Uncoiling and blanking process of automobile sheet

A technology for uncoiling and blanking and sheet metal, which is applied in the field of uncoiling and blanking of automobile sheets, can solve the problems of low utilization rate and waste of coil materials, and achieve the effects of improving production efficiency, reducing cutting steps and reducing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Single blanking process is adopted.

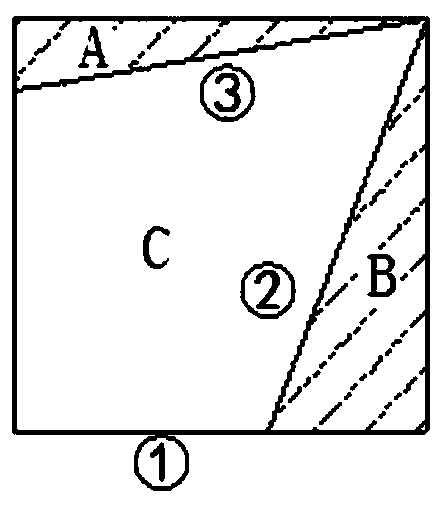

[0032] Such as figure 2 As shown, make layout for incoming coil material. Monomer blanking process includes the following steps:

[0033] For incoming coil materials, cut off the triangular scraps A and B at the sides of numbers ② and ③ to obtain the required finished board C.

[0034] In this way, the material utilization rate was 71.9%.

Embodiment 2

[0036] The traditional uncoiling blanking process is adopted.

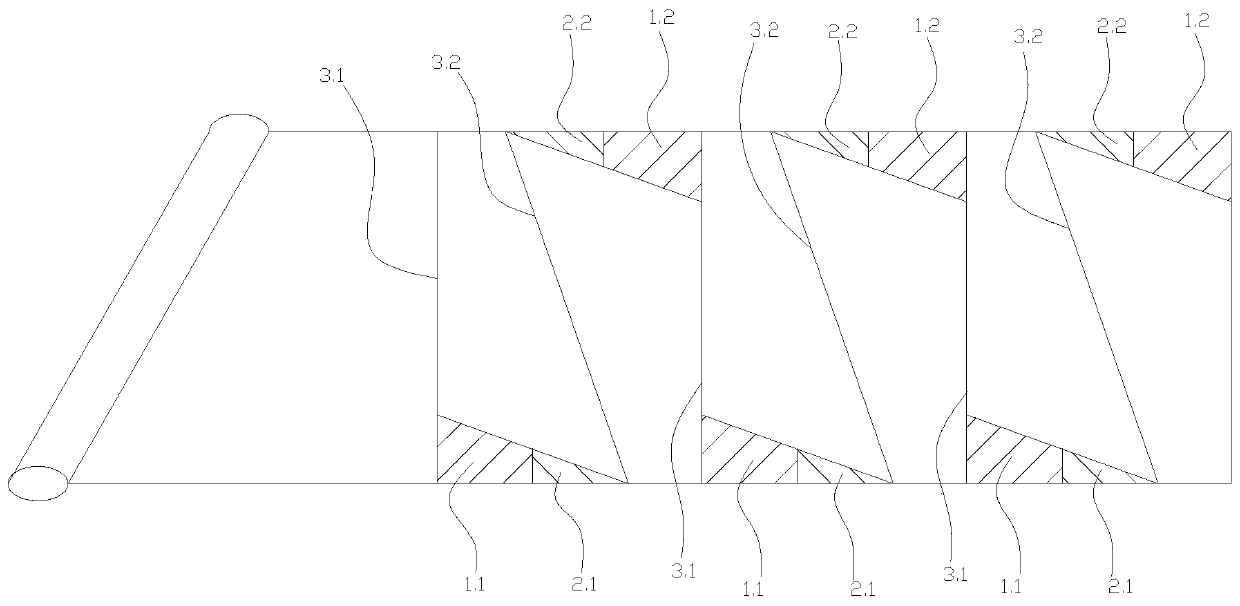

[0037] Such as figure 1 As shown, make layout for incoming coil material. The traditional uncoiling blanking process includes the following steps:

[0038] first resection figure 1 Part 1.1 and 1.2 trapezoidal waste; the second step cuts off figure 1 Part 2.1 and 2.2 of the triangular waste; the third step along figure 1 Cut off the track shown in 3.1 and 3.2, cut and separate the coil material, and produce two finished boards, which are main stacking and side stacking respectively.

[0039] In this way, the material utilization rate is 88.85%

Embodiment 3

[0041] The uncoiling and blanking process of the present invention is adopted.

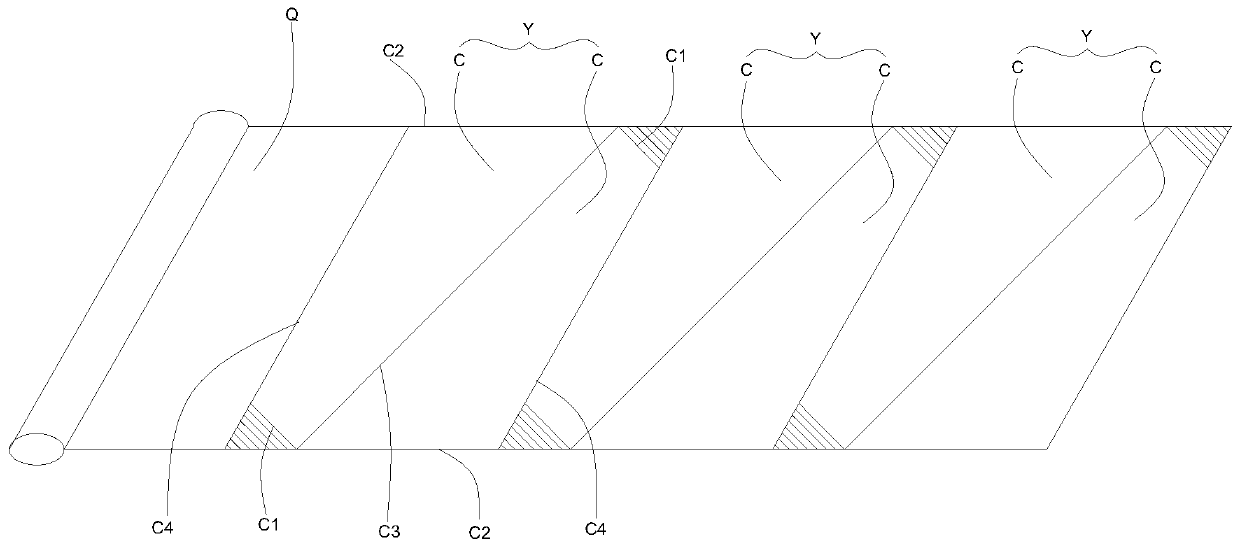

[0042] Such as image 3 As shown, make layout for incoming coil material. The uncoiling blanking process includes the following steps:

[0043] S1, providing incoming coil material Q that is horizontally conveyed along the length direction;

[0044] S2, according to the layout set in advance, cut off the triangular area formed by the short side C1, the upper or lower side of the coil material Q, and the straight line where the side C4 is located as waste;

[0045] S3, cutting out two finished boards C along the direction of side C4;

[0046] S4, the incoming coil material Q continues to be conveyed horizontally along the length direction, and steps S2 and S3 are repeated to repeatedly cut the incoming coil material Q.

[0047] In this way, the material utilization rate was 95.41%.

[0048] Through the above research, the following conclusions can be drawn: 1, the material utilization rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com