Small plastic part laser melting extrusion molding method and apparatus thereof

A technology of extrusion molding and laser melting, which is applied in the field of laser melting extrusion molding methods and devices for high-precision micro-sized plastic parts, can solve problems such as weld lines, and achieve the effects of eliminating weld lines, saving energy consumption, and high absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

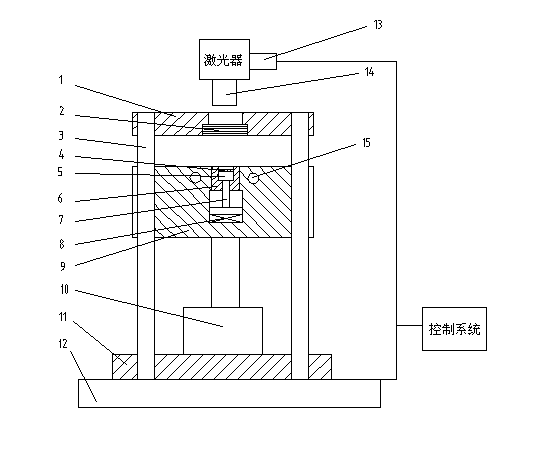

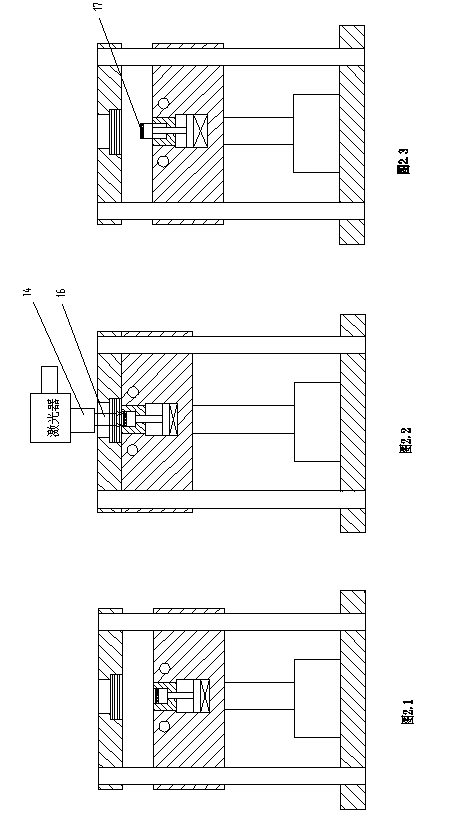

[0039] Such as figure 2 shown.

[0040] A laser melting extrusion molding device for micro-miniature plastic parts, it comprises the following steps:

[0041] a. According to the volume and weight of plastic parts, customize pre-processed plastic blanks, which can be powder, solid particles, etc.; calculate and determine the extrusion force, extrusion time, mold opening and closing time, etc. required for the molding process; set Determine the control program and operation commands of the control system.

[0042] b. Work preparation, accurate calculation and determination of laser parameters, so that the laser power, irradiation time, spot diameter, focal length, spot energy distribution and spot shape output by the infrared laser meet the processing requirements; the temperature heating controller starts to heat the moving template, and the heating temperature 5 to 20 degrees below the glass transition temperature of the plastic material;

[0043] c. When the work starts,...

example 1

[0050] Laser melting and extrusion molding of micro plastic gears, the material of micro plastic gears is PA12, the diameter of addendum circle is 1.2mm, the diameter of dedendum circle is 1mm, the number of teeth is 24, and the tooth thickness is 0.8mm. PA12 physical parameters: density 1.02g / cm 3 , Heat distortion temperature 68~150°C, melting temperature 186~190°C. First, the weight of each gear is calculated to be about 0.78mg; the laser parameters are selected as spot diameter 2mm, laser power 1W, focal length 100mm, and irradiation time 0.5s; the heating temperature range of the moving template is set to 60~65°C. Mold manufacturing must meet the requirements, especially, the mold cavity of the shaped core is precisely machined according to the outer dimensions of the plastic gear parts, and the movable core and the shaped core are precisely matched to ensure that the movable core can slide and cooperate in the shaped core. When the work starts, the extrusion mold is ope...

example 2

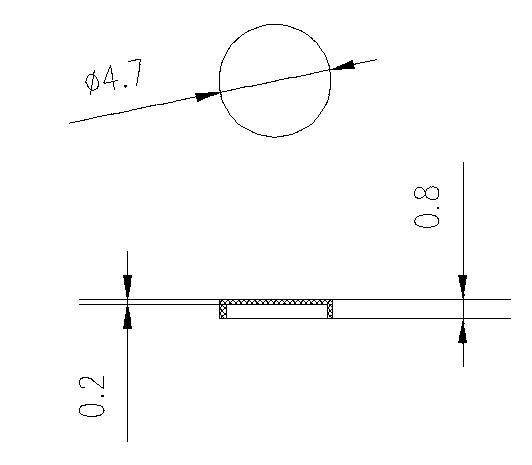

[0052] Laser melting extrusion molding of small shell plastic parts, small shell plastic parts such as image 3 As shown, the diameter of the outer circle is 4.7mm, the wall thickness is 0.2mm, the height is 0.8mm, the material is PC, and the physical parameters of PC are: density 1.19g / cm 3 , Heat distortion temperature 120~200°C, melting temperature 240~290°C. First, the weight of each plastic part is calculated to be about 2.7mg; the laser parameters are selected as spot diameter 5mm, laser power 5W, focal length 100mm, and irradiation time 0.2s; the heating temperature range of the moving template is set as: 105~115°C. When the work starts, the extrusion mold is opened, the servo motor controls the brake plate to move downward, and at the same time the movable core moves downward in the fixed core, take 2.7mg of plastic PC powder material and add it to the mold cavity; after feeding, the servo motor controls the brake plate to move upward , until the movable template and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com