Automatic laser engraving system based on computer vision and service method of automatic laser engraving system

A computer vision and laser engraving technology, applied in decorative arts, processing models, etc., can solve problems such as excessive manual contact, achieve the effect of improving accuracy, reducing product scrap rate, and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

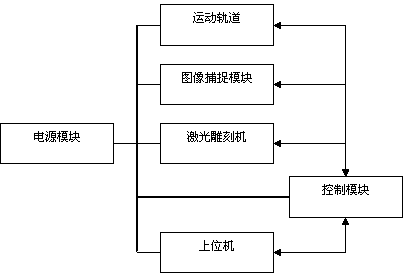

[0039] An automatic laser engraving system based on computer vision, including:

[0040] A motion track: used to carry and drive the product to reciprocate during the production process;

[0041] An image capture module: used to obtain a video image of a certain position of the product on the moving track;

[0042] 1. Laser engraving machine: laser engraving for products;

[0043] A control module: send control signals to control the start and stop of the motion track, the image capture module and the laser engraving machine respectively;

[0044] A host computer: control the motion of the motion track by interacting with the instructions of the control module, obtain images from the image capture module, perform product matching identification and positioning, and control the laser engraving machine to laser engrave the product;

[0045] A power supply module: providing power for the motion track, image capture module, laser engraving machine, control module and host comput...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com