USB data transmission connector packaging device and method

A technology for data transmission and assembly devices, which is applied to the assembly/disassembly, connection, and manufacture of contact boxes/bases of contacts, etc., which can solve the problem of increased cutting steps, increased complexity of the cutting mechanism control system, large elastic rebound, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

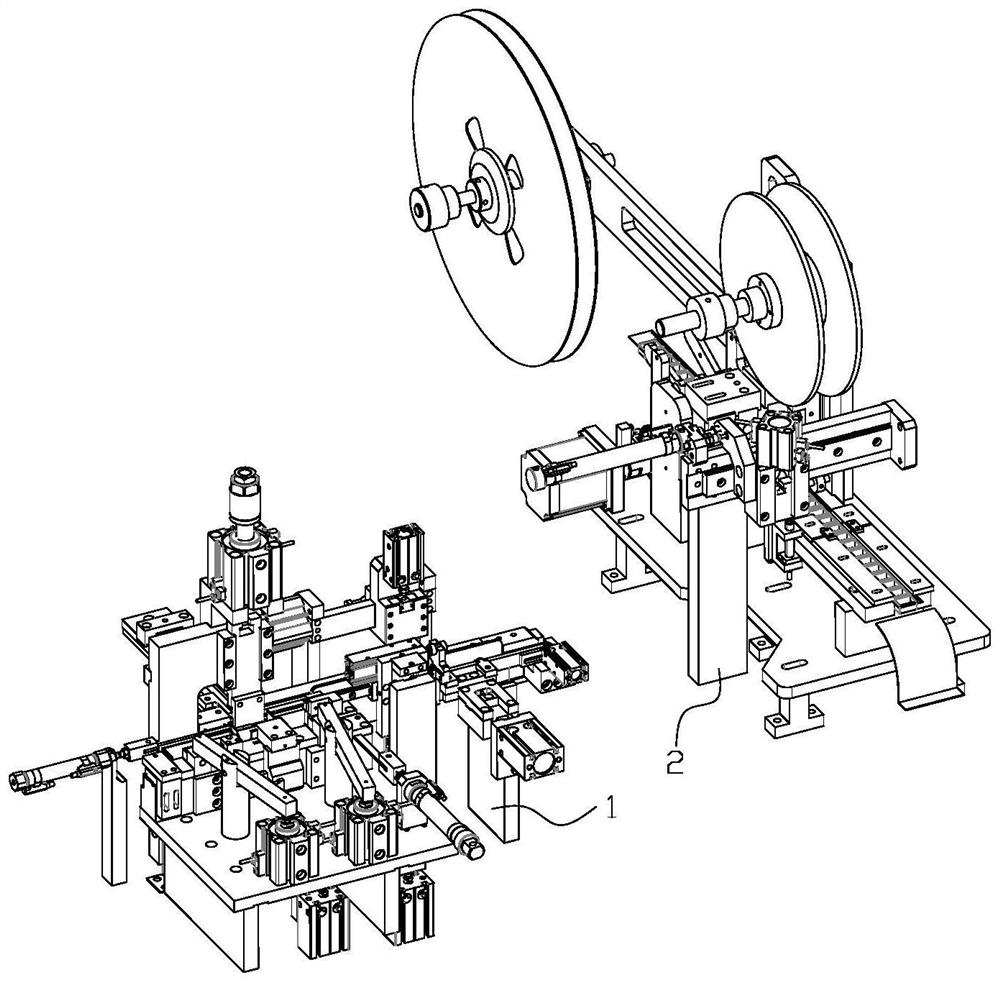

[0036] Such as Figure 1-21 A USB data transmission joint assembly and packaging equipment is shown, the equipment includes a workbench and an assembly device 1 and a packaging device 2 fixed on the workbench; the input end of the assembly device 1 is connected to the shell feeding station and the tongue feed respectively The stations are connected, the output end of the assembly device 1 is connected with the input end of the packaging device 2; the input end of the packaging device 2 is connected with the carrier tape feeding station, and the output end of the packaging device 2 is connected with the unloading station; the assembly device 1 is used for USB Assembling of the data transmission connector; the packaging device 2 is used for packaging the assembled USB data transmission connector into a carrier tape.

[0037] The product flow direction of the USB data transmission connector is: assembly device 1 to packaging device 2 .

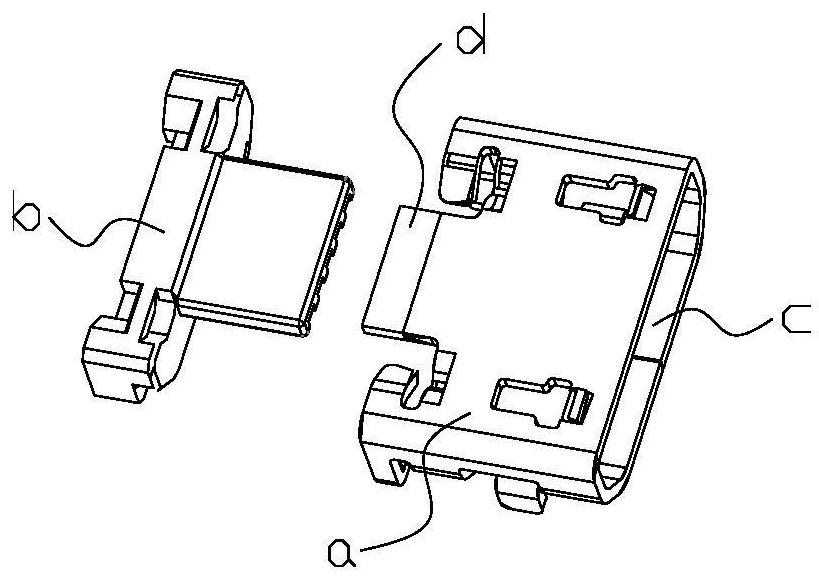

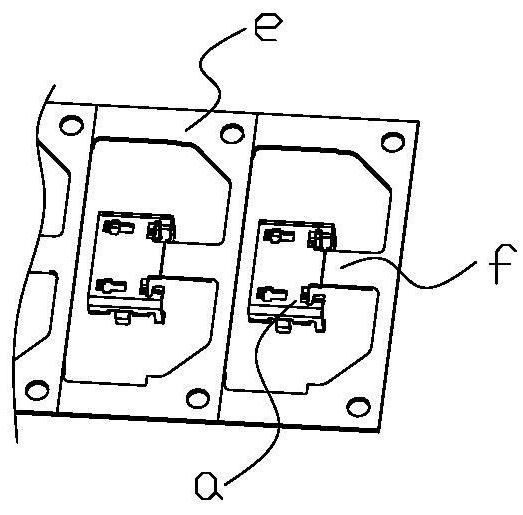

[0038] Such as figure 2 Shown is a sche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com