Method for producing a monocrystalline or polycrystalline semiconductor material

A polycrystalline semiconductor, semiconductor technology, applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve problems such as complex structure, achieve the effect of effective control, improved process parameter definition, and rapid melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

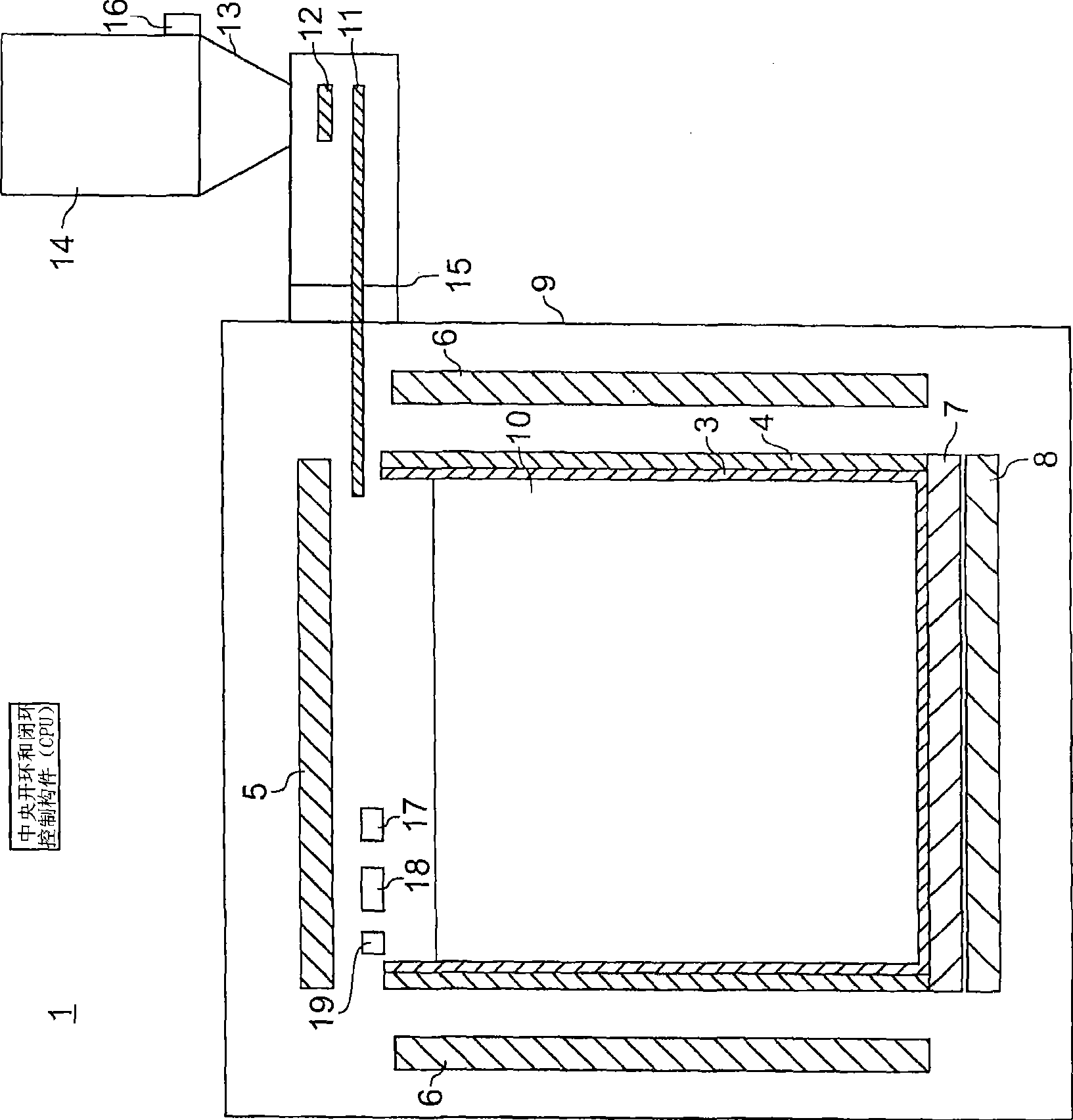

[0040] according to figure 1 , the crystallization system (whose whole is indicated by reference numeral 1) comprises a quartz crucible 3 completely and in close proximity contained in an upwardly open box-like support system 4, in order to provide a crystallization system already at the melting temperature of silicon The lower softened quartz crucible 3 provides sufficient mechanical support. The quartz crucible 3 reaches up to the upper edge of the support system 4, thus excluding direct contact of the silicon melt with graphite or other contaminating materials. Quartz crucible 3 is commercially available quartz crucible, and it has for example 550 * 550mm 2 、720×720mm 2 or 880×880mm 2 of the bottom area, and has an inner coating as the crucible SiO 2 between the silicon and the separator layer. The upper heater 5 is provided above the crucible, and its bottom area is greater than or equal to the bottom area of the crucible. A jacketed heater 6 surrounding the crucib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com