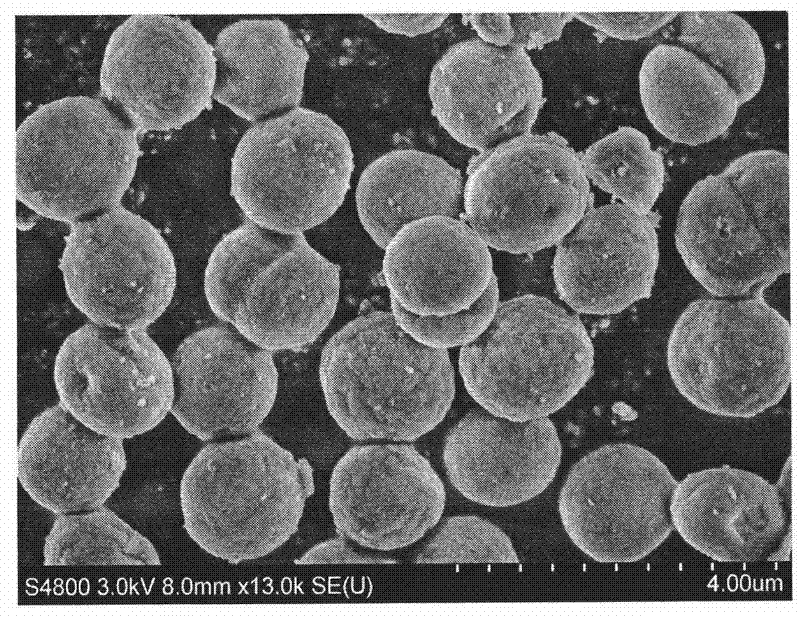

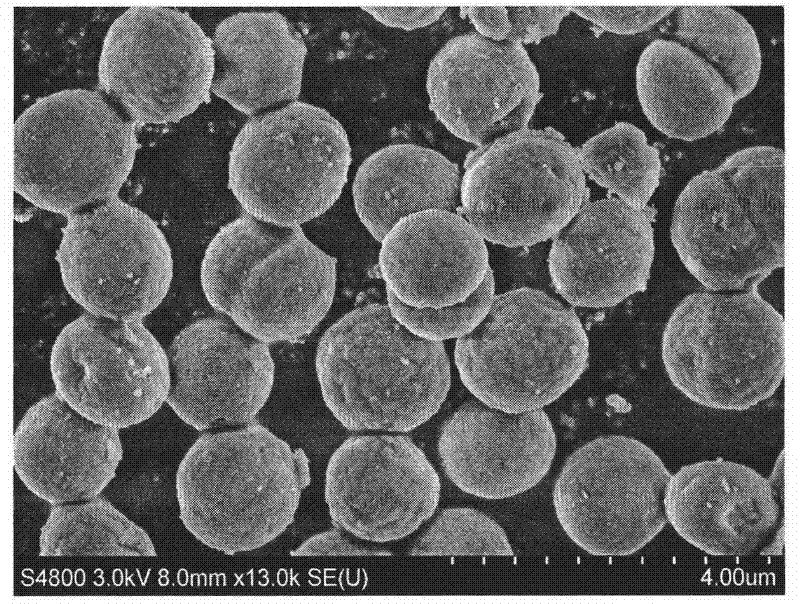

Method for preparing monodisperse silicon dioxide sphere by using blue algae as template

A silicon dioxide, monodisperse technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of sensitivity, unclearness, difficulty in silicon dioxide particles, etc., and achieve the effect of high product purity, economical utilization and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Processing of freshly collected cyanobacteria

[0031] 1. Centrifugal concentration: Collect fresh cyanobacteria by centrifugation. The rotating speed of the centrifuge is 2500 rpm, and the centrifuge is centrifuged for 10 minutes (adjust the rotating speed and time of the centrifuge according to the amount of algae sedimentation).

[0032] 2. Aldehyde fixation: fix cyanobacteria with formaldehyde solution.

[0033] 3. Cleaning: Wash the cyanobacteria soaked in the formaldehyde solution with double distilled water, and wash it several times, about 5 minutes each time, to remove the residual solvent on the surface.

[0034] 4. Dehydration: Collect the cleaned cyanobacteria by centrifugation, centrifuge at a speed of 2500 rpm, and centrifuge for 10 minutes. The cyanobacteria were dehydrated with gradients from 30% to 100% alcohol solution, about 20 minutes each time. Use 100% alcohol to dehydrate twice, and the dehydration time is about 20 minutes each time.

[003...

Embodiment 2

[0042] 1) Processing of freshly collected cyanobacteria

[0043] 1. Centrifugal concentration: Collect fresh cyanobacteria by centrifugation. The rotating speed of centrifuge is 3000 rev / min, centrifugation 10min.

[0044] 2. Aldehyde fixation: fix cyanobacteria with formaldehyde solution.

[0045] 3. Cleaning: Wash the cyanobacteria soaked in the formaldehyde solution with double distilled water, and wash it several times, about 10 minutes each time, to remove the residual formaldehyde solution on the surface.

[0046] 4. Dehydration: Centrifuge to collect the cleaned cyanobacteria, centrifuge at a speed of 3000 rpm, and centrifuge for 10 minutes. Gradient dehydration was carried out with 30% to 100% alcohol solution, each time about 30 minutes. Use 100% alcohol to dehydrate twice, and the dehydration time is about 30 minutes each time.

[0047] 2) Preparation of monodisperse silica microspheres using treated cyanobacteria as a template

[0048] Add absolute ethanol, doubl...

Embodiment 3

[0053] The difference between this embodiment and the specific example 1 is: the process of preparing monodisperse silica microspheres using the treated cyanobacteria as a template.

[0054] Add absolute ethanol, double-distilled water, and ammonia water into the centrifuge tube at a volume ratio of 5:5:2, and mix evenly to form solution I. Put tetraethyl orthosilicate and ethanol co-solvent at a volume ratio of 4:5 in the centrifuge tube After uniform mixing in , solution II was formed. This preparation process is carried out in two steps:

[0055] The first infiltration: take 24 milliliters of the above-mentioned solution I with a centrifuge tube, put the treated cyanobacteria into a centrifuge tube filled with solution I, put the centrifuge tube in a constant temperature oscillator, and shake it at a low speed. Permeate at 25°C for 45h. After the infiltration at this stage is over, the infiltrated cyanobacteria are washed with double distilled water to remove excess solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com