Board discharge device in glass magnesium board production line

A board-out device and a technology of glass-magnesium boards, which are applied in stacking and receiving devices, transportation and packaging, thin material handling, etc., can solve the problems of labor-intensive and low-level automation of the production line, and achieve improved production efficiency, high-efficiency automated production, Avoid the effect of reducing the reliability of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

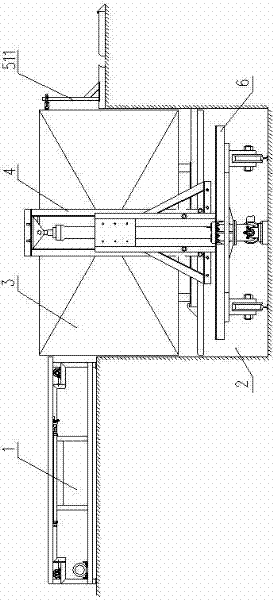

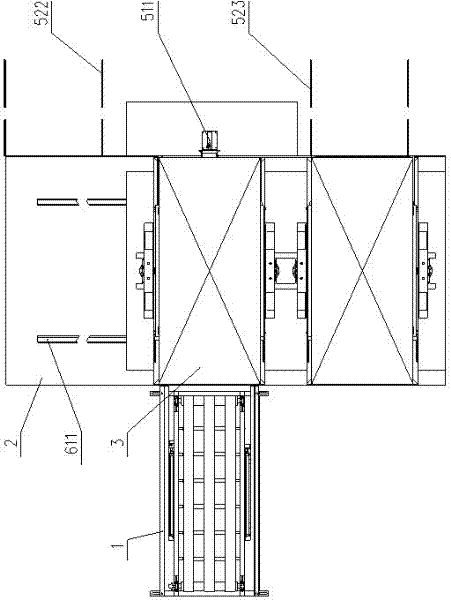

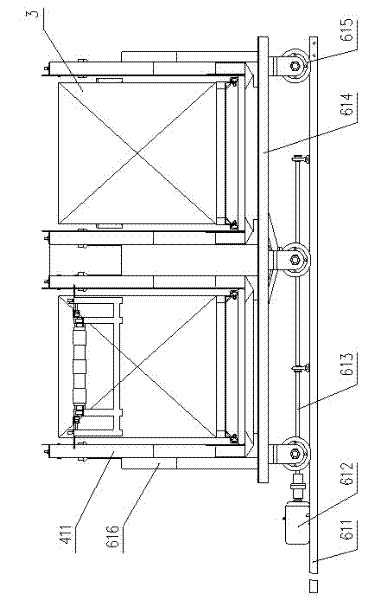

[0028] like figure 1 , figure 2 , image 3 As shown, the plate output device in the glass magnesium plate production line of the present invention includes a plate conveying device 1 connected to the tail end of the production line. The tail end of the plate conveying device 1 is provided with a pit 2 that can accommodate three lifting mechanisms. The conveying device is facing the middle of the pit 2; in the pit 2, there is a flat trolley mechanism 6 whose running direction is perpendicular to the conveying direction of the glass magnesium plate, and two lifting frames are fixedly installed on the flat trolley 614 in the flat trolley mechanism 6 Mechanism 4, each elevating frame mechanism 4 is provided with a transporting cage trolley 311, the structure of transporting cage trolley 311 sees Figure 11 , Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com