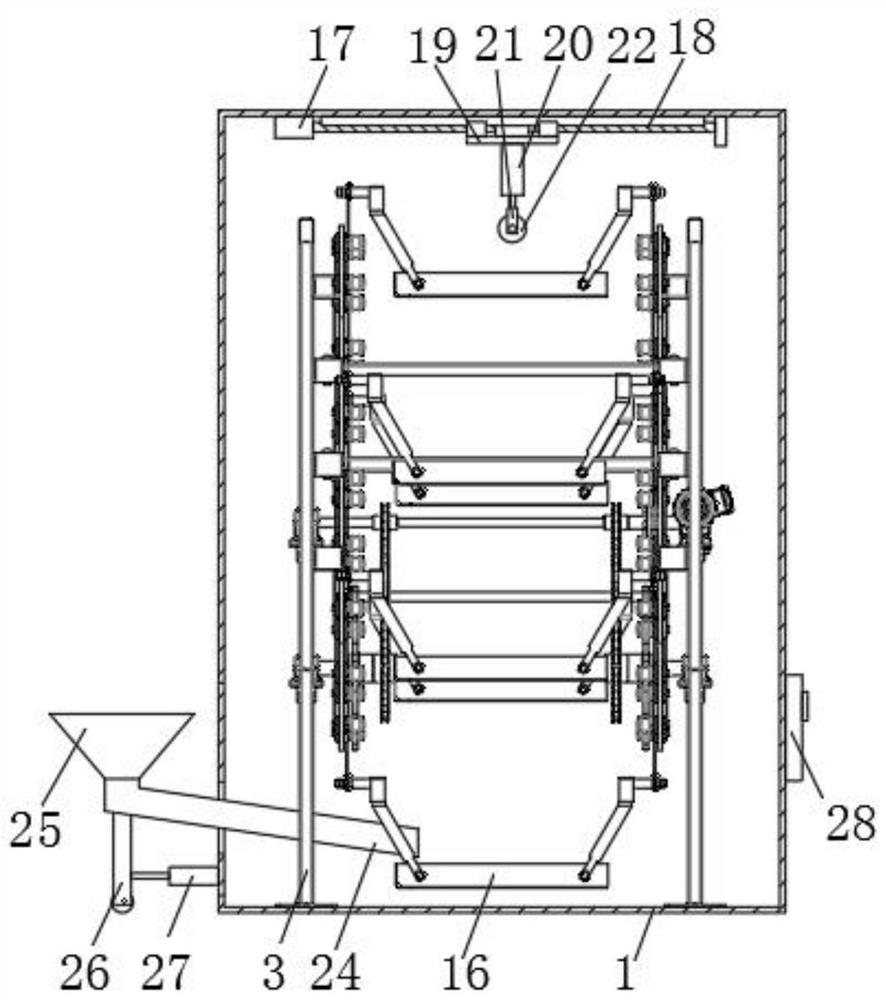

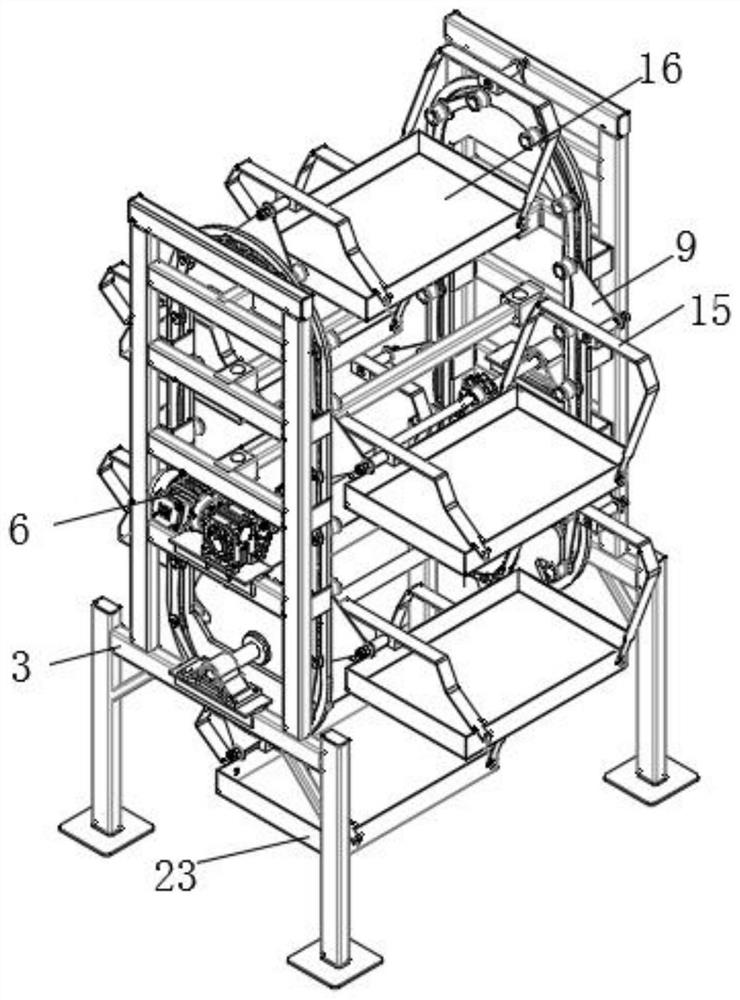

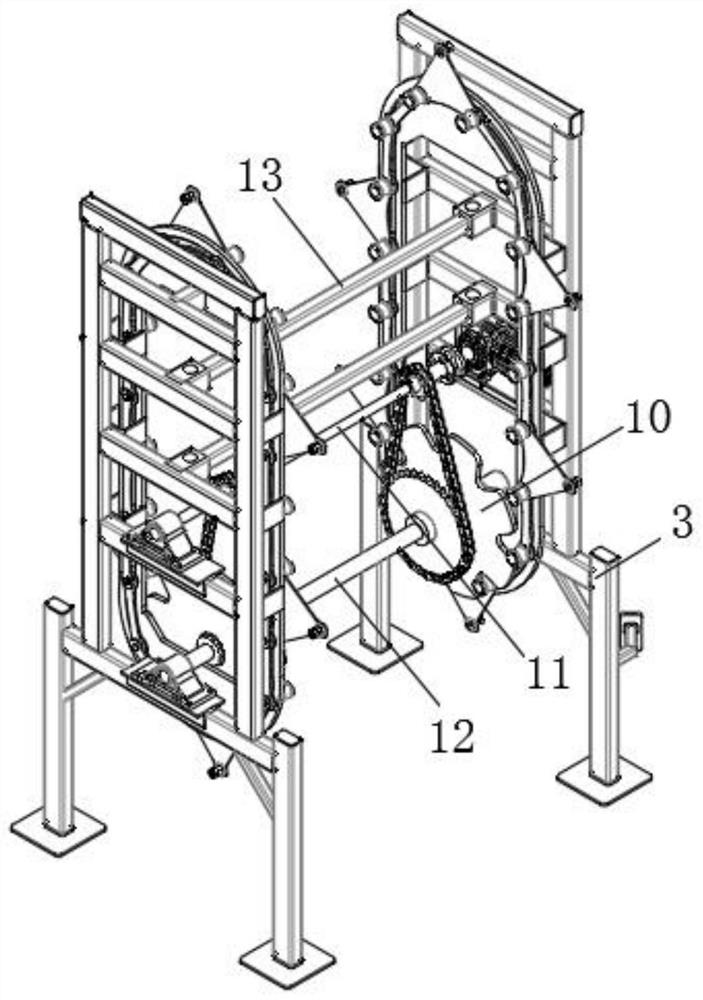

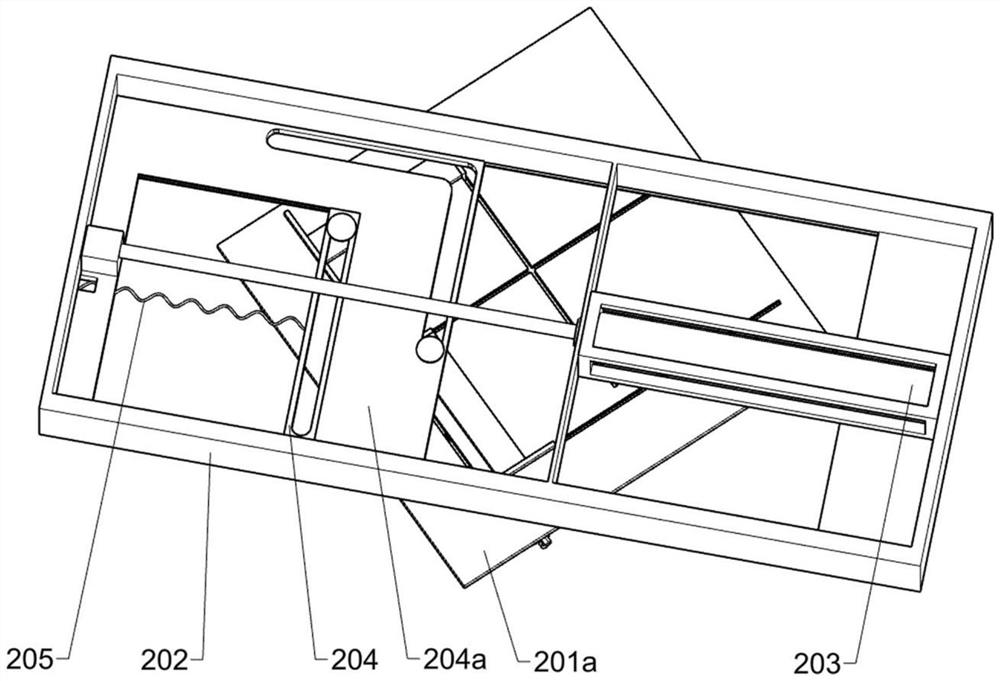

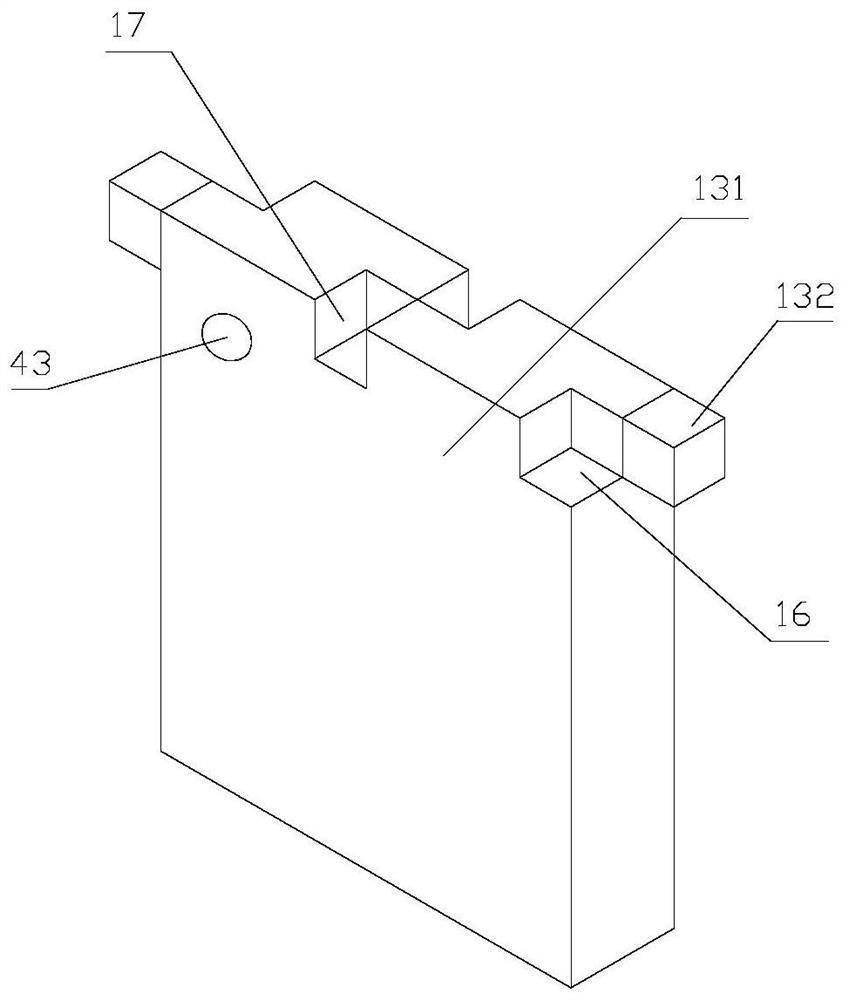

Crab-shaped automatic climbing jig and method for bars and feeding equipment

PendingCN114473609AIncrease flexibilityImprove adaptabilityMetal working apparatusStructural engineeringMachining time

The invention provides a crab-shaped automatic climbing jig and method for bars and feeding equipment. The crab-shaped automatic climbing jig comprises a rack with a clamping platform, a bottom layer lifting mechanism, a middle layer climbing mechanism and a top layer clamping mechanism, and a feeding through groove is formed in the clamping platform; the middle-layer climbing mechanism comprises a floating seat located under the feeding through groove, climbing racks are symmetrically clamped on the two sides of the floating seat, conical teeth are arranged on the two sides of the floating seat in a protruding mode, sawtooth clamping grooves are formed in the side walls of the climbing racks, the conical teeth and the sawtooth clamping grooves are meshed to form directional limiting clamping connection, and the climbing racks are in translation driving connection through a climbing power device. The Z-direction reference bearing position is effectively changed through matched operation of the driving assembly and matching of a sawtooth clamping groove like a crab claw, and the Z-direction reference bearing position can be applied to machining of materials with different lengths or the materials can achieve the automatic lifting function. The application range of the jig is expanded, the flexibility and adaptability are improved, meanwhile, the cutting step is omitted, manpower and machining time are shortened, and the working efficiency is improved.

Owner:日达智造科技(如皋)有限公司

Homogenizing plate with good heat preservation and heat insulation effects and preparation method thereof

InactiveCN112094133ALight in massGuaranteed thermal insulation performanceCeramic shaping plantsPress rollersPolyesterFiber

The invention discloses a homogeneous plate with good heat preservation and heat insulation effects and a preparation method thereof. The homogeneous plate is prepared from the following raw materialsin parts by weight: 25-30 parts of lime powder, 22-25 parts of quartz sand, 18-22 parts of aluminum silicate fiber, 14-18 parts of borax, 10-12 parts of polyether polyol, 7-9 parts of polyester polyol, 6-8 parts of triethylenediamine, 2-3 parts of potassium isooctoate-dipropylene glycol, 5-7 parts of pentane, 4-8 parts of pentafluoropropane, 3-7 parts of water, 4-9 parts of tris(2-chloropropyl) phosphate, 4-8 parts of a foam stabilizer B8460, and 24-45 parts of polyphenylpolymethylene polyisocynate; according to the formula, the homogenizing plate has the advantages of low thermal conductivity, low density, high strength, light overall mass and good heat preservation and insulation, the step of cutting is omitted by injecting the castable into the storage box, a plurality of homogenizingplates can be continuously produced, the operation is automatic, the labor intensity is low, and the production efficiency is high.

Owner:阜阳市三郁包装材料有限公司

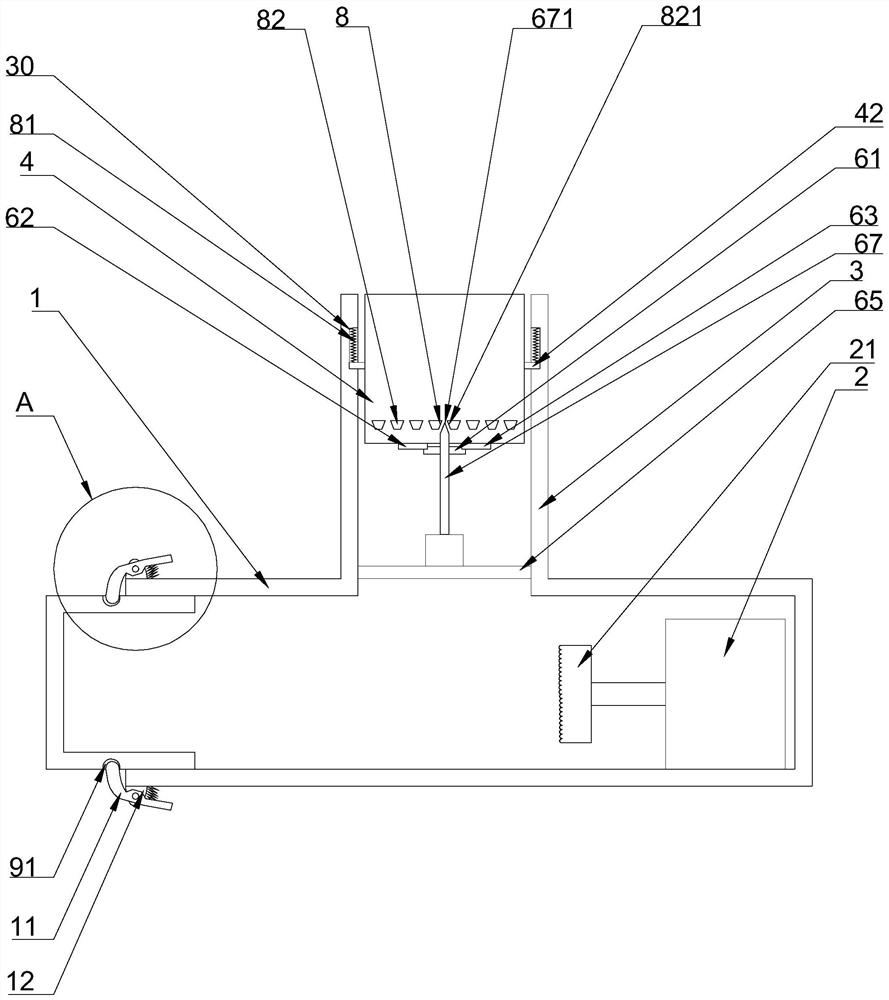

Food packaging equipment

ActiveCN108528871BStir wellWell mixedRotary stirring mixersPackagingStructural engineeringFood packaging

The invention relates to the technical field of food packaging, and discloses a food packaging equipment, which includes a frame, a conveyor belt and a quantitative mechanism; the quantitative mechanism includes a stirring box and a motor, and a rotating shaft is arranged in the stirring box, and a slideway is arranged on the rotating shaft; There is a stirring shaft inside, the stirring shaft is fixed with a permanent magnet, and the two side walls of the stirring box are fixed with electromagnets; there is a long iron rod on one side wall of the stirring box, a short iron rod on the other side wall of the stirring box, and a The first airbag, the second airbag is set under the short iron rod; the bottom of the mixing box is connected with the discharge pipe, the upper part of the discharge pipe is slidably connected with the second closing plate, and the lower part of the discharge pipe is slidably connected with the first closing plate; the conveyor belt is located at the outlet The bottom of the material tube is installed on the frame, and the conveyor belt is intermittently driven by the sheave mechanism. The invention has a simple structure, can quantify the food to be packaged, and the conveyor belt can intermittently transmit the packaging bags.

Owner:重庆新滋味食品有限公司

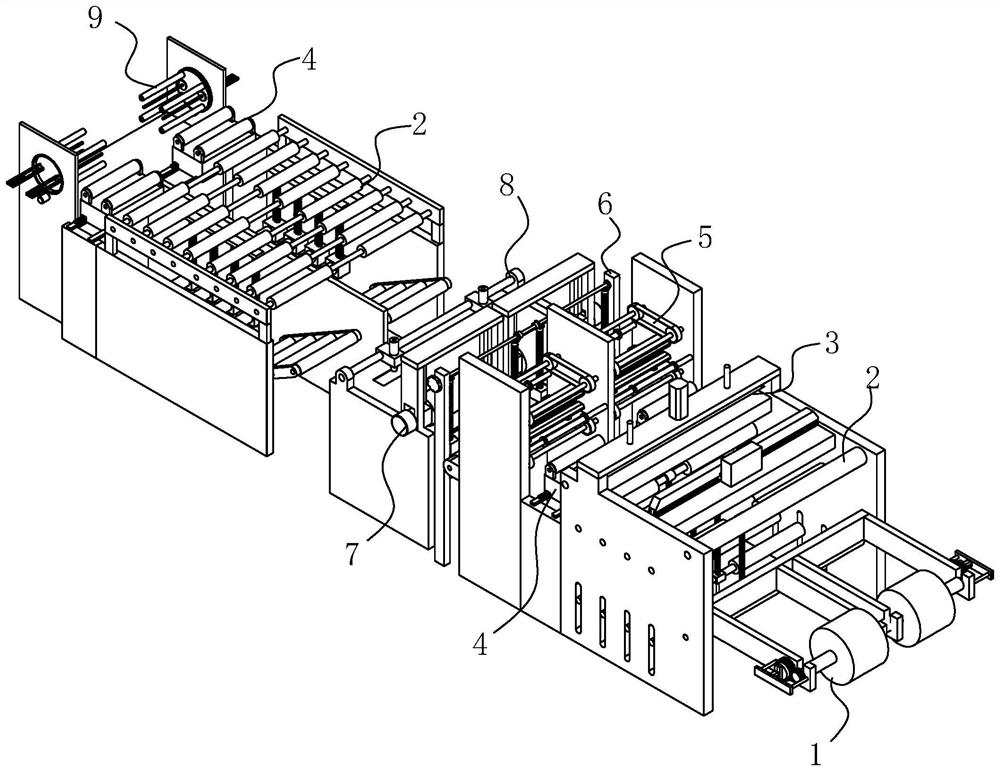

Silicon rod cutting equipment and system

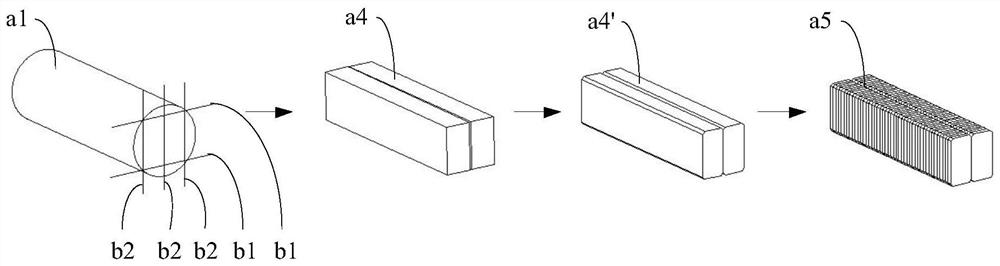

PendingCN114454361AReduce the cross-sectional areaGuaranteed conversion efficiencyEdge grinding machinesWorking accessoriesWire wheelWire cutting

The embodiment of the invention provides silicon rod cutting equipment and system.The silicon rod cutting equipment comprises a base, a vertical base, a bearing table and a linear cutting head device; the vertical base is arranged on the base in the vertical direction and provided with a sliding guide piece extending in the vertical direction. The silicon rod is vertically arranged on the bearing table; the linear cutting device or the bearing table is matched with the sliding guide piece to vertically slide; the wire cutting device comprises two first cutting wire wheel sets and at least three second cutting wire wheel sets, cutting wires wound around the first cutting wire wheel sets are parallel to one another, and the wire cutting device is used for cutting the silicon rod along the first cutting face. The cutting lines wound on the second cutting line wheel sets are parallel to one another and used for cutting the silicon rod along the second tangent plane. The second tangent plane is perpendicular to the first tangent plane, and at least two small silicon rods with rectangular sections and edge materials are obtained. According to the silicon rod cutting equipment and system provided by the embodiment of the invention, the technical problem of cutting a small silicon wafer through a large silicon wafer in a traditional scheme can be solved.

Owner:QINGDAO GAOCE TECH CO LTD

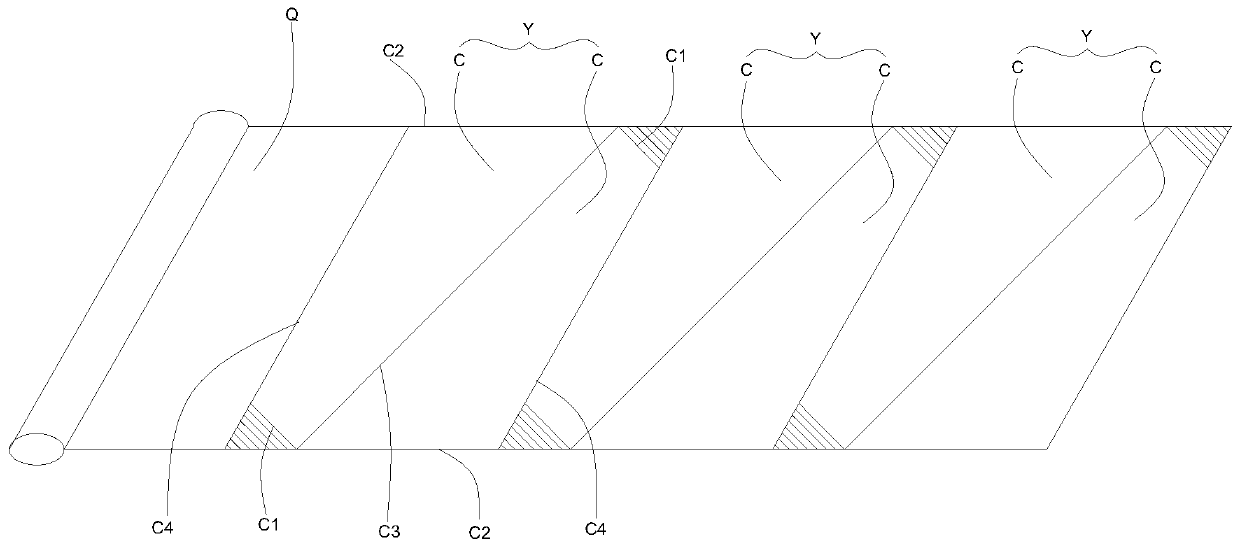

Production equipment and technology of even-back vest bag

ActiveCN112373123BReduce uneven croppingReduce stackingBag making operationsPaper-makingIndustrial engineeringSupport plane

The present application discloses a production equipment and a process for an even-back vest bag, which relates to the technical field of bag making. The discharging device arranged at the discharging end of the frame also includes a die-cutting device arranged between the heat-sealing device and the discharging device; the die-cutting device includes a die-cutting bracket, a workbench arranged at the top of the die-cutting bracket, and a die-cutting device fixed on the die-cutting bracket. A support frame at the top of the workbench, a die-cutting block connected to the support frame, a die-cutting roller rotatably connected with the die-cutting block, and a die-cutting die set on the die-cutting roller. The present application has the effect of optimizing the production process and reducing the occurrence of irregular cutting of the bag body.

Owner:QINGDAO ZHOUSHI PLASTIC PACKAGE

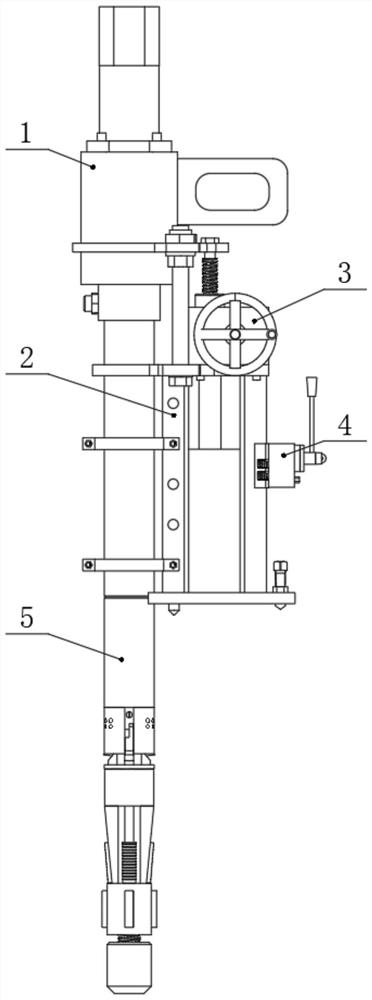

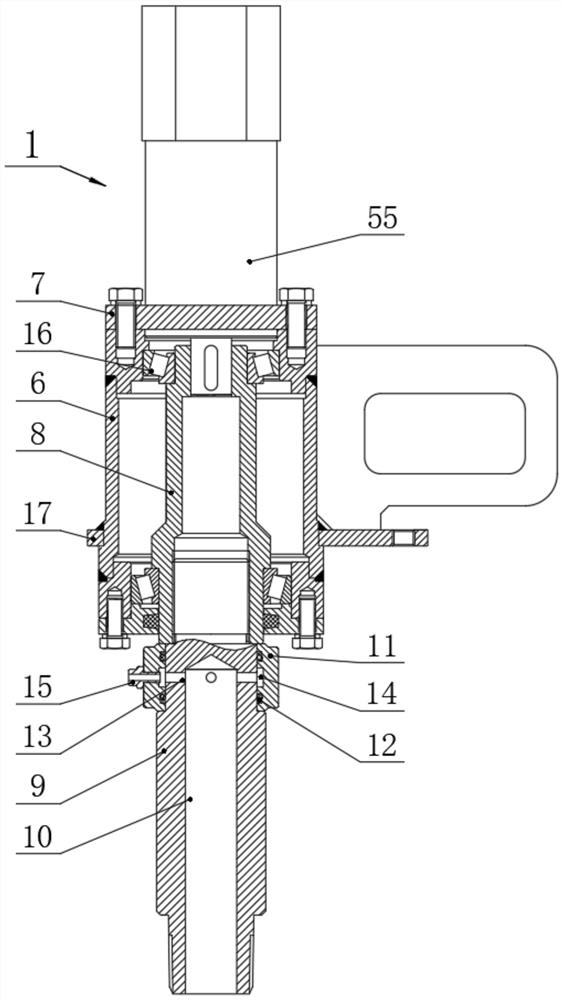

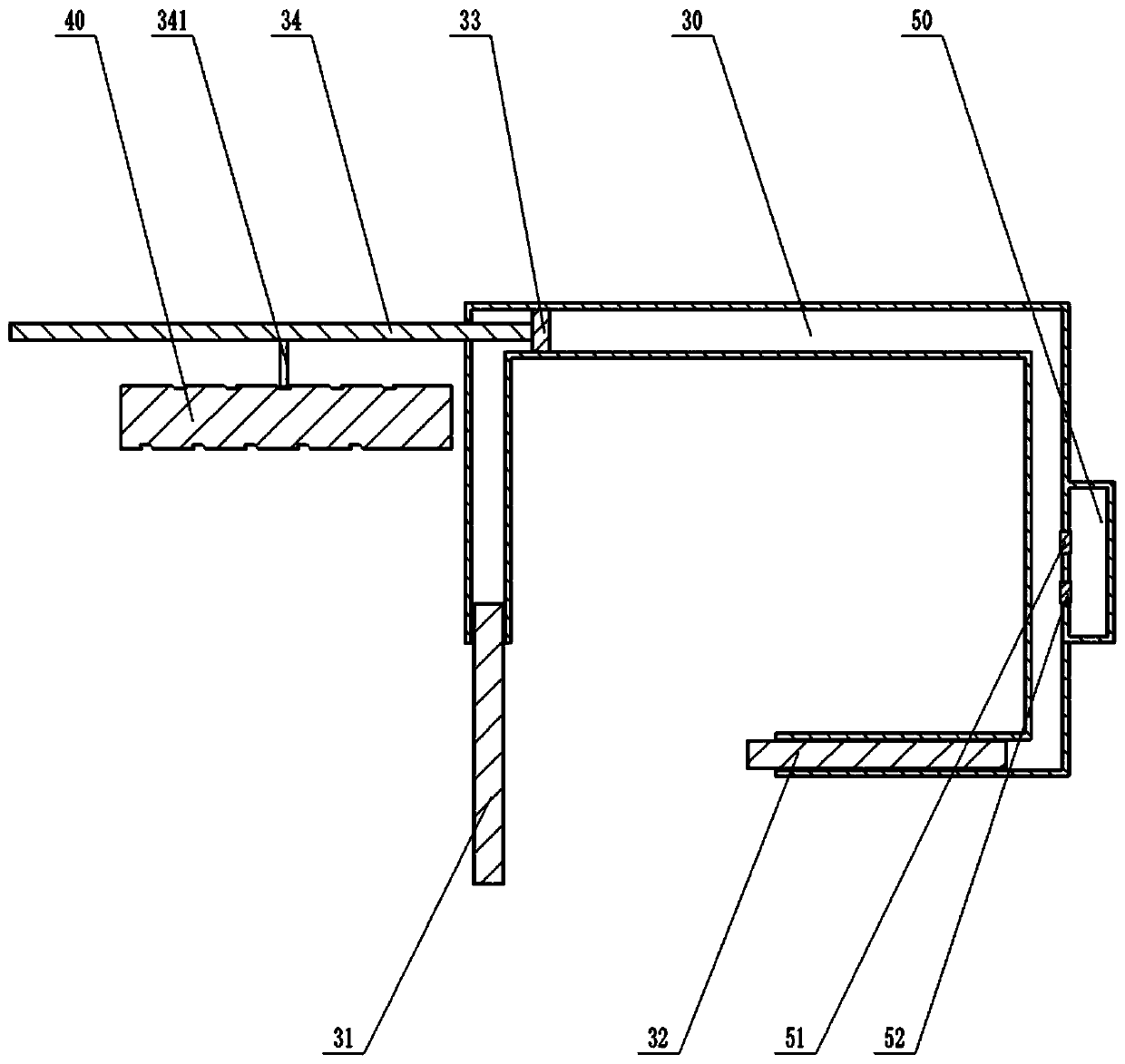

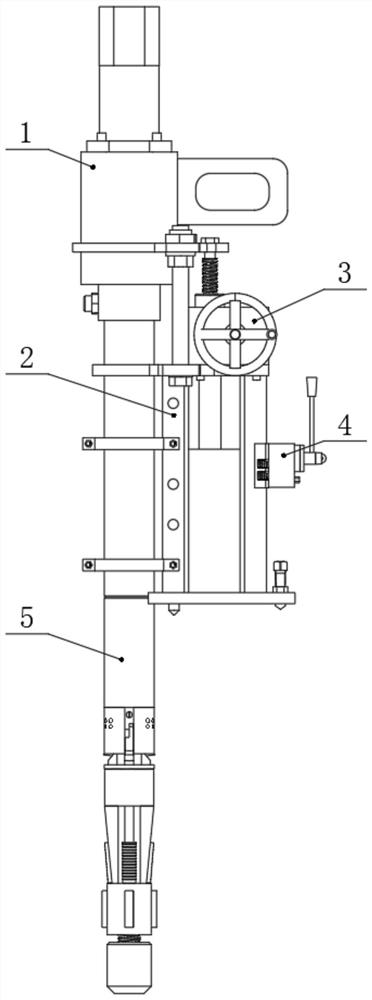

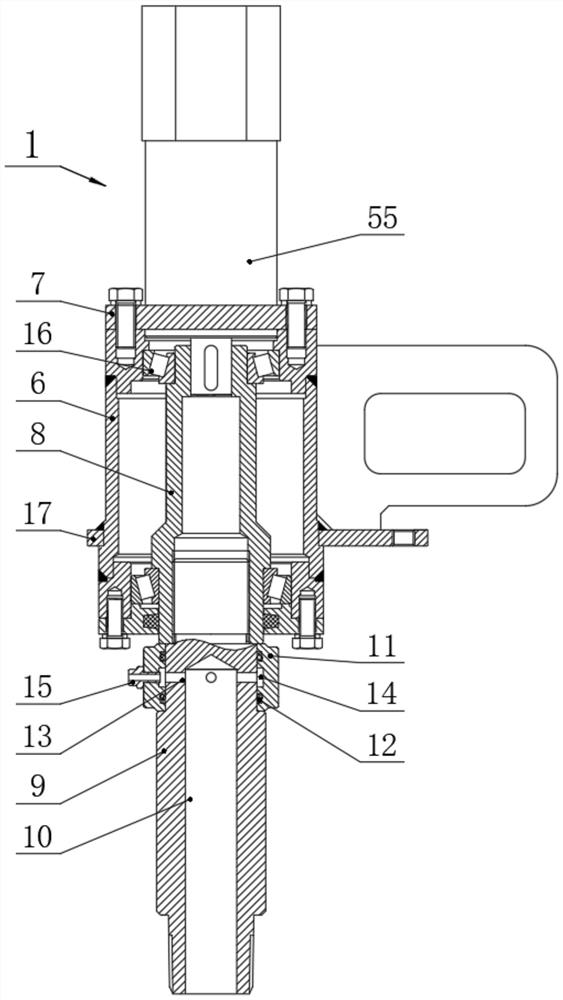

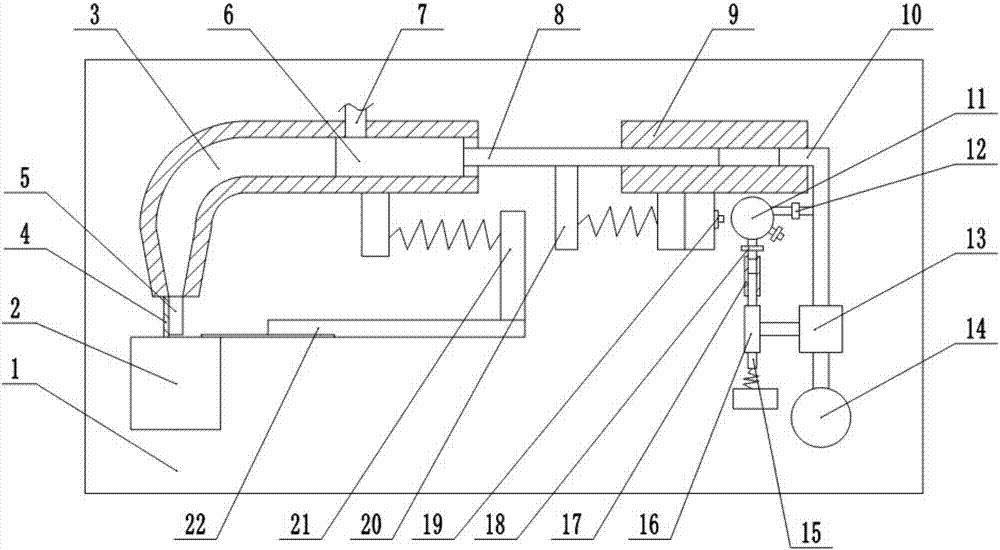

Hydraulic pipe cutter for horizontal freezing pipe in tunnel

ActiveCN112496440AReduce volumeReduce weightFeeding apparatusTube shearing machinesHydraulic motorHydraulic pump

The invention discloses a hydraulic pipe cutter for a horizontal freezing pipe in a tunnel, comprising a frame. Guide rods are fixedly connected to the two sides of the top of the frame; sliding sleeves are slidably connected to the surfaces of the guide rods; driving mechanisms are fixedly connected to the side faces of the sliding sleeves; a feed mechanism is fixedly connected to the middle of the top of the frame; the end of a movable rod of the feed mechanism is fixedly connected with the driving mechanisms; and the bottoms of the driving mechanisms are in transmission connection with a mechanical inner cutter mechanism. According to the invention, the driving mechanisms are arranged, the power of the driving mechanisms is a hydraulic motor, the hydraulic motor is small in size, lightin weight, resistant to impact and relatively stable in power output, so that a stable power source can be provided for the mechanical inner cutter mechanism; the hydraulic motor can be used only by matching with a common hydraulic pump station, so that construction and movement can be conveniently performed in a tunnel with narrow space; and the hydraulic pump station and the pipe cutter are of asplit structure, the hydraulic pump station is placed at the bottom of the tunnel during operation, and the pipe cutter operation can be performed only by moving the pipe cutter.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

A continuous high-efficiency compression molding device for peel residue

The invention discloses a continuous and efficient compression molding device for the peel residues. The continuous and efficient compression molding device comprises a molding pipeline, a telescopiccylinder used for rolling the peel residues, a molding die for assisting the molding of the peel residues and a feeding pipeline used for allowing the peel residues to enter the molding pipeline, themolding die is detachably arranged at one end of the molding pipeline, the telescopic cylinder is arranged in the molding pipeline, a pressing plate is arranged at the output end of the telescopic cylinder, the feeding pipeline communicates with the molding pipeline, a cutting device used for cutting the blocked peel into the residues is arranged on the feeding pipeline, and the cutting device comprises a processing cylinder, a cutting assembly and a driving assembly; and the processing cylinder is slidably arranged in the feeding pipeline, the processing cylinder is provided with a bottom plate, a feeding hole for allowing the peel residues to enter the molding pipeline is formed in the bottom plate, the cutting assembly comprises two cutter blades and two telescopic assemblies, one end of each of the telescopic assembly is connected with the corresponding cutter blade, the other end of each of the telescopic assemblies is connected with the inner wall of the processing cylinder, thetelescopic assemblies maintain the mutual separation of the two cutter blades, and the driving mechanism controls the two cutter blades to cut in a staggered mode.

Owner:JIANGSU JINGAN AGRI EQUIP

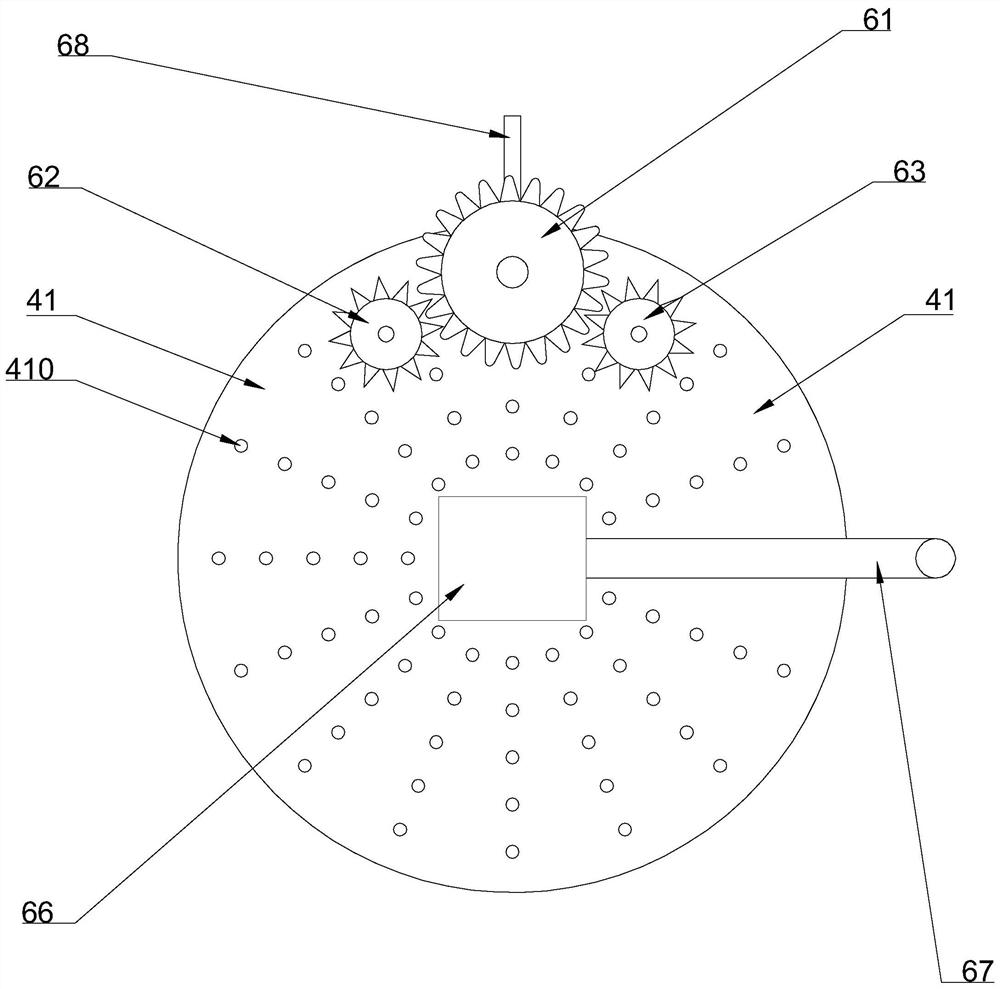

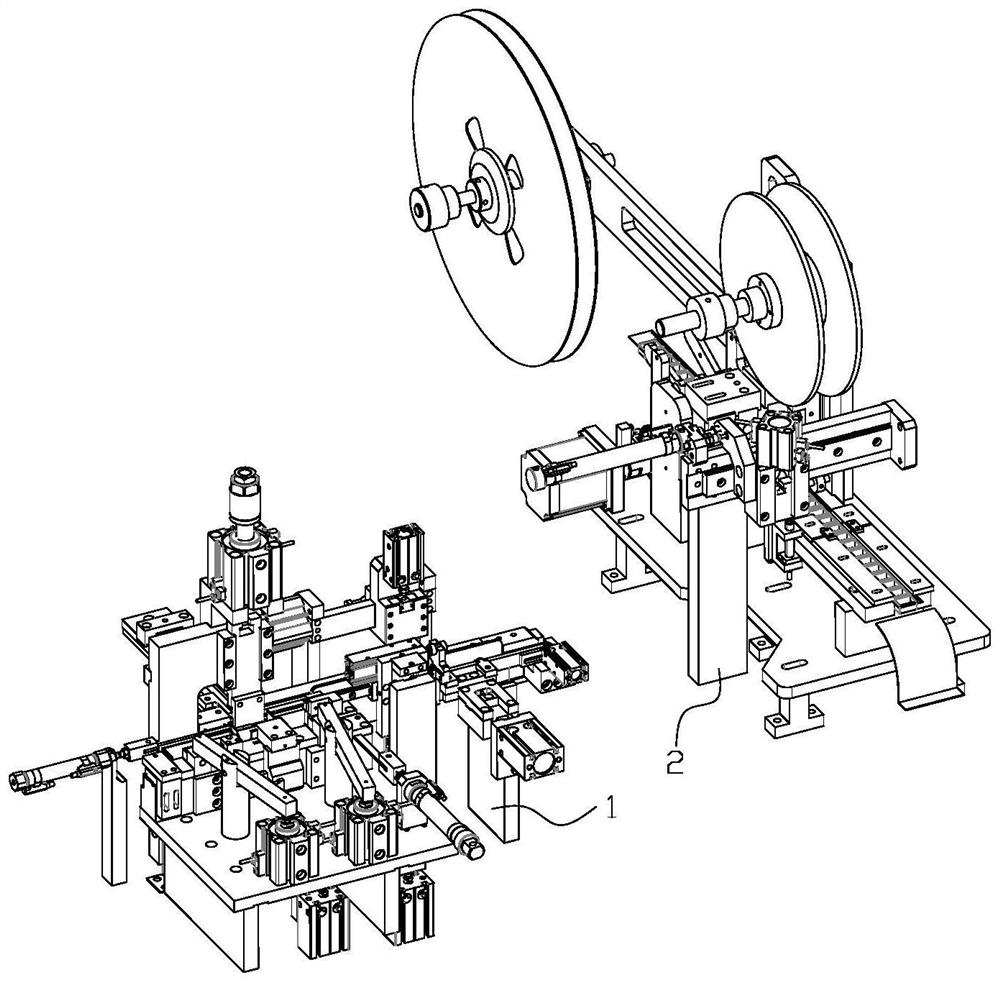

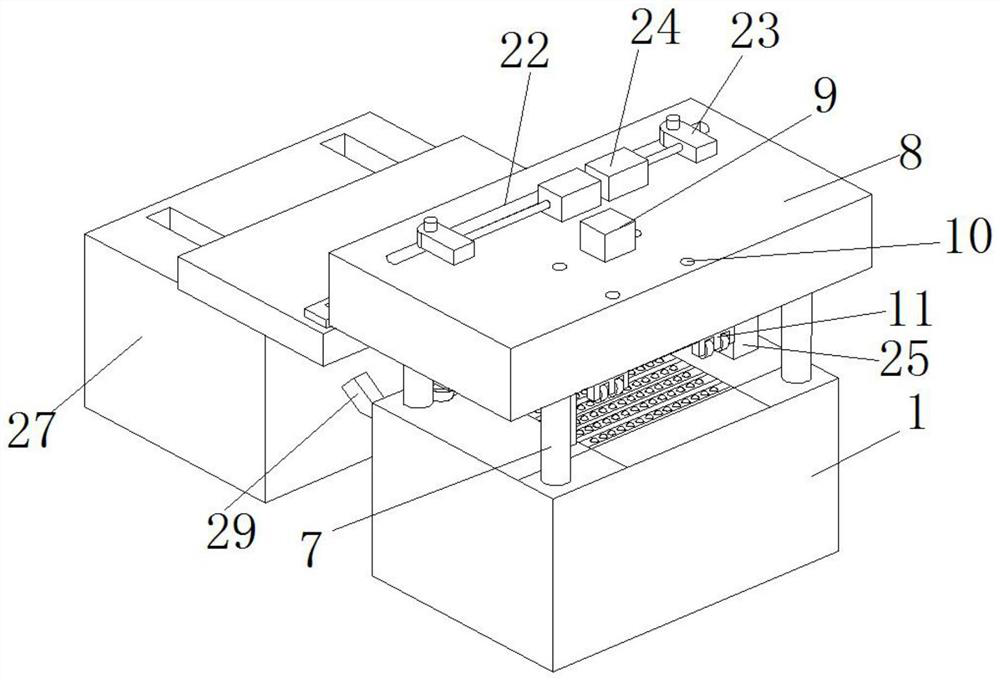

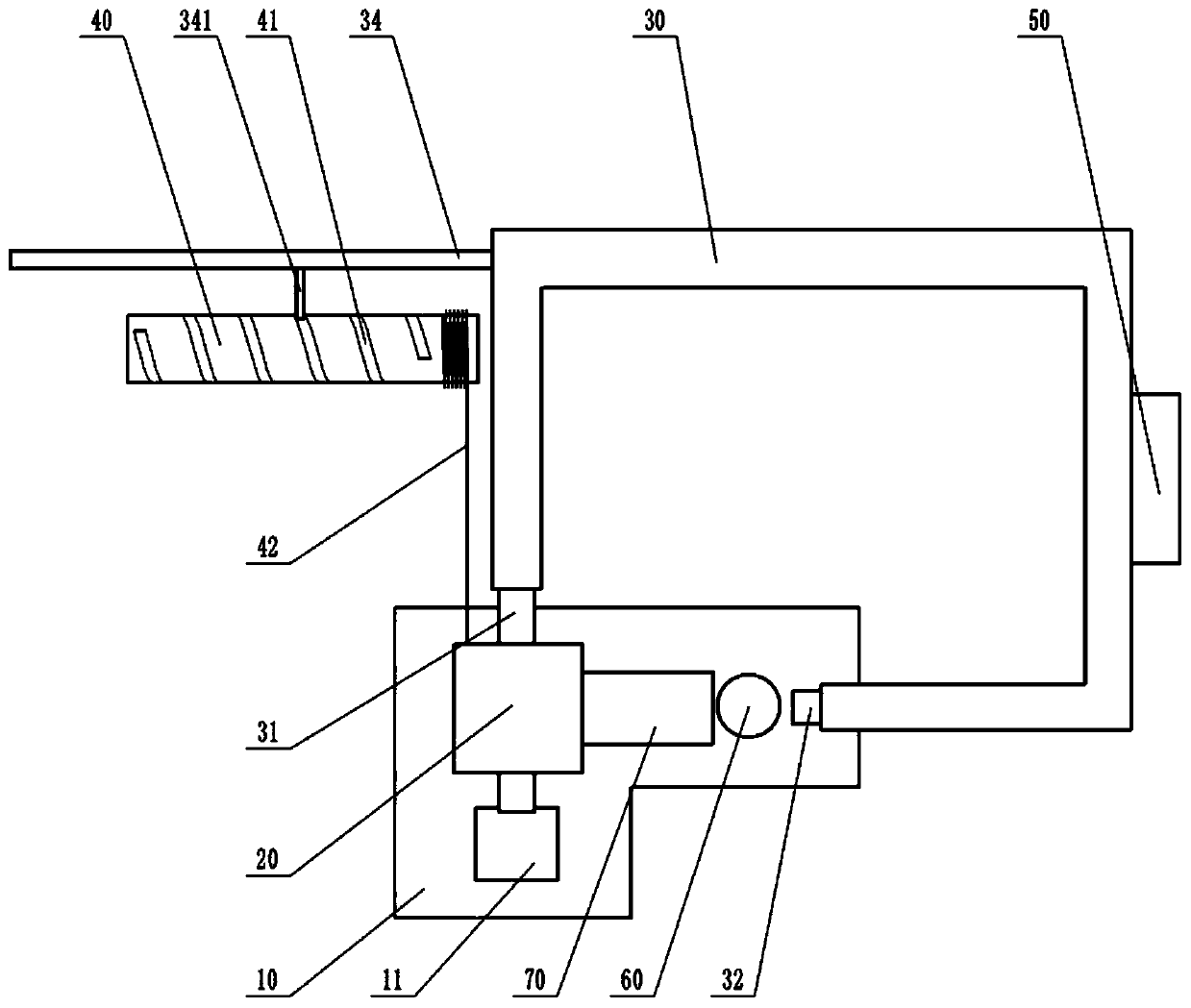

Automatic feeding device

ActiveCN108818115AReduce labor intensityReduce labor costsMetal working apparatusEngineeringUltimate tensile strength

The invention belongs to the technical field of machining, and particularly discloses an automatic feeding device. The device comprises a rack, a transmission unit, a storage unit and a machining unit; the machining unit comprises a workbench and a stamping mechanism; the storage unit comprises a cutting mechanism and a storage cylinder; the transmission unit comprises a communicating pipe and a rotating column, a torsional spring is connected between the rotating column and the rack, and hydraulic oil is arranged in the communicating pipe; one side of the communicating pipe is slidably connected with a first plunger, and the other side of the communicating pipe is internally slidably connected with a second plunger; the first plunger and the second plunger are located on two adjacent sides of the stamping mechanism respectively, and the storage unit is located between the first plunger and the stamping mechanism; a piston is slidably connected with the interior of the communicating pipe, and a push rod with one end penetrating through the communicating pipe is fixed to the piston; a spiral groove is formed in the rotating column, and a connecting rod is arranged on the push rod; apulling wire is connected between the rotating column and the stamping mechanism. By the adoption of the device, automatic feeding can be achieved, and the labor intensity of workers is effectively reduced.

Owner:WENZHOU UNIVERSITY

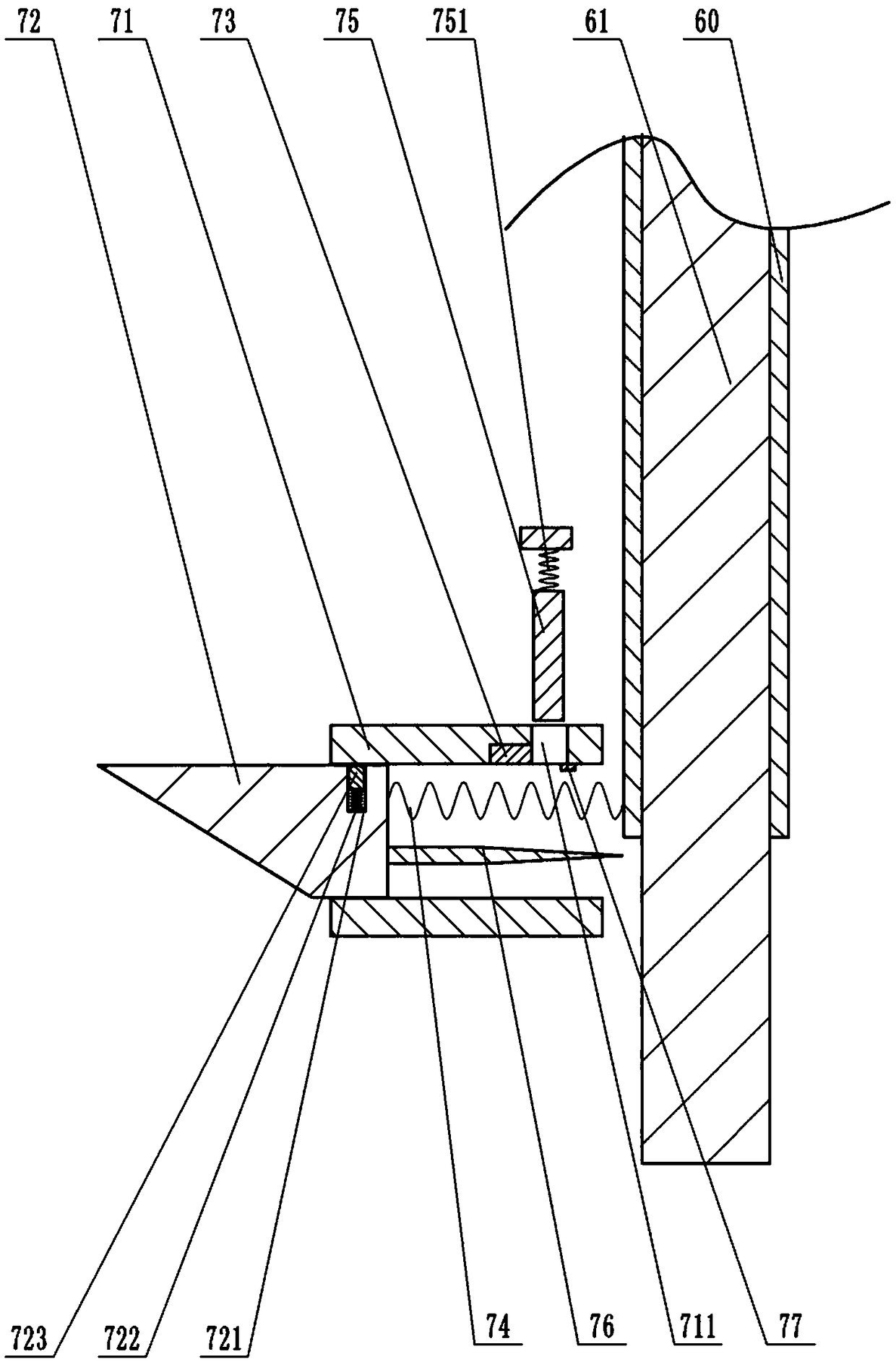

USB data transmission connector packaging device and method

InactiveCN112490822APrecise bending and pressingImprove cutting efficiencyContact member cases/bases manufactureContact member assembly/disassemblyTape driveUSB

The invention relates to the field of USB data transmission connectors. A USB data transmission connector packaging device comprises a connector moving mechanism, a carrier tape feeding mechanism, a heat sealing film feeding mechanism, a carrier tape driving mechanism, a carrier tape conveying mechanism and a carrier tape collecting mechanism. The output end of the connector moving mechanism is connected with the output end of the assembling device and the input end of the carrier tape conveying mechanism. The output end of the carrier tape feeding mechanism and the output end of the heat sealing film feeding mechanism are connected with the input end of the carrier tape conveying mechanism. The output end of the carrier tape driving mechanism is connected with the carrier tape, and the carrier tape is matched with the assembled USB data transmission connector; the carrier tape conveying mechanism is matched with the carrier tape, and the output end of the carrier tape conveying mechanism is connected with the input end of the carrier tape collecting mechanism. According to the device, the carrier tape conveying position is prevented from changing by arranging the carrier tape driving mechanism, and accurate conveying of the carrier tape is guaranteed.

Owner:董存清

High-hardness nodular cast iron roller sheet and casting method thereof

The invention relates to the technical field of mechanical casting, and particularly discloses a high-hardness nodular cast iron roller sheet and a casting method thereof. The high-hardness nodular cast iron material is prepared from the following chemical components in percentage by mass: 2.9-3.4% of C, 1.35-1.7% of Si, 0.55-0.85% of Mn, less than or equal to 0.06% of P, less than or equal to 0.02% of S, 0.35-0.85% of Cr, 0.25-0.8% of Mo, 0.3-0.7% of Ni, less than or equal to 0.02% of Ba, 0.04-0.07% of Mg, 0.01-0.03% of RE, and the balance of Fe and inevitable impurities. The high-hardness nodular cast iron roller sheet is high in working layer hardness and high in internal toughness, the using performance of the roller sheet is significantly improved, and the service life of the roller sheet is significantly prolonged.

Owner:河北津西钢铁集团重工科技有限公司

Metal cutting table based on metal corner distance measurement

InactiveCN113601268AChange real-time monitoringAvoid changeArc welding apparatusMeasurement/indication equipmentsMicrometerEngineering

The invention discloses a metal cutting table based on metal corner distance measurement, the metal cutting table comprises an equipment base, a spherical seat is arranged at the top of the equipment base, a spherical shaft is movably mounted in the spherical seat, and electric micrometers are mounted at two ends of the equipment base. Bases of the electric micrometers and a distance measuring rod are fixedly provided with point laser mounting seats, the top of each point laser mounting seat is fixedly provided with a point laser, a mounting table is fixedly mounted above the equipment base through a supporting rod, a hydraulic device is mounted on the mounting table, and a guide rail rod is arranged beside the hydraulic device. Compared with the prior art, the metal cutting table has the following beneficial effects that a laser device is arranged to measure other positions of a profile to obtain the position change of the profile, the position of the profile can be adjusted at any time in the cutting process, the position change of the profile is monitored in real time, the situation that a reference value is changed due to repeated mechanical movement of the laser device is avoided, cutting steps are reduced, and errors are avoided.

Owner:赵雪峰

Automatic feeding device

ActiveCN108818115BReduce labor intensityReduce labor costsMetal working apparatusEngineeringUltimate tensile strength

The invention belongs to the technical field of machining, and particularly discloses an automatic feeding device. The device comprises a rack, a transmission unit, a storage unit and a machining unit; the machining unit comprises a workbench and a stamping mechanism; the storage unit comprises a cutting mechanism and a storage cylinder; the transmission unit comprises a communicating pipe and a rotating column, a torsional spring is connected between the rotating column and the rack, and hydraulic oil is arranged in the communicating pipe; one side of the communicating pipe is slidably connected with a first plunger, and the other side of the communicating pipe is internally slidably connected with a second plunger; the first plunger and the second plunger are located on two adjacent sides of the stamping mechanism respectively, and the storage unit is located between the first plunger and the stamping mechanism; a piston is slidably connected with the interior of the communicating pipe, and a push rod with one end penetrating through the communicating pipe is fixed to the piston; a spiral groove is formed in the rotating column, and a connecting rod is arranged on the push rod; apulling wire is connected between the rotating column and the stamping mechanism. By the adoption of the device, automatic feeding can be achieved, and the labor intensity of workers is effectively reduced.

Owner:WENZHOU UNIV

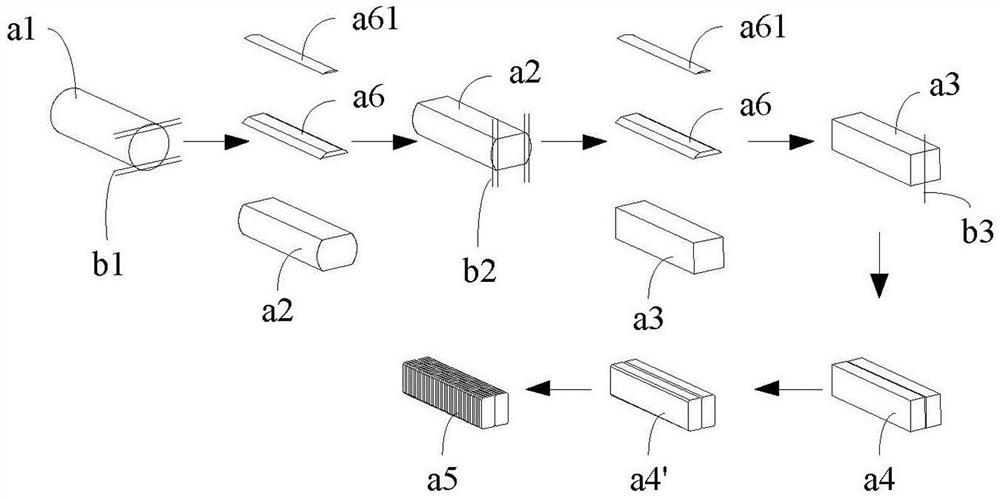

Silicon rod cutting equipment and system

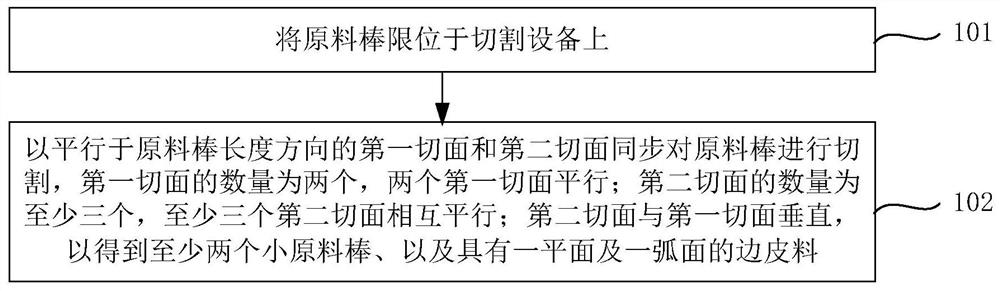

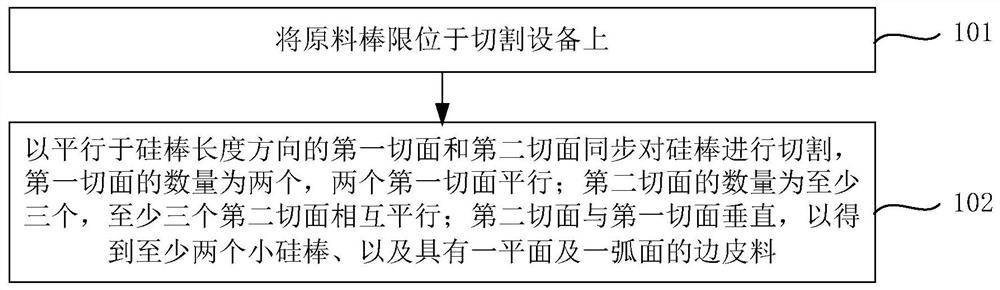

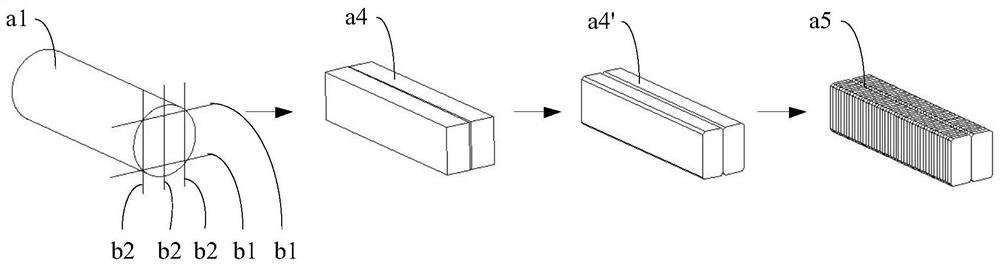

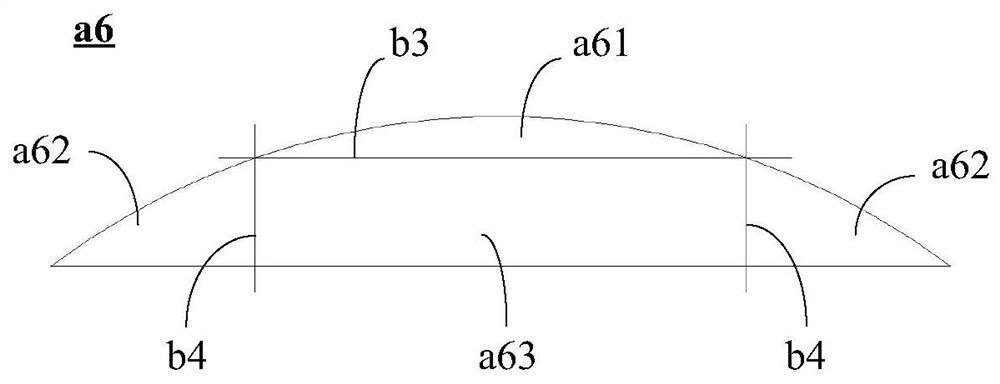

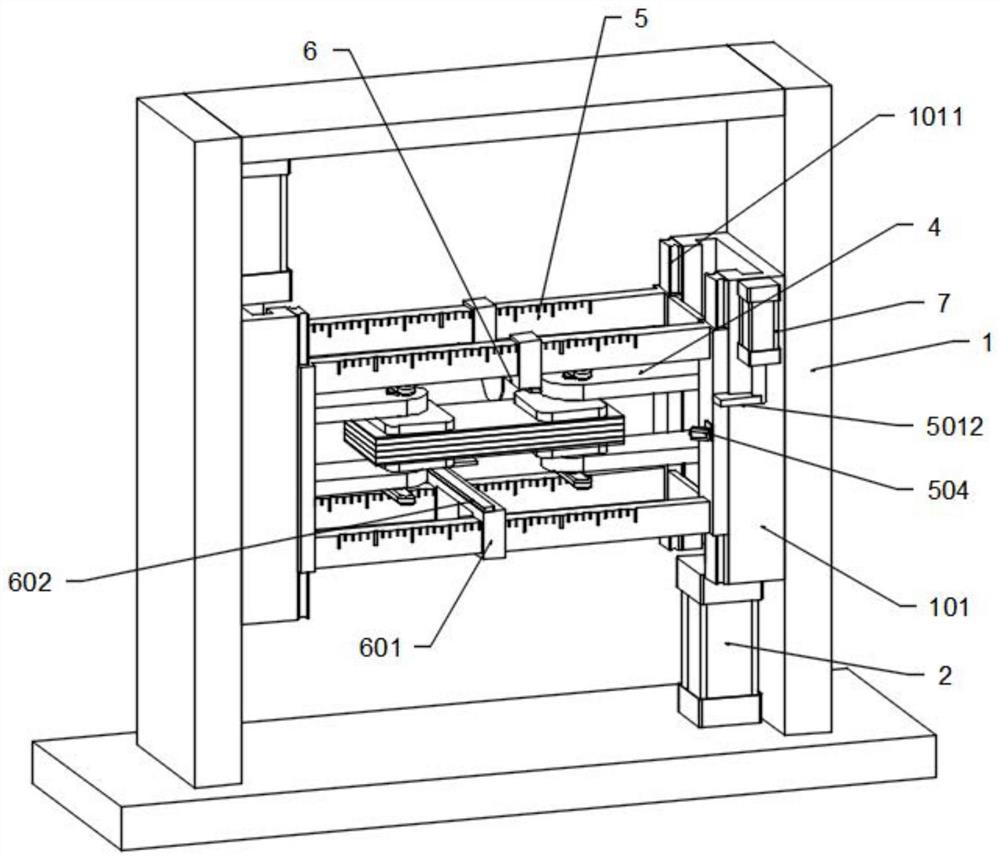

PendingCN114474441AReduce cutting stepsImprove efficiencyEdge grinding machinesWorking accessoriesSilicon chipWire cutting

The embodiment of the invention provides silicon rod cutting equipment and system.The silicon rod cutting equipment comprises a base, a main rack, a bearing table and a linear cutting device; a cutting space is formed between a top plate of the main rack and the base; the bearing table is used for bearing silicon rods; the linear cutting device and the bearing table can slide relatively in the horizontal direction. The wire cutting device comprises two first cutting wire wheel sets and at least three second cutting wire wheel sets, cutting wires wound around the first cutting wire wheel sets are parallel to one another, and the wire cutting device is used for cutting the silicon rod along the first cutting face. The cutting lines wound on the second cutting line wheel sets are parallel to one another and used for cutting the silicon rod along the second tangent plane. The second tangent plane is perpendicular to the first tangent plane, and at least two small silicon rods with rectangular sections and edge materials are obtained. According to the silicon rod cutting equipment and system provided by the embodiment of the invention, the technical problem of cutting a small silicon wafer through a large silicon wafer in a traditional scheme can be solved.

Owner:QINGDAO GAOCE TECH CO LTD

Plate strength detection device based on fabricated house building construction

PendingCN114813553AResolution timeSolve adhesivenessUsing mechanical meansMaterial analysisAdhesiveBonding process

The invention provides a plate strength detection device based on fabricated house building construction, and relates to the technical field of building material strength detection. An inner frame of the detection table is fixedly connected with two hydraulic push cylinders, one hydraulic push cylinder is located on the upper left side in the frame, and the other hydraulic push cylinder is located on the lower right side in the frame; the pressure detector is fixedly connected to the output end of the hydraulic push cylinder; the device is provided with a stable positioning auxiliary mechanism, a wood board is locally cut through the effect of a cutting and alignment adjustment mechanism, a cutting assembly can be aligned more quickly and accurately through laser alignment, and the problem that the existing bonding strength detection equipment is not convenient to carry is solved. The problems that when a multi-layer board is connected with detection equipment, the surface of a wood board is connected with the detection equipment through an adhesive, the bonding process is tedious, fixing of the adhesive needs to wait for a certain period of time, the adhesive remaining on the surface of the detection equipment after detection is not easy to remove, and next use is affected are solved.

Owner:汪志丹

Hydraulic pipe cutting machine for horizontally frozen pipes in tunnels

ActiveCN112496440BReduce volumeReduce weightFeeding apparatusTube shearing machinesHydraulic motorHydraulic pump

The invention discloses a hydraulic pipe cutting machine for horizontally frozen pipes in a tunnel, which includes a frame. Guide rods are fixedly connected to both sides of the top of the frame. The surface of the guide rod is slidably connected to a sliding sleeve. A drive mechanism is fixedly connected; a knife feed mechanism is fixedly connected in the middle of the top of the frame, and the end of the movable rod of the knife feed mechanism is fixedly connected with the drive mechanism; the bottom of the drive mechanism is connected with a mechanical inner knife mechanism. In the present invention, by setting the driving mechanism, the power of the driving mechanism is a hydraulic motor, the hydraulic motor is small in size, light in weight, impact-resistant, and the power output is relatively stable, which can provide a stable power source for the mechanical internal cutter mechanism, and the hydraulic motor only needs to cooperate Generally, the hydraulic pump station can be used, which is convenient for construction and movement in tunnels with small spaces, and the hydraulic pump station and the pipe cutter adopt a split structure. When operating, the hydraulic pump station is placed at the bottom of the tunnel, and only the cutting pipe needs to be moved. The machine can carry out pipe cutting machine operation.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Household electric appliance accessory casting device

The invention relates to a household electric appliance accessory casting device which comprises a rack. A pressure casting barrel and a mould are arranged on the rack. The pressure casting barrel communicates with a discharging pipe. An outlet of the discharging pipe faces an inlet of the mould. A cutting port is reserved between the outlet of the discharging pipe and the inlet of the mould. A pressure casting block is connected into the pressure casting barrel in a sliding mode. The pressure casting block is fixedly connected with a push rod. A piston cylinder is arranged on the rack. The push rod is connected into the piston cylinder in a sliding mode. The side, away from the push rod, of the piston cylinder communicates with an air inlet pipe. An air pump is fixed to the rack. A valveis arranged on the air inlet pipe. A time-delay mechanism used for increasing the opening degree of the valve in a time-delay mode is further arranged on the rack. The rack is in sliding connection with a cutter used for cutting pressure casting materials in the cutting port. An ejection rod used for pushing the cutter is fixed to the push rod. Compared with the prior art, by arranging the pressure casting block, the time-delay mechanism, the cutter and the like according to the scheme, the operating efficiency is improved, and operating steps are also simplified.

Owner:SHANDONG TAIKAI PRECISION CASTING

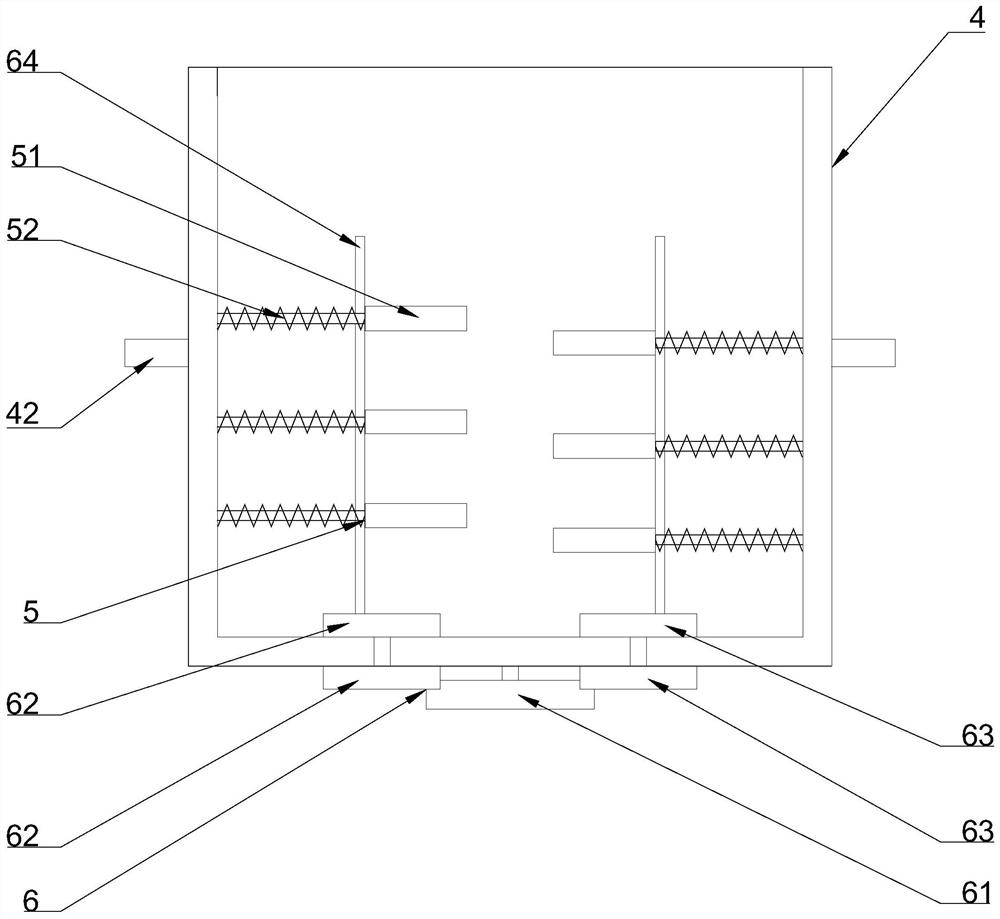

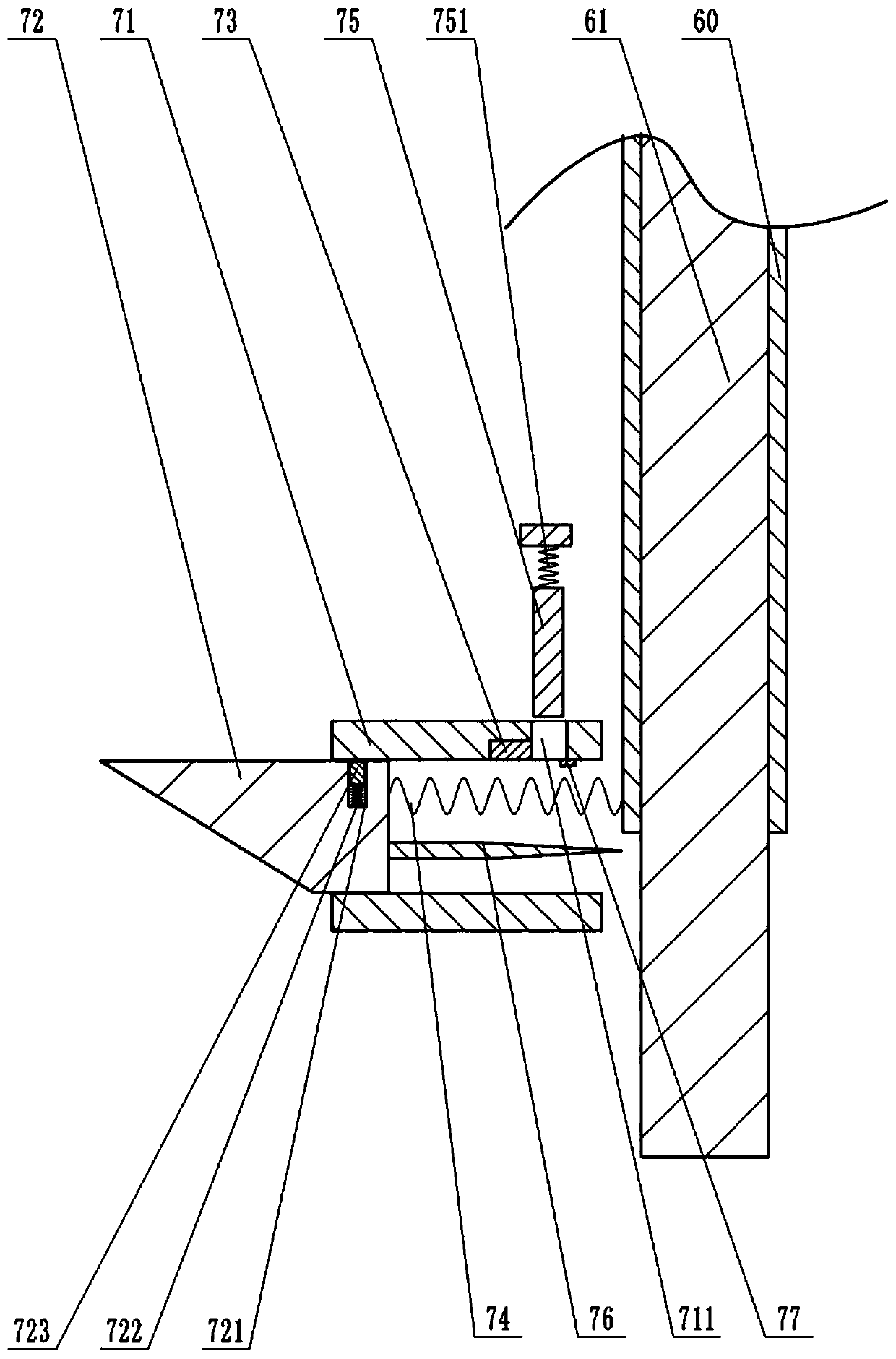

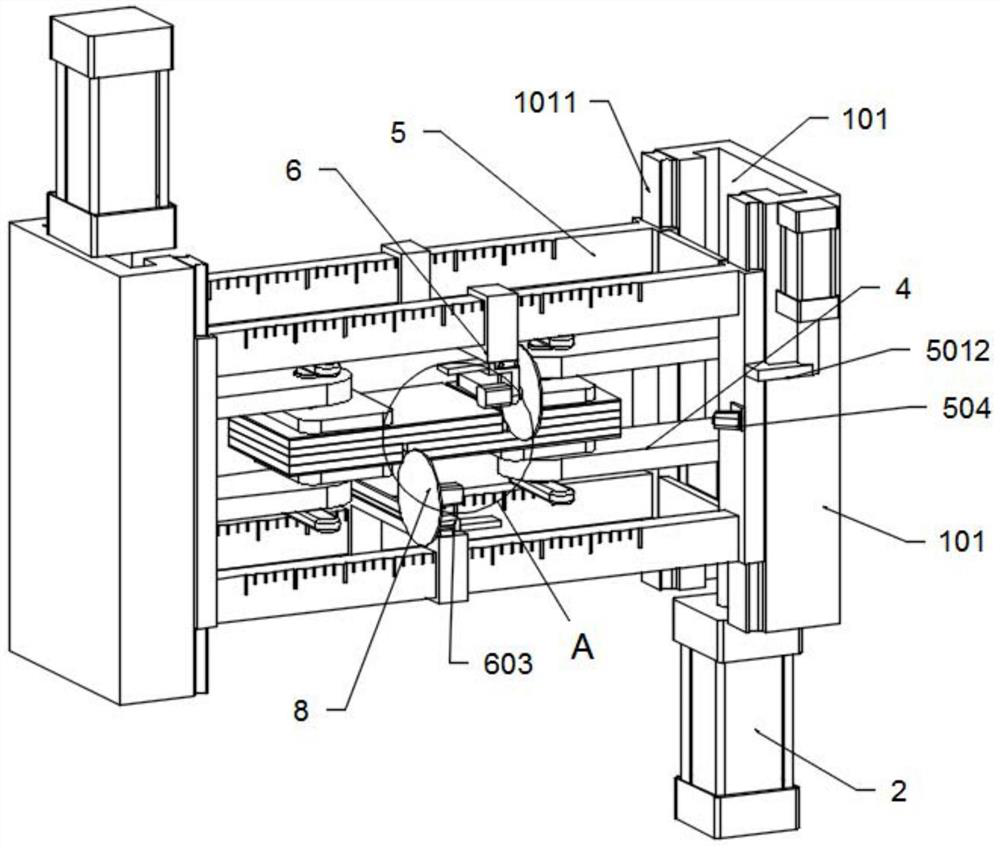

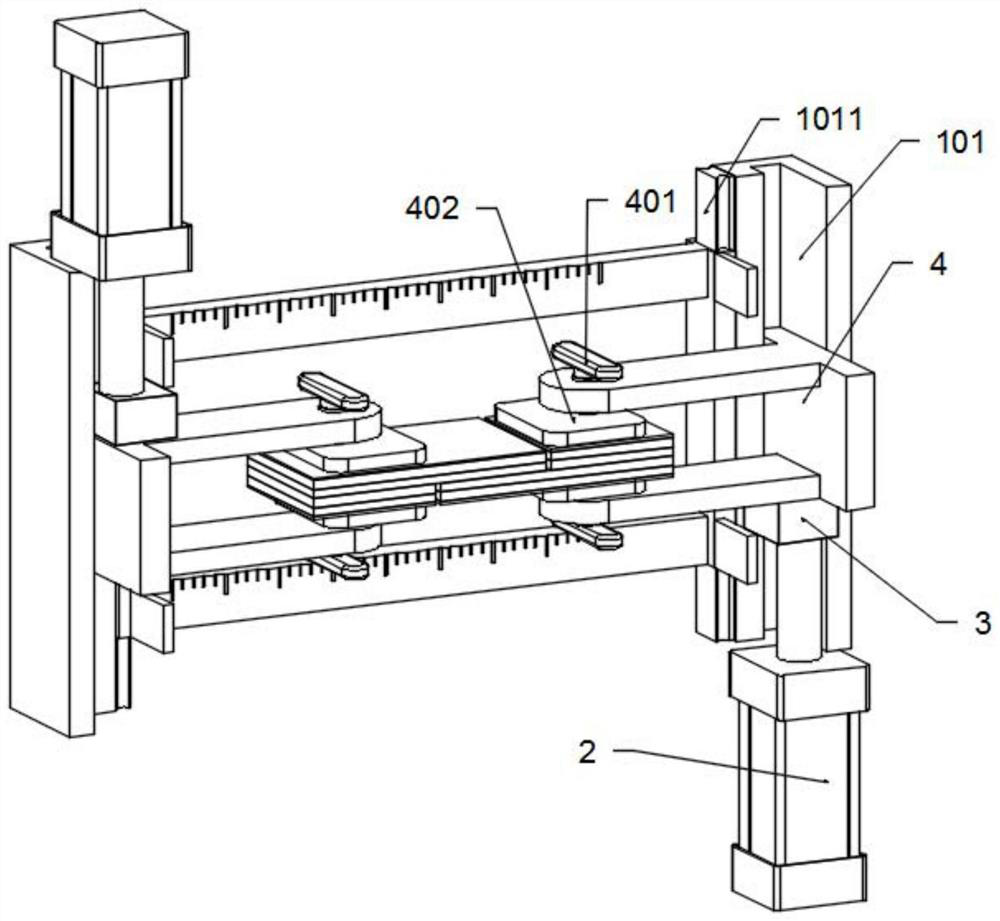

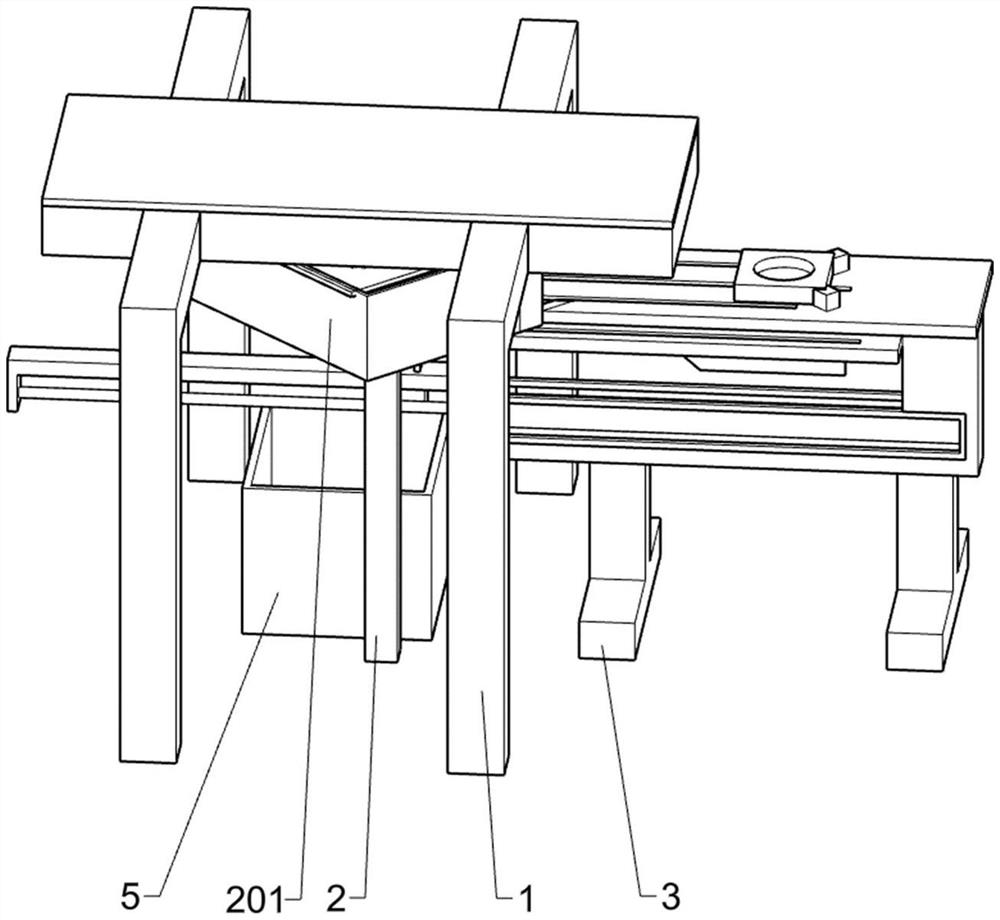

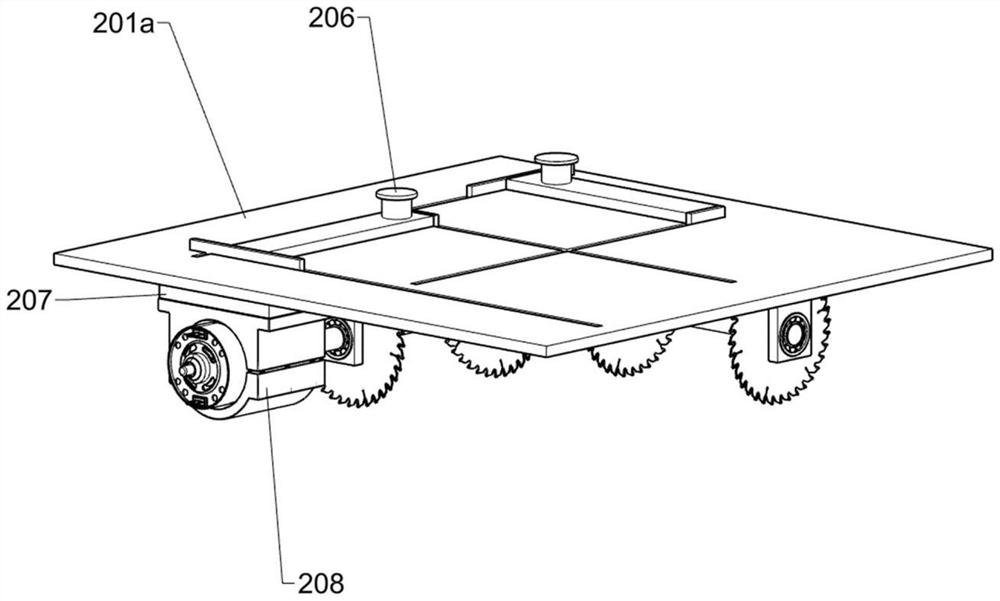

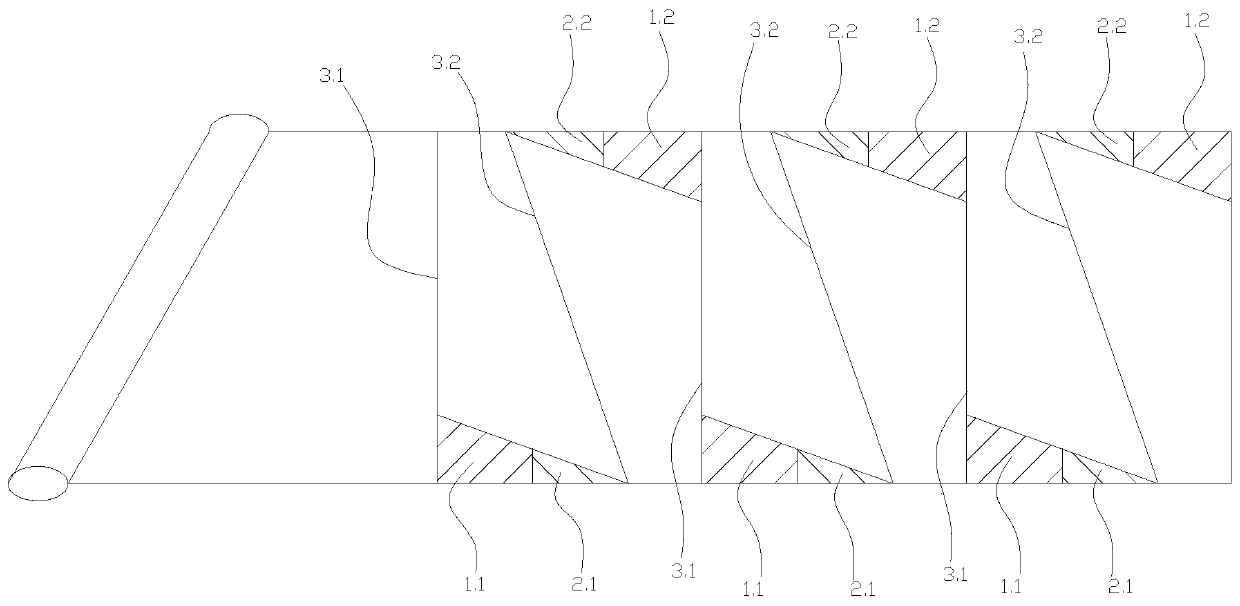

A solid wood processing side staggered precision cutting wood art base cutting device

ActiveCN112277077BReduce cutting stepsShorten the timeFeeding devicesCircular sawsSolid woodStructural engineering

The invention relates to a cutting device, in particular to a cutting device for solid wood processing side staggered precision cutting wooden art base. The technical problem to be solved by the present invention is to provide a cutting device for solid wood processing, side staggered precision cutting and wood base cutting device with uniform cutting angle, high efficiency side staggered and precise cutting, which ensures the safety of operators. The technical solution of the present invention provides a cutting device for solid wood processing side staggered precision cutting wooden art base, including a first support frame, a cutting mechanism, a support mechanism and a material box; four first support frames are arranged in an array, and the cutting mechanism It is fixedly connected with the first support frame, the support mechanism is located below the cutting mechanism, the support mechanism cooperates with the cutting mechanism, and the material box is placed vertically below the support mechanism. The present invention adds a cutting mechanism, which realizes simultaneous cutting of symmetrical angles, shortens the cutting steps by half, saves time for corner cutting, and improves work efficiency.

Owner:佛山市顺德区玉威精密木工刀锯有限公司

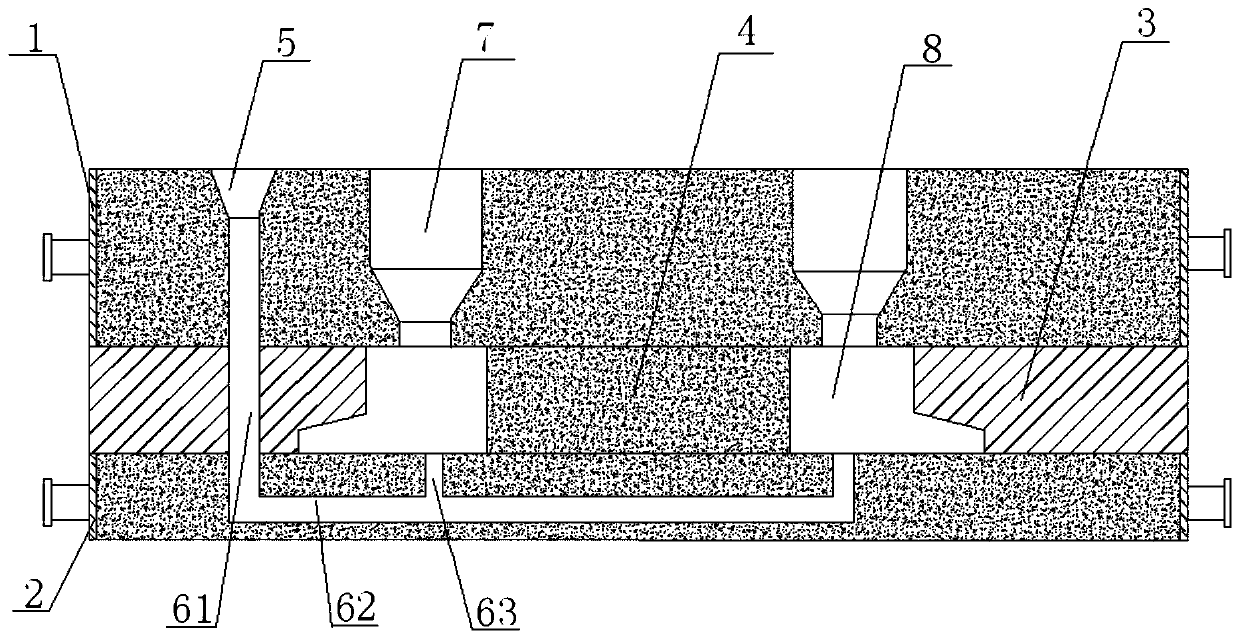

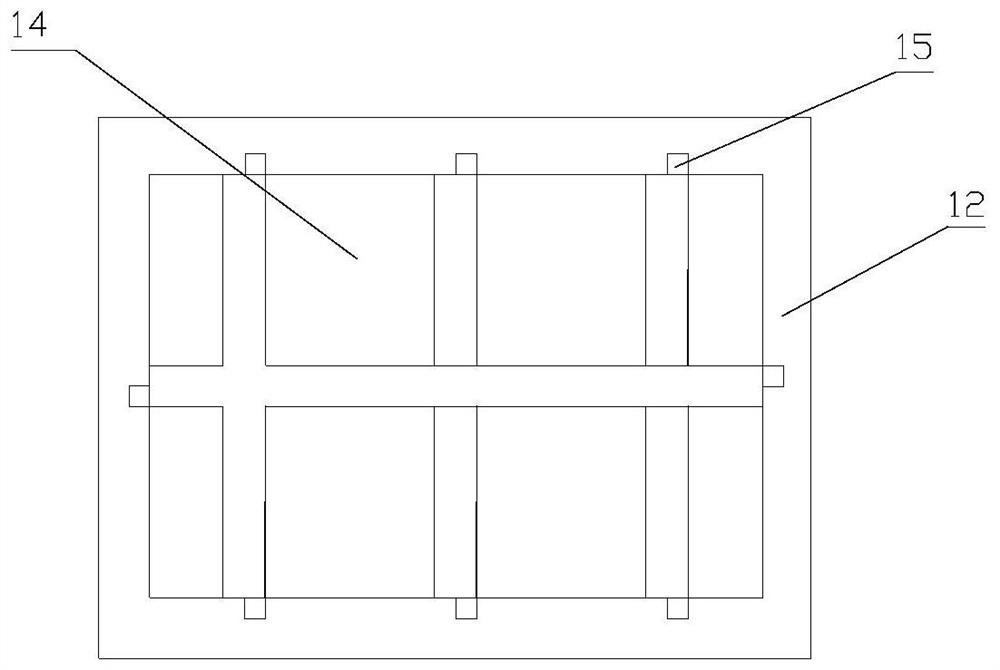

Lightweight high-strength autoclaved aerated concrete block and manufacturing device thereof

PendingCN113183282AEasy to collectReduce cutting stepsShaping press ramClassical mechanicsEngineering

The invention relates to the technical field of concrete, in particular to a lightweight high-strength autoclaved aerated concrete block and a manufacturing device thereof. A forming frame is fixedly connected with a supporting frame, and each assembling partition plate is connected with the adjacent assembling partition plate in a clamped mode and located in the forming frame. The first air cylinder is fixedly connected with the supporting frame and located below the forming frame, a connecting frame is movably connected with the first air cylinder, and below the connecting frame, each top plate is fixedly connected with the connecting frame and located in a corresponding rectangular hole. Grids of different sizes can be formed by using different numbers of assembling partition plates, concrete building blocks of different sizes can be manufactured by pouring slurry into the grids respectively, and then the formed concrete building blocks can be ejected out of the forming frame by using the first air cylinder, so that the cutting step is omitted, and the cost is reduced.

Owner:南京瞬拍信息科技有限公司

A cutting-free scaffold fastener bolt maintenance machine

ActiveCN104139292BFor quick replacementImprove work efficiencyMetal working apparatusMedial axisRust

The invention relates to a no-cut scaffold fastener bolt maintaining machine. The no-cut scaffold fastener bolt maintaining machine comprises a tray bracket, a motor fixed in the tray bracket, and an intermediate shaft driven by the motor and supported on the tray bracket, wherein one end of the intermediate shaft is fixed with one end of a fast T-shaped spanner; a first groove is formed in the other end of the fast T-shaped spanner, and is matched with a no-cut scaffold fastener bolt cap in shape; the no-cut scaffold fastener bolt maintaining machine further comprises a nut spanner component arranged on the tray bracket and capable of sliding and rotating along the tray bracket; the nut spanner component comprises an end provided with a second groove; the second groove is matched with a no-cut scaffold fastener bolt in shape; and when an end provided with a second groove nut spanner component is rotated to a horizontal position, the axis of the second groove is overlapped with the axis of the first groove. The no-cut scaffold fastener bolt maintaining machine can realize automatic feeding, is high in working efficiency, omits the cutter cutting step because of the bolt rust, has the benefits of economy, practicability, safety and reliability, and is an efficient tool for fastener bolt maintenance.

Owner:CHINA NUCLEAR IND 24 CONSTR

Uncoiling and blanking process of automobile sheet

The invention provides an automobile panel uncoiling blanking technology. The shortest edge is set as a waste cutting edge, the waste area can be lowered, and therefore the coil material utilization rate is improved; the shortest edge is set as the waste cutting edge, after the length is decreased, disposable cutting can be performed, cutting steps are simplified, and the production efficiency isimproved.

Owner:WUHAN BAOSTEEL CENT CHINA TRADE

Appliance switch forming device

Owner:ANHUI KAICHENG ELECTRIC APPLIANCE CO LTD

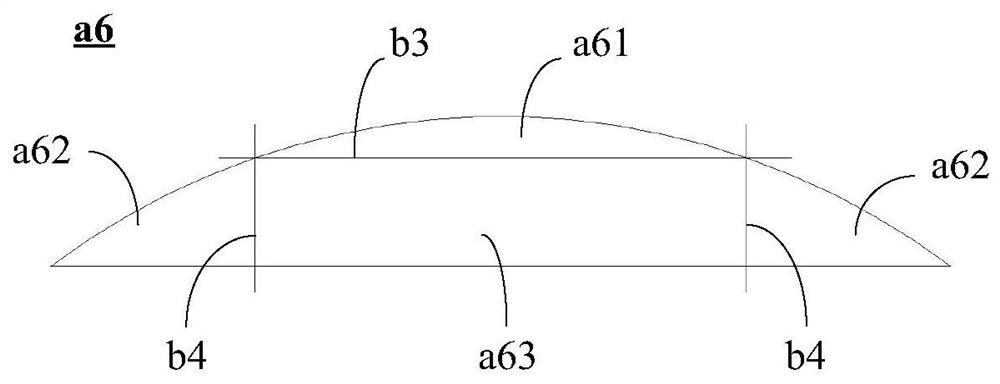

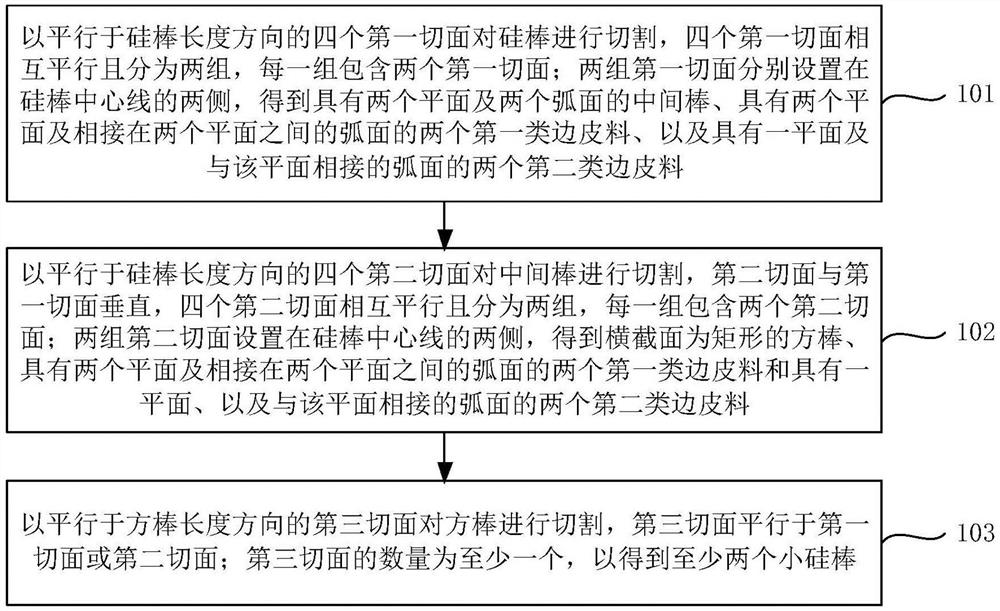

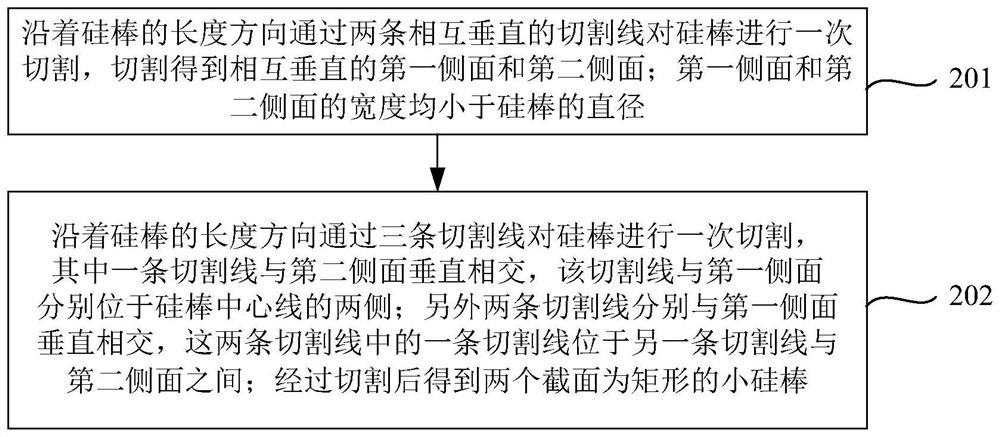

Silicon rod cutting method, device and system

PendingCN114454362AReduce cutting stepsImprove product qualityFine working devicesEngineeringStructural engineering

The embodiment of the invention provides a silicon rod cutting method, device and system, and the method comprises the steps: cutting a silicon rod through four first cutting surfaces parallel to the length direction of the silicon rod, and obtaining a middle rod with two planes and two cambered surfaces, two first-class edge leather materials and two second-class edge leather materials; four second tangent planes parallel to the length direction of the silicon rod are used for cutting the middle rod, the second tangent planes are perpendicular to the first tangent planes, and a square rod with the rectangular cross section, two first-class edge leather materials and two second-class edge leather materials are obtained; and the square rod is cut by a third section parallel to the length direction of the square rod, the third section is parallel to the first section or the second section, and at least two small silicon rods are obtained. The embodiment of the invention provides a silicon rod cutting method, equipment and system. The defects caused by cutting a large-piece structure into a small-piece structure in a traditional scheme can be overcome.

Owner:QINGDAO GAOCE TECH CO LTD

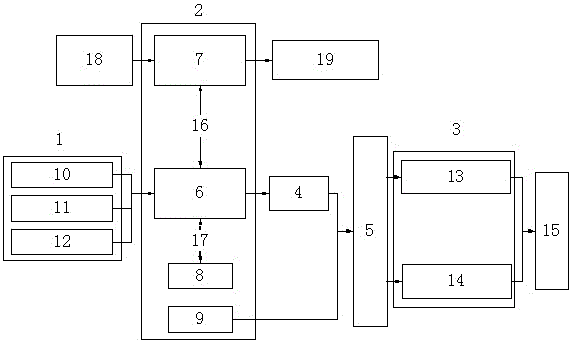

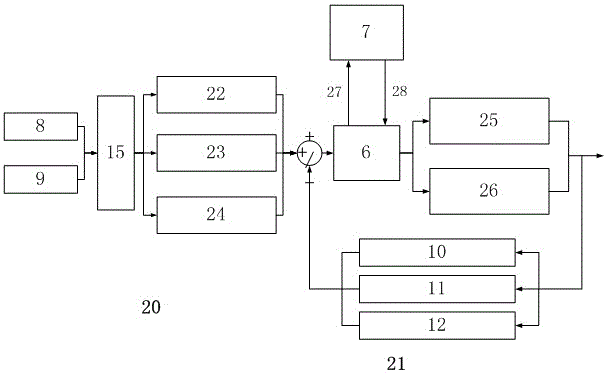

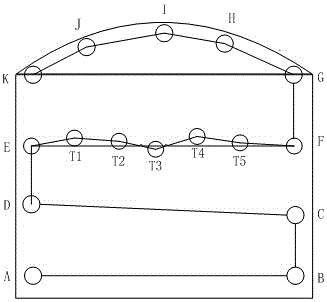

A roadheader memory cutting control system and method thereof

InactiveCN103147756BImprove forming qualityHigh control precisionSlitting machinesComputer control systemAutomatic control

The invention relates to a heading machine memory cutting control system and a method of the heading machine memory cutting control system. The heading machine memory cutting control system is composed of a detection unit, a control unit, a proportion amplification plate, a load sensitivity type proportion reversal valve group and an execution unit, wherein the control unit comprises a PCC (programmable computer controller), an intelligent operation control panel, a remote controller and a machine body operating handle; and heading machine memory cutting comprises a manual demonstration process and a memory automatic cutting process. The method comprises the following steps that: firstly, a heading machine driver utilizes the remote controller or the machine body operating handle to operate the heading machine to cut once according to a top plate and a bottom plate of a coal seam and the coal rock distribution condition, and an airborne computer control system records information a demonstration path detected by the detection unit; and then the recorded keypoint data is subjected to path matching and intelligent optimization, a control signal is sent to the execution unit according to the path after optimizing, so that a cutting head is automatically controlled to move along a demonstration track, and the memory automatic cutting is performed. The heading machine memory cutting control system is also provided with a boundary control function in the whole memory cutting process, and the tunnel shaping quality when the manual cutting and memory automatic cutting are performed is ensured. The heading machine memory cutting control system and the method of the heading machine memory cutting control system provide a new control means for heading of a coal road boom-type roadheader under the condition with stable surrounding rock of roadway.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

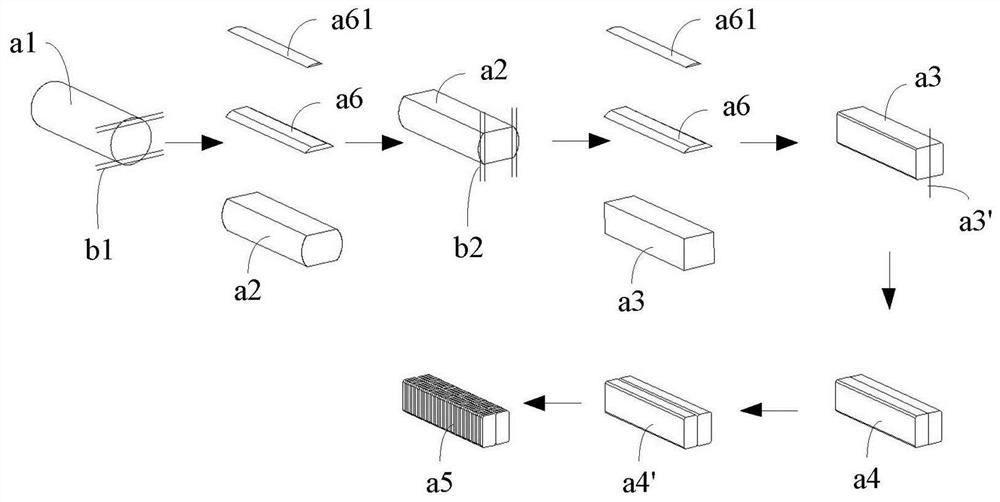

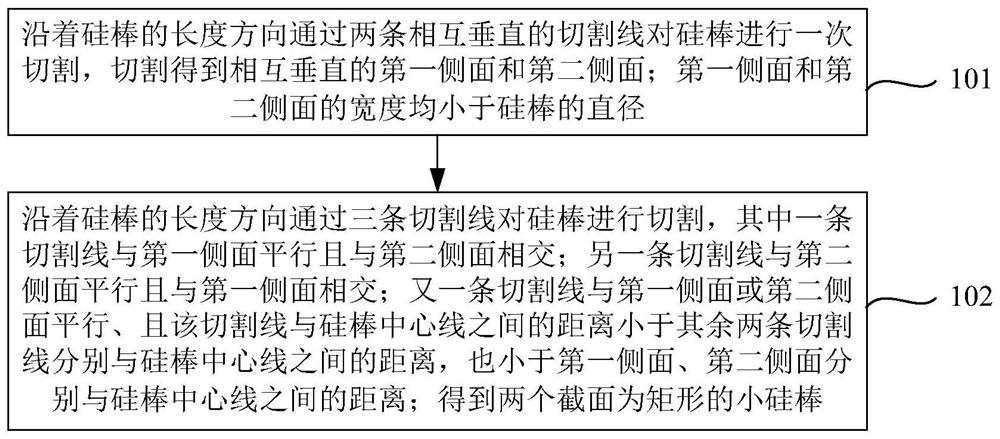

Method for cutting silicon rod through cross line, cutting equipment and cutting system

PendingCN114643654AGuaranteed conversion efficiencyImprove yieldFine working devicesWire cuttingEngineering

The embodiment of the invention provides a method for cutting a silicon rod through a cross line, cutting equipment and a cutting system.The method comprises the steps that the silicon rod is cut once through two cutting lines perpendicular to each other in the length direction of the silicon rod, a first side face and a second side face are obtained through cutting, and the width of each side face is smaller than the diameter of the silicon rod; the silicon rod is cut through three cutting lines, and one cutting line is parallel to the first side face and intersects with the second side face; the other cutting line is parallel to the second side surface and intersects with the first side surface; another cutting line is parallel to the first side face or the second side face, and the distance between the cutting line and the center line of the silicon rod is smaller than the distance between the other two cutting lines and the center line of the silicon rod and is also smaller than the distance between the first side face and the center line of the silicon rod and the distance between the second side face and the center line of the silicon rod; and two small silicon rods with rectangular sections are obtained. According to the method for cutting the silicon rod through the cross line, the silicon rod with the small size can be directly obtained, and the silicon wafer is formed through slicing.

Owner:QINGDAO GAOCE TECH CO LTD

A kind of recycling equipment for special wire and cable of power distribution cabinet

InactiveCN107845454BSave pay-off speedImprove securityBasic electric elementsApparatus for removing/armouring cablesEngineeringAutomation

Owner:佛山市欧能电气设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com