A continuous high-efficiency compression molding device for peel residue

A technology of compression molding and peel residue, which is applied to presses, manufacturing tools, etc., can solve the problems of difficult processing and manufacturing, difficult cleaning, and slow compression speed, so as to save cutting steps, facilitate secondary processing, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

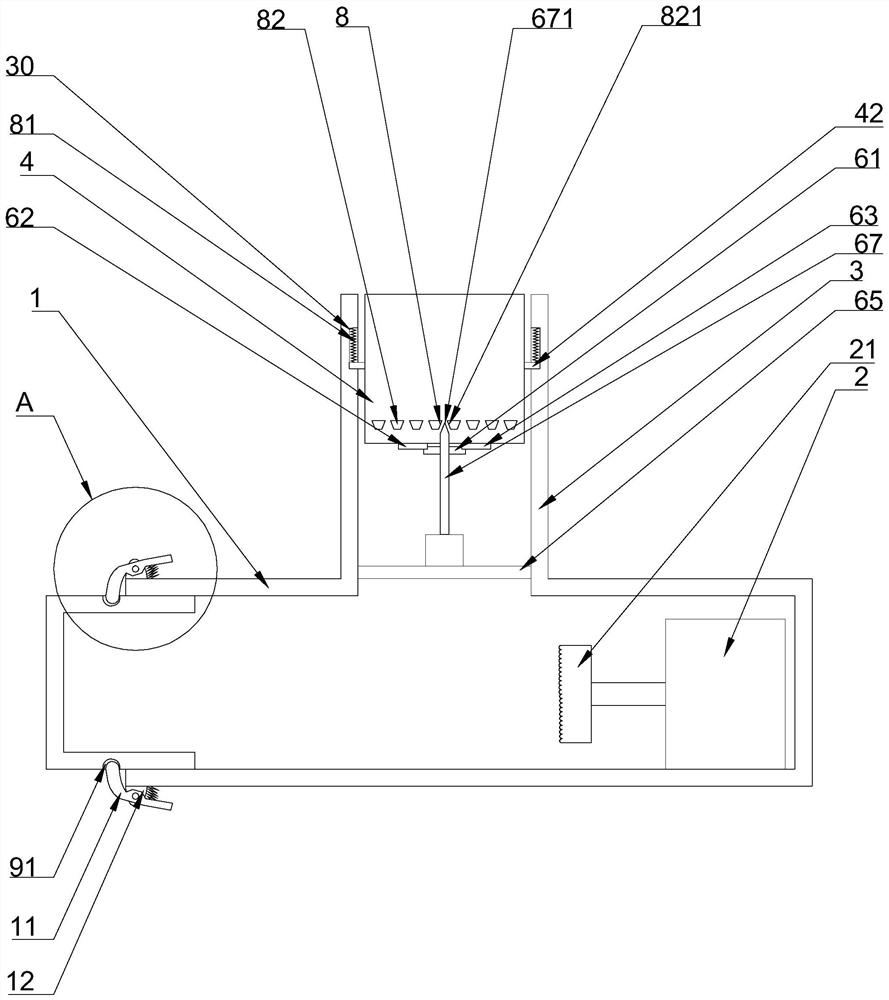

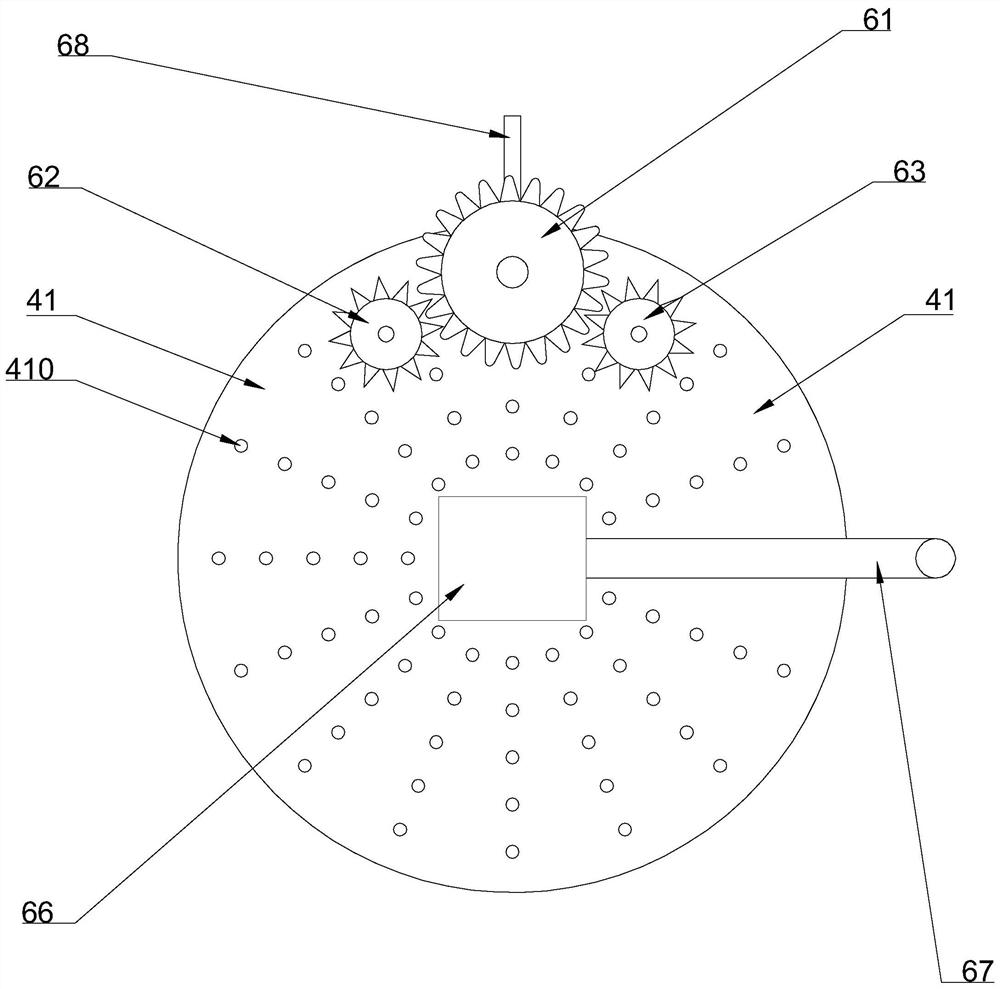

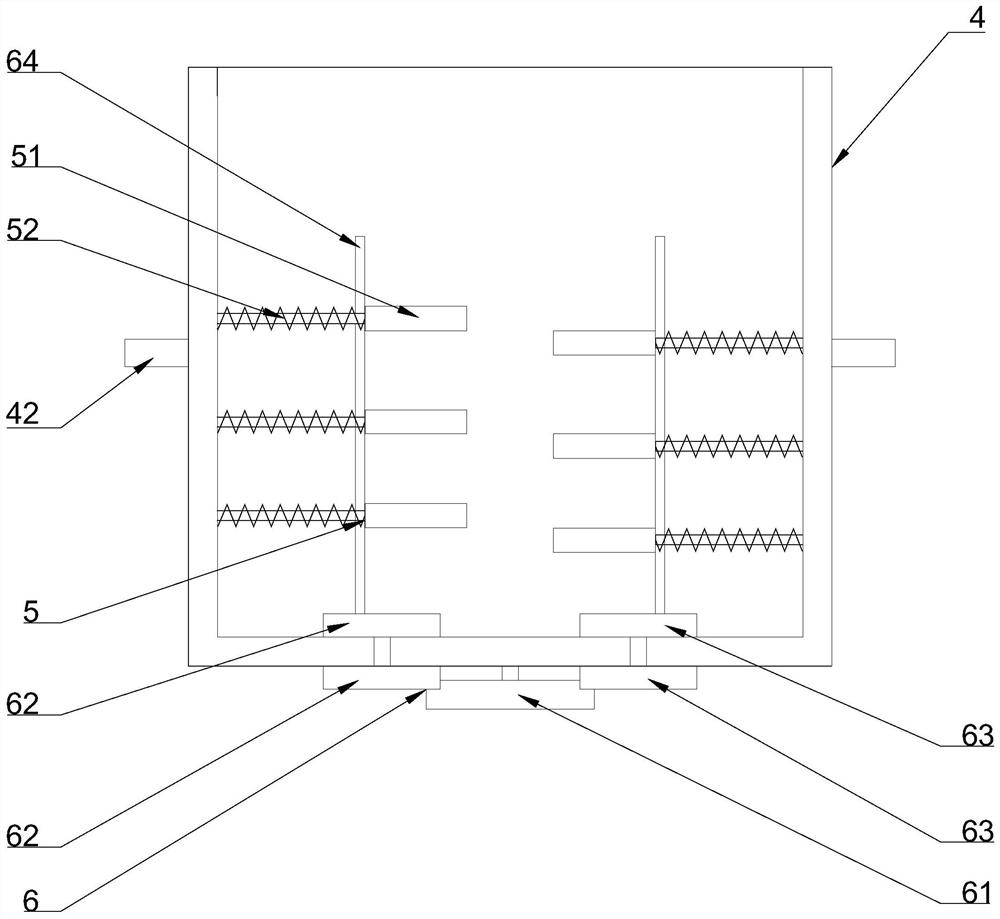

[0025] As an improved specific embodiment, the drive assembly 6 includes a driving gear 61, two first gears 62, two second gears 63, two movable rods 64, a bracket 65, a rotating motor 66, a conflict rod 67 and Drive rod 68, the driving gear 61 is rotatably arranged on the side of the bottom plate 41 facing the forming pipe 1, the two first gears 62 are coaxially arranged on the upper and lower sides of the bottom plate 41, and the two second gears 63 are coaxially arranged on the bottom plate On the upper and lower sides of 41, the first gear 62 and the second gear 63 on the side of the bottom plate 41 facing the forming pipe 1 mesh with the driving gear 61, and the first gear 62 and the second gear 63 on the side of the bottom plate 41 facing away from the forming pipe 1 The movable rod 64 is arranged eccentrically and symmetrically. The outer peripheral walls of the two movable rods 64 are respectively in conflict with the side of the blade 51 facing the telescopic assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com