Environment-friendly chemical reaction kettle device with tail gas collection function

A tail gas collection and reaction kettle technology, applied in chemical/physical/physical-chemical stationary reactors, gas treatment, chemical instruments and methods, etc., can solve the problems of inconvenient collection, easy escape and pollution of waste gas, and achieve extended use. Longevity, improving the reaction rate, and preventing the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

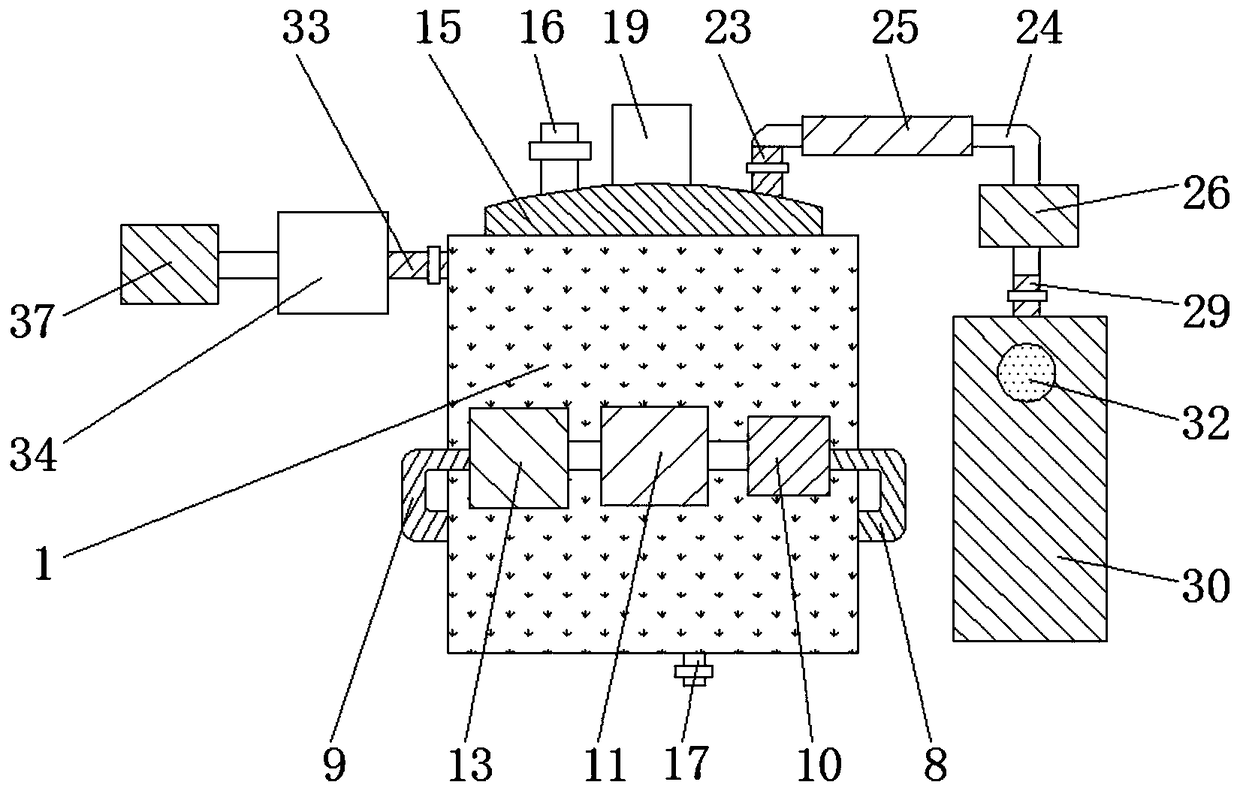

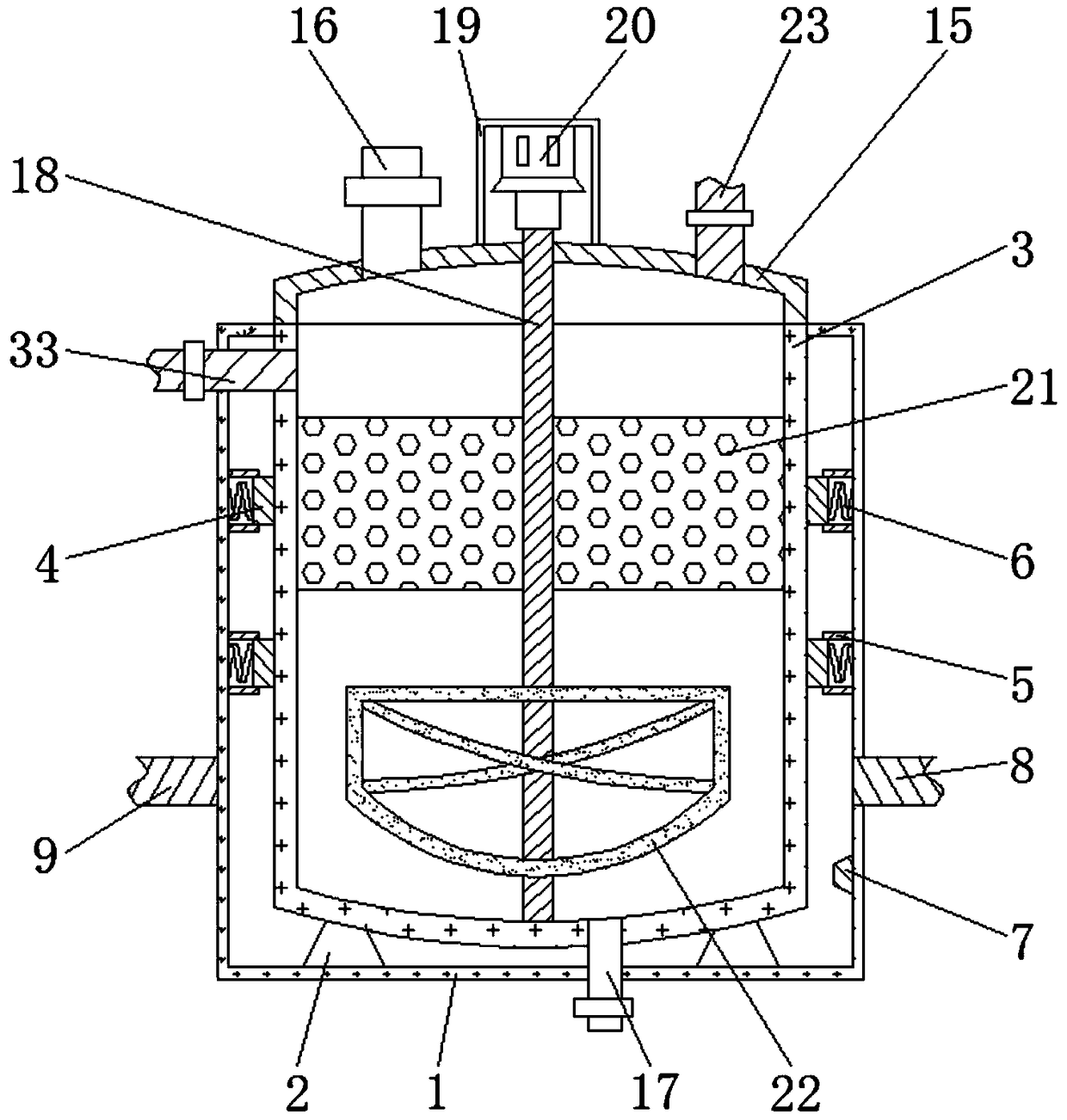

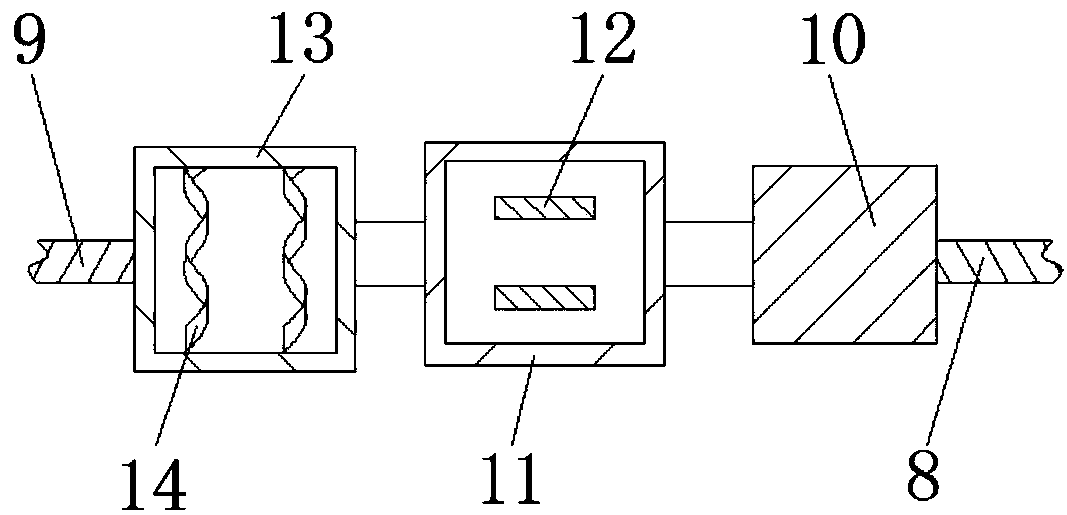

[0026] refer to Figure 1-5 , a reaction kettle device with exhaust gas collection for environmental protection, including a protective shell 1, the two ends and both sides of the bottom inner wall of the protective shell 1 are equipped with support seats 2 through bolts, and the top outer walls of the four support seats 2 pass through Bolts are installed with the same vertical reaction cylinder 3, the top and bottom of the outer wall of the reaction cylinder 3 are welded with four limit blocks 4 distributed in an annular array, and the top and bottom of the two ends of the protective shell 1 and the inner walls on both sides Both are welded with a fixed block 5, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com