Energy-saving boiler

An energy-saving boiler technology, applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of reducing the heating effect of the device, not being able to use heat effectively, and affecting the service life of the device, so as to reduce pressure and improve Effects of stability and utilization improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

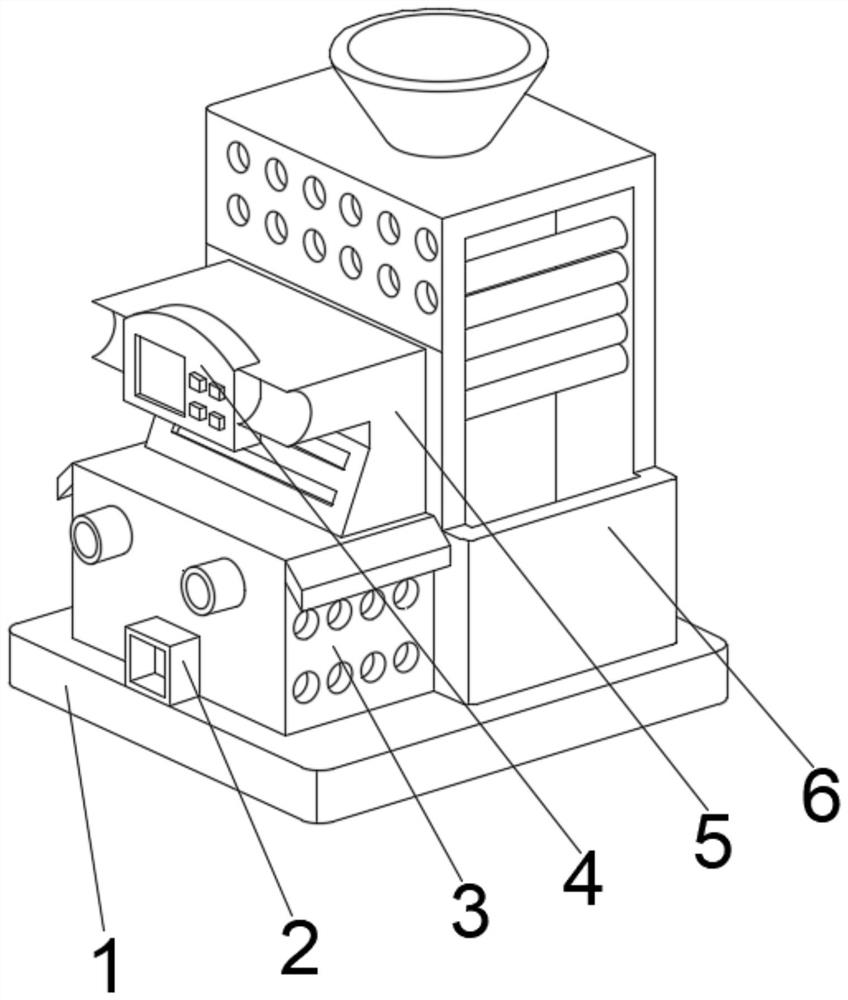

[0033] see Figure 1-2 , the present invention provides a technical solution: an energy-saving boiler, including a base plate 1, a heating device 6 is fixedly connected to the top right side of the base plate 1, and a heating box is fixedly connected to the bottom of the outer wall on the left side of the heating device 6 at the top of the base plate 1 3. The right side of the top of the heating box 3 is fixedly connected with a heat insulation board 5, and the top of the left outer wall of the heat insulation board 5 is provided with a control panel 4, and the right outer wall of the control panel 4 runs through the heat insulation board 5 and extends to the heat insulation board Inside of 5, the middle position of the left side outer wall bottom of heating box 3 is provided with air vent 2.

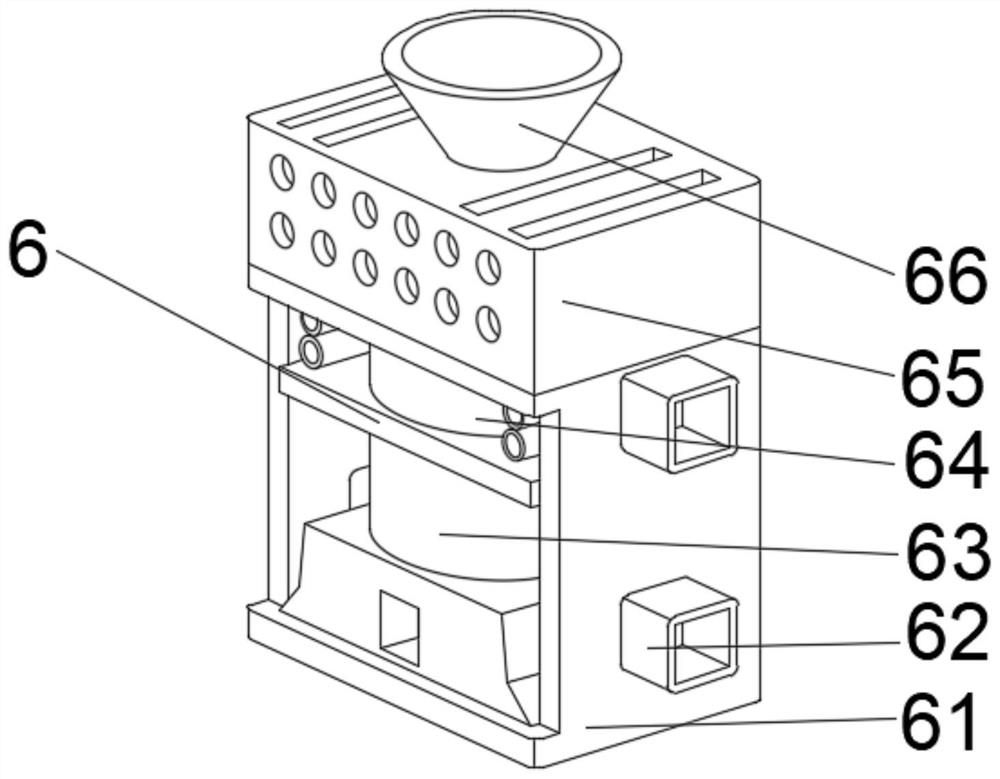

[0034] The heating device 6 includes a boiler body 61, the outer walls of both sides of the boiler body 61 are provided with connecting pipes 62, the bottom of the inner cavity of the b...

Embodiment 2

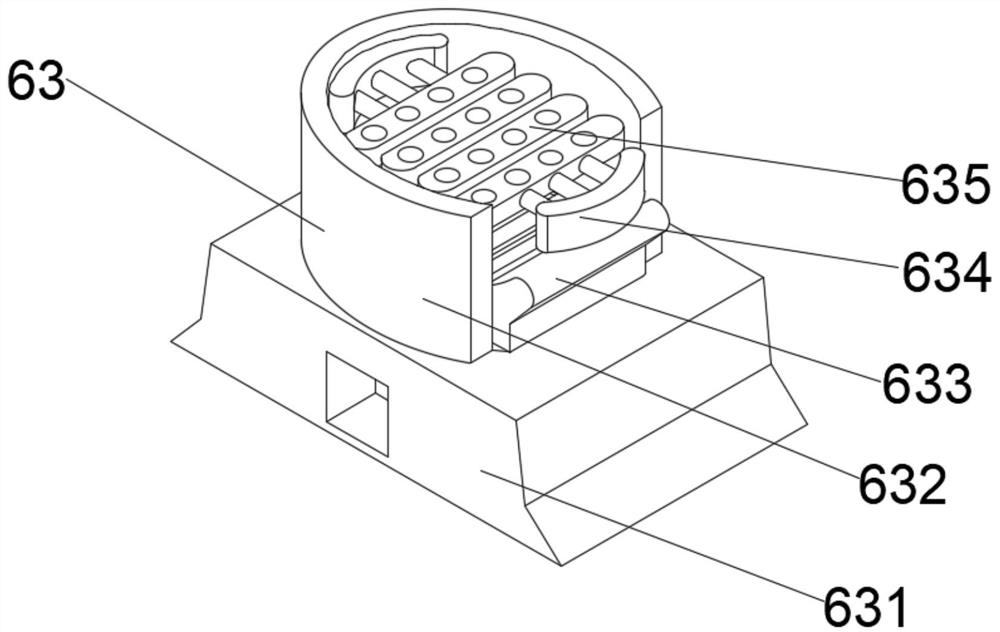

[0037] see Figure 1-4 , on the basis of Embodiment 1, the present invention provides a technical solution: Component 1 of the preheating mechanism 63 includes a heat exchange seat 631, and the middle position of the top of the heat exchange seat 631 is fixedly connected with an insulating layer 633, and the heat exchange seat 631 The top is located on both sides of the insulation layer 633 and is provided with a sealed shell 632. The bottom of the sealed shell 632 runs through the heat exchange seat 631 and extends to the inside of the heat exchange seat 631. The top of the inner wall on both sides of the sealed shell 632 is provided with a temperature control member 634. A heat conducting frame 635 is fixedly connected to a side of the temperature element 634 away from the sealing shell 632 .

[0038] Wherein, the component one of protection mechanism 64 comprises bottom set plate 641, and the top middle position of bottom set plate 641 is fixedly connected with water storag...

Embodiment 3

[0041] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: component 2 of the preheating mechanism 63 includes a fixed connection frame d1, and the bottom of the inner cavity of the fixed connection frame d1 is fixedly connected with an auxiliary preheating element d2 , the top of the auxiliary preheating part d2 is fixedly connected with the piston plate d3, the top of the piston plate d3 is fixedly connected with the preheating induction part d4, and the front middle part of the preheating induction part d4 is provided with a cooling hole d5.

[0042] Wherein, the second component of the protective mechanism 64 includes a protective shell t1, the middle position of the inner cavity top of the protective shell t1 is fixedly connected with the heating main body t2, and the inner cavity bottom of the protective shell t1 is located on both sides of the heating main body t2. The top of the plate d5 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com