Tower crane standard knot bearing upper air supporting formwork steel platform structure and construction method

A platform structure and construction method technology, applied in the direction of building structure support, building structure support, formwork/formwork/working frame, etc., to achieve the effect of high erection height, clear force transmission, and convenient transportation of vehicles and large machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

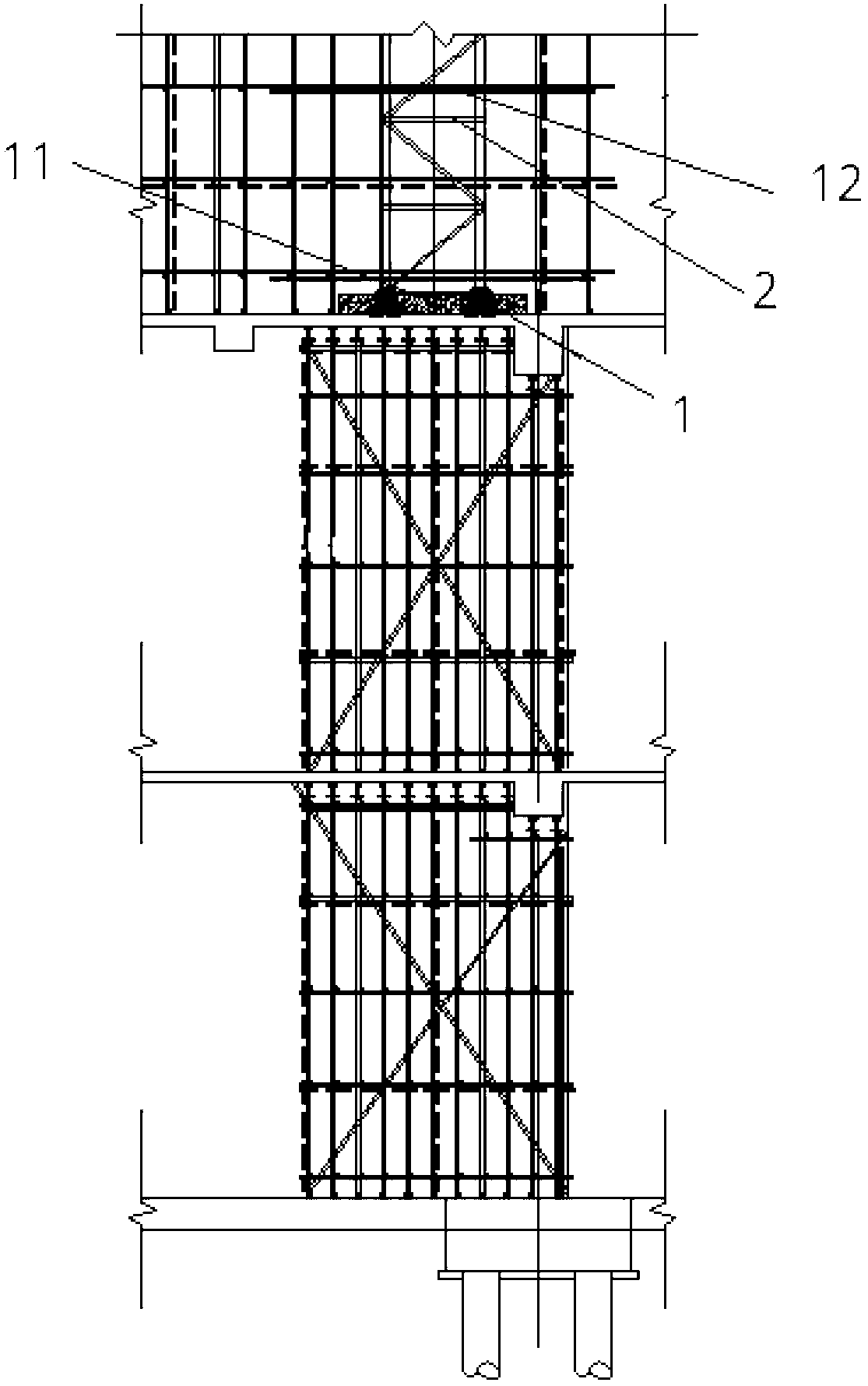

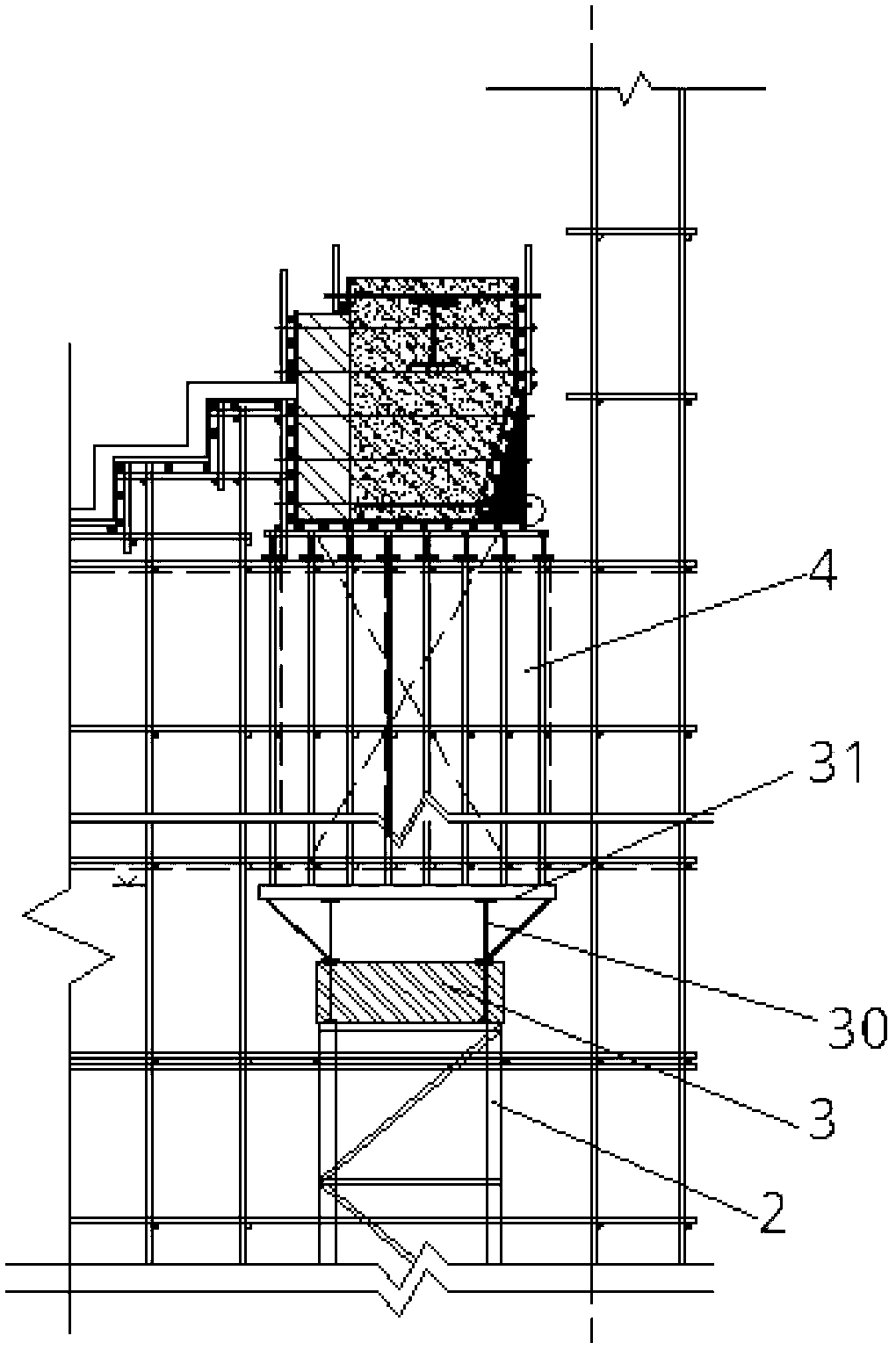

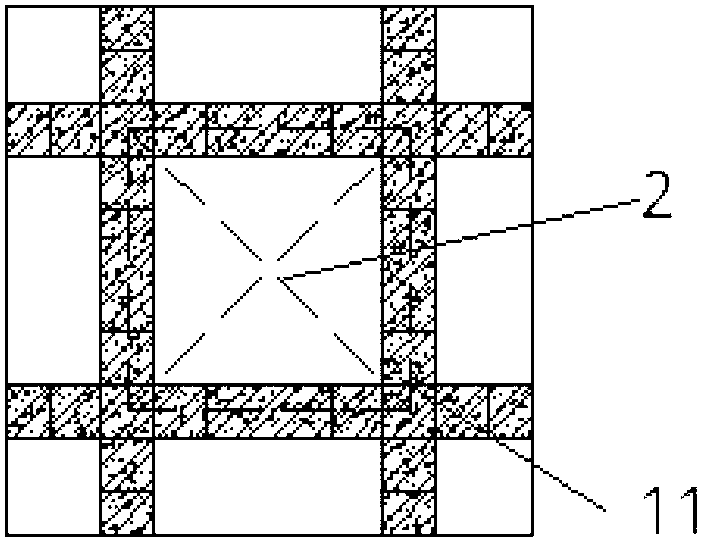

[0028] Such as Figure 1 to Figure 5 The tower crane standard section supports the high-altitude formwork steel platform structure, which includes the tower crane standard section lattice column foundation 1 and the tower crane standard section 2 of the lattice column structure installed on the tower crane standard section lattice column foundation. Surrounded by surrounding formwork supports 12, the top of the tower crane standard section is provided with a mouth-shaped or I-shaped top support 3, a steel platform is installed on the top support, and a steel pipe support frame 4 is installed on the steel platform. A well-shaped concealed beam 11 is arranged in the lattice column foundation of the tower crane standard section, and the bottom of the tower crane standard section is fastened with bolts embedded in the concealed beam. The lattice column of the tower crane standard section is provided with hoops along the height of the column to connect with the surrounding formwork...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com