Injection part cutting machine

A technology for injection molding parts and cutting machines, applied in metal processing and other directions, can solve the problems of increasing work error rate, one-time cutting completion, increasing labor costs, etc., and achieve the effect of reducing cutting steps, reducing production costs, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

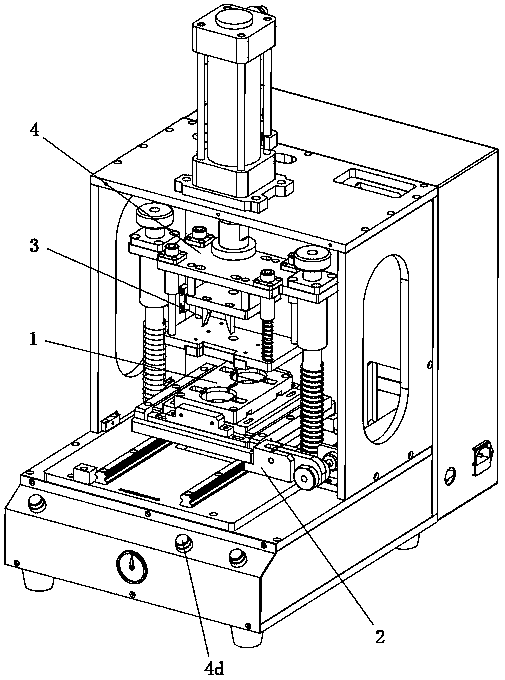

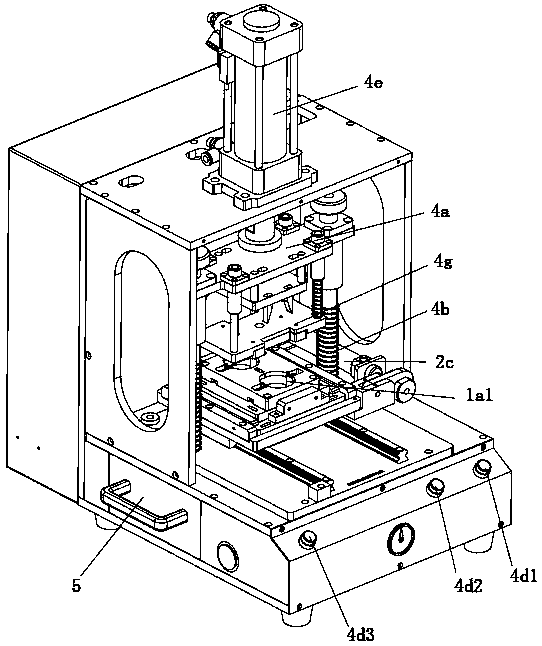

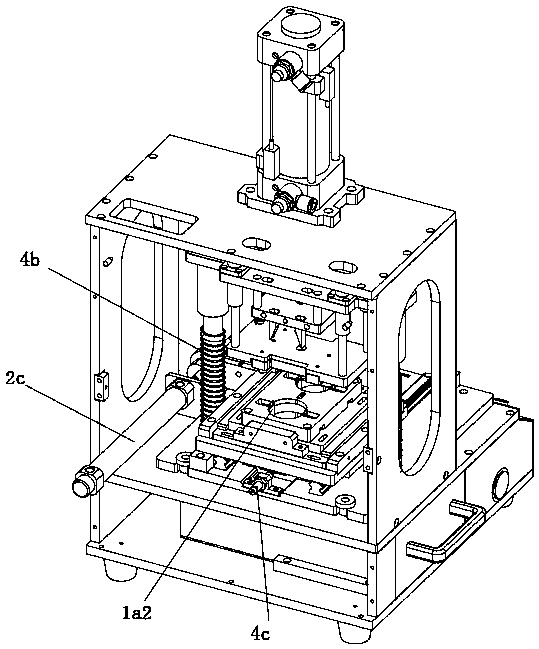

[0024] refer to Figure 1 to Figure 8 The injection molded parts cutting machine shown in the figure includes a positioning jig 1 for clamping the injection molded parts, a moving mechanism 2 for driving the positioning jig 1 to move, and a cutting assembly for cutting the nozzle of the injection molded parts 3 and the lifting assembly 4 that drives the cutting assembly 3 to lift up and down. The positioning fixture 1 includes a holding plate 1a for placing the injection molded parts and a clamping assembly 1a1 for clamping the injection molded parts. The moving mechanism 2 includes a The sliding assembly of the fixture 1 and the driving assembly for driving the positioning fixture 1 to slide on the sliding assembly, the lifting assembly 4 includes a lifting platform 4a and a buffer assembly 4b, and also includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com