Magnetic hollow silicon dioxide microspheres and preparation method thereof

A technology of hollow silica and silica, which is applied in the preparation of microspheres, microcapsule preparations, alkali metal oxides/hydroxides, etc., can solve the problem that the particle size uniformity of the template is not easy to control, and achieve magnetic nanoparticles The effect of controllable quantity, high product purity and controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Dehydration of freshly collected cyanobacteria with different concentrations of ethanol

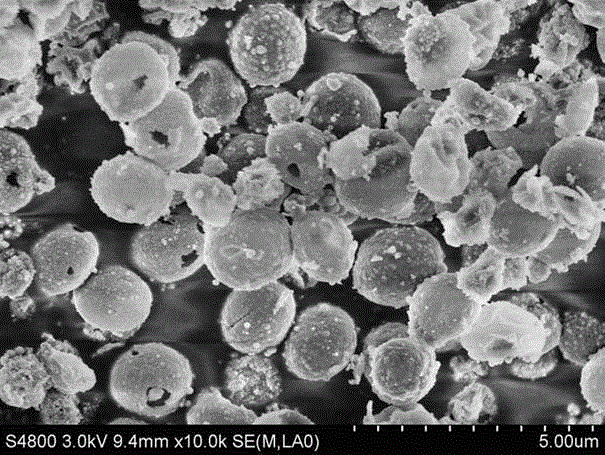

[0026] 2) Preparation of magnetic hollow silica microspheres using treated cyanobacteria as templates

[0027] Add 0.046mol Fe 3+ and 0.023mol Fe 2+ , to obtain solution I; mix absolute ethanol, double distilled water, and ammonia water in a volume ratio of 3:3:1 to obtain solution II. The preparation process is carried out in three steps:

[0028] Step 1: Add the treated cyanobacteria into solution I, stir at a low speed, and infiltrate at 20°C for 24 hours. After infiltration, wash the cyanobacteria three times with double distilled water to remove the solvent on the surface of the cyanobacteria;

[0029] The second step: Put the cyanobacteria treated in the first step into 23mL solution II, stir at a low speed, infiltrate at 20°C for 30h, wash with double distilled water three times, and centrifuge to obtain the magnetic Fe 3 o 4 particles of cyanobacteria;

[0030] Th...

Embodiment 2

[0033] The difference between this embodiment and the specific example 1 is: the process of preparing magnetic hollow silica microspheres using the treated cyanobacteria as a template, and other steps are the same as in the first example;

[0034] Add 0.046mol Fe 3+ and 0.023mol Fe 2+ , to obtain solution I; mix absolute ethanol, double distilled water, and ammonia water in a volume ratio of 3:3:1 to obtain solution II. The preparation process is carried out in three steps:

[0035] Step 1: Add the treated cyanobacteria into solution I, stir at low speed, and infiltrate at 30°C for 30 hours. After infiltration, wash the cyanobacteria three times with double distilled water to remove the solvent on the surface of the cyanobacteria;

[0036] The second step: Put the cyanobacteria treated in the first step into 23mL solution II, stir at a low speed, infiltrate at 25°C for 40h, and obtain the magnetic Fe contained inside. 3 o 4 particles of cyanobacteria;

[0037] The third ...

Embodiment 3

[0040] The difference between this embodiment and the specific example 1 is: the process of preparing magnetic hollow silica composite microspheres using the treated cyanobacteria as a template, and other steps are the same as in the first example;

[0041]Add 0.046mol Fe to 100mL of double distilled water that has passed nitrogen 3+ and 0.023mol Fe 2+ , to obtain solution I; mix absolute ethanol, double distilled water, and ammonia water in a volume ratio of 5:5:2 to obtain solution II. The preparation process is carried out in three steps:

[0042] Step 1: Add the treated cyanobacteria into solution I, stir at a low speed, and infiltrate at 40°C for 48 hours. After infiltration, wash the cyanobacteria three times with double distilled water to remove the solvent on the surface of the cyanobacteria;

[0043] The second step: Put the cyanobacteria treated in the first step into 24mL solution II, stir at a low speed, infiltrate at 25°C for 48h, and obtain the magnetic Fe con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com