Leadless ceramic chip type gas sensor

A technology of gas sensor and ceramic chip, which is applied in the field of gas sensor, can solve the problems of restricting the expansion and development of the industrial scale of gas sensor production, large dispersion of component performance parameters, limiting development and use direction, etc., and achieving high efficiency Automated production, outstanding practicability, and the effect of solving poor seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

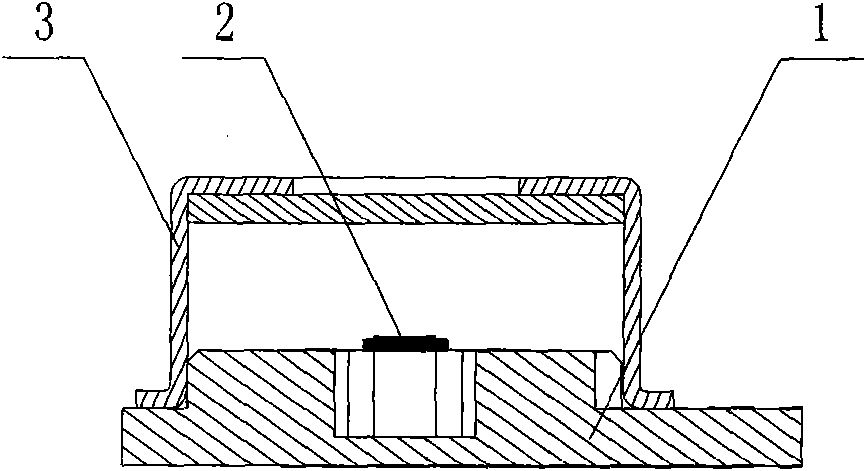

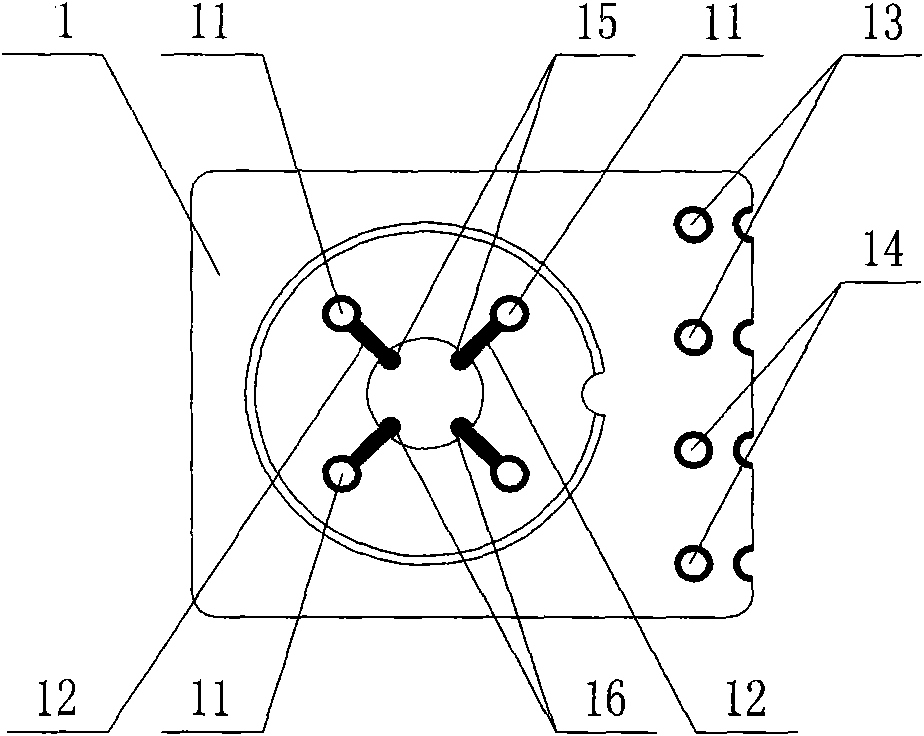

[0018] Such as figure 1 As shown, a leadless ceramic chip gas sensor, it includes a ceramic base 1, a ceramic chip gas sensor chip 2 and a metal shell 3, the ceramic base 1 and the ceramic chip gas sensor chip 2 Encapsulated in the metal case 3;

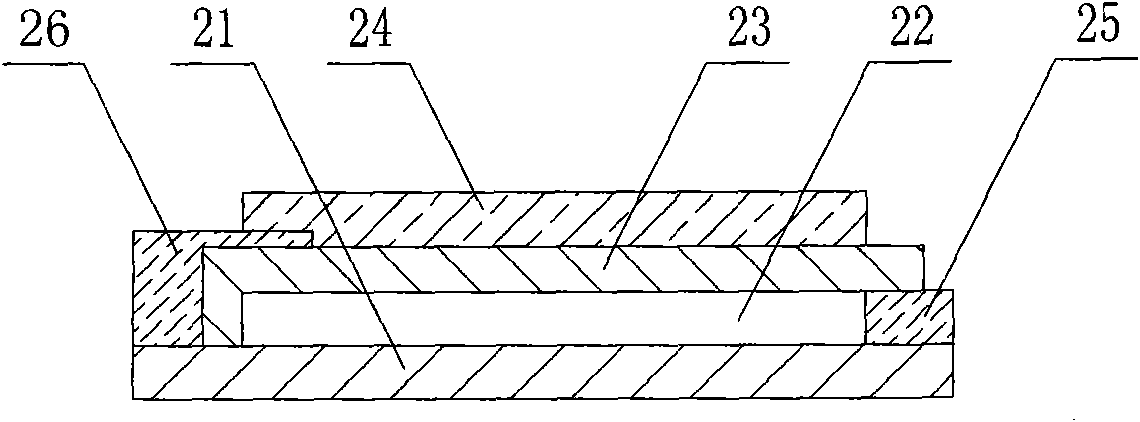

[0019] Such as figure 2 As shown, the ceramic chip gas sensor chip 2 includes a ceramic substrate 21, a heating resistor 22, a heating electrode 25 connected to the heating resistor 22, an isolation layer 23, a gas sensitive material 24 and a measuring electrode 26 connected to the gas sensitive material 24 , wherein one side of the ceramic substrate 21 and one side of the heating resistor 22 are printed together using thick film screen printing technology, and the other side of the heating resistor 22 and the side of the isolation layer 23 are printed using thick film silk Printed together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com