Resin-bonded grinding wheel

A technology of bonding agent and resin, which is applied in the direction of abrasives, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient improvement of abrasive grain retention, and achieve excellent grinding ability, high surface accuracy, and less shedding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

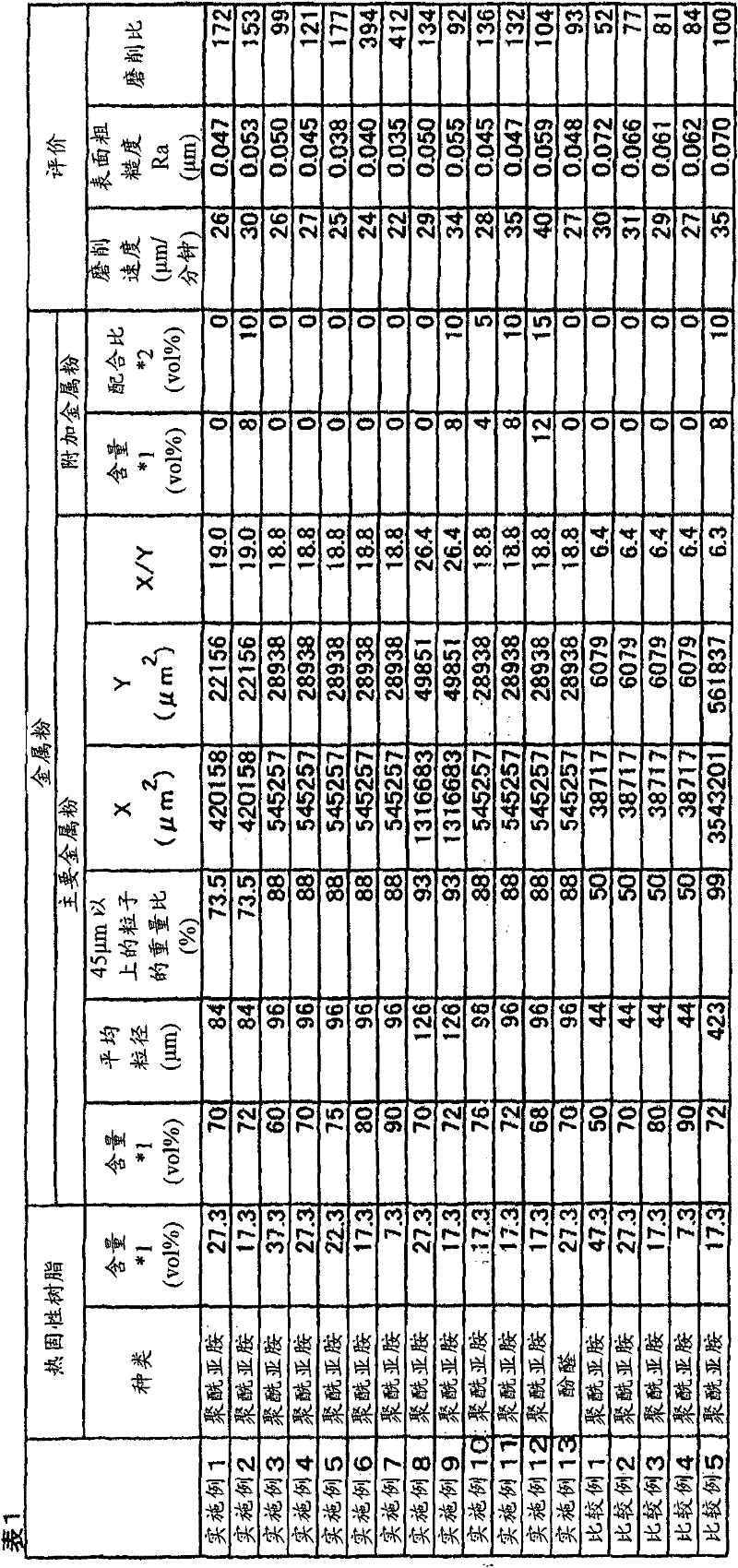

Embodiment 1~13 and comparative example 1~5

[0059] Abrasive grains, a thermosetting resin, and metal powder were combined as shown in Table 1, and samples provided with resin-bonded grinding wheels were produced by the following method.

[0060] In addition, among the abrasive grains, diamond abrasive grains having an average particle diameter of 6.8 μm were used, and the ratio to the total volume of the resin bonding layer was adjusted to 2.7% by volume. In addition, a polyimide resin and a phenolic resin were used as the thermosetting resin, specifically, Imidaroi KIR-30 (trade name, manufactured by Kyosera Chemical Co., Ltd.) name, manufactured by Ea Uota Co., Ltd.) as the phenolic resin. In addition, when the additional metal powder is used, powdered iron particles having an average particle diameter of 10 µm and a X' / Y' ratio of less than 10 are used.

[0061] Sample manufacturing method

[0062] 1. Mix the raw materials with a V-shaped pulverizer

[0063] 2. Fill the raw material mixture into the forming mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com