Homogenizing plate with good heat preservation and heat insulation effects and preparation method thereof

A technology for thermal insulation and quality boards, which is applied in the direction of manufacturing tools, ceramic products, auxiliary molding equipment, etc., can solve the problems of low production efficiency, high production efficiency, and low labor intensity of homogeneous boards, and achieves light weight and low density. , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

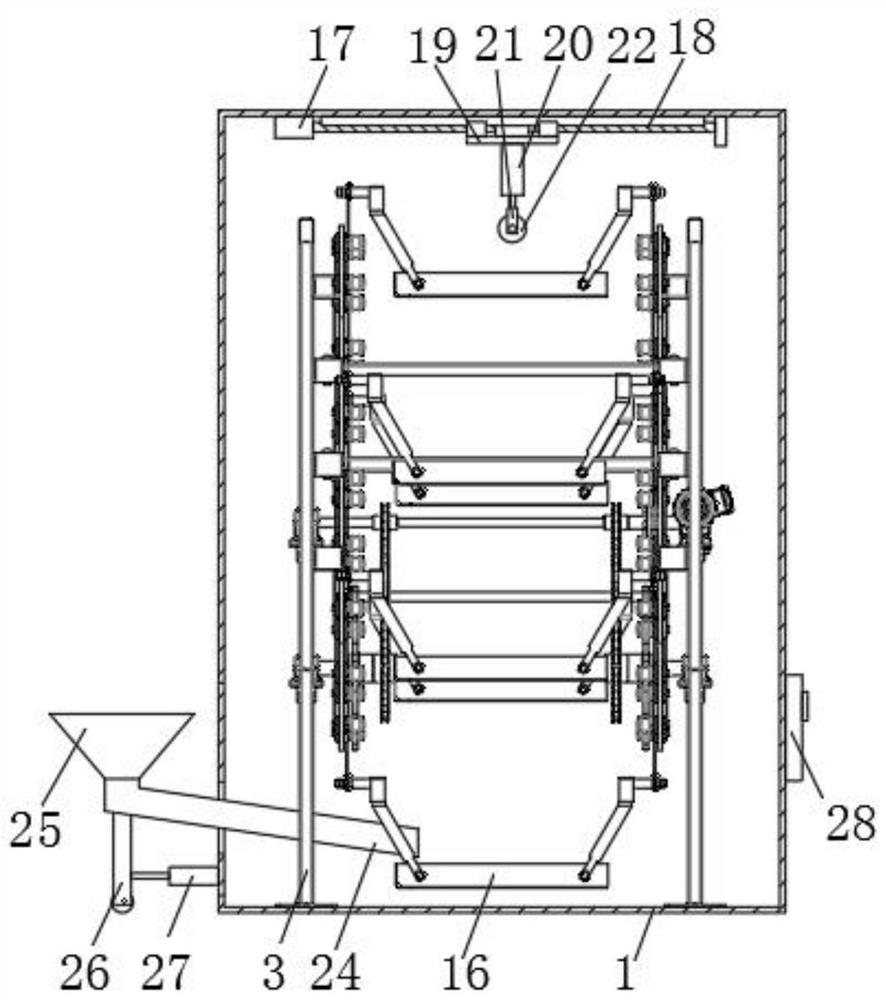

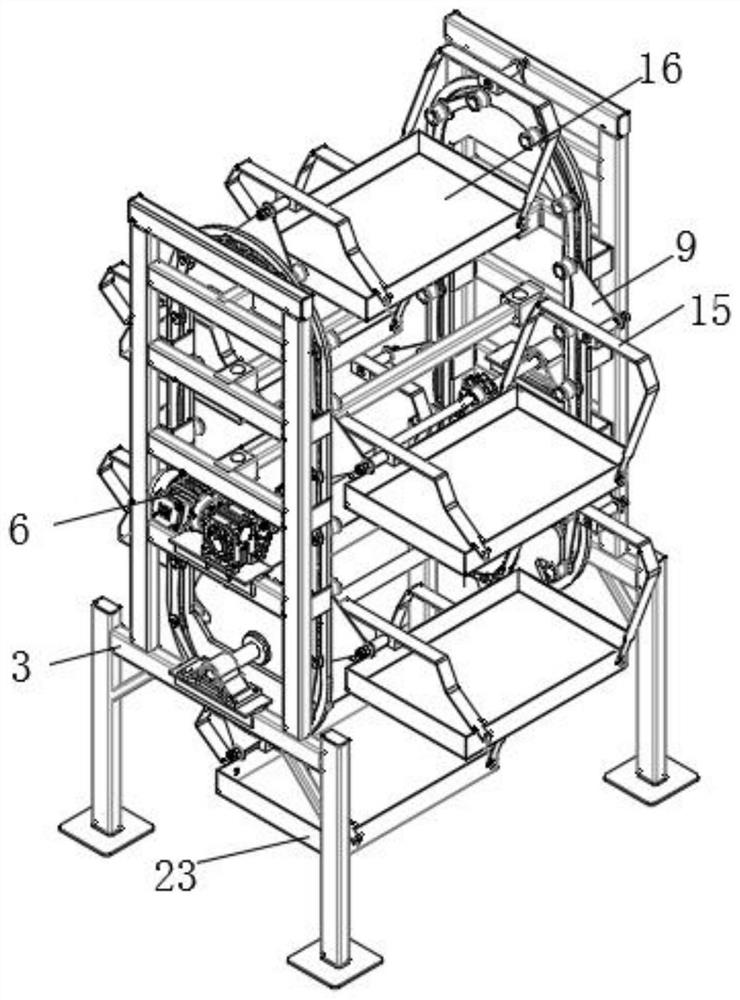

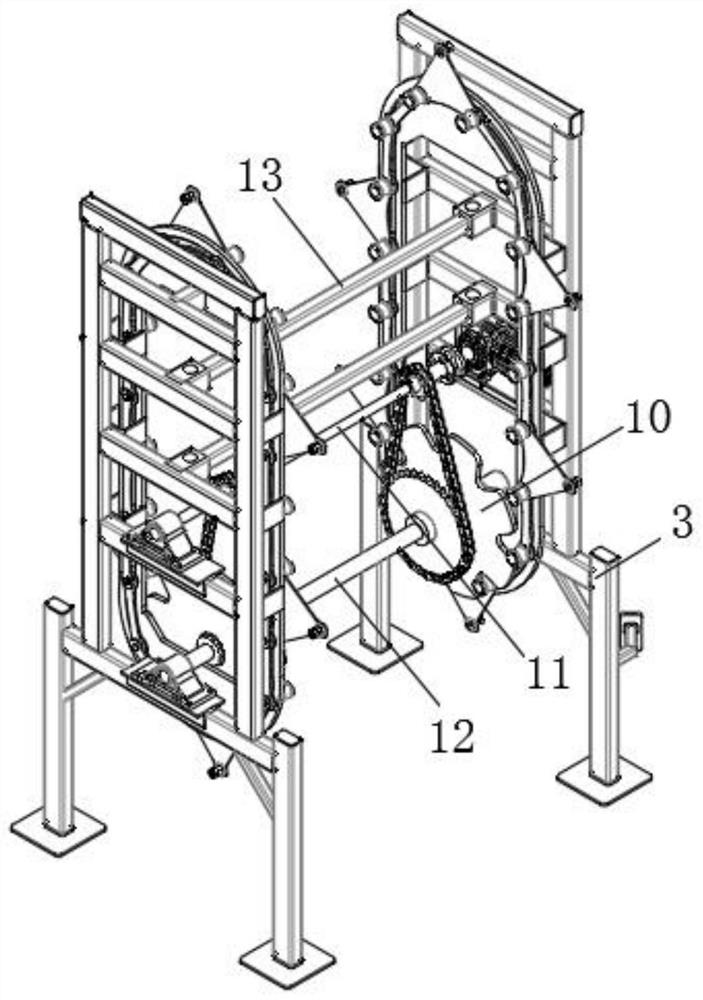

[0032] Such as Figure 1-5 As shown, a homogeneous board with good thermal insulation effect, the homogeneous board is prepared by the following raw materials in parts by weight:

[0033] 25 parts of lime powder, 22 parts of quartz sand, 18 parts of aluminum silicate fiber, 14 parts of borax, 10 parts of polyether polyol, 7 parts of polyester polyol, 6 parts of triethylenediamine, potassium isooctanoate-dipropylene glycol 2 5 parts of pentane, 4 parts of pentafluoropropane, 3 parts of water, 4 parts of tris(2-chloropropyl) phosphate, 4 parts of foam stabilizer B84604, and 24 parts of polyphenylpolymethylene polyisocyanate.

[0034] A method for preparing a homogeneous board with good thermal insulation effect, the method specifically includes the following steps:

[0035] Step 1, polyether polyol, polyester polyol, triethylenediamine, potassium isooctanoate-dipropylene glycol, pentane, pentafluoropropane, water, tris (2-chloropropyl) phosphate and foam stabilizer Put B8460 i...

Embodiment 2

[0039] Such as Figure 1-5 As shown, a homogeneous board with good thermal insulation effect, the homogeneous board is prepared by the following raw materials in parts by weight:

[0040] 30 parts of lime powder, 25 parts of quartz sand, 22 parts of aluminum silicate fiber, 18 parts of borax, 12 parts of polyether polyol, 9 parts of polyester polyol, 8 parts of triethylenediamine, potassium isooctanoate-dipropylene glycol 3 Parts, 7 parts of pentane, 8 parts of pentafluoropropane, 7 parts of water, 9 parts of tris(2-chloropropyl) phosphate, 8 parts of foam stabilizer B84608, 45 parts of polyphenyl polymethylene polyisocyanate.

[0041] A method for preparing a homogeneous board with good thermal insulation effect, the method specifically includes the following steps:

[0042] Step 1, polyether polyol, polyester polyol, triethylenediamine, potassium isooctanoate-dipropylene glycol, pentane, pentafluoropropane, water, tris (2-chloropropyl) phosphate and foam stabilizer Put B84...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com