A roadheader memory cutting control system and method thereof

A control system and technology for roadheaders, which are used in earth-moving drilling, cutting machinery, etc., can solve the problems of low work efficiency, low section cutting quality, and poor working conditions, so as to improve work efficiency, reduce labor intensity, and reduce labor costs. The effect of the truncation step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, in conjunction with the accompanying drawings and preferred embodiments, the specific implementation methods, Structure, characteristic and effect thereof are as follows in detail.

[0059] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the drawings. Through the description of specific embodiments, the technical means and effects of the present invention to achieve the intended purpose can be understood more deeply and specifically. However, the accompanying drawings are only for reference and description, and are not used to explain the present invention. limit.

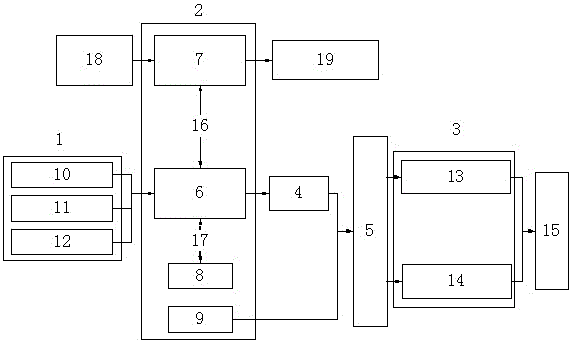

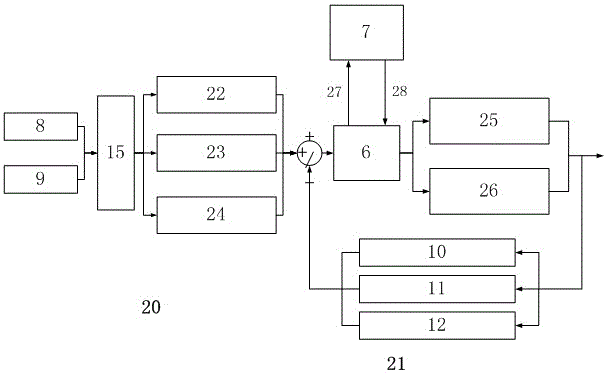

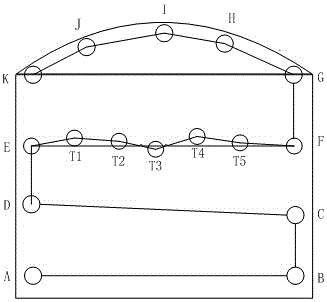

[0060] The roadheader memory cutting control system and method thereof of the preferred embodiment of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com