Inductor used for class D power amplifier and manufacturing method of inductor

A production method and inductance technology, applied in the direction of inductors, fixed inductors, fixed signal inductors, etc., can solve the problems of inability to absorb materials, low production efficiency, complicated alignment, etc., to reduce processes, realize automatic feeding, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary, and is not intended to limit the scope of the present invention and its application.

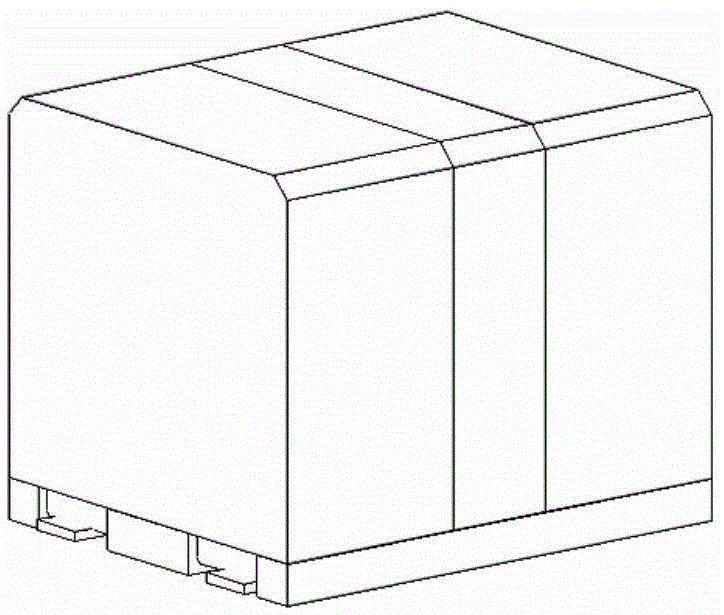

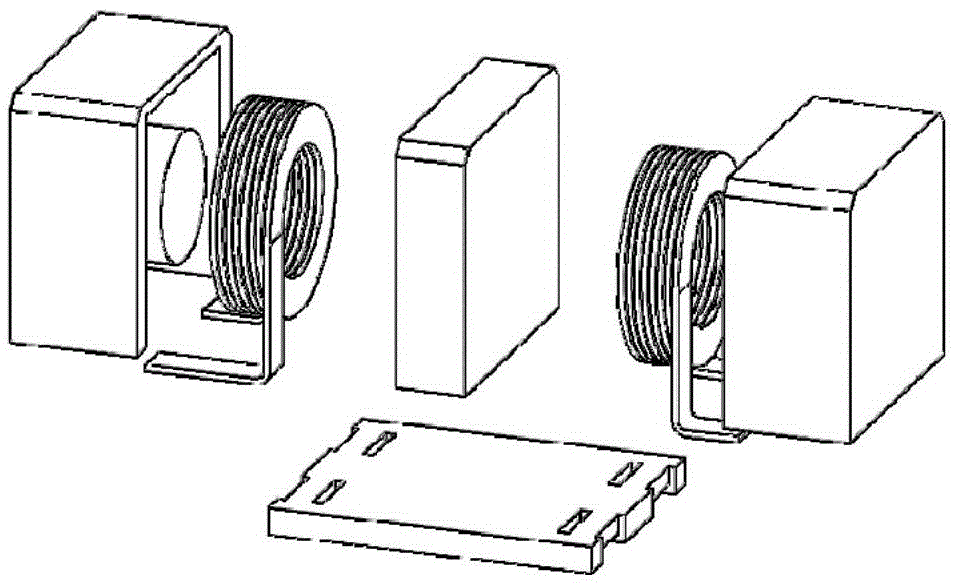

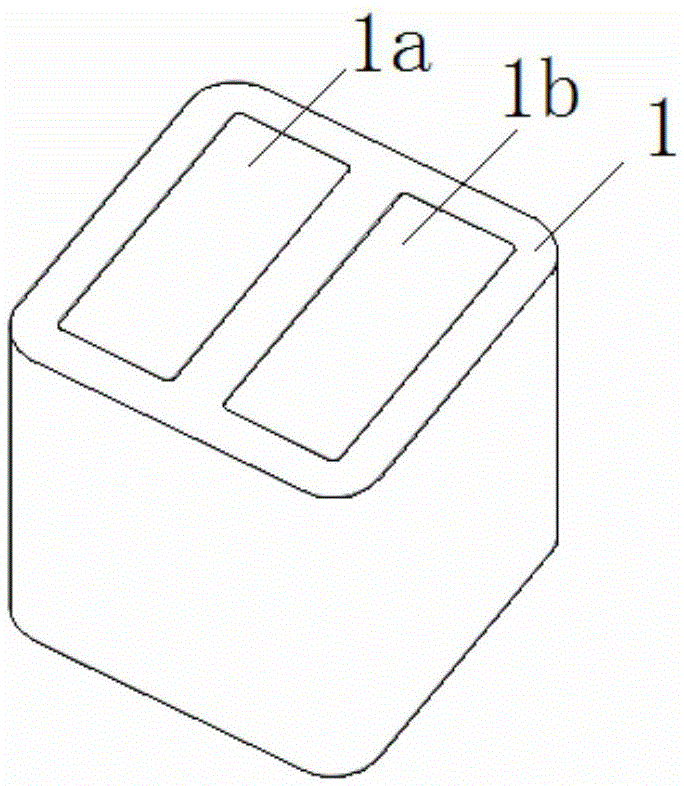

[0033] Refer to Figure 3 to Figure 7 In one embodiment, a class D power amplifier inductor includes a cap core 1, two rod cores 21, 22, two coil windings 31, 32, and a base 5. The cap core 1 The top surface of the cap core 1 is closed, and the bottom surface of the cap core 1 is opened to form two cavities 1a, 1b, and the two cavities 1a, 1b are separated by a middle wall, and the two rod cores 21 , 22 is independent of the cap core 1, the two rod cores 21, 22 are inserted into the two coil windings 31, 32, and the two coil windings 31, 32 with the rod cores 21, 22 are inserted respectively In the two cavities 1a, 1b, the base 5 covers the bottom surface of the cap core 1, and the terminals of the coil are led out from the electrode holes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com