Industrial production method for removing active carbon in adipic acid solution

A production method and technology of activated carbon, which are applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, separation methods, etc., can solve the problems of unfavorable system safety and stability, difficult treatment of waste activated carbon, increase of leakage points of devices, etc. problems, to achieve the effect of improving equipment production capacity, improving safety and reliability, and reducing leakage points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

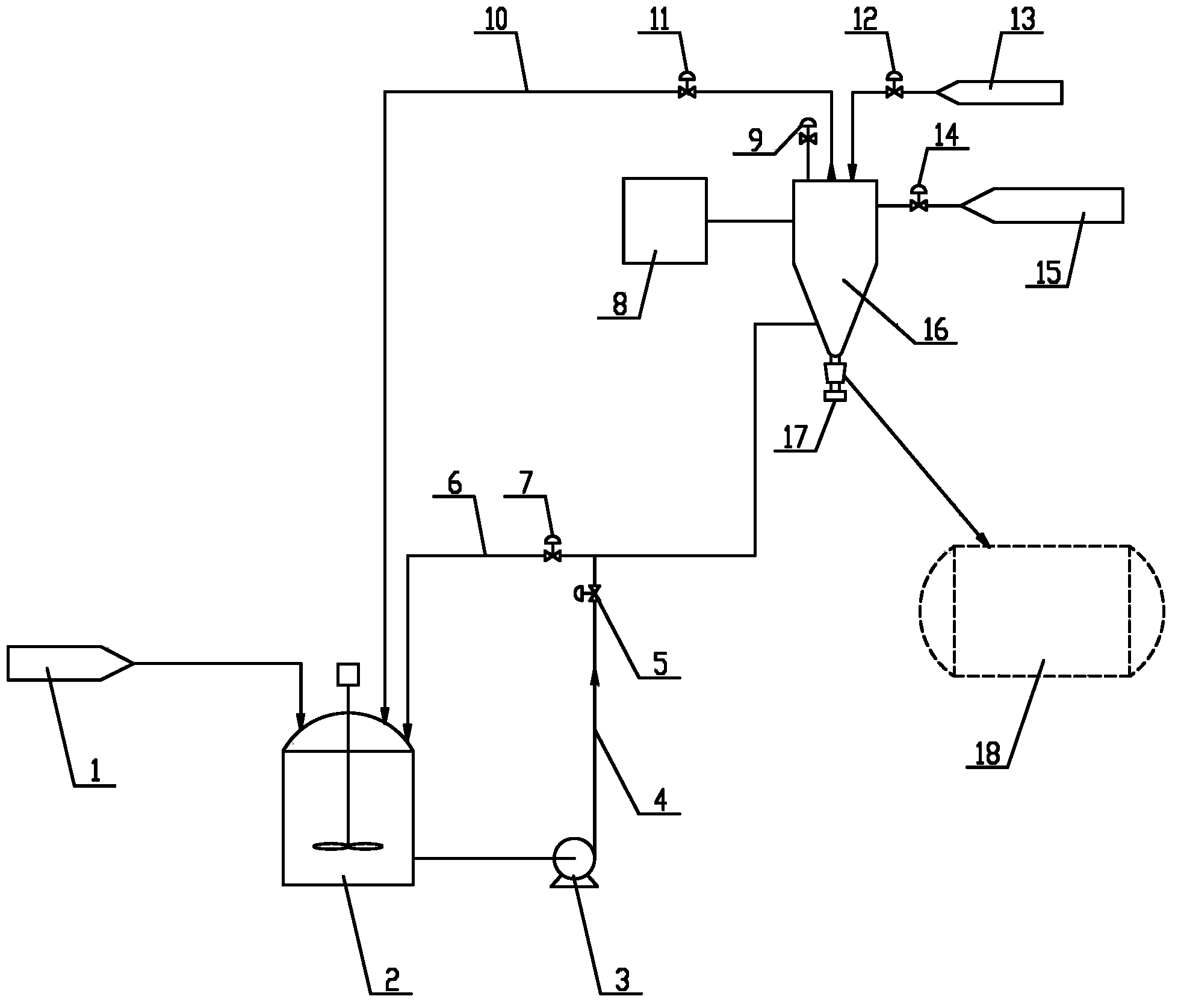

[0027] As shown in the figure, this embodiment discloses a system for removing activated carbon in adipic acid solution, which mainly includes an activated carbon treatment tank 2 , a feed pump 3 and a static cluster filter 16 .

[0028] The material 1 to be treated, that is, the adipic acid solution containing activated carbon, is sent to the activated carbon treatment tank 2, and the activated carbon treatment tank 2 is equipped with a stirrer to ensure that the activated carbon is evenly distributed in the solution.

[0029] The activated carbon treatment tank 2 is connected with a feed pump 3, and the feed pump 3 is connected to a static cluster filter 16 through a feed pipeline 4, and a feed valve 5 is arranged on the feed pipeline 4. The static cluster filter 16 adopts a candle wick filter element, and the structural form of the static cluster filter 16 is a combined structure of six filter tubes and a central outlet tube.

[0030] The static cluster filter 16 is connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com