Composite stamping die

A stamping die and mold technology, applied in the field of mold equipment, can solve the problems of low production efficiency, many process equipment, poor economic benefits, etc., and achieve the effect of improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

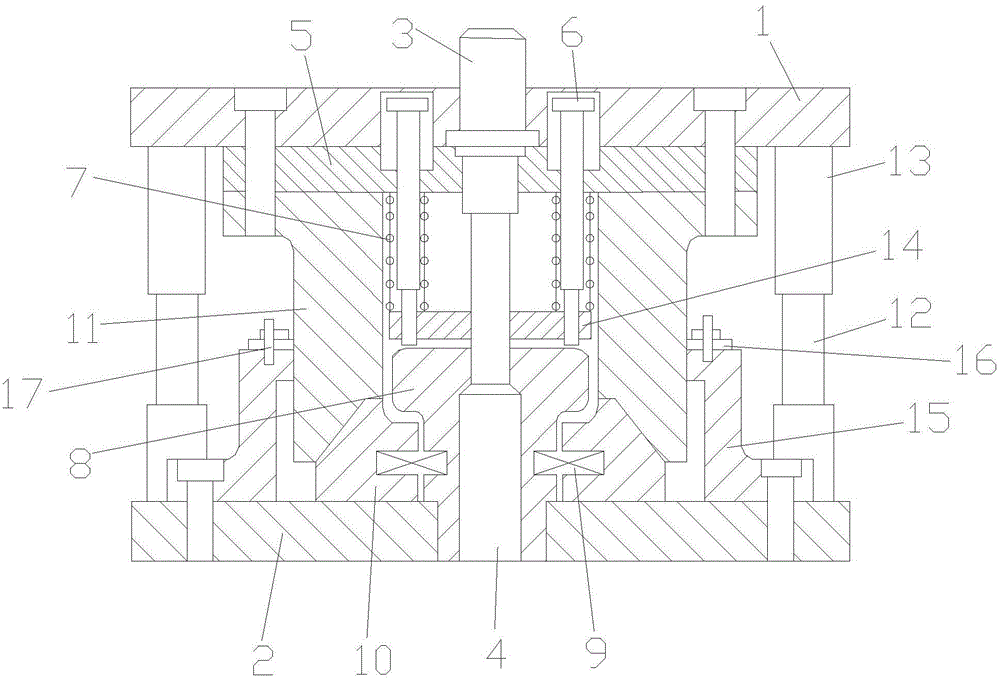

[0025] refer to figure 1 As shown, a composite stamping die comprises an upper die base 1, a lower die base 2, a die handle 3 and a punching punch 4, the die handle 3 is arranged in the middle of the upper die base 1, and the punching punch 4 is arranged on the lower die base 2. In the middle part, the mold handle 3 is fixedly connected with the punching punch 4, and a mounting plate 5 is arranged under the upper die base 1, and a pull rod 6 is arranged inside the mounting plate 5, and springs 7 are arranged at both ends of the pull rod 6, The outer side of the punching punch 4 is provided with a forming punch 8, a spring 9 and a movable wedge 10 in sequence, the forming punch 8 is connected with the movable wedge 10 through a spring 9, and the movable wedge 10 is provided with a fixed wedge 11. The movable wedge 10 is compatible with the fixed wedge 11, and the two ends of the lower mold base 2 are provided with guide pillars 12 and guide sleeves 13, and the lower mold base 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com