Protective film cutting device

A protective film and cutting technology, which is applied in metal processing and other directions, can solve the problems of increasing the burden on enterprises, low cutting precision, and increasing costs, and achieve the effects of reducing uneven cutting, improving the effect of film sticking, and saving use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

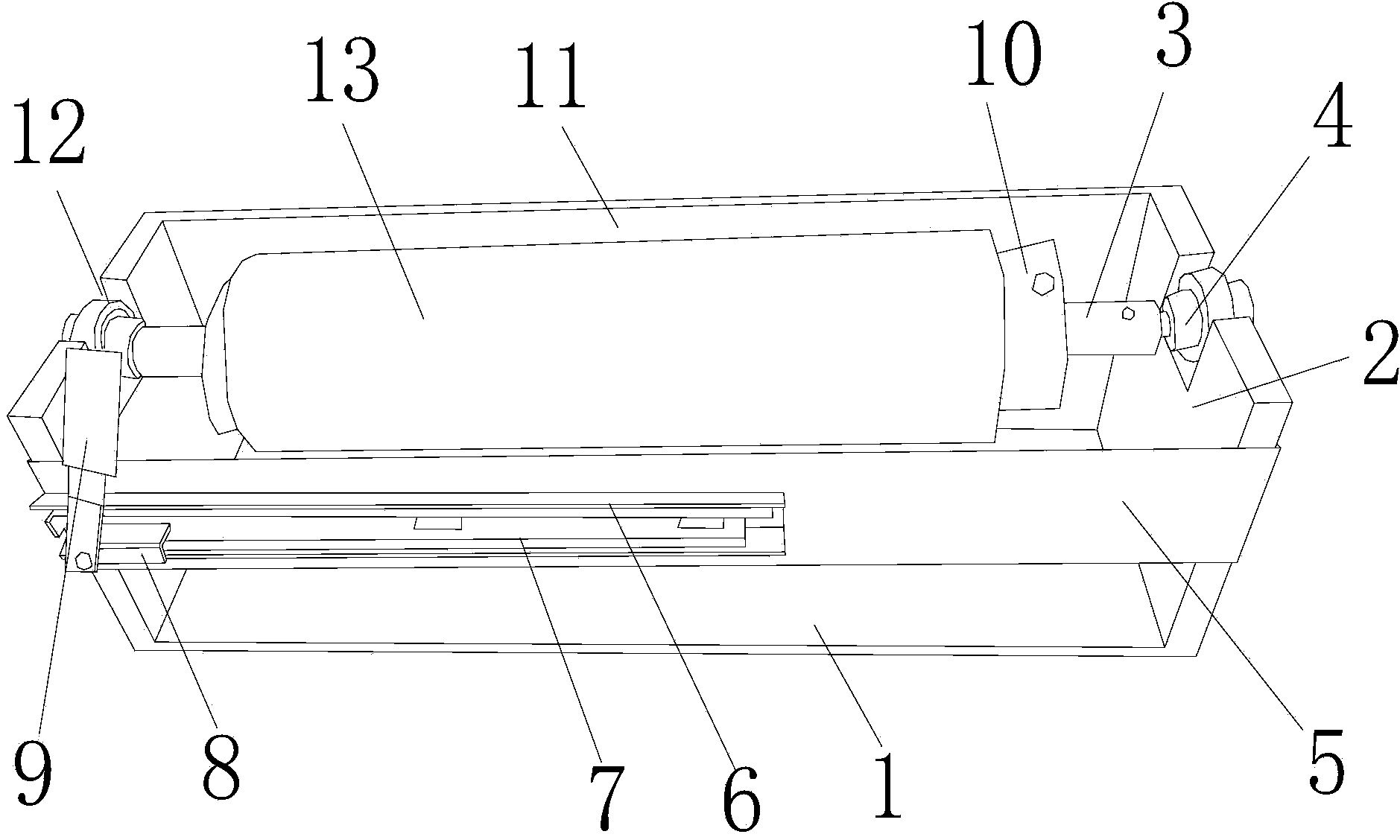

[0014] Such as figure 1 As shown, a protective film cutting device includes a bottom plate 1, side plates 2 located on both sides of the bottom plate 1, a rotating shaft 3, a bearing 4, a front panel 5, a slide rail frame 6, a slide rail 7, a slider 8 and a cutting The knife 9 has a notch 12 on the two side plates 2 respectively, and a slot is provided on the inner wall of the notch 12, the bearing 4 is installed in the notch 12 through the slot, and the rotating shaft 3 is detachably mounted on the Between the two bearings 4, a front panel 5 is arranged at the front of the two side plates 2, and a slide rail frame 6 is arranged on the front surface of the front panel 5, and a slide rail 7 is arranged on the slide rail frame 6, and a slide rail 7 is arranged on the slide rail 7. A slide block 8 capable of sliding along the slide rail 7 is arranged on the top, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com