Hot plate type giant tire vulcanizing equipment

A hot plate and equipment technology, which is applied in the field of hot plate giant tire vulcanization equipment, can solve the problems of bulky size and complex structure, and achieve the effects of compact equipment structure, high heating efficiency, and improved orientation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

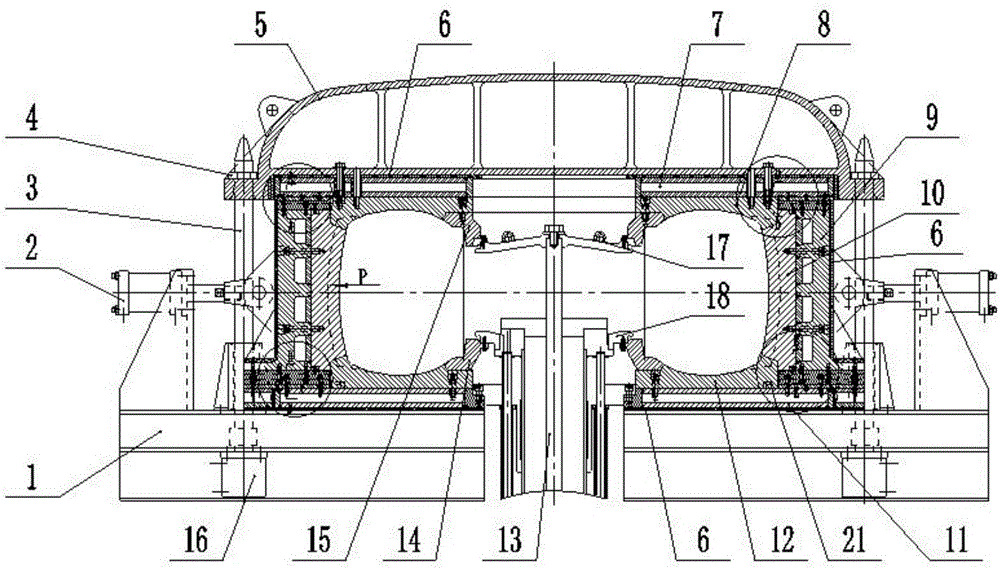

[0061] The giant tire mold includes an upper steel ring 15 and a lower steel ring 14, the upper steel ring 15 is matched with the upper side plate 8, the lower steel ring 14 is matched with the lower side plate 12, and the middle of the base 1 is set as hollow Structure, the hollow structure is provided with a central mechanism 13, and a capsule chuck on the top of the central mechanism 13, the capsule chuck includes a capsule upper chuck 17 and a capsule lower chuck 18, the capsule upper chuck 17 The lower chuck 18 and the lower capsule 18 cooperate with the upper steel ring 15 and the lower steel ring 14 to clamp the upper and lower edges of the capsule.

[0062] During vulcanization, the block 10 is opened by the slider 9 in the radial direction of the slider guide key 902 under the action of the block opening and closing drive device 2 to remove the upper side plate 8, and the center mechanism 13 drives the lower steel ring 14, the capsule The upper chuck 17 and the lower cap...

Embodiment 2

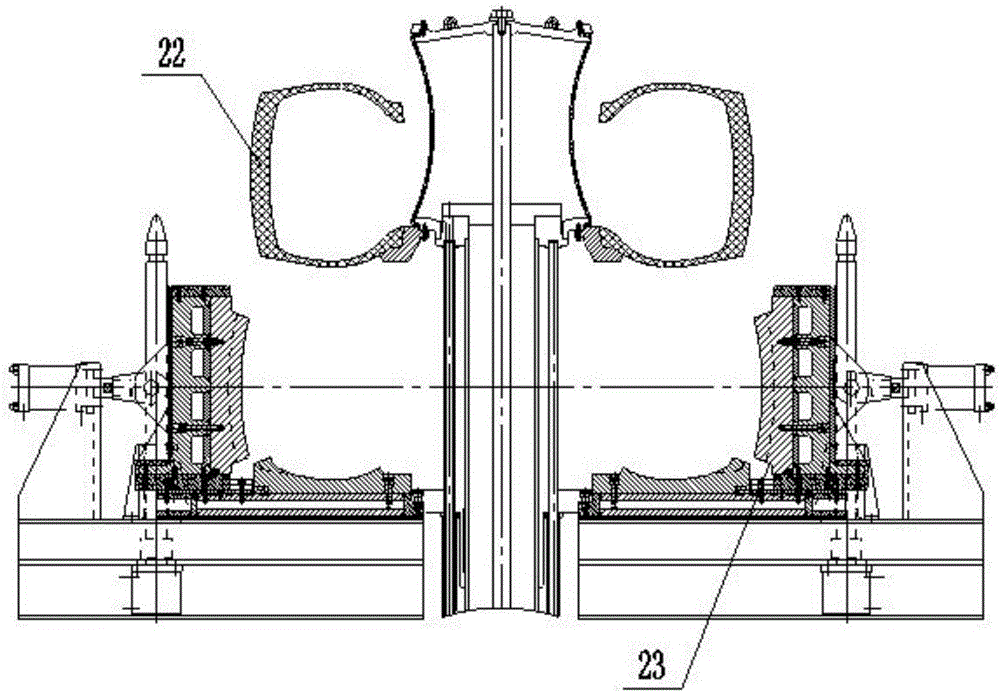

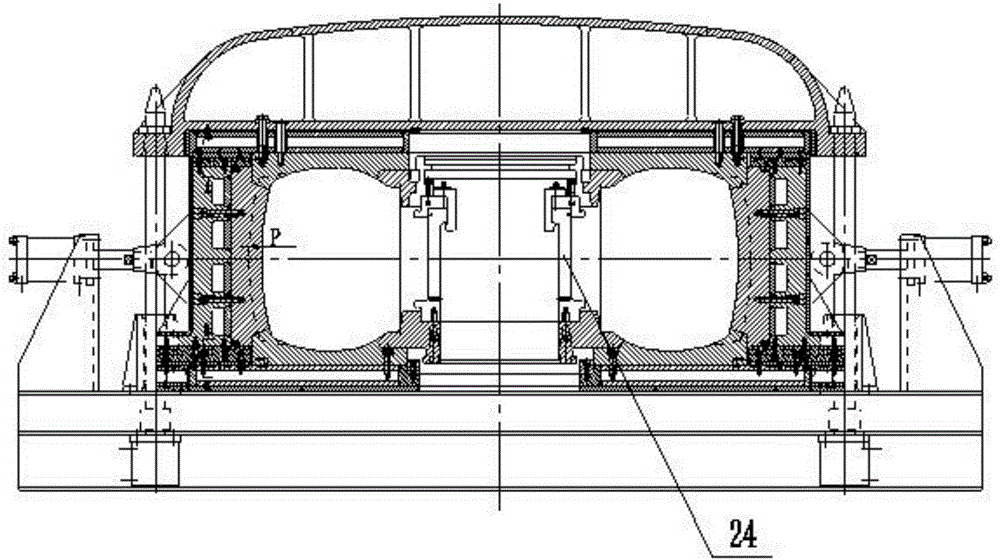

[0065] The same parts as in the first embodiment will not be repeated, such as image 3 , Figure 4 As shown, a clamping mechanism 24 is provided between the upper steel ring 15 and the lower steel ring 14. The clamping mechanism 24 includes an upper clamping ring 242 and a lower clamping ring 241. The lower clamping ring 241 and the lower steel ring 14 is matched, the upper clamping ring 242 is provided with a locking ring 243, the locking ring 243 is matched with the upper steel ring 15, and the upper clamping ring 242 and the lower clamping ring 241 are also provided with a securing block 244. This structure does not require an additional central mechanism 13, which saves costs.

[0066] During vulcanization, the upper side plate 8 is removed. After the tire blank 22 is installed on the external shaping equipment, it is fixed on the locking ring 243 with a lifting mechanism, and the clamping mechanism 24, the capsule and the tire blank 22 are hoisted into the vulcanizing equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com