Coal slime water two-stage filtration process

A coal slime water and coal slime technology, applied in the direction of filtration separation, separation device, separation method, etc., can solve the problems of slow filtration speed, small processing capacity of filter press, high solid content of filtrate, etc., and achieve short filtration cycle and fast filtration speed , The effect of low solid content of filtrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

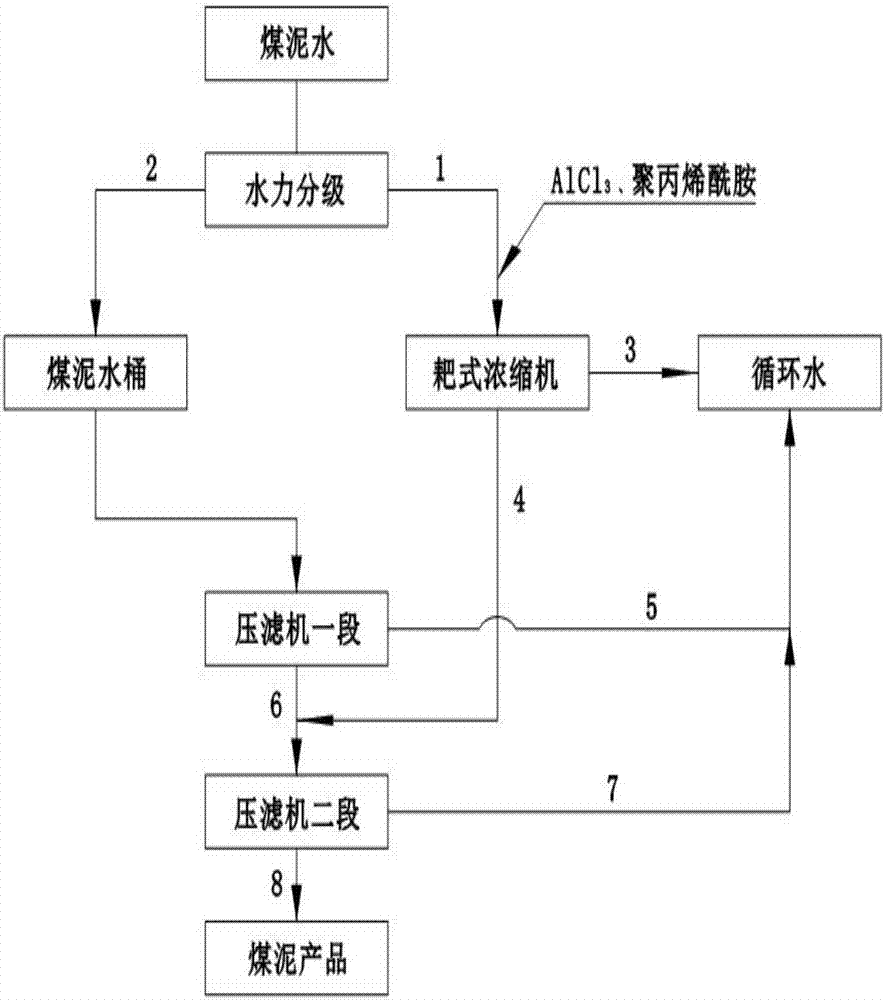

[0016] The coal slime water with a particle size of less than 0.074mm in the coal slime is 60% and the feed concentration is 400g / L. The filter area of the filter press is 78.5cm 2 , filter chamber thickness 2.5cm, under filter pressure 0.4Mpa, carry out coal slime water two-stage filtration as example, the coal slime water two-stage filtration process embodiment of the present invention is:

[0017] A. Use the hydraulic grading cyclone to classify the coal slime water 0.074mm, and the hydraulic grading cyclone overflow (1) containing the coal slime with a particle size of less than 0.074mm enters the rake thickener, and the hydraulic grading cyclone containing the coal slime with a particle size greater than 0.074mm Flow device underflow (2) enters the coal slime bucket;

[0018] B. Add AlCl3, polyacrylamide successively in the rake thickener, the overflow (3) of the rake thickener enters circulating water, and the underflow (4) of the rake thickener is used as the feeding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com