Method for producing phosphoric acid by using (93-98)% concentrated sulfuric acid to extract phosphate rock and its equipment

A 93%-98%, concentrated sulfuric acid technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of complex process, low extraction rate, high energy consumption, flexible process control, and improved extraction rate. , the effect of compact device layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] Adopt the 60,000 tons / year P of the present invention 2 o 5 Phosphoric acid extraction unit

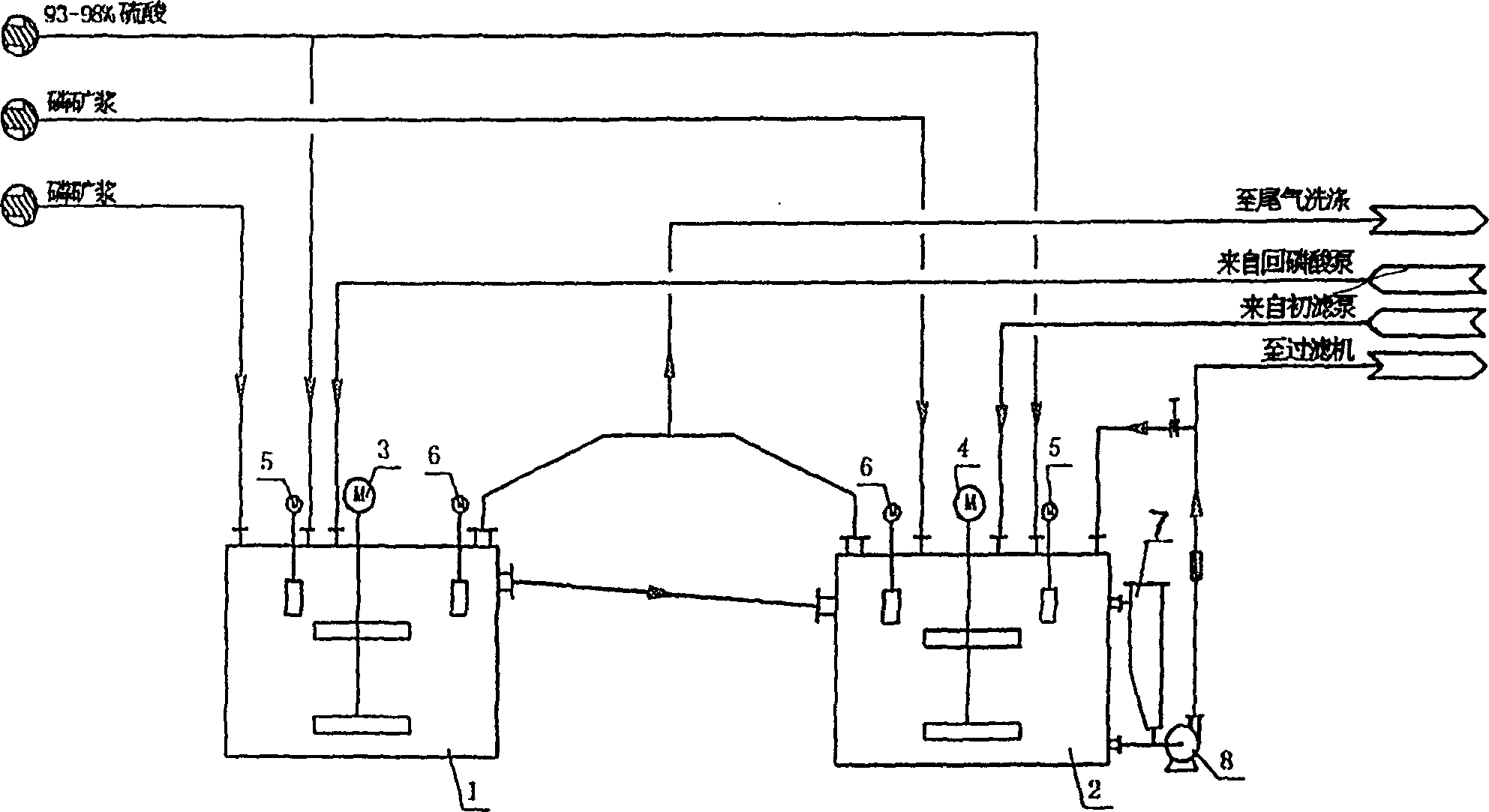

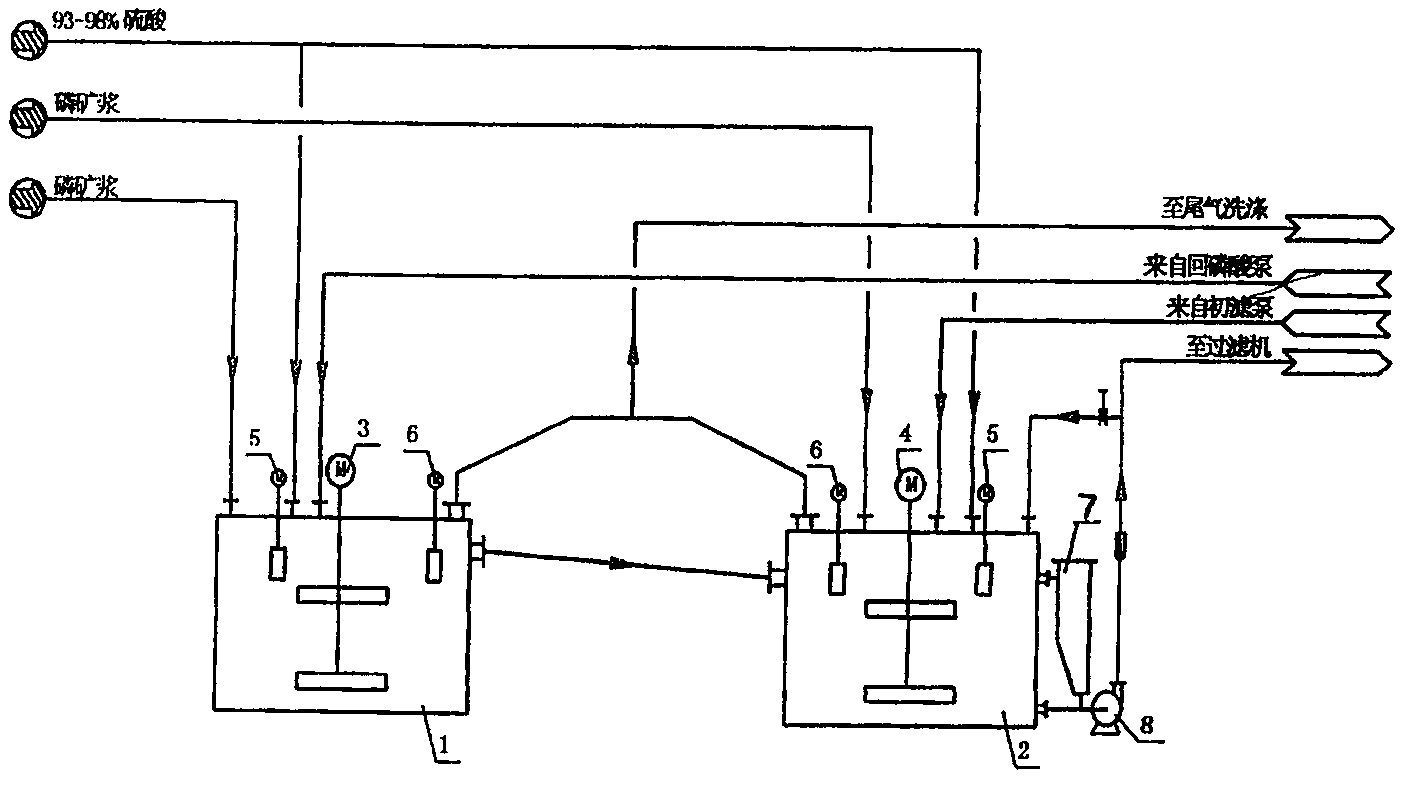

[0039] See attached picture.

[0040] An equipment for producing phosphoric acid by extracting phosphate rock with 93%-98% concentrated sulfuric acid, including two equal-volume reaction tanks 1 and 2, 1# reaction tank 1 and 2# reaction tank 2, and the structure is a vertical circular storage tank , its effective volume is 2.0~2.5m 3 / tpdP 2 o 5 , 1# reaction tank 1 and 2# reaction tank 2 are respectively equipped with a central stirring paddle 3 and 4 with a large circulation capacity, and 4 sulfuric acid distributors 5 and 4 surface coolers 6 and 2 are respectively installed around the central stirring paddle 3 and 4 The #reaction tank is connected with the slurry pump 8 and the chute 7. The overflow pipe on the 1# reaction tank 1 leads to the 2# reaction tank 2.

[0041] Its technological process and parameters are:

[0042] A method of extracting phosphate rock with ...

example 2

[0044] Adopt 120,000 tons / year P of the present invention 2 o 5 Phosphoric acid extraction unit

[0045] See attached picture. The device structure is the same as Example 1.

[0046] Its technological process is:

[0047] Raw material 93%-98% concentrated sulfuric acid is added to 1# reaction tank and 2# reaction tank at 8:2 (wt), and phosphate rock slurry is added to 1# reaction tank and 2# reaction tank at 7:3 (wt), the effective size of 1# reaction tank and 2# reaction tank Both are Φ11000×6900, with a total effective volume of 1083m 3 , The residence time of the reaction slurry is 4.75 hours, the motor power of the central stirring paddle is 185kW, the 1# reaction tank and the 2# reaction tank are equipped with 6 sulfuric acid distributors and 6 surface coolers. 1# reaction tank temperature 85°C, P 2 o 5 Concentration 22~23%wt, liquid-solid ratio 3.0:1, stirring power 0.275kW / m 3 ; 2# reaction tank temperature 72°C, P 2 o 5 Concentration 23-24%wt, liquid-solid ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com