Plate strength detection device based on fabricated house building construction

A technology for building construction and strength testing. It is applied to measuring devices, mechanical devices, and materials analysis. It can solve problems such as affecting the next use, cumbersome bonding process, and unfavorable testing, so as to improve positioning efficiency, stable and convenient fixation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

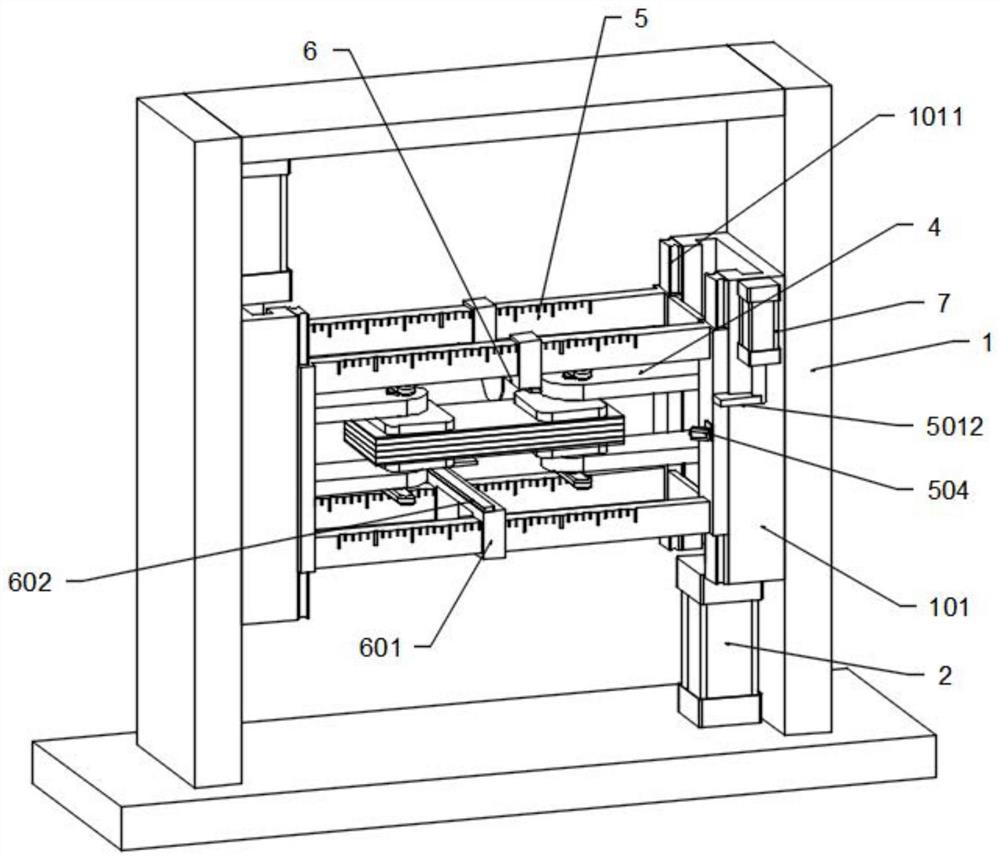

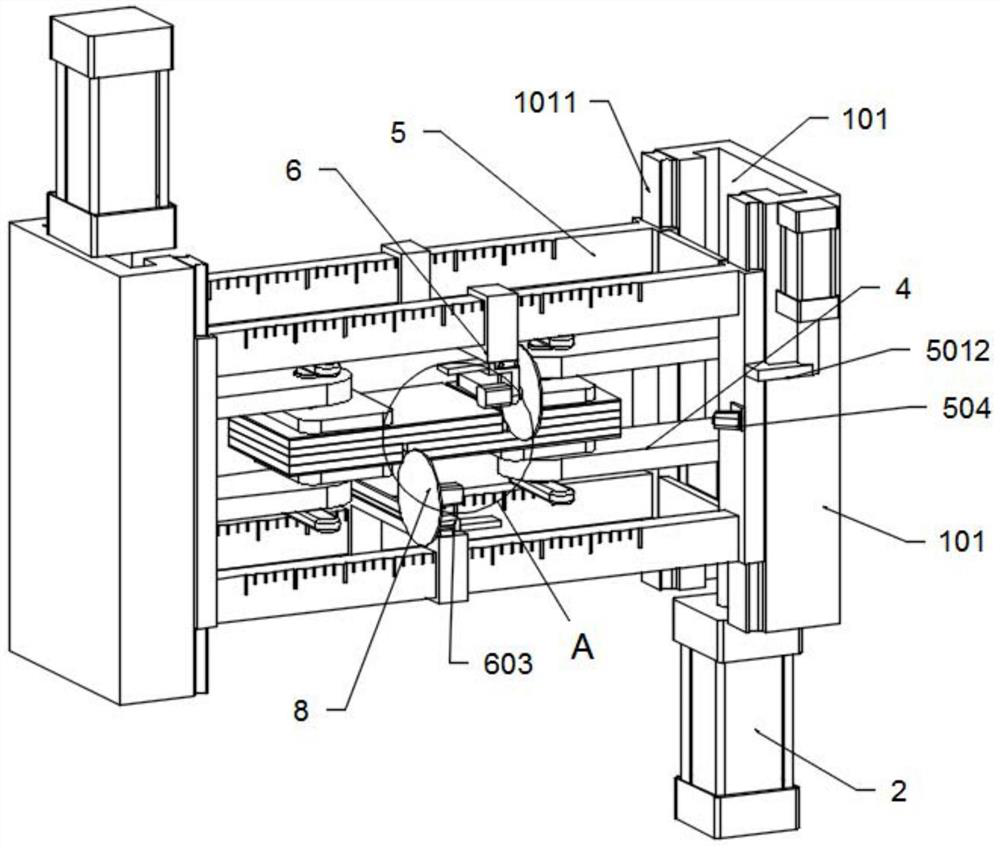

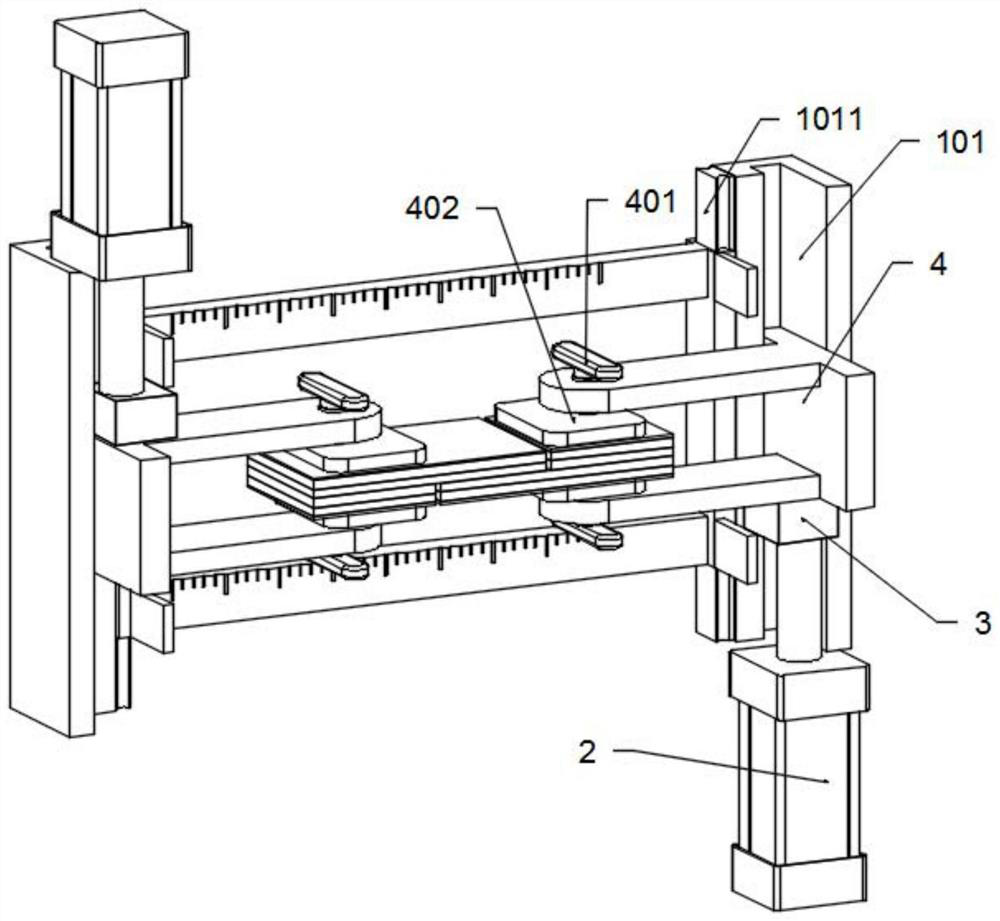

[0032] Example: please refer to Figure 1 to Figure 8 :

[0033] The invention proposes a board strength detection device based on the construction of prefabricated houses, comprising: a detection table 1; an inner frame of the detection table 1 is fixedly connected with two hydraulic push cylinders 2, one of which is located in the frame On the upper left side, another hydraulic push cylinder 2 is located on the lower right side of the frame; the pressure detector 3, the pressure detector 3 is fixedly connected to the output end of the hydraulic push cylinder 2; the positioning clamp block 4, the positioning clamp block 4 is fixedly connected to the pressure detection The instrument 3; the lifting adjustment frame 5, the lifting adjustment frame 5 is slidably connected to the inner side of the test table 1; the horizontal translation frame 6, the horizontal translation frame 6 is provided with two places, and the two horizontal translation frames 6 are respectively slidably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com