Metal cutting table based on metal corner distance measurement

A technology of metal cutting and corners, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of affecting the measured value, many cutting steps, and affecting the measurement accuracy, so as to reduce cutting steps and avoid errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

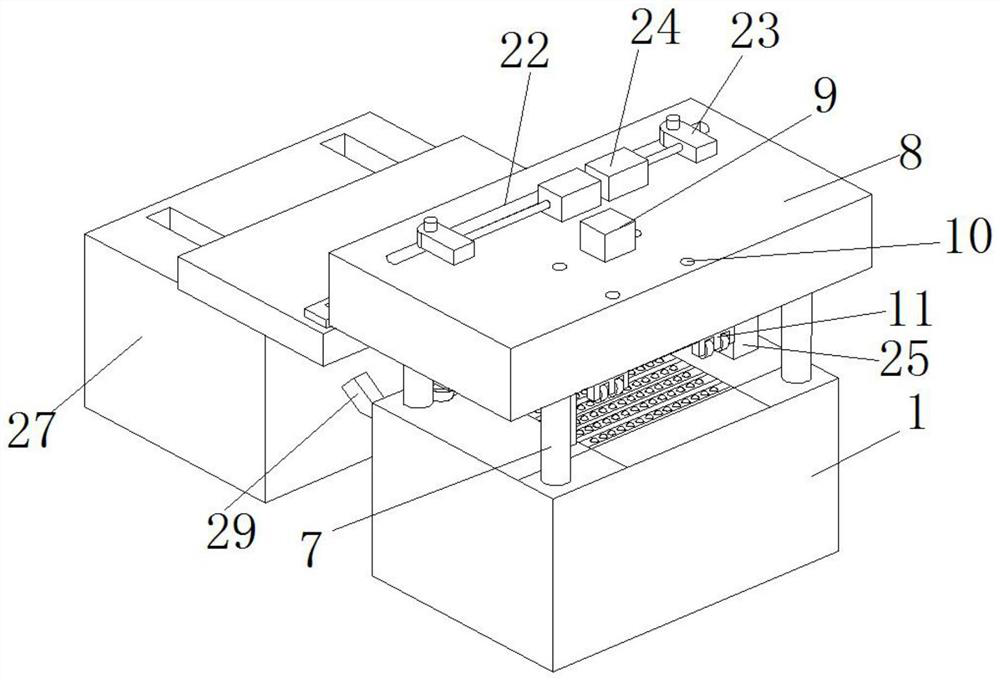

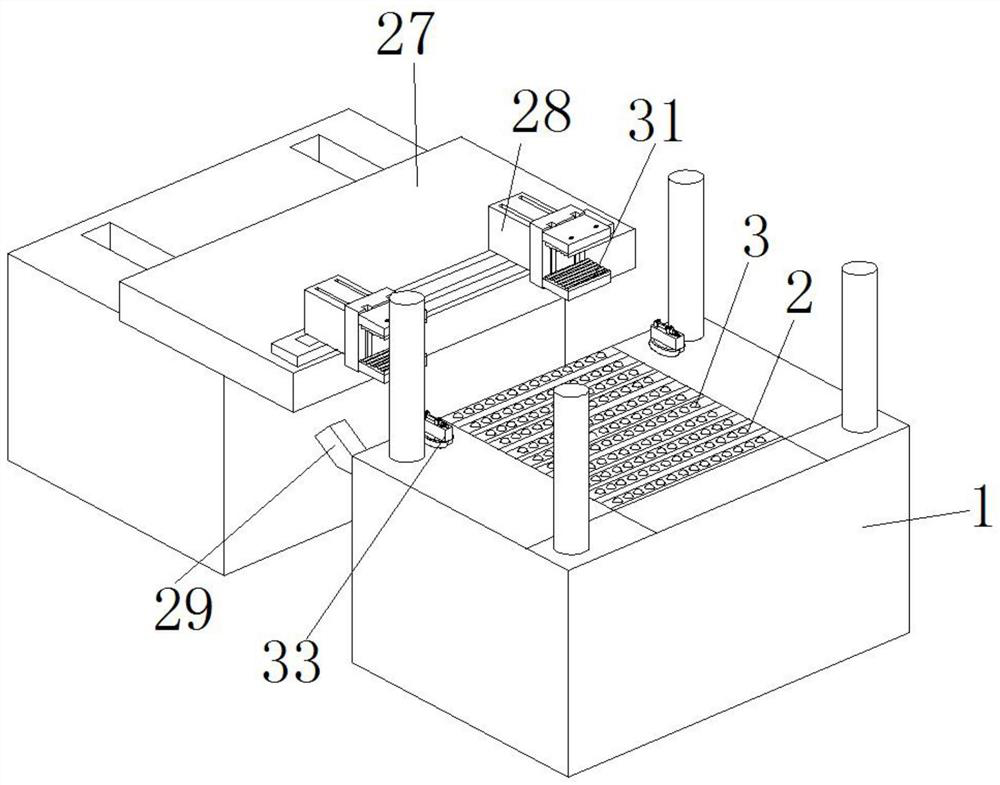

[0034] Such as Figure 1-10 As shown, a metal cutting table based on metal corner distance measurement includes an equipment base 1 .

[0035] By adopting the above technical scheme: the top of the equipment base 1 is provided with a spherical seat 2, and a spherical shaft 3 is movably installed in the spherical seat 2, and an electric micrometer 4 is installed at both ends of the equipment base 1. The base of the micrometer 4 and the distance measuring rod are all fixedly installed with a point laser mount 5, the top of the point laser mount 5 is fixedly mounted with a point laser 6, and the top of the equipment base 1 is fixedly mounted with a mounting platform 8 through a support rod 7 , a hydraulic device 9 is installed on the installation platform 8, a point laser device 29 is arranged on the equipment base 1, a wired laser device is arranged below the installation platform 8, and the electric micrometer 4 is installed through an angle measuring instrument refitting platf...

Embodiment 2

[0042] Such as Figure 1-10 As shown, a metal cutting table based on metal corner distance measurement, including.

[0043] By adopting the above-mentioned technical scheme: a guide rail bar 10 is arranged beside the hydraulic device 9, and the guide rail bar 10 is connected with a pressing device 11, and the pressing device 11 includes a fixed plate 12, and the fixed plate 12 is fixedly installed on the On the frame 13, the four corners of the bottom of the mounting frame 13 are provided with pressure roller mounts 14, and the bottom corners of the bottom of the pressure roller mounts 14 are all provided with pressure roller mounting bearings, and the pressure roller mounting bearings are movable to install pressure rollers. wheel 15, the pressing wheel 15 is connected with the first transmission shaft 16, the first transmission shaft 16 is connected with the second transmission shaft 17, and the second transmission shaft 17 is connected with the third transmission shaft 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com