Twin-screw extruder die head for plastic particle production

A twin-screw extruder and plastic pellet technology, applied in the field of plastic pellet production and processing equipment, can solve the problems of reducing the extrusion efficiency of the twin-screw extruder, no patent publications have been found, wasting manpower and material resources, and saving manpower The effect of transitivity, prolonging the molding time, and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0020] The structures, connections and methods not described in detail in this patent application can be understood as common knowledge in this field.

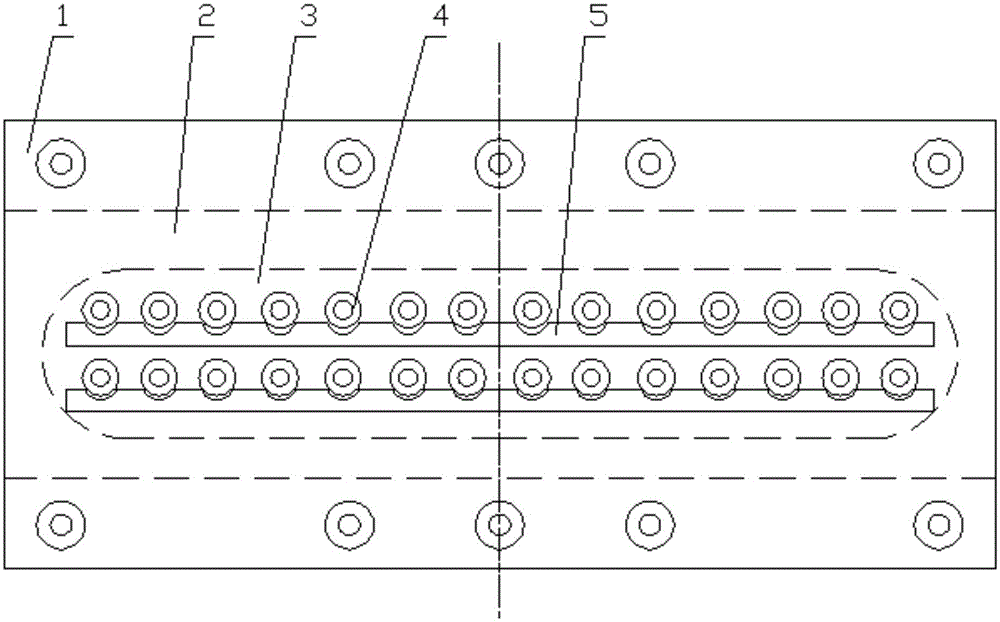

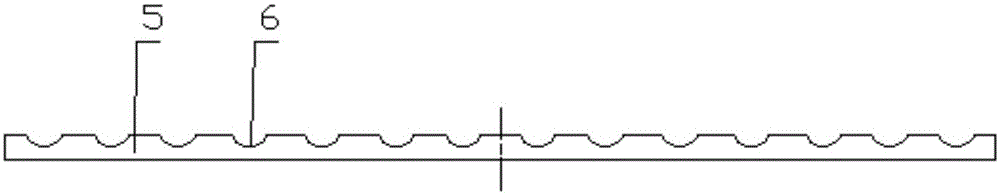

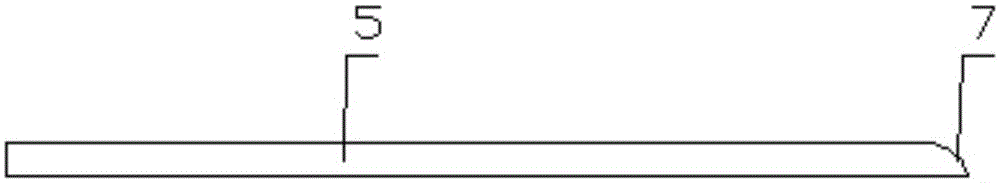

[0021] A twin-screw extruder die head for the production of plastic granules, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the head includes a die body 1 that can be fixedly connected to the head of a twin-screw extruder, a positioning guide groove 2, a grooved flow channel 3, a die hole 4 and a molding strip plastic support plate 5. In the middle of the inner side of the die body, a positioning guide groove connecting the radial direction of the machine head is formed. In the middle of the bottom of the positioning guide groove, a groove-type flow channel is formed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com