Electrical equipment connector lead temperature measuring device prepared by adopting fusible alloy

A technology of fusible alloys and electrical equipment, applied in measuring devices, thermometers with physical/chemical changes, thermometers, etc., can solve problems such as inconvenient pasting, inconsistent bonding areas, and easy misleading, so as to achieve obvious warning effects and avoid Time-consuming and labor-intensive, accurate fault heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

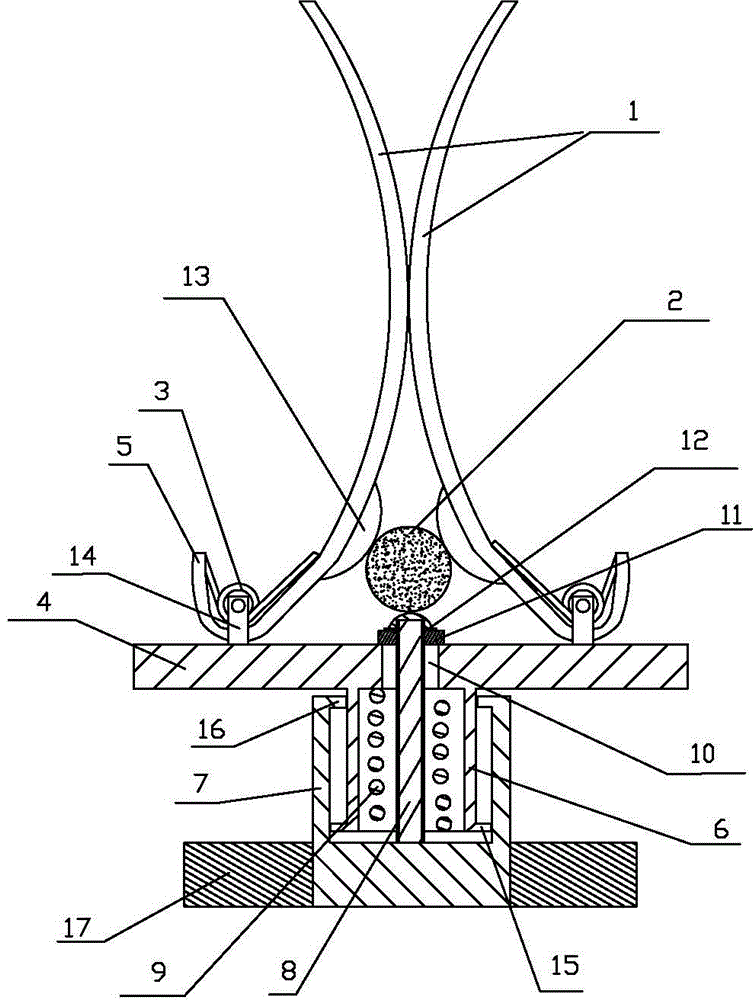

[0016] The temperature measuring device for electrical equipment joint wires made of fusible alloys includes an arc-shaped elastic clip 1, and the arc-shaped elastic clip 1 is provided with two left and right pieces, and the middle parts of the left and right two arc-shaped elastic clips 1 are opposite to each other. Contact, the upper openings of the left and right arc-shaped elastic clips 1 are snapped into the electrical equipment connector wire 2 through the upper openings of the left and right arc-shaped elastic clips 1, characterized in that: the left and right The lower ends of the two arc-shaped elastic clips 1 are provided with a semicircular curved section 5, and a coil spring 3 for clamping the lower ends of the left and right two arc-shaped elastic clips 1 is arranged in the semicircular curved section 5. The shaft end of the spring 3 is fixed to the circular seat plate 4 through the support plate 14, and the lower end of the left and right arc-shaped elastic clips ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com