Thickening process of coarse adipic acid

A kind of adipic acid and process technology, which is applied in the separation/purification of carboxylic acid compounds, filtration separation, fixed filter element filter, etc., which can solve the problems of limited production capacity of the device, poor production continuity of the thickening system, and high equipment failure rate. , to achieve the effects of short filtration cycle, improved equipment production capacity, and long service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

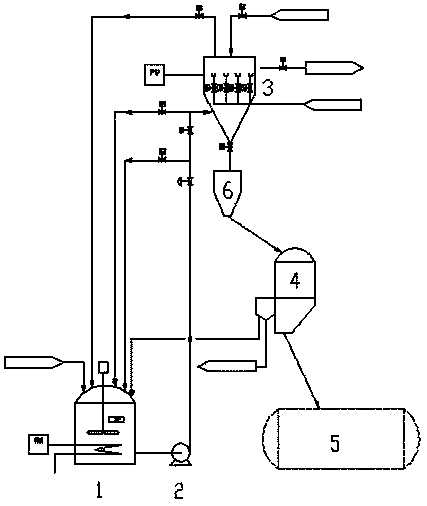

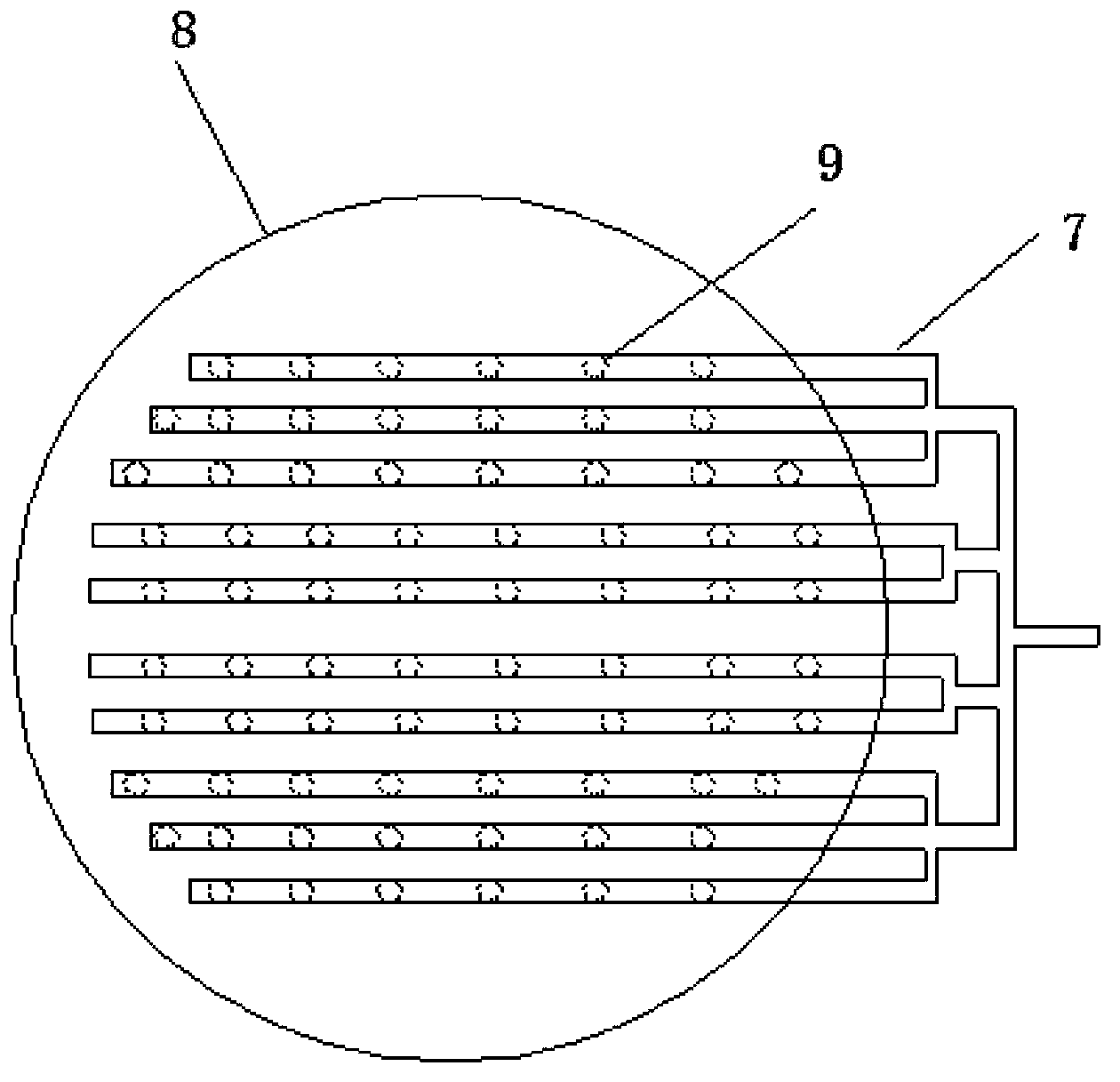

[0033] A thickening process for crude adipic acid, in which a static cluster thickener is used, the thickener is composed of a thickener shell side 7 and a thickener tube side 8, and a candle wick filter element is used to increase Several filter elements 9 are arranged on the filter tube of the tube side of the thickener. The whole operation process adopts sequential automatic control program.

[0034] At the beginning of a filtration cycle, the control system first runs a self-inspection program to check whether the liquid levels in the crude adipic acid slurry tank 1 and the crude adipic acid thickener 3 are normal. If the liquid level is normal, enter the filtration program .

[0035] The filtering process is as follows:

[0036] (1) Feeding: Open the feed valve at the outlet of the feed pump 2 of the crude acid thickener to pump the crude adipic acid slurry into the crude adipic acid thickener 3, and the opening time is 180 seconds. The regulating valve controls the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com