Semi-finished grinding process of cement wind selection pre-grinding and device thereof

A pre-grinding and air-selection technology, which is applied in the field of cement grinding, can solve the problems of poor particle shape of the material discharged from the roller press, affecting the operability of concrete, and affecting the strength of clinker, etc. Reduce reactive power waste and reduce the effect of over-grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

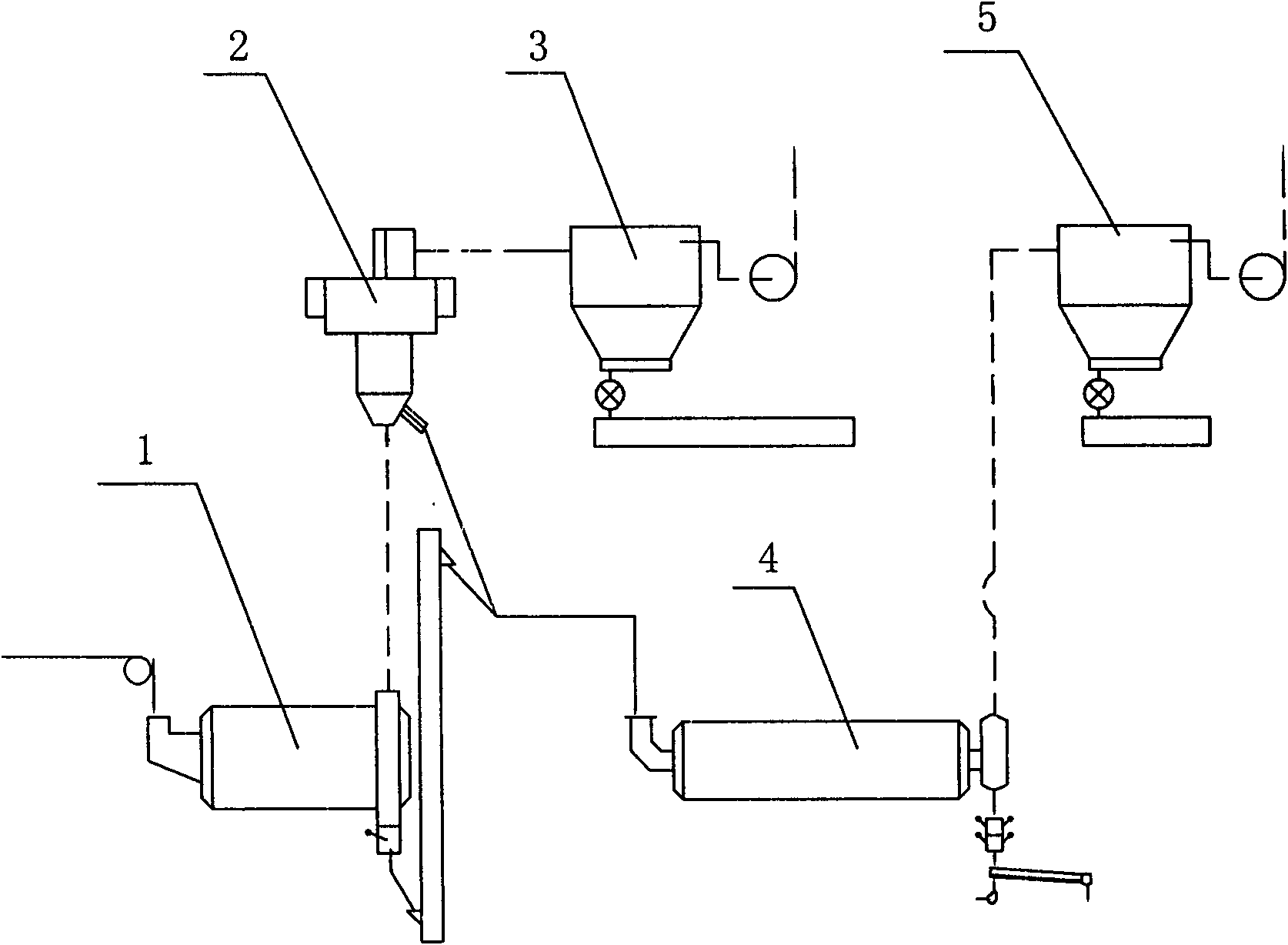

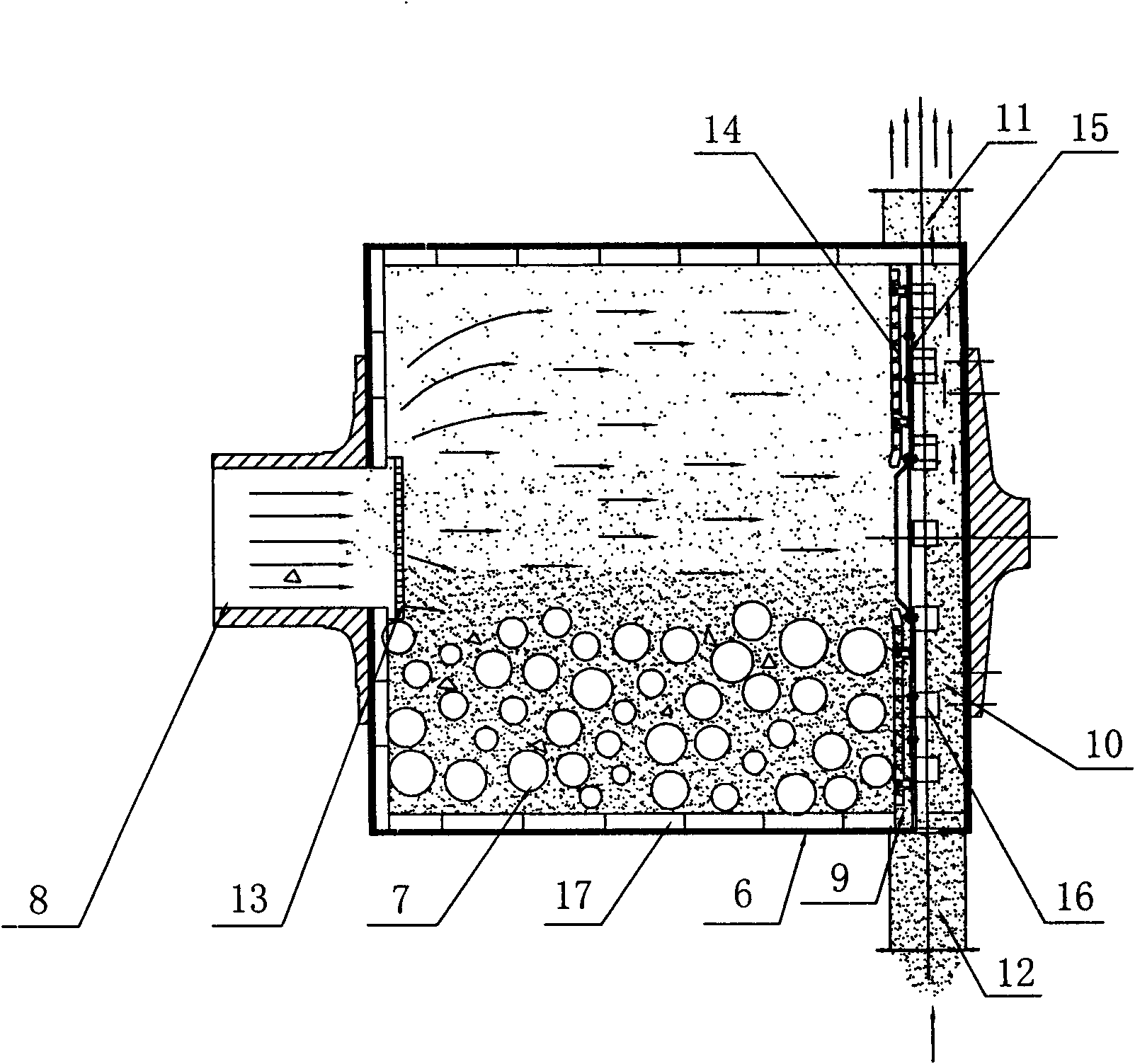

[0017] This embodiment is a kind of cement winnowing pre-grinding to do the semi-final grinding process, and the technological process is as follows: figure 1 shown, proceed as follows:

[0018] (1) Use wind selection pre-grinding machine 1 to carry out grinding rough selection to cement material;

[0019] (2) After the cement material is pre-ground by air selection in step (1), the fineness of some cement particles in the discharged material meets the requirements of the finished product, and the particle shape is relatively good. These fine powder materials rise with the air flow and pass through the dynamic powder separator 2. After sorting, the fine powder is directly used as a cement product after passing through the dust collector 3, and the coarse powder discharged from the winnowing pre-grinder 1 and the coarse powder discharged from the dynamic separator 2 are mixed together to enter the next step;

[0020] (3) Put the mixed coarse powder of step (2) into the ball mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com