Automatic cutting assembly equipment for draw-bar box and production process of automatic cutting assembly equipment

A technology for automatic cutting and assembling equipment, which is applied to other household appliances, household components, household appliances, etc. It can solve the problems of not being suitable for mass production, reducing production efficiency, and cumbersome assembly process, so as to achieve strong practicability and improve production. Efficiency, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

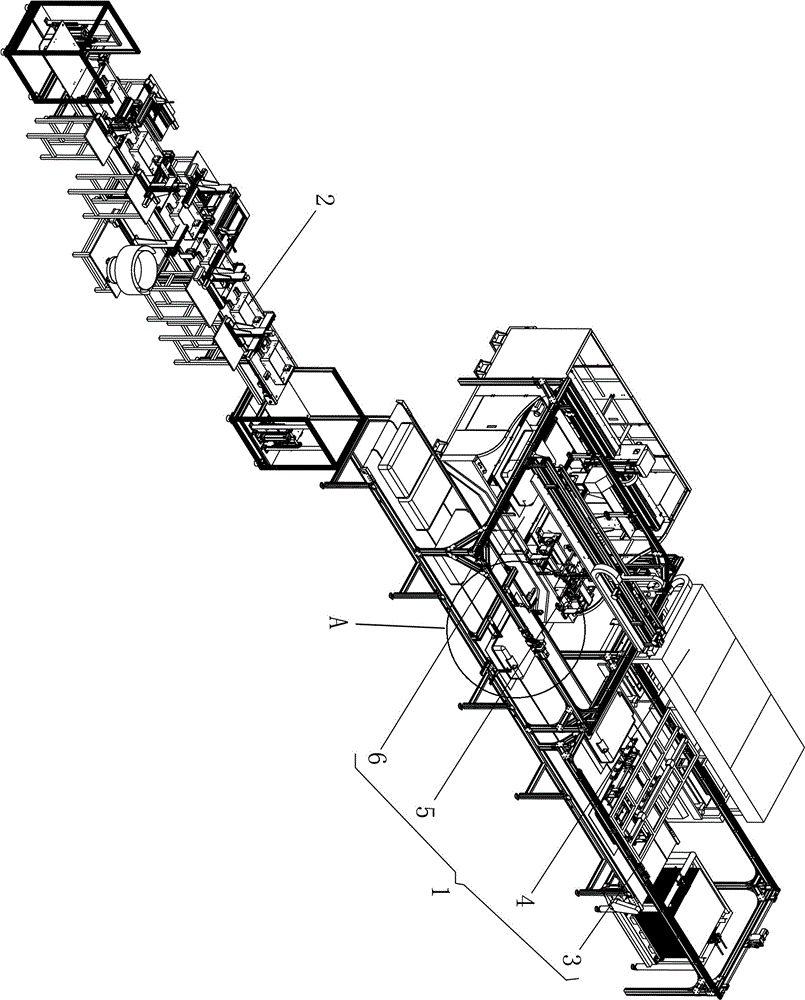

[0035] Such as Figure 1-8 As shown, an automatic cutting and assembling equipment for a trolley case and its production process, the overall equipment is composed of a processing part 1 and an assembling part 2, and the processing part 1 includes a feeding device 3 linked and matched by a whole frame, a blister Machine 4, detection device 5 and cutting device 6;

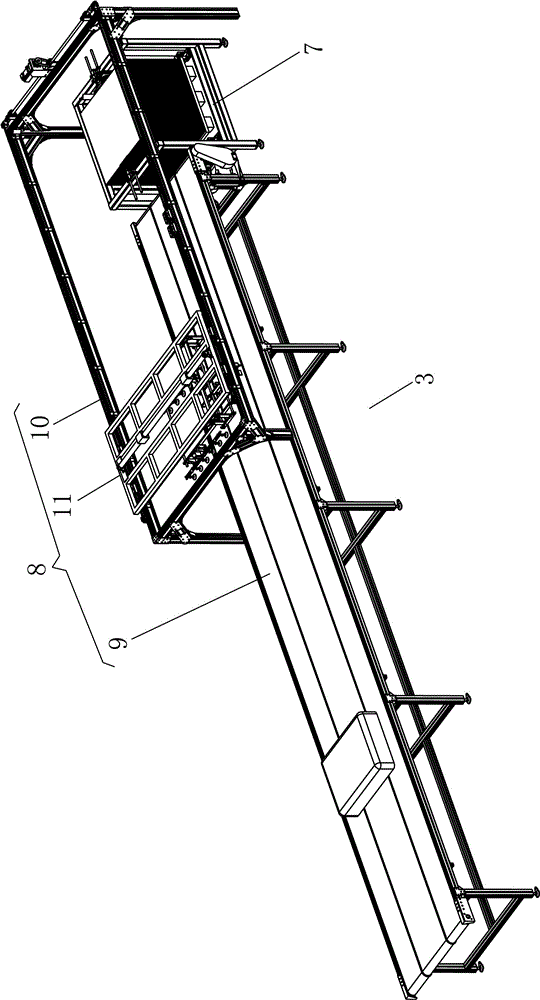

[0036] The feeding device 3 includes a lifting mechanism 7 and a conveying mechanism 8 that are respectively arranged on the frame, and the conveying mechanism 8 includes a feeding table 9 for conveying materials through a feeding belt, a slide rail 10 installed on the frame and The material suction assembly 11 slidably installed on the slide rail 10, through the material suction assembly 11, the raw materials in the lifting mechanism 7 are sucked and transported to the plastic suction machine arranged on the side of the feeding device 3 4 in;

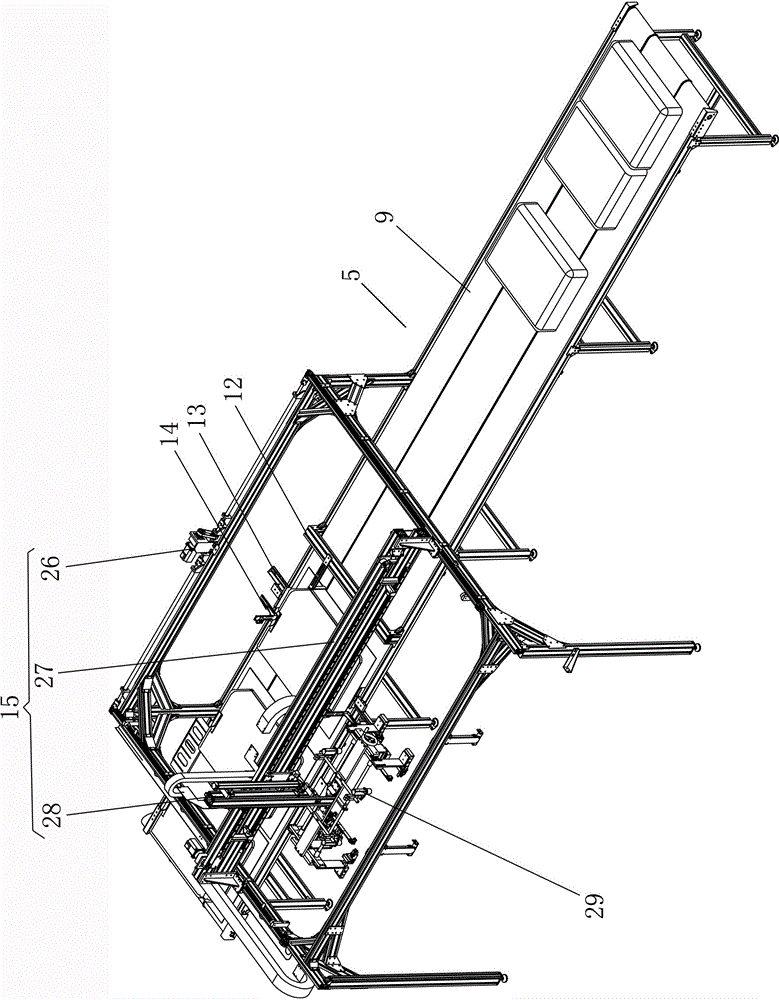

[0037]The detection device 5 includes a positioning mechanism 12, a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com