Machining equipment with cleaning function

A mechanical processing and equipment technology, applied in the field of mechanical processing equipment with cleaning function, can solve the problems of increasing the workload of processing personnel, affecting the efficiency of mechanical processing, etc., and achieves the effect of convenient and fast application and improved application effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

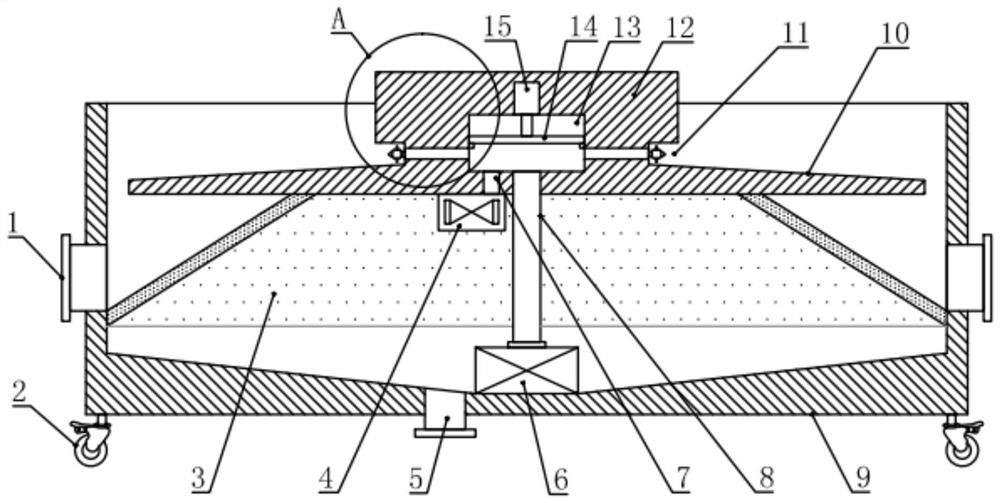

[0020] see figure 1 and 5 , in the embodiment of the present invention, a kind of mechanical processing equipment with cleaning function comprises processing box 9, and the inner side of described processing box 9 is provided with annular bottom plate 10, and the upper side of annular bottom plate 10 is fixed with processing table 12, and processing The lower outer ring of the table 12 is provided with an annular groove 11, and a plurality of flushing and exhausting heads 16 are installed in the circumferential direction of the annular groove 11. The inner side of the processing table 12 is also provided with a pressure relief chamber 13, and a plurality of flushing and exhausting heads 16 are provided. The lower part of the pressure relief chamber 13 is respectively communicated with the lower part of the pressure relief chamber 13 through the branch pipe 17. A pressure relief device for depressurizing the pressure relief chamber 13 is also installed in the processing table 1...

Embodiment 2

[0023] see Figure 1-5 , the difference between this embodiment and embodiment 1 is:

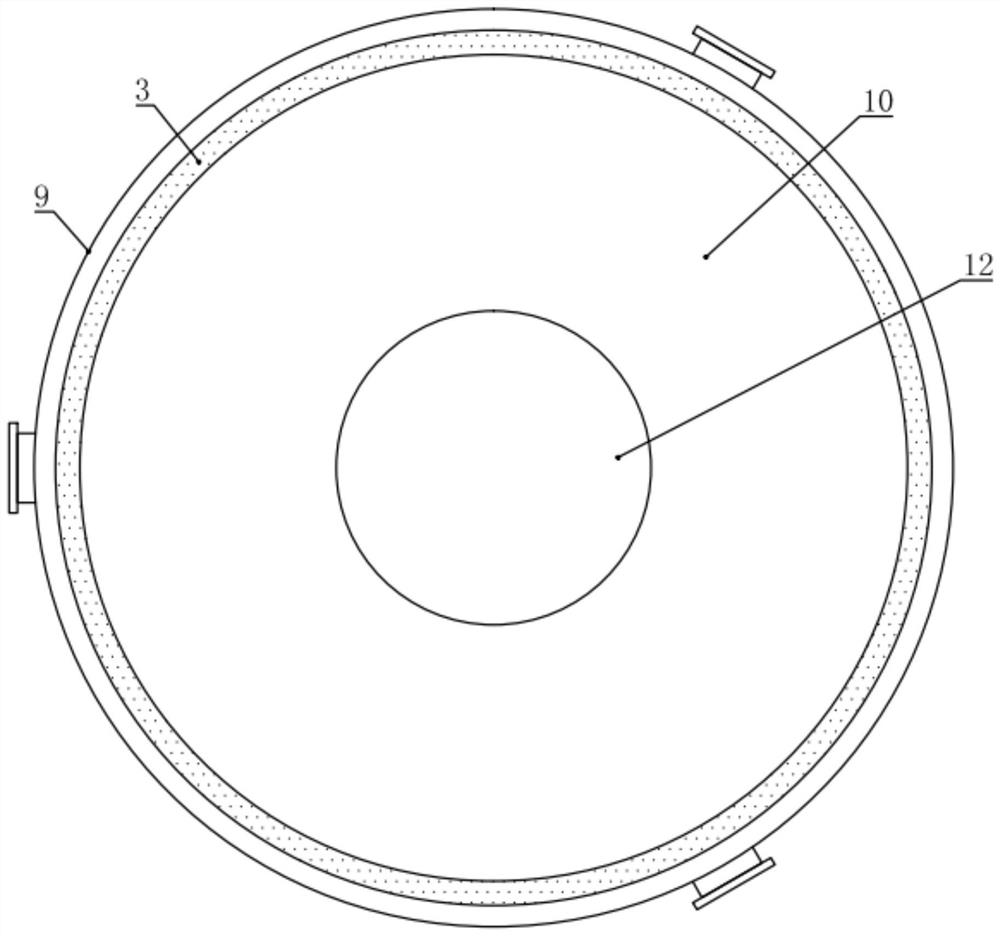

[0024] In the present embodiment, the processing box 9 is a cylindrical barrel structure with an upper opening, and the inner bottom of the processing box 9 is arranged downward in the middle; the processing table 12 is a cylindrical structure, and the annular bottom plate 10 is a circle. Disc-shaped structure, and the processing table 12, the annular bottom plate 10 and the processing box 9 are coaxially arranged, and the processing table 12 and the annular bottom plate 10 are integrally processed and formed; the upper surface of the annular bottom plate 10 is set with an outer ring inclined downward, which is beneficial to impurities The vertical distance between the outer ring of the annular bottom plate 10 and the inner wall of the processing box 9 is less than 5cm, and the impurities can fall.

[0025] The miscellaneous net cylinder 3 is a tapered cylinder structure with a small top an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com