Sanding room dust removal cabinet

A technology of grinding room and dust removal chamber, which is applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problem of difficult removal of sediment, and achieve the effect of high degree of automation, high dust removal efficiency and reasonable structure layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

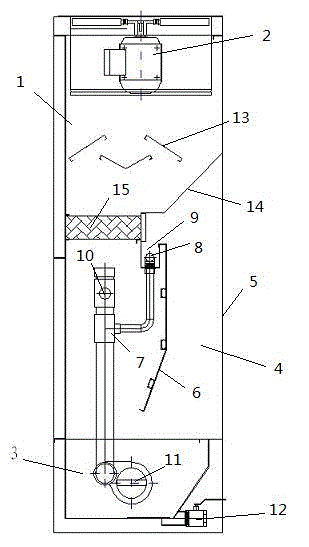

[0025] Such as figure 1 As shown, a dust removal cabinet for a grinding room includes a cabinet body 1 and a control device, the cabinet body has a top wall, side walls and a base, the top wall is provided with a fan 2, and a water tank 3 is provided above the base, The cabinet body 1 has a dust removal chamber 4 .

[0026] The dust removal chamber 4 is formed by a base, a part of side walls and a partition device arranged in the cabinet body 1 . One side of the dust removal chamber 4 of the cabinet 1 is provided with a dust suction port 5. Preferably, the dust removal chamber 4 can be set as an open chamber, that is, the dust suction port 5 is connected to the entire side of the dust removal chamber. The walls are the same size.

[0027] The dust removal chamber 4 is provided with a two-stage filter device and a water supply system for providing water to the filter device. The first-stage filter device is a vertically arranged water curtain filter device, which is compose...

Embodiment 2

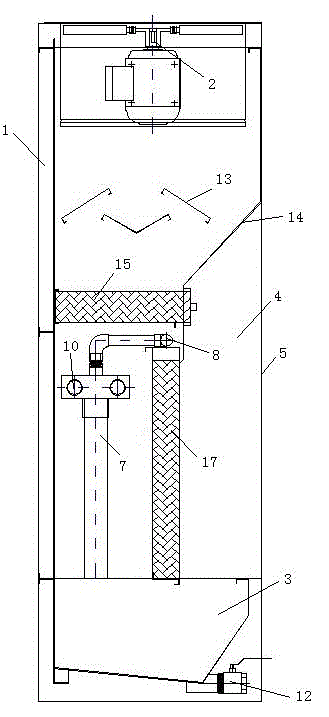

[0034] Such as figure 2 As shown, in embodiment 2, the deflector 6 in the water curtain filter device in embodiment 1 is replaced by a filter paper dust removal wall 17, and the filter paper dust removal wall 17 is a gas permeable wall formed by bending and bonding several pieces of filter paper . In this embodiment, the water outlet 8 can be directly placed on the top of the filter paper dust removal wall 17, and the water flowing out through the water outlet 8 flows down from the top of the filter paper dust removal wall 17 along the wall to form a water curtain.

[0035] All the other are with embodiment 1.

Embodiment 3

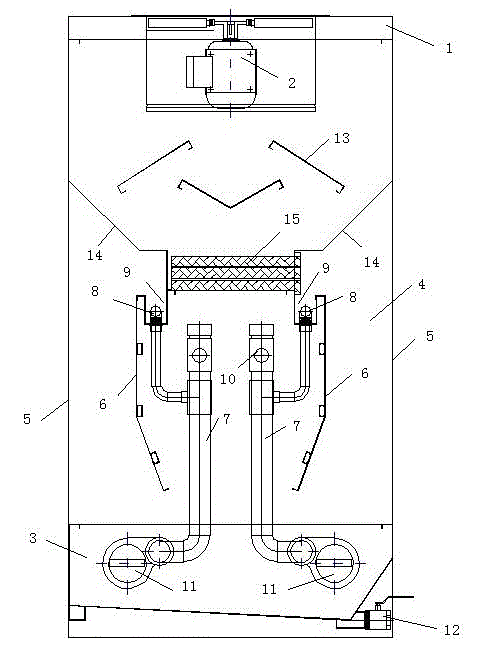

[0037] Such as image 3As shown, in embodiment 3, the dust removal chamber 4 in embodiment 1 is arranged as a double-sided symmetrical structure. Specifically, the two symmetrical sides of the dust removal chamber 4 are provided with dust suction ports 5, water curtain filter, water The mist filtering device and the water supply system are arranged symmetrically in the dust removal chamber, an airtight baffle 14 is arranged above the two water curtain filtering devices, and a filter paper dust removing device 15 is arranged above the water mist filtering device.

[0038] All the other are with embodiment 1.

[0039] The dust removal cabinet for the grinding room with such a symmetrical structure realizes simultaneous dust removal on both sides of the cabinet body, further enhancing the dust removal efficiency of the dust removal cabinet for the grinding room.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com