Filtration apparatus and filter washing method therefor

a technology of filtration apparatus and filter washing method, which is applied in the direction of separation process, filtration separation, transportation and packaging, etc., can solve the problems of difficult to reduce manufacturing costs, limit the diameter the backwashing mechanism is not easily removed during maintenance so as to improve the strength of the filter element, improve the maintainability, and reduce the dimension of the filtration apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

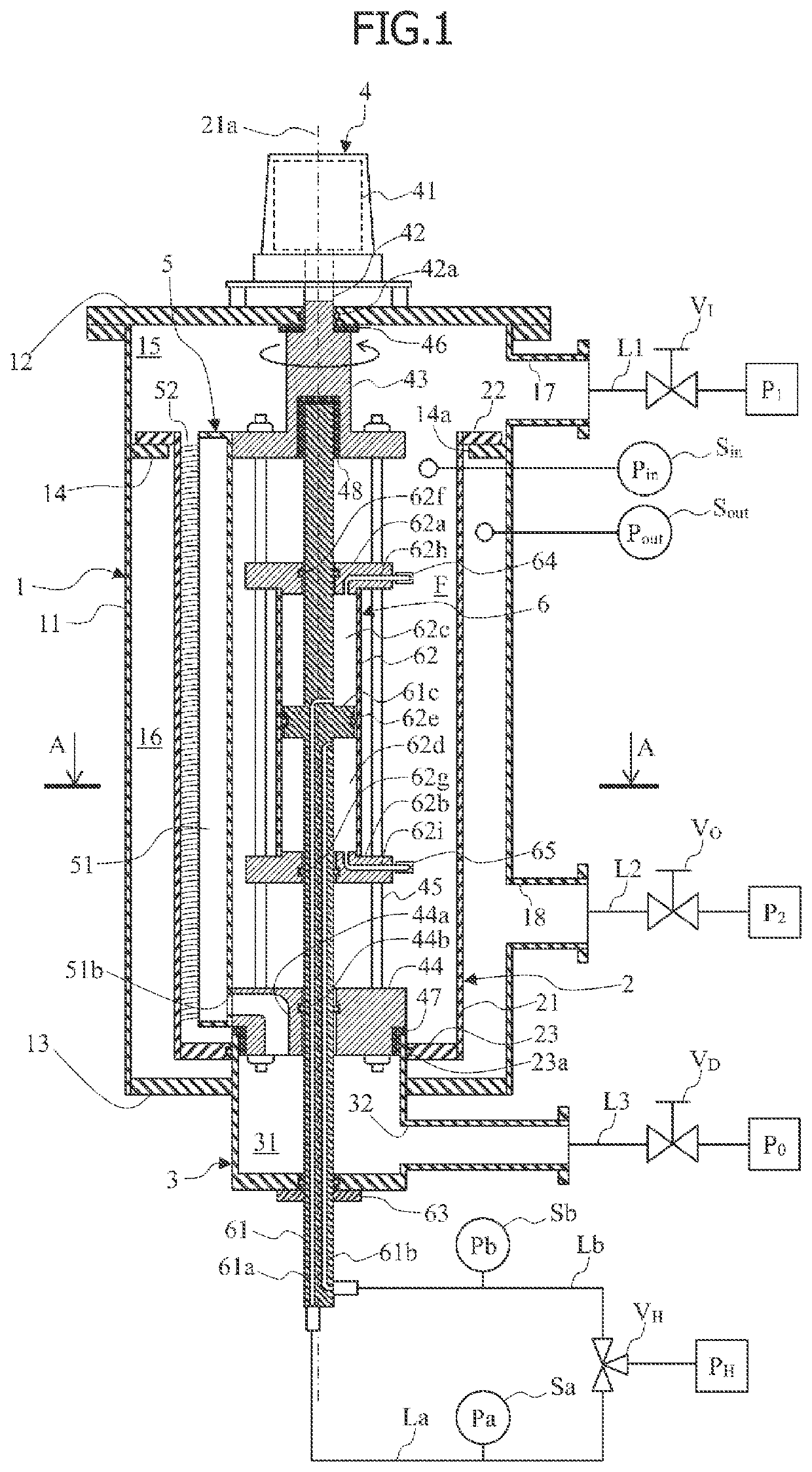

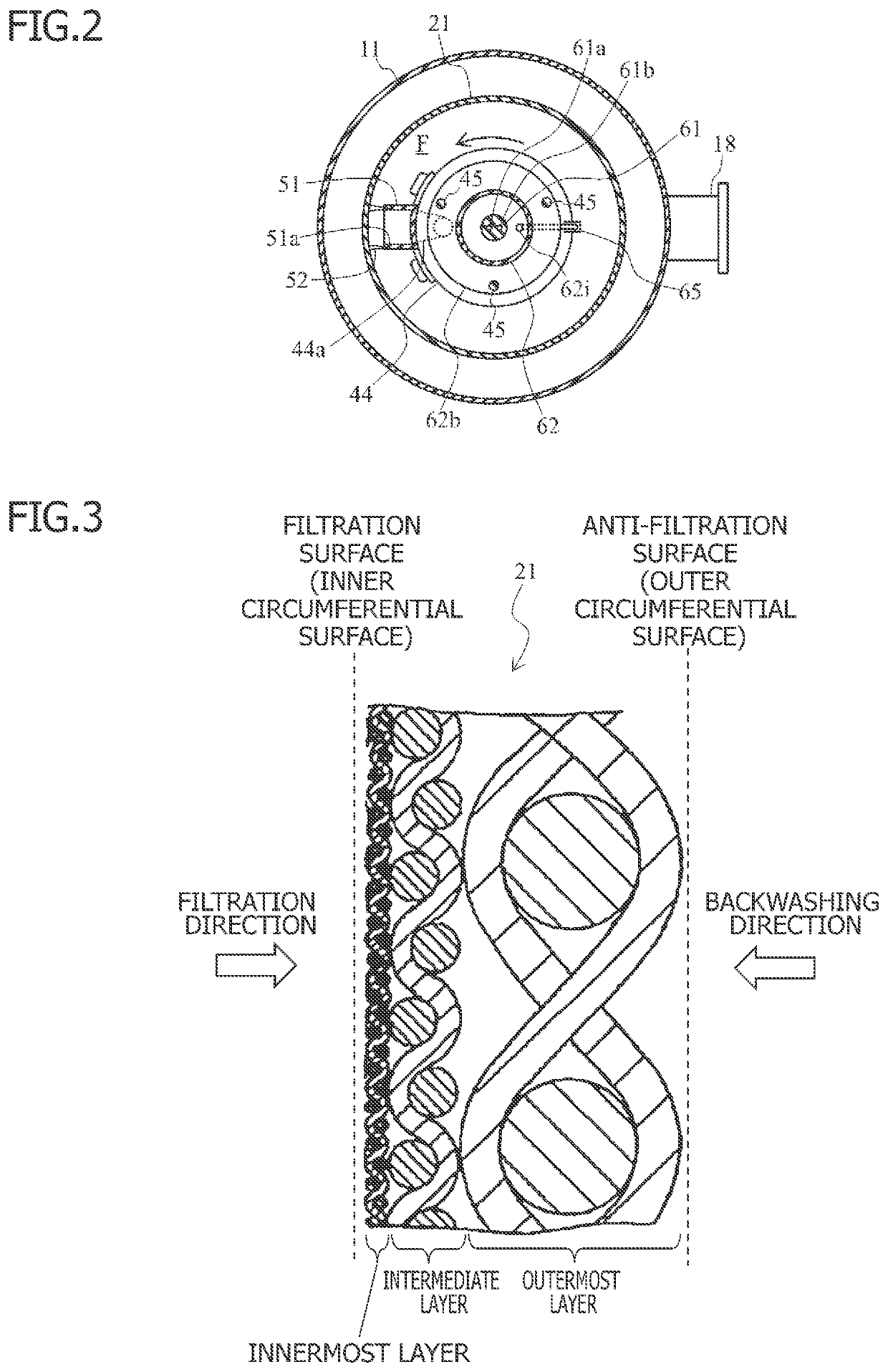

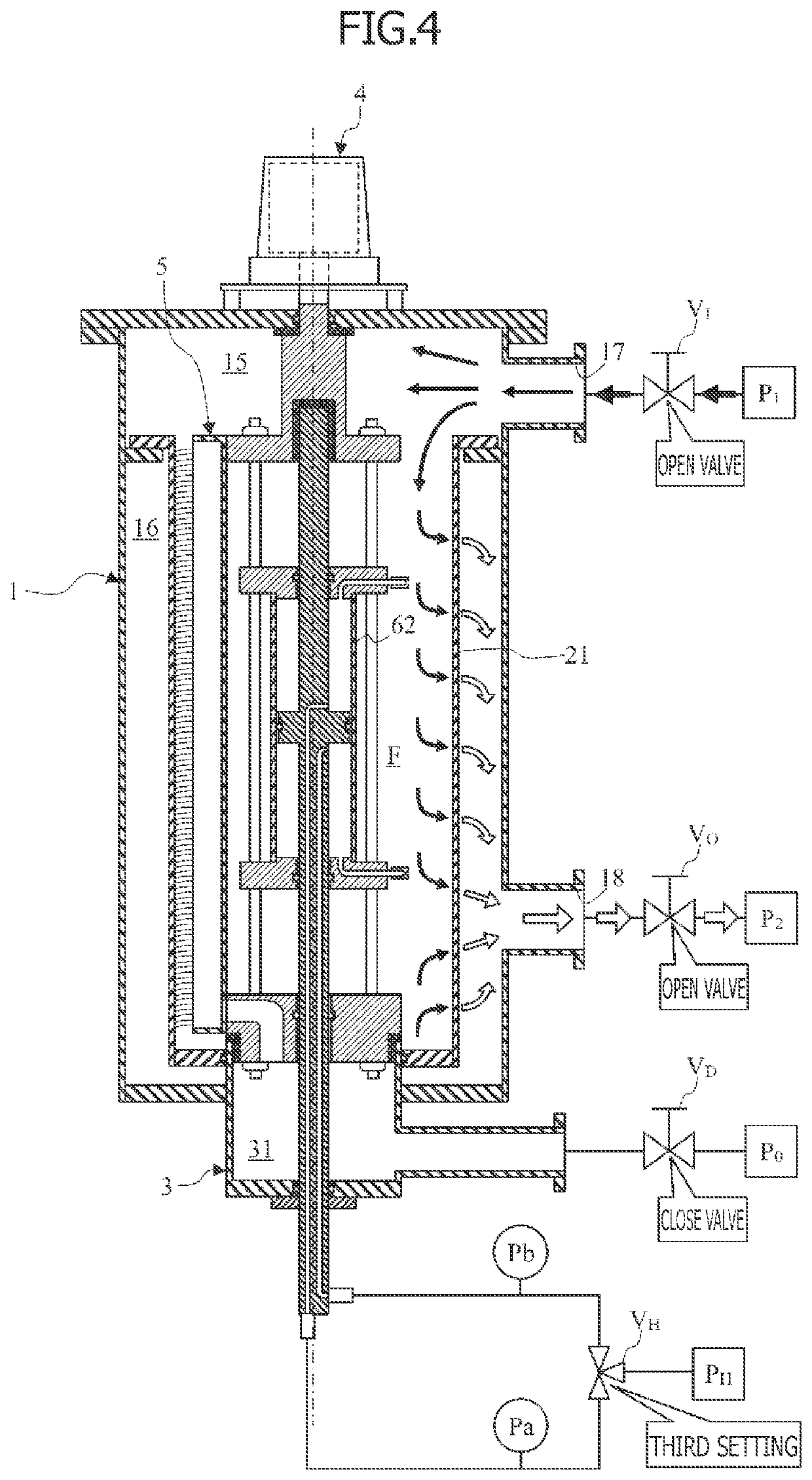

[0032]FIGS. 1 and 2 show an example of a filtration apparatus according to a first embodiment. The filtration apparatus has a filtering function of making various fluids to be filtered (hereinafter, referred to as “target fluids”) pass through a built-in filter element to perform filtration. Examples of the target fluids include river water, lake water, or seawater, liquid used in general industry such as cooling water or process liquid for various apparatuses, oil such as lubricating oil or diesel fuel oil, various raw material gases used in chemical factories, or ship ballast water. Specifically, the filtration apparatus includes a casing 1 and a filter unit 2 as a configuration that embodies the filtering function.

[0033]The casing 1 is a tubular body (for example, a cylindrical body) 11 forming an outer shell of the filtration apparatus, and has a closed space therein with a first casing lid plate 12 that closes one end opening and a second casing lid plate 13 that closes the oth...

second embodiment

[0085]FIGS. 11 and 12 shows an example of a filtration apparatus according to a second embodiment. In the present embodiment, differences from the first embodiment will be mainly described, and components similar to those of the filtration apparatus according to the first embodiment are denoted with the same reference numerals and description will be omitted for simplicity. The same applies to the following other embodiments.

[0086]As described in the first embodiment, when the backwashing is performed prior to the high-pressure washing, almost all fine particulate trapped materials trapped from the filtration surface side of the filter element 21 are removed together with the backwashing fluid. However, when the backwashing is insufficient, the fine particulate trapped materials may be peeled off by the high-pressure washing and remain in the internal space F of the filter element 21. Therefore, in consideration of the possibility that the trapped materials of the filter element 21 ...

third embodiment

[0094]FIG. 15 shows an example of a filtration apparatus according to a third embodiment. The filtration apparatus of the present embodiment is different from the filtration apparatus of the first embodiment in that the piston rod 61 is fixed to the first end rotating body 43 and the second end rotating body 44 so as not to be relatively rotatable and rotates integrally with the rotary drive mechanism 4. For this reason, the following components in the first embodiment are omitted in the present embodiment. That is, the intermediate bearing 48 for supporting the piston rod 61 so as to be rotatable relative to the first end rotating body 43 and the fixture 63 for fixing the piston rod 61 to the backwashing drain case 3 are omitted. Furthermore, since the piston rod 61 is closely fixed to the inner circumferential surface of the through hole of the second end rotating body 44, the sealing member 44b between the second end rotating body 44 and the piston rod 61 is omitted.

[0095]An annu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| rotary speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com