Method for producing technical grade ribose phosphate, food grade ribose phosphate and industry ammonium diacid phosphate using wet-process ribose phosphate

A technology of industrial monoammonium phosphate and wet-process phosphoric acid, which is applied in the field of phosphorus chemical industry, can solve the problems of removing impurities, unable to purify comprehensively and deeply, and achieve the effect of increasing added value, good adaptability and application prospect, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

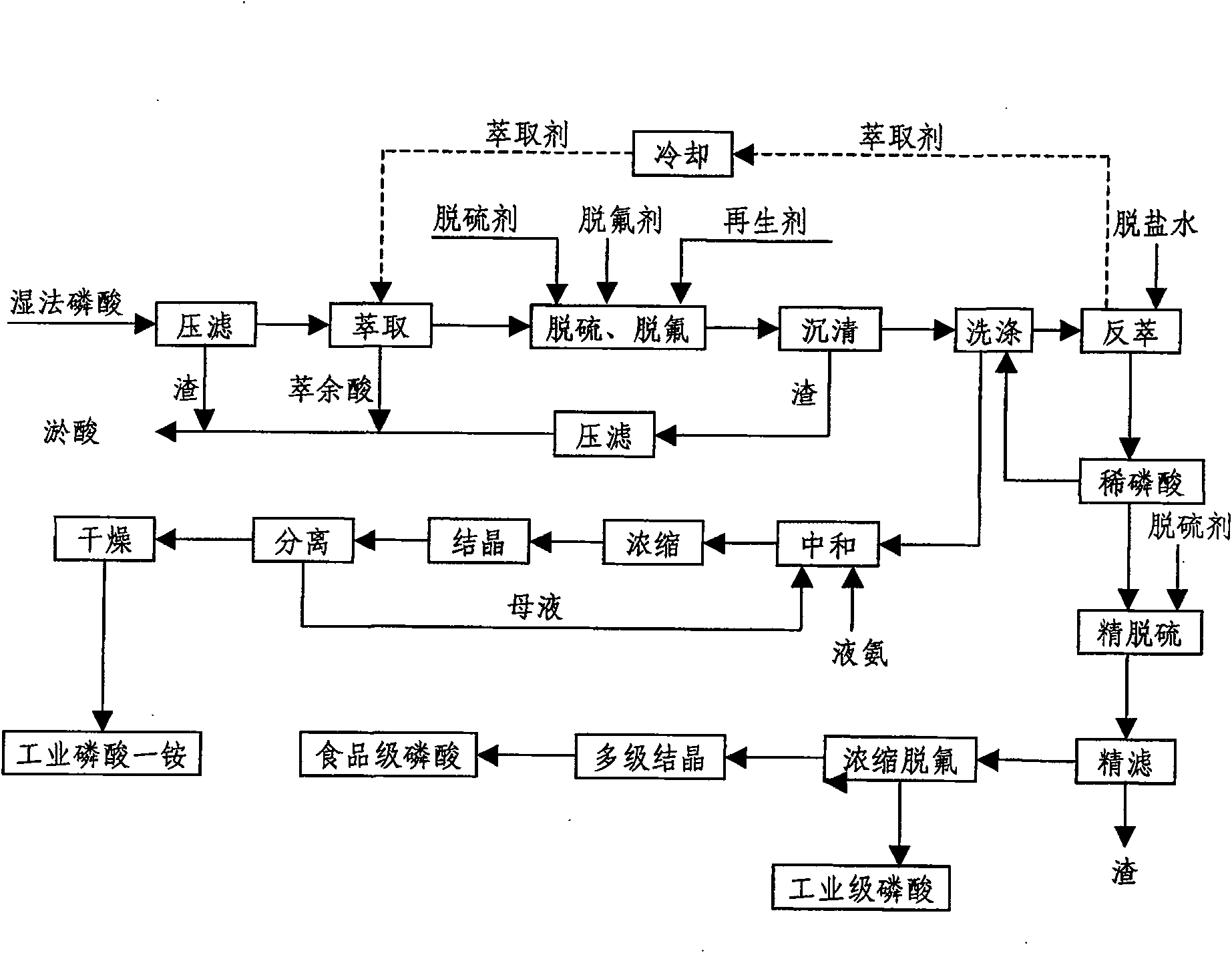

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0029] Such as figure 1 Shown, a kind of method of the present invention prepares industrial-grade phosphoric acid, food-grade phosphoric acid and industrial monoammonium phosphate with wet process phosphoric acid, it is characterized in that carry out as follows:

[0030]Step 1, the wet-process phosphoric acid is pumped into a vertical full-automatic filter press to remove solids, and the clear liquid obtained enters the upper part of the extraction tower, and an extractant of 6 times the volume of the clear liquid is added to the lower part of the extraction tower, and the extractant is Tributyl phosphate, kerosene, and hydrogen peroxide, the ratio of which is 2:1:0.00005, is mixed and extracted at 50°C to form an organic phase (main extractant, dilute phosphoric acid, and some anions, etc.) and a raffinate phase (mainly Dilute phosphoric acid, some cation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com