Method for preparing ammonium sulfate by conversion of phosphogyspum with polycrystalline method

A technology of phosphogypsum and ammonium sulfate, which is applied in the comprehensive utilization of resources and the field of chemical industry, can solve the problem of filtration strength of calcium carbonate filter cake that does not involve the transformation product, does not involve the continuous conversion process of phosphogypsum by polycrystalline method, and does not involve the washing of calcium carbonate filter cake. Water utilization and other issues, to achieve the effect of feasible project investment, good filtration intensity and remarkable social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

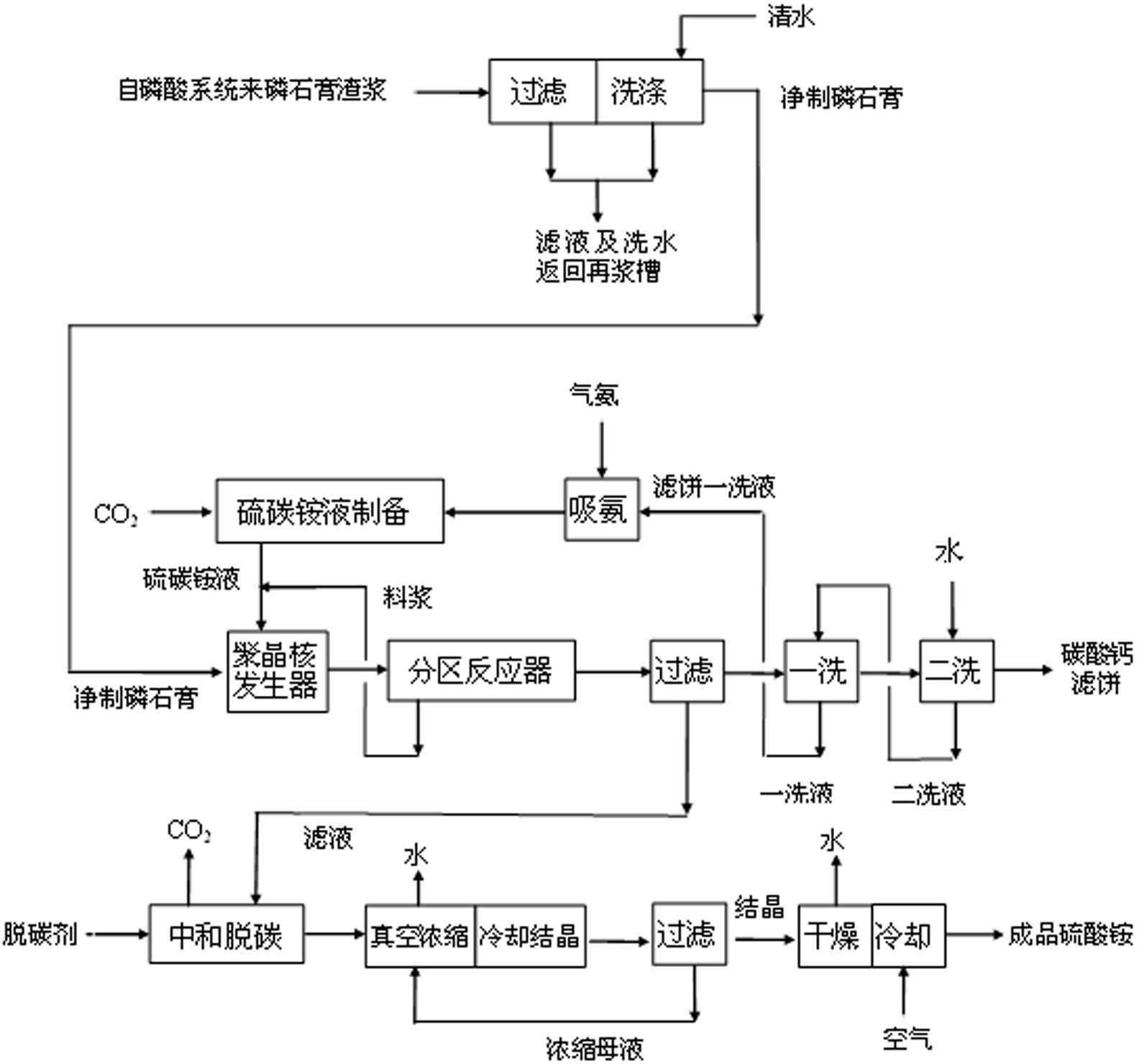

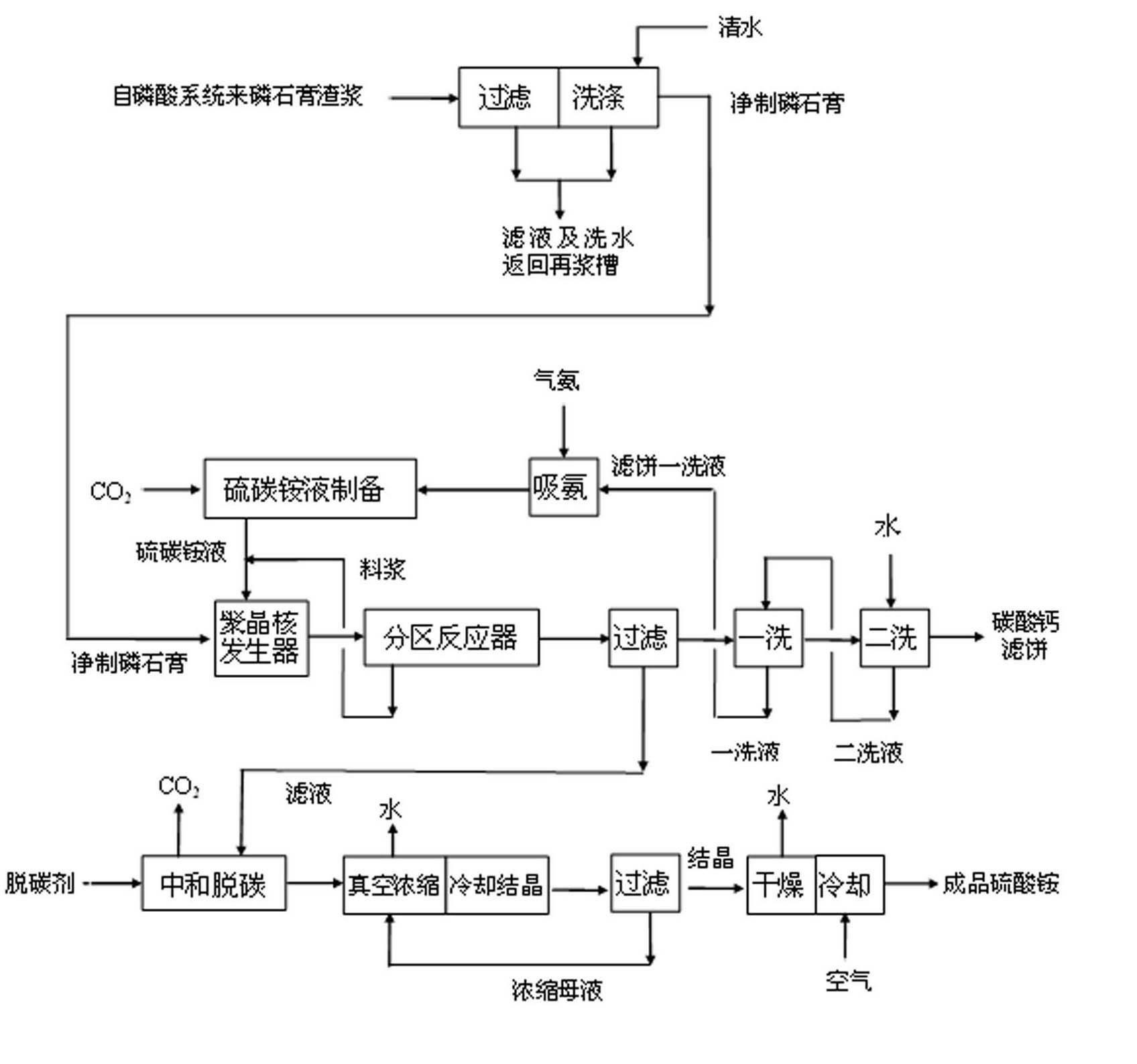

[0037] Such as figure 1 As shown, the 2000 tons / year phosphogypsum pilot plant production line of ammonium sulfate, the main process equipment is as follows:

[0038] a. Conversion crystallizer: composed of calcium carbonate polycrystalline nucleus generator and three cylindrical reactors with stirring (V=2m 3 ,φ1300×1600) in series;

[0039] b. The carbonization tower is a vertical packed tower, φ640×120000;

[0040] c. Phosphogypsum filter washing machine: flip filter, F=4m 2 ;

[0041] d. Ammonium sulfate filtrate concentrator: vacuum double-effect evaporator, evaporation capacity 2t / h water;

[0042] e. Ammonium sulfate crystallization drying, cooler: hot and cold air vibration drying fluidized bed, processing capacity 1.5t / h ammonium sulfate crystallization.

[0043] In this example, phosphogypsum, liquid ammonia, CO 2 , water as the main raw material, the production process and operation control steps of ammonium sulfate and co-production of calcium carbonate slag ...

Embodiment 2

[0062] Production unit, ammonium sulfate output, technological process, operation control step are identical with embodiment 1, and technological process expresses opinion figure 1 .

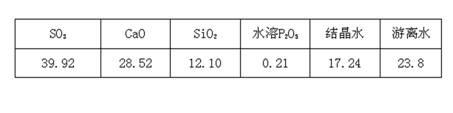

[0063] ⑴Phosphogypsum raw material

[0064] The chemical composition of the phosphogypsum raw material used in this example, dry basis mass %

[0065]

[0066] ⑵The raw material of ammonium sulfocarbonate solution in this example

[0067] The prepared ammonium sulfocarbonate solution contains ammonium sulfate W% 13.00 and ammonium carbonate W% 35.50.

[0068] (3) The typical process conditions of conversion crystallization in this example

[0069] The typical process conditions of conversion crystallization in this example

[0070]

[0071] ⑷ Technical performance indicators of the implementation results of this example

[0072] Implementation Results Technical Performance Indicators

[0073]

Embodiment 3

[0075] Production unit, ammonium sulfate output, technological process, operation control step are identical with embodiment 1, and technological process expresses opinion figure 1 .

[0076] ⑴Phosphogypsum raw material

[0077] The chemical composition of the net phosphogypsum raw materials used in this example (mass % on a dry basis)

[0078]

[0079] ⑵The raw material of ammonium sulfocarbonate solution in this example

[0080] The obtained sulfur bicarbonate liquid contains ammonium sulfate W% 17.00 and ammonium carbonate W% 28.20.

[0081] (3) The typical process conditions of conversion crystallization in this example

[0082] The typical process conditions of conversion crystallization in this example

[0083]

[0084] ⑷ Technical performance indicators of the implementation results of this example

[0085] Implementation Results Technical Performance Indicators

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com