Automatic feeding device

An automatic material feeding and blank technology, applied in metal processing, etc., can solve the problems of high safety hazards and high labor intensity of manual feeding, and achieve the effect of reducing labor costs, reducing cutting steps, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

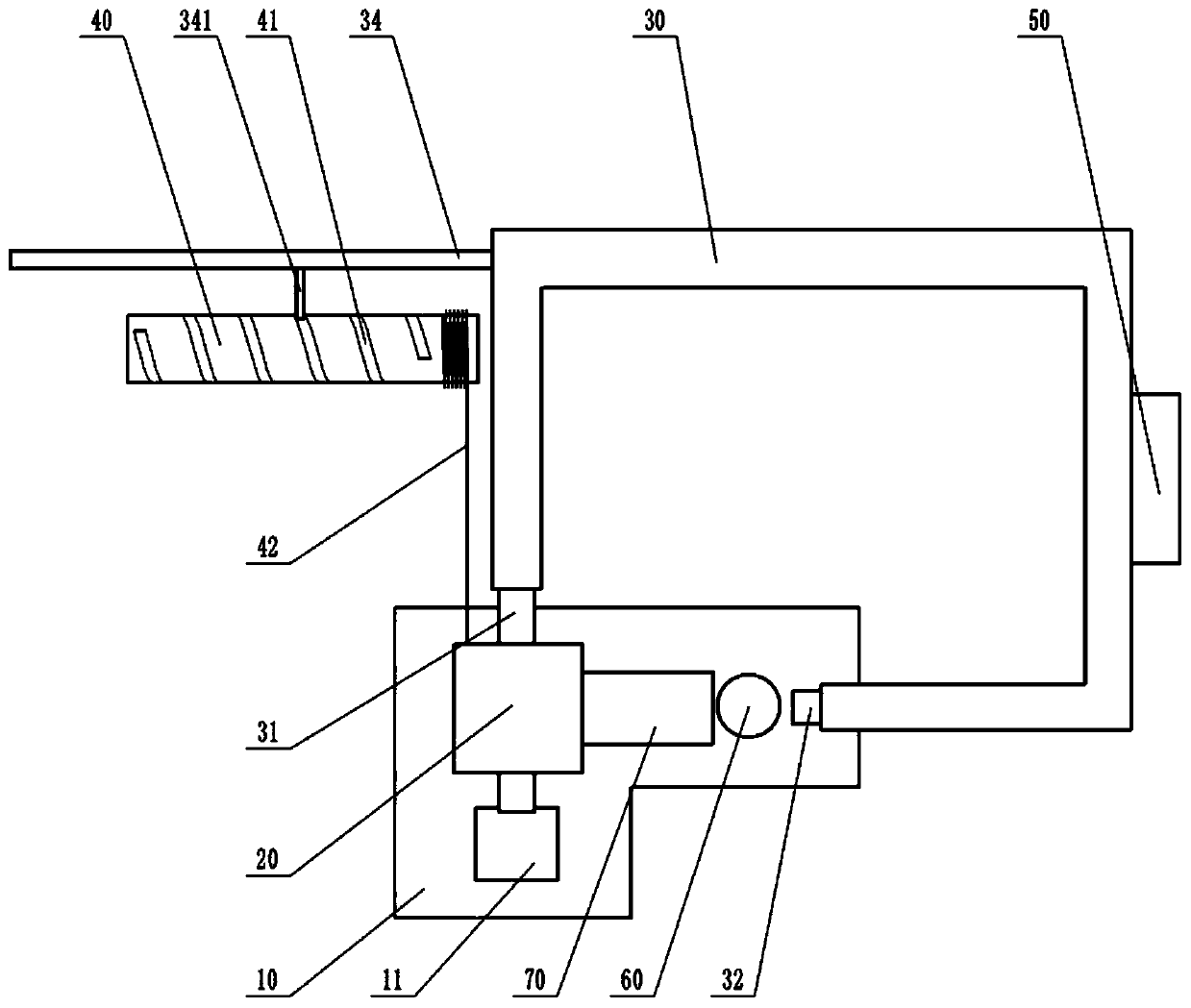

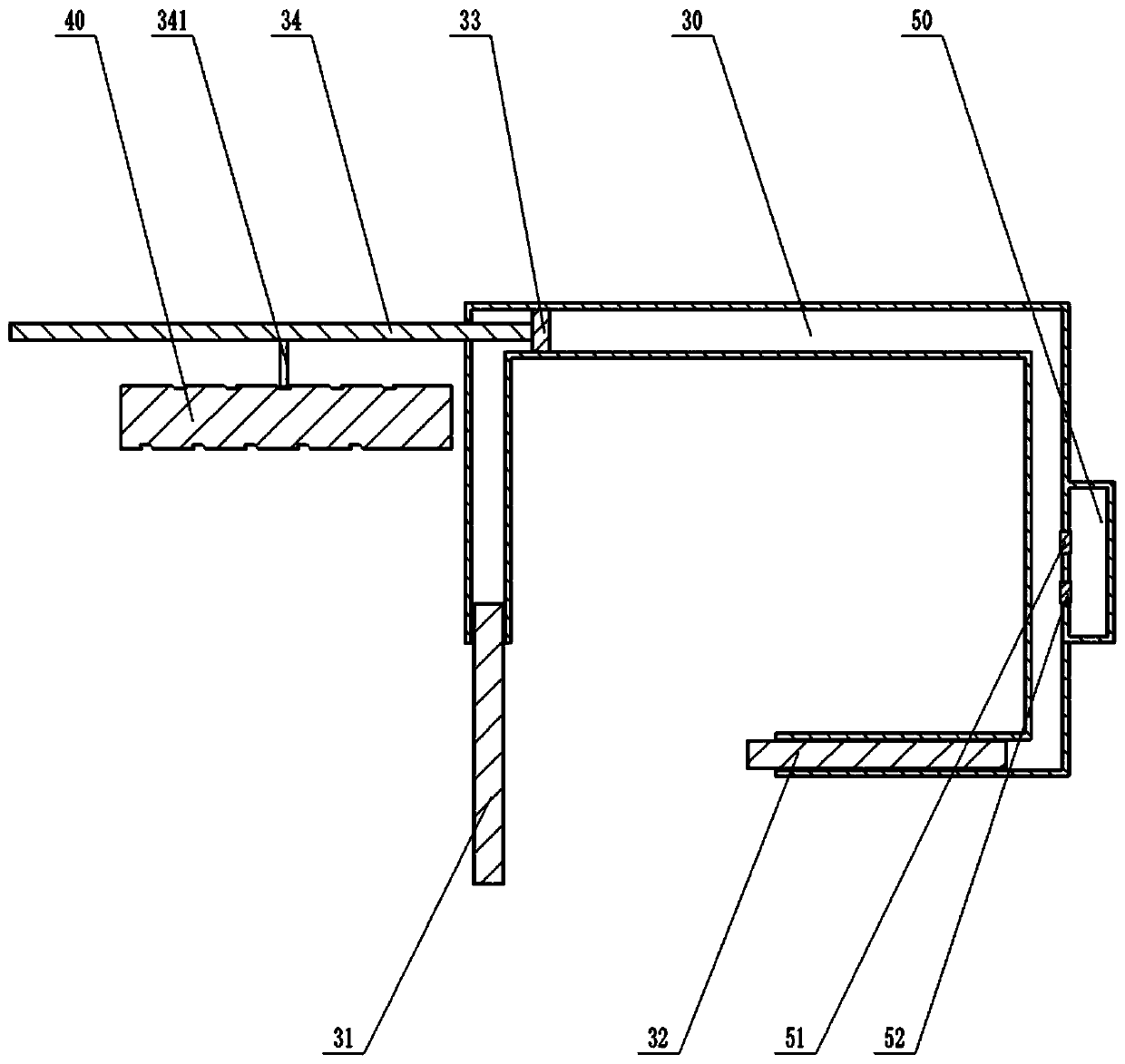

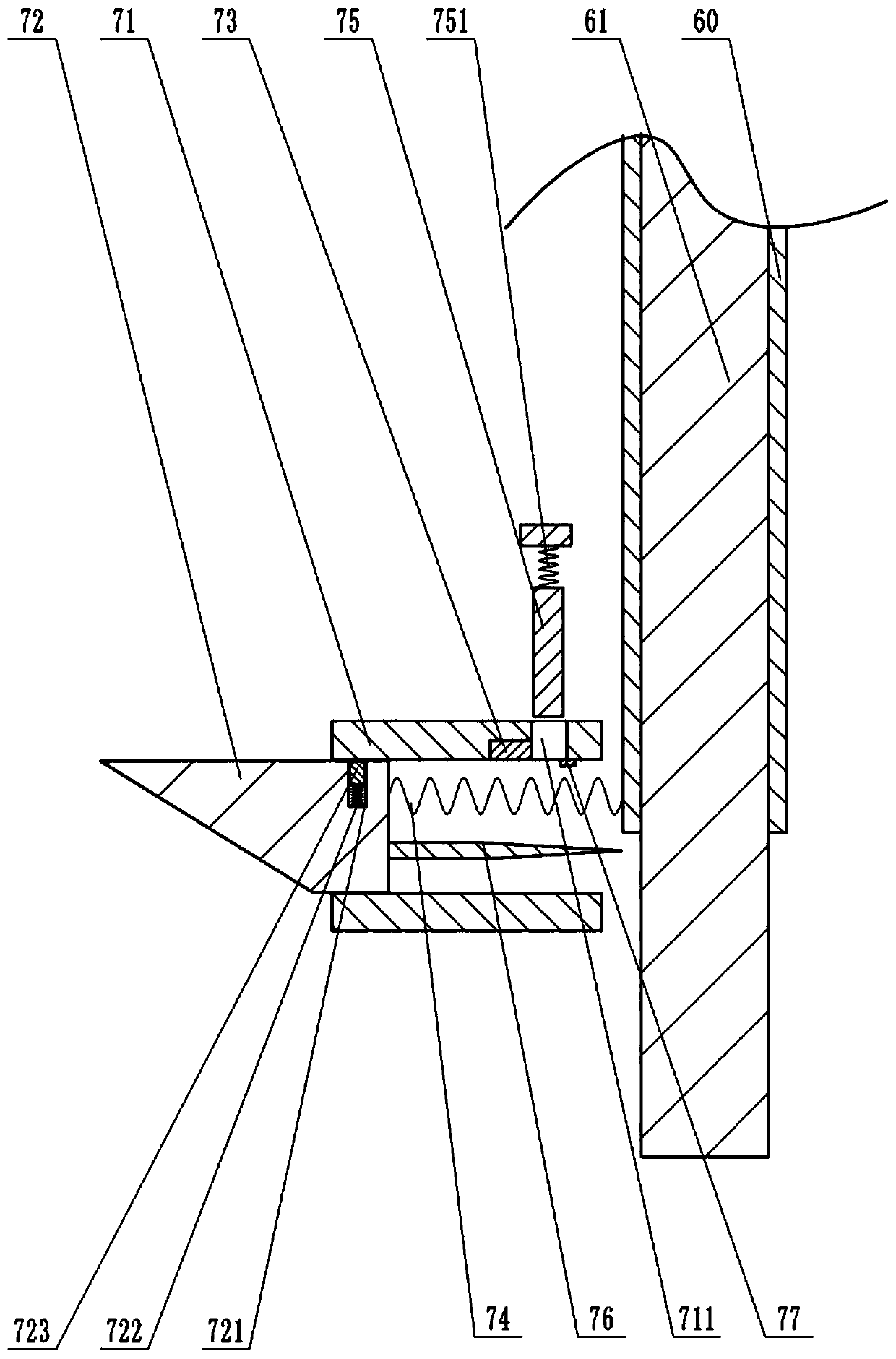

[0021] Instructions attached Figures 1 to 4 The reference signs in include: workbench 10, blanking chute 11, stamping mechanism 20, hydraulic cylinder 21, mounting plate 22, pressing block 23, punch 24, second wedge 25, communication pipe 30, second plunger 31. First plunger 32, piston 33, push rod 34, connecting rod 341, rotating column 40, groove 41, coil 42, liquid storage tank 50, one-way liquid inlet valve 51, one-way liquid discharge valve 52, storage Cylinder 60, blank 61, cutting mechanism 70, sliding sleeve 71, through hole 711, first wedge 72, chute 721, first spring 722, clip 723, electromagnet 73, second spring 74, ejector rod 75 , the third spring 751, the cutting knife 76, the first switch 77.

[0022] Such as figure 1 As shown, the automatic feeding device includes a frame, a transmission unit, a storage unit and a processing unit. The processing unit includes a wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com