Method for obtaining fine methanol products by using methanol to olefins (MTO) methanol products

A technology of refined methanol and products, applied in the direction of separation methods, chemical instruments and methods, preparation of organic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

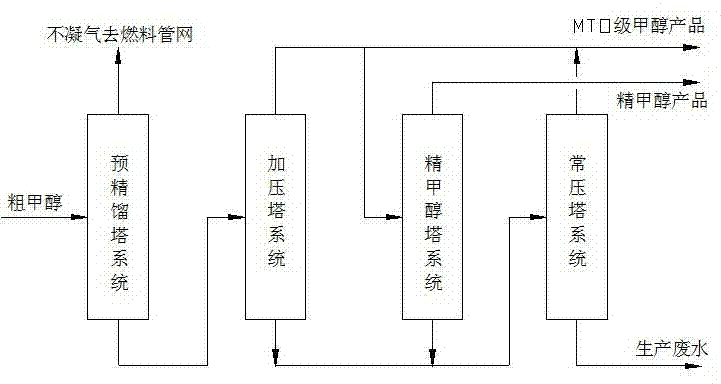

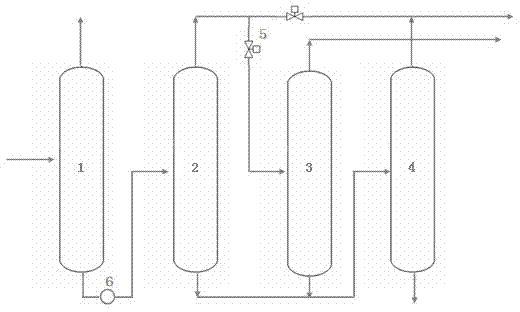

[0033] Such as figure 2 Shown: A kind of equipment that utilizes MTO methanol products to obtain refined methanol products, and a set of refined methanol rectification system is added on the basis of the existing MTO methanol three-tower rectification equipment. The equipment specifically includes: a pre-rectification tower 1, a pressurized rectification tower 2, a refined methanol rectification tower 3, and an atmospheric rectification tower 4. The raw material inlet in the middle of the pre-rectification tower 1 is supplied with crude methanol through a pipeline. The system is connected, the tower top outlet of the pre-rectification tower 1 is connected with the exhaust gas treatment system or the fuel pipe network through the pipeline, and the tower still outlet is connected with the raw material inlet in the middle part of the pressurized rectification tower 2 through the pipeline and the booster pump 6 The outlet at the top of the pressurized rectification tower 2 is con...

Embodiment 2

[0037] This embodiment is a flow process with an annual output of 300,000 tons of MTO grade methanol and a by-product of 24,000 tons of refined methanol (see figure 1 ), using equipment such as figure 2 shown.

[0038]Crude methanol flow rate ~ 45900kg / h enters the three-tower rectification system of MTO grade methanol, discharges non-condensable gas from the top of the pre-rectification tower, and produces MTO grade methanol from the top of the pressurized rectification tower and the top of the atmospheric rectification tower. Among them, 18,887 kg / h of MTO grade methanol is extracted from the top of the pressurized rectification tower, and 19,953 kg / h of MTO grade methanol is mined from the top of the atmospheric distillation tower, and the bottom liquid of the atmospheric distillation tower is pumped to the sewage treatment system. The device produced a total of 38.840t / h of MTO grade methanol.

[0039] The content of MTO grade methanol is 95%, which cannot meet the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com