Method for cutting silicon rod through cross line, cutting equipment and cutting system

A reticle and cutting line cutting technology, applied in stone processing equipment, fine working devices, manufacturing tools, etc., can solve problems such as defects, small silicon wafer cross-section damage, and cutting difficulty, to ensure conversion efficiency, reduce Cutting steps, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

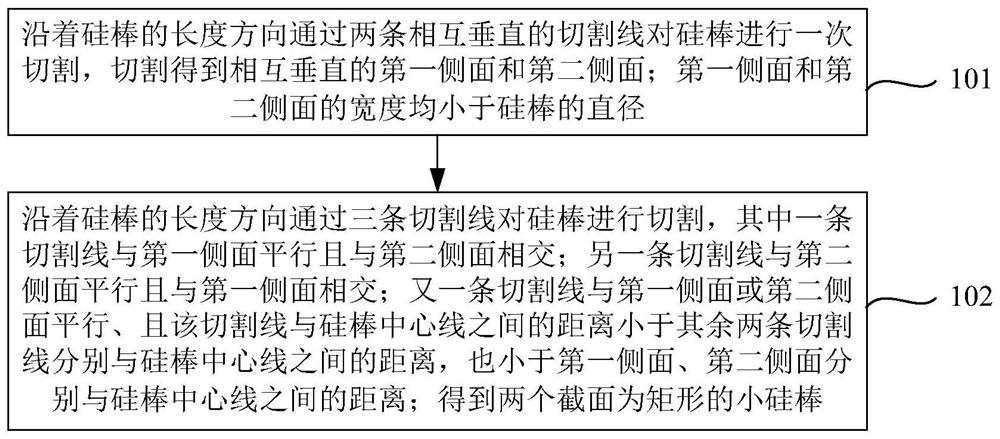

Embodiment 1

[0042] This embodiment provides a method for cutting a silicon rod with a cross line, which is used for cutting a single crystal silicon rod or a polycrystalline silicon rod. The cross section of the silicon rod can be circular, oval or irregular. This embodiment is described by taking a silicon rod with a circular cross section as an example. The silicon rod is cylindrical and has two circular end faces and a circumferential side surface located between the two end faces. The center line of the silicon rod passes through the two end faces. The center of the circle is perpendicular to the two end faces. The longitudinal direction of the silicon rod is a direction parallel to the center line of the silicon rod.

[0043] The silicon rod can be cut by cutting equipment such as a square cutter, and the cutting equipment is provided with a cutting line for cutting the silicon rod. Specifically, the cutting wire may be a diamond wire on which a plurality of fine-grained diamonds a...

Embodiment 2

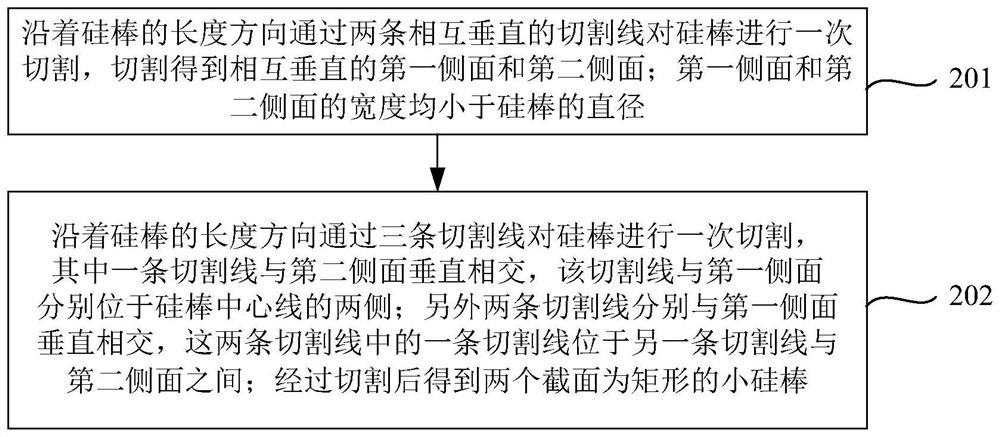

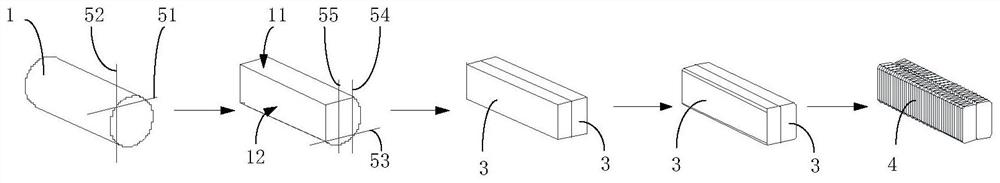

[0058] figure 2 The flow chart of the method for reticle cutting silicon rod provided in the second embodiment of the present application, image 3 This is a schematic structural diagram of the cross-cut silicon rod provided in the second embodiment of the present application. like figure 2 and image 3 As shown, the present embodiment provides a method for one-time cutting using three cutting lines, the method comprising:

[0059] In step 201, the silicon rod is cut once along the length direction of the silicon rod through two mutually perpendicular cutting lines to obtain mutually perpendicular first and second side surfaces; the widths of the first and second side surfaces are both smaller than those of the silicon rod. diameter of the rod.

[0060] The two cutting lines in this step are the first cutting line 51 and the second cutting line 52, the first cutting line 51 and the second cutting line 52 are perpendicular, and neither of them passes through the center li...

Embodiment 3

[0082] Based on the above embodiments, this embodiment provides a method for cutting a silicon rod with a cross line.

[0083] Figure 5 The flow chart of the method for reticle cutting silicon rod provided in the third embodiment of the present application, Image 6 This is a schematic structural diagram of the cross-cut silicon rod provided in the third embodiment of the present application. like Figure 5 and Image 6 As shown, the method for reticle cutting a silicon rod provided in this embodiment includes:

[0084] Step 301: Cut the silicon rod once along the length direction of the silicon rod through two mutually perpendicular cutting lines to obtain mutually perpendicular first side and second side; the widths of the first side and the second side are both smaller than diameter of the rod.

[0085] The two cutting lines in this step are the first cutting line 51 and the second cutting line 52, the first cutting line 51 and the second cutting line 52 are perpendic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com