Diffusion impervious layer modification for flexible substrate

A flexible substrate and barrier layer technology, applied in coatings, climate sustainability, metal material coating technology, etc., can solve problems such as cracking and lower battery yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

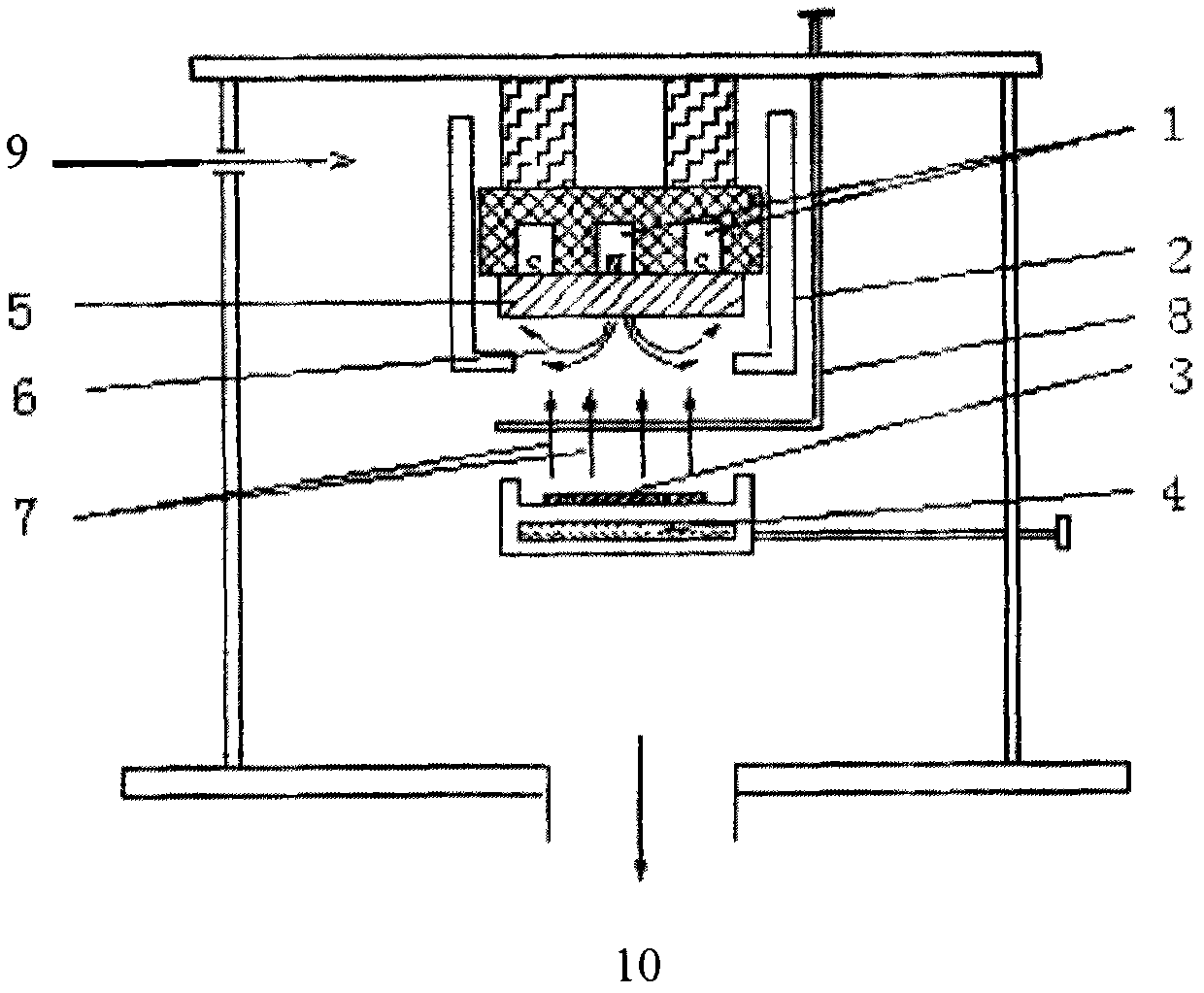

Image

Examples

Embodiment Construction

[0018] The present invention is further described in detail in conjunction with the following examples.

[0019] Stainless steel with a thickness of 25 μm was selected as the flexible substrate, and the method of ultrasonic cleaning was adopted. The solvent and the order of use were: stainless steel cleaning agent (15min) → deionized water (15min) → nitrogen drying.

[0020] Place the cleaned stainless steel substrate in the horizontal facing magnetron sputtering target equipment, using a chromium target with a purity of more than 99.5%, the sputtering gas is argon with a purity of 99.999%, the working pressure is 2.0Pa, and the background vacuum 3.0×10 -3 Pa, the substrate temperature is 200°C, and the distance between the target and the substrate is 100mm. During sputtering, argon gas is pre-sputtered to clean the target surface, and sputtering starts after the glow stabilizes. Sputtering 5-20min ends.

[0021] Using this method to sputter a 1-2 μm thick chromium barrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com