Equipment for recovering cooling liquid for machining tool

A technology for processing machine tools and recycling equipment, which is applied to metal processing equipment, metal processing machinery parts, filter circuits, etc. It can solve problems such as the inability to remove solid particulate matter and dust, reduce the service life of the filter, and fail to achieve the filtering effect. The effect of reducing working pressure, improving filtration strength and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

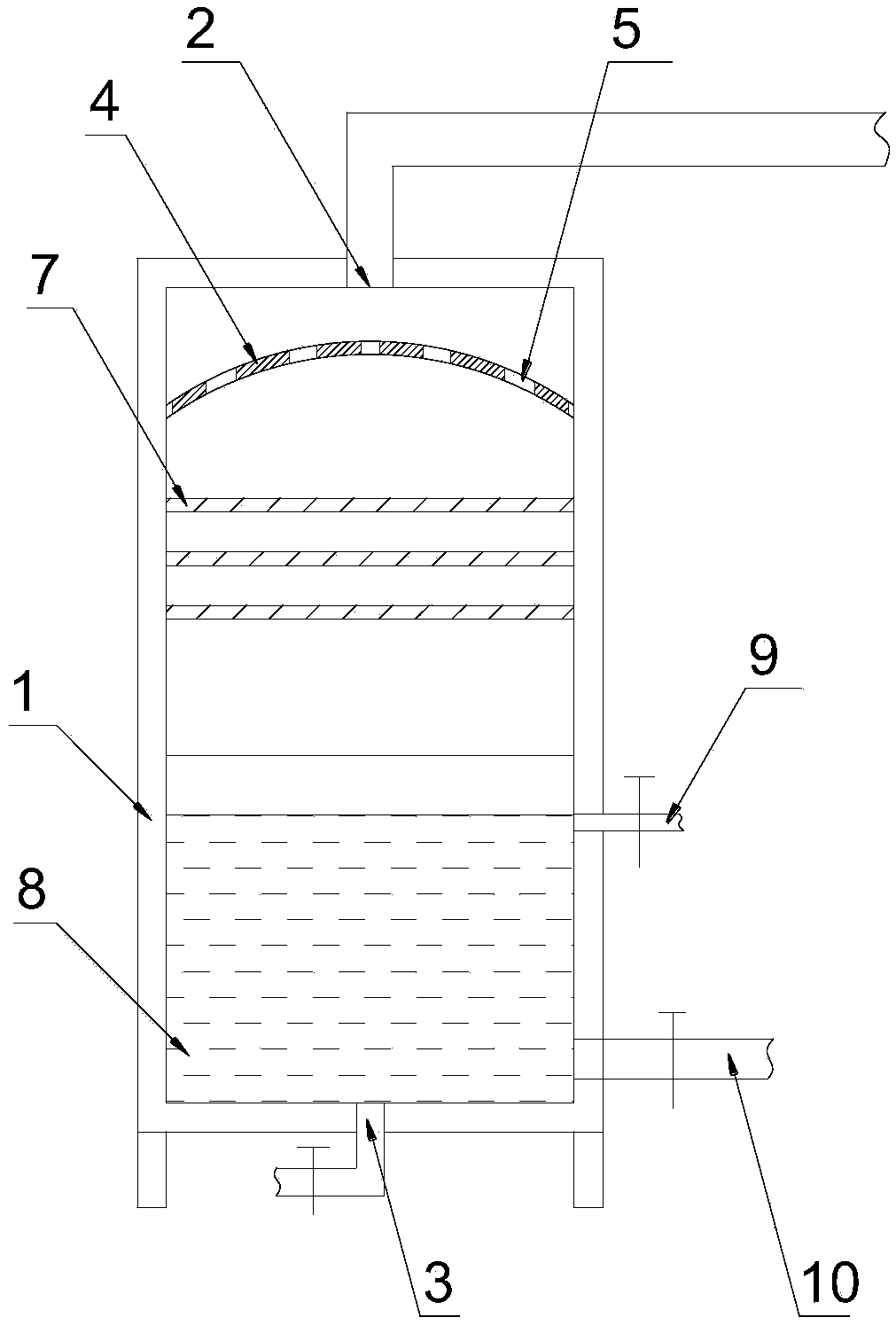

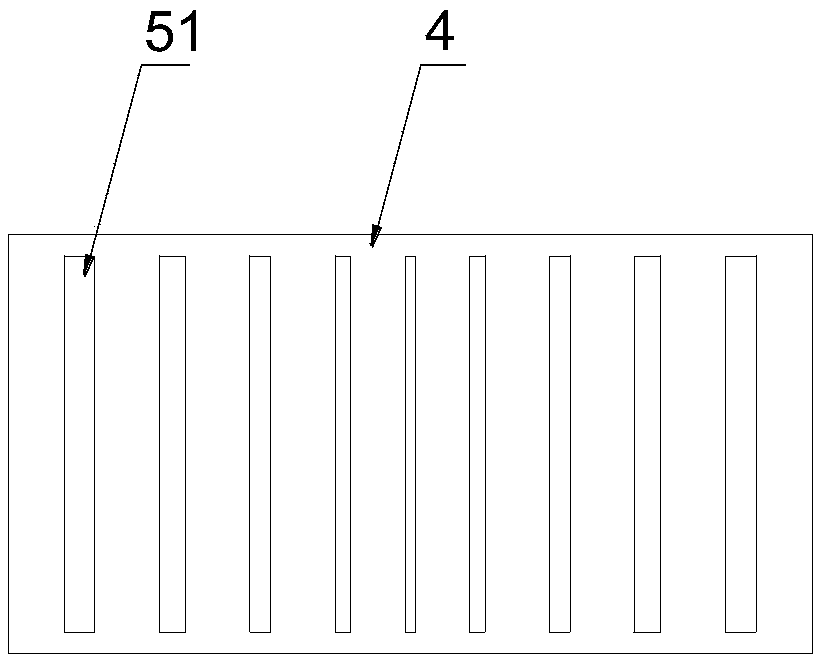

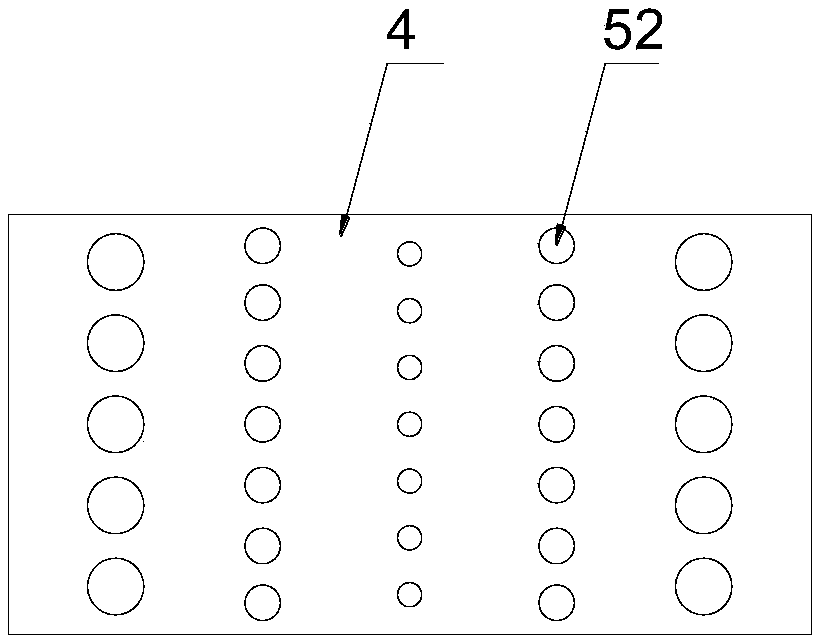

[0022] Such as Figure 1-3 as shown, figure 1 It is a structural schematic diagram of the cooling liquid recovery equipment for processing machine tools proposed by the present invention; figure 2 It is a top view of the splitter plate in the coolant recovery equipment for processing machine tools proposed by the present invention; image 3 It is a schematic diagram of other embodiments of the splitter plate in the cooling liquid recovery equipment for processing machine tools proposed by the present invention.

[0023] refer to Figure 1-3 , a cooling liquid recovery device for processing machine tools proposed by the present invention, including a recovery box 1, a splitter plate 4 and a multi-layer filter plate 7 arranged inside the recovery box 1, and also includes a sewage discharge pipe 9 and a liquid outlet pipe 10;

[0024] A liquid inlet port 2 for connecting a liquid inlet pipe is provided at the middle position on the top of the recovery box 1;

[0025] The spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com