Main duct construction method laid down tunnel structure article

A technology of tunnel structure and construction method, which is applied in the direction of tunnels, tunnel linings, mining equipment, etc., and can solve the problems of difficult insertion into subsequent main pipelines, cumbersome operations, excessive manpower and material costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

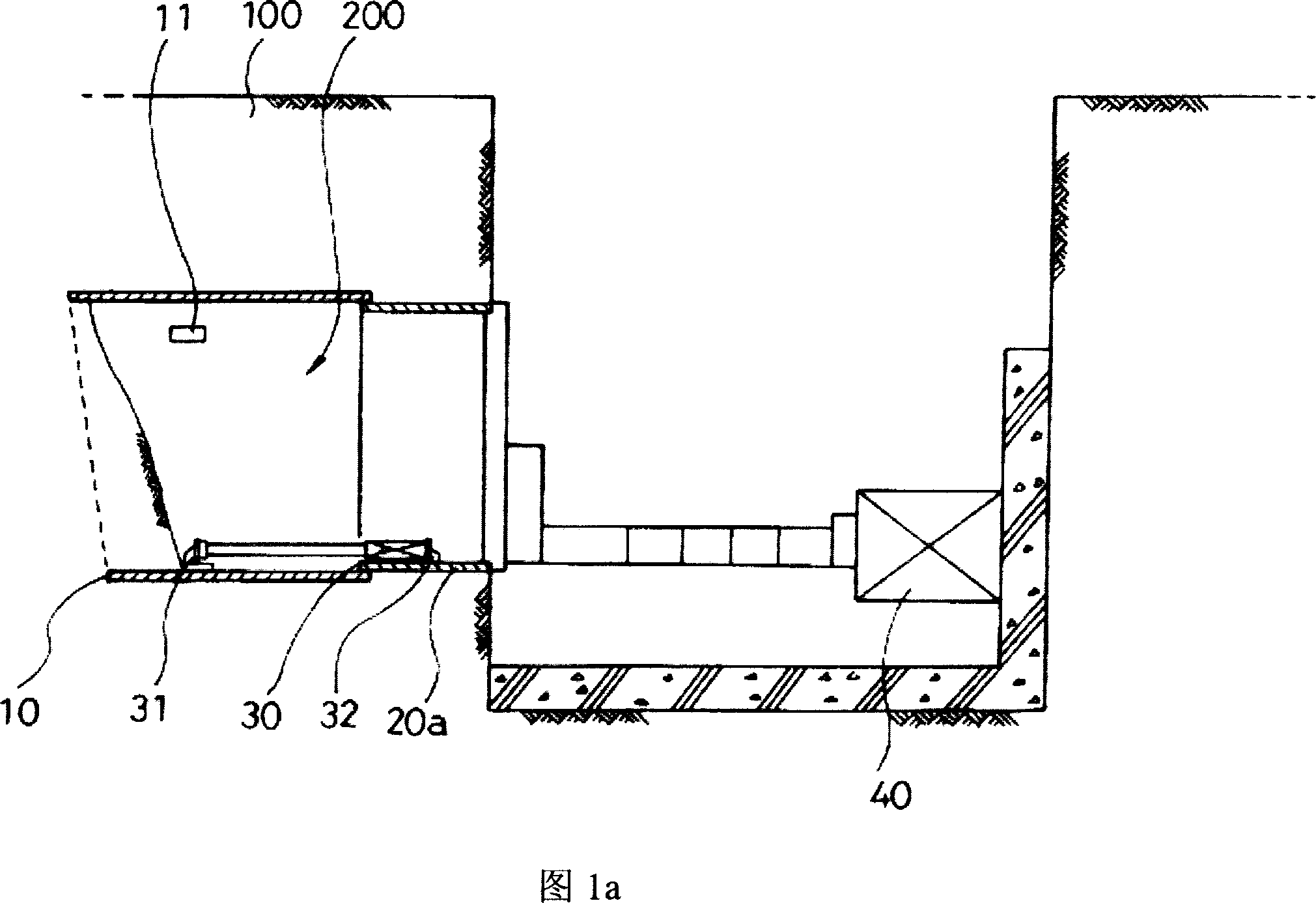

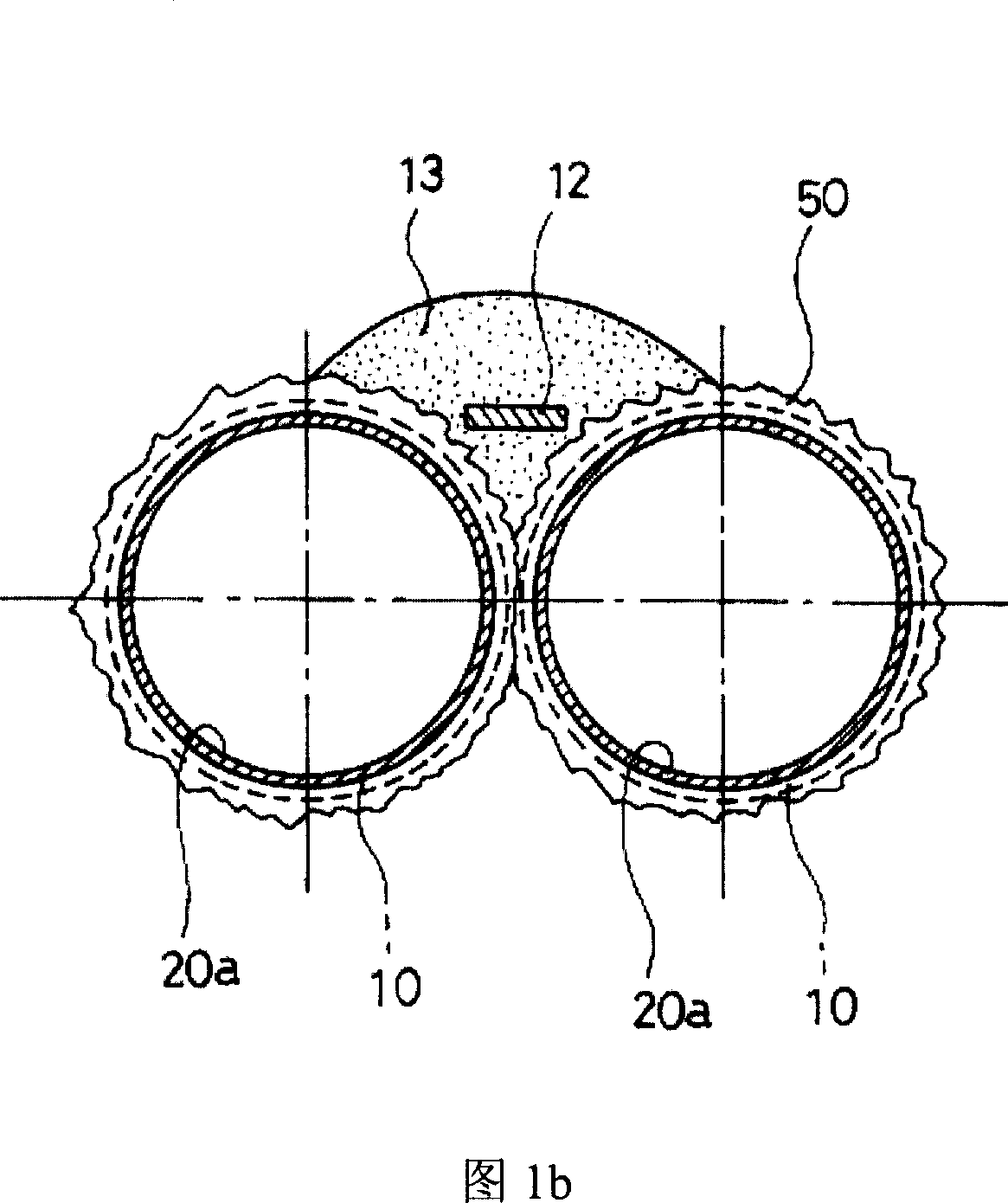

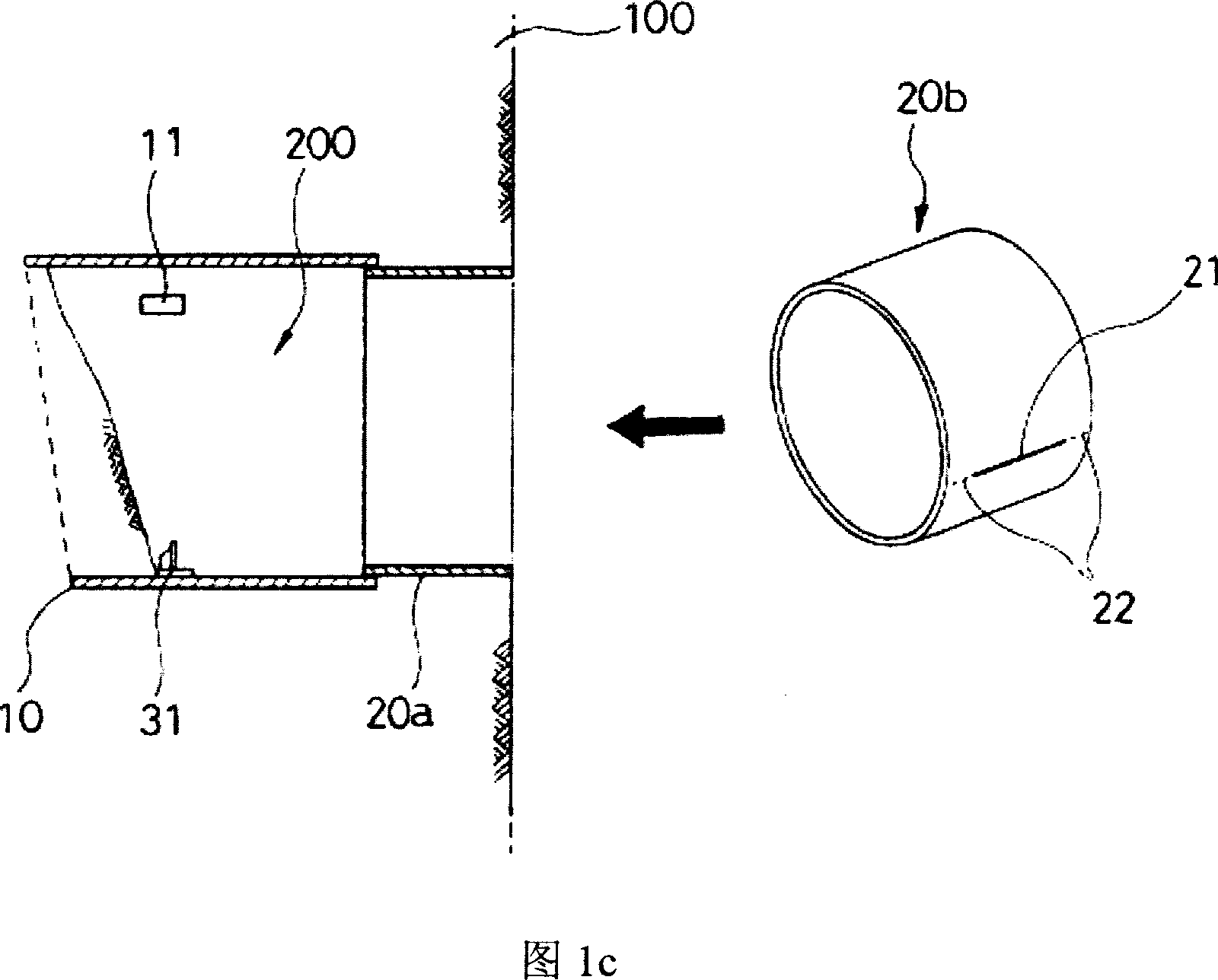

[0038]In order to lay tunnel structures in various forms suitable for terrain or underground conditions, the present invention connects and arranges circular main pipes made of steel pipes cut into predetermined lengths along straight lines or curves for long distances underground, including: as shown in Figure 1a, Before and after the inner surface of the pilot pipe 10 and the inside of the initial main pipe 20a inserted in the pilot pipe 10, a certain number of reaction platforms 31, 32 corresponding to each other are respectively arranged at predetermined intervals. Under the condition that the oil / pneumatic cylinder 30 load is respectively arranged between, utilize the oil hydraulic jack 40 to press the steps of the pilot pipe 10 and the initial main pipeline 20a in the underground 100; In the initial main pipeline 20a, excavate the surrounding soil through the input port 11 of the collapse prevention plate formed on the pilot pipe 10, and then, as shown in Figure 1b, put i...

Embodiment 2

[0046] In the present invention, as shown in Figure 2a, in order to lay tunnel structures in various forms suitable for terrain or underground 100 conditions, a circular main pipe 20 made of steel pipes cut to a predetermined length is arranged underground along a straight line or a curved line for a long distance. include:

[0047] Before and after the inner surface of the pilot pipe 10 and the inside of the inserted initial main pipe 20a, a certain number of reaction platforms 31, 32 corresponding to each other are respectively arranged at predetermined intervals, and between the reaction platforms 31, 32 on both sides of the advancing direction are respectively provided with Under the condition that the oil / pneumatic cylinder 30 is loaded, the steps of using the hydraulic jack 40 to press the pilot pipe 10 and the initial main pipe 20a underground 100;

[0048] When the pilot pipe 10 and the initial main pipe 20a are pressed in, the surrounding soil is dug out through the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com