Preparation method of bismuth-containing paramagnetic Faraday optical rotation glass

A Faraday optical rotation and paramagnetic technology, which is applied in the field of preparation of paramagnetic Faraday optical glass, can solve the problems of low melting temperature, high content of rare earth oxides and high Verdet constant, and achieves low melting temperature and rare earth oxides. The effect of high content and large Feld's constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: 1) First, 28 mol% of Er was 2 O 3 , 16 mol% Bi 2 O 3 , 17mol% B 2 O 3 , 35mol% Al 2 O 3 , 3mol% SiO 2 , 0.5 mol% Sb 2 O 3 and 0.5mol% ZrO 2 After mixing evenly, the batch material is formed;

[0024] 2) Then, add the prepared batches into a corundum crucible at 1200°C in two times. After adding the lid, the temperature is raised to 1300°C within 10 minutes. Continue to keep warm for 1h;

[0025]3) Finally, pour the molten glass into a graphite mold at 500°C, cool it and put it into a furnace at 550°C, keep it for 3 hours, and cool it to room temperature at a cooling rate of 1°C / min to obtain a paramagnetic material containing bismuth. Faraday Optical Glass.

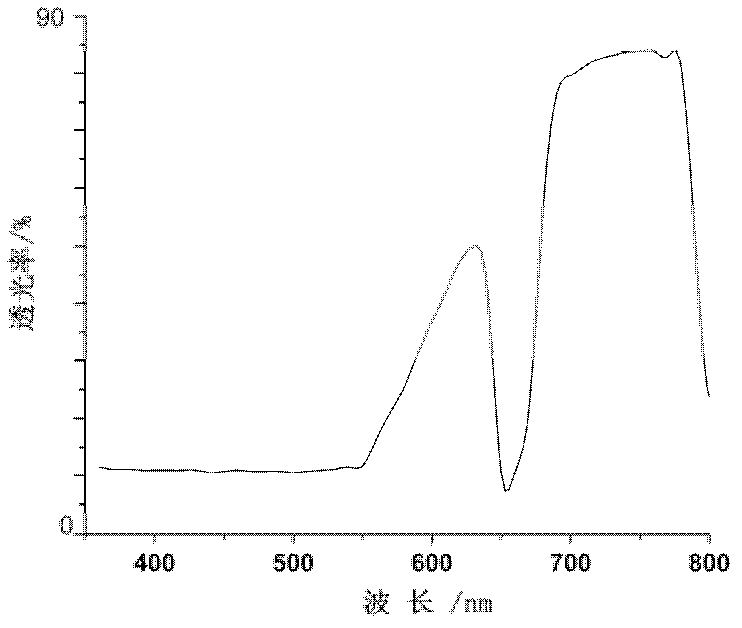

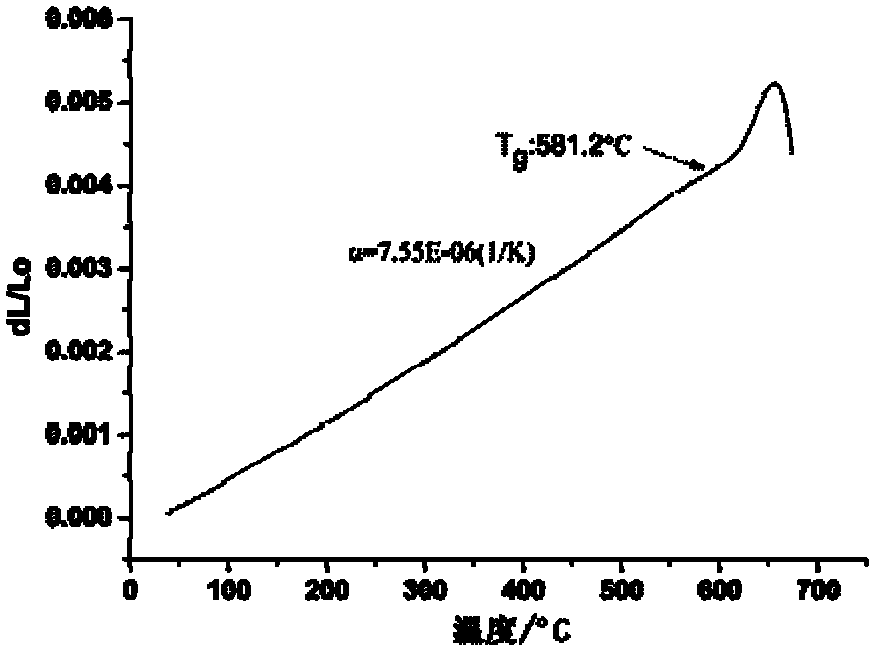

[0026] The Verdet constant of the sample tested by the WFC Faraday effect tester is -0.21min / Oe.cm, and the transmittance curve of the sample tested by the spectrophotometer is as follows figure 1 As shown, the linear expansion curve of the test sample by NETZSCH DIL 402PC is as follows f...

Embodiment 2

[0029] Example 2: 1) First, according to the mole fraction, 32 mol% of Er was 2 O 3 , 15mol% Bi 2 O 3 , 18mol% B 2 O 3 , 32mol% Al 2 O 3 , 2mol% SiO 2 , 0.5 mol% Sb 2 O 3 and 0.5mol% ZrO 2 After mixing evenly, the batch material is formed;

[0030] 2) Then, add the prepared batches into a corundum crucible at 1200°C in two times. After adding the lid, the temperature is raised to 1350°C within 10 minutes. Continue to keep warm for 1h;

[0031] 3) Finally, pour the molten glass into a graphite mold at 500°C, cool it and put it into a furnace at 550°C, keep it for 3 hours, and cool it to room temperature at a cooling rate of 1°C / min to obtain a paramagnetic material containing bismuth. Faraday Optical Glass.

[0032] The Verdet constant of the sample tested by the WFC Faraday effect tester was -0.24min / Oe.cm.

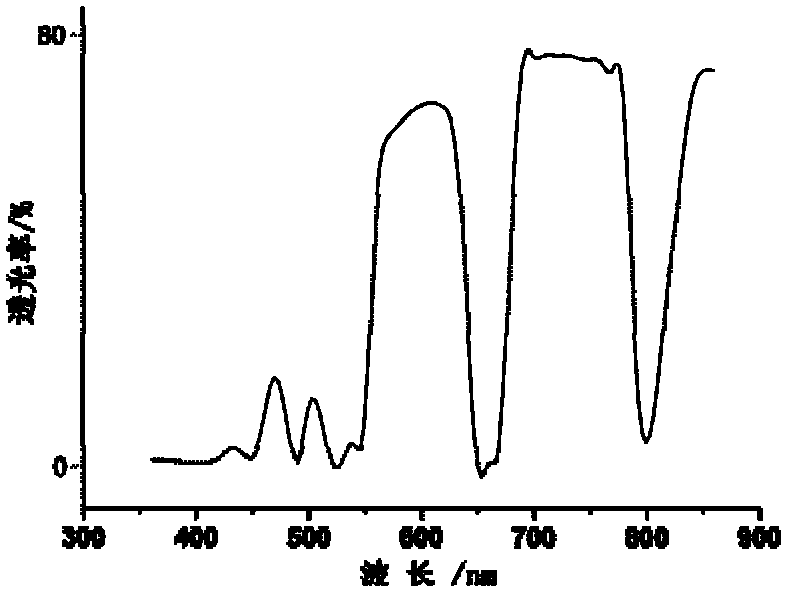

[0033] see attached image 3 , is the transmittance curve of the prepared bismuth-containing paramagnetic Faraday rotatory glass in the visible light range...

Embodiment 3

[0035] Example 3: 1) First, according to the mole fraction, 17 mol% of Er was 2 O 3 , 15mol% Bi 2 O 3 , 30mol% B 2 O 3 , 36mol% Al 2 O 3 and 2mol% SiO 2 After mixing evenly, the batch material is formed;

[0036] 2) Then, add the prepared batches into a corundum crucible at 1100°C in two times. After adding the lid, the temperature is raised to 1200°C within 10 minutes. Continue to keep warm for 1h;

[0037] 3) Finally, pour the molten glass into a graphite mold at 500°C, cool it and put it into a furnace at 550°C, keep it for 3 hours, and cool it to room temperature at a cooling rate of 1°C / min to obtain a paramagnetic material containing bismuth. Faraday Optical Glass.

[0038] The Verdet constant of the sample tested by the WFC Faraday effect tester was -0.13min / Oe.cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com