Method for manufacturing resin diamond line by non-plating diamond

A resin diamond wire and diamond technology, applied in the direction of manufacturing tools, stone processing equipment, fine working devices, etc., can solve the problems of harming the health of operators, complicated metal coating process, serious environmental pollution, etc. Conducive to long-term development and high cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

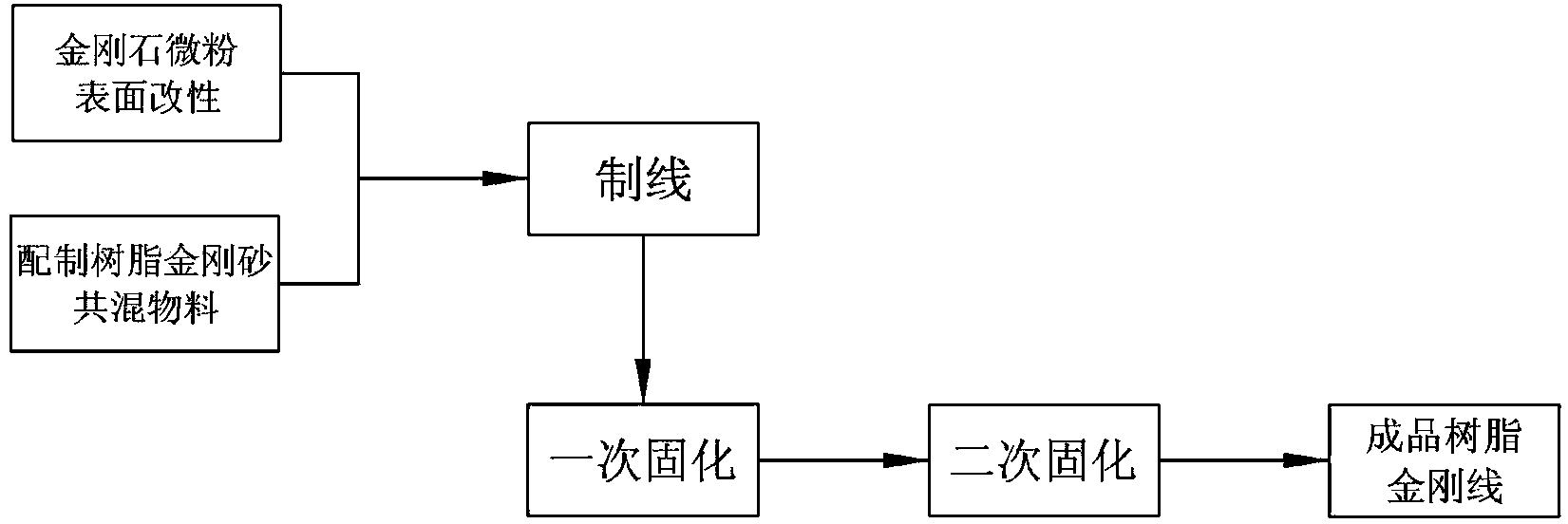

[0032] Embodiment 1: adopt the method of the present invention, produce resin diamond wire with non-plated diamond micropowder, production process is as follows:

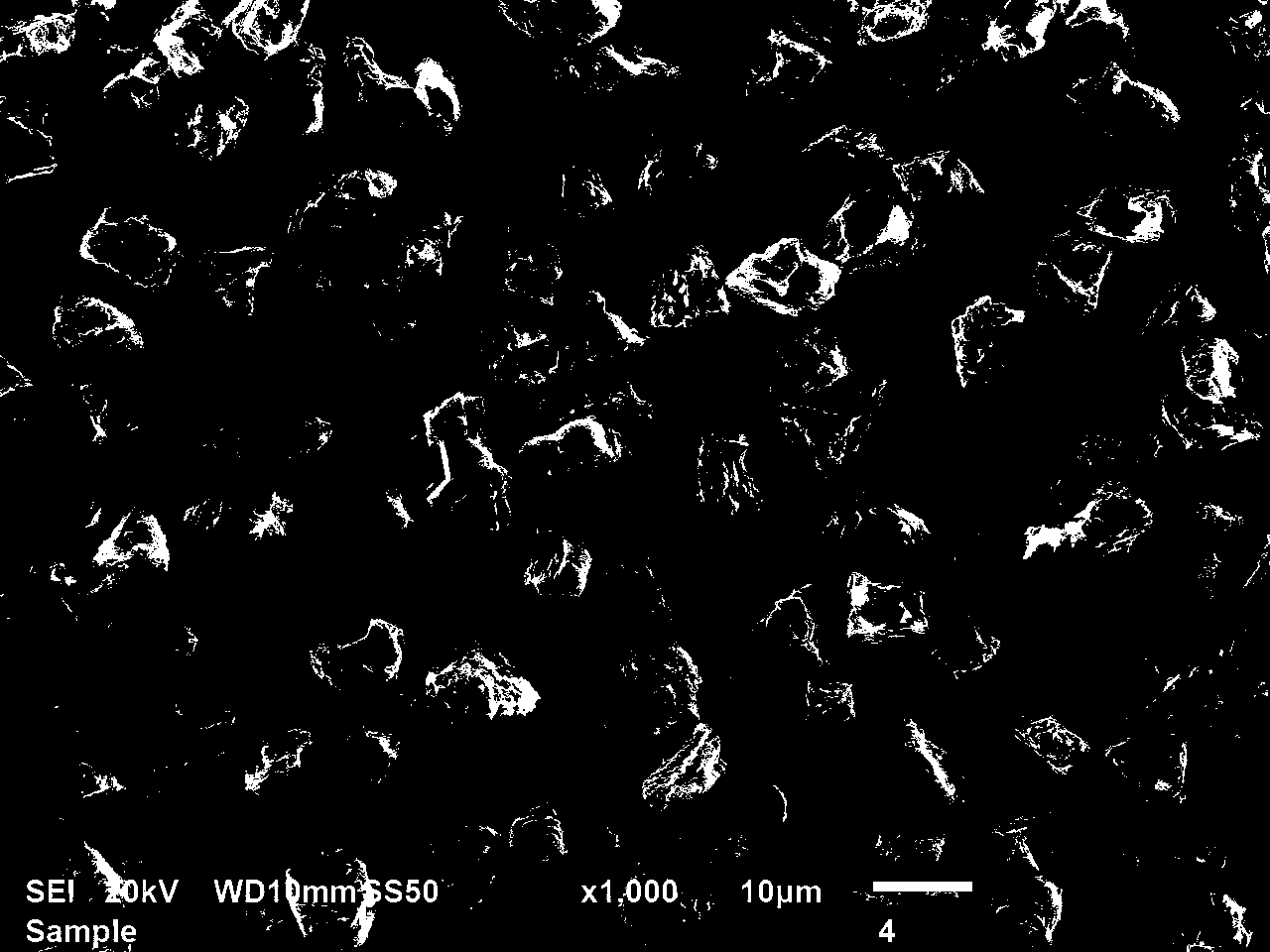

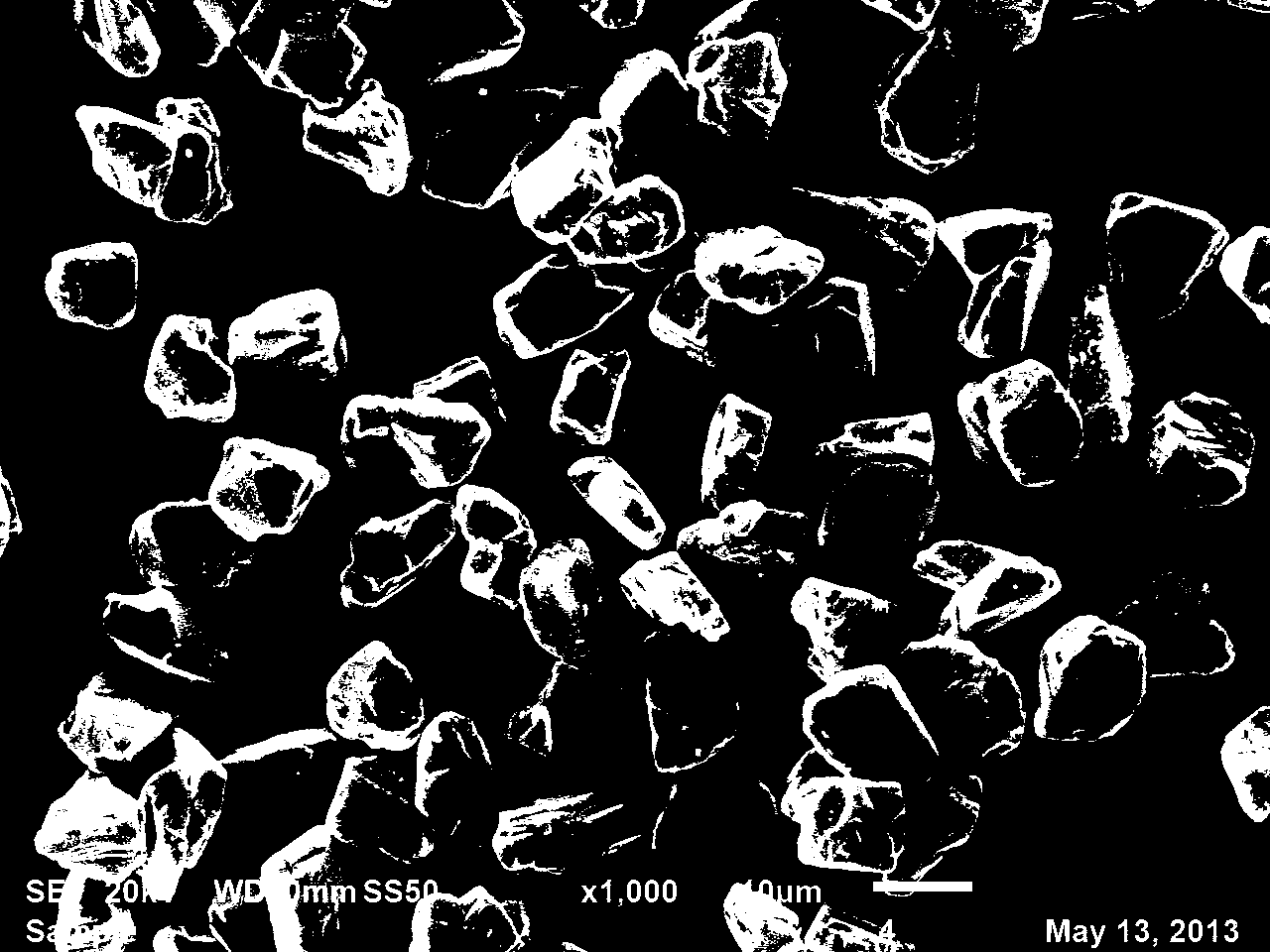

[0033] (1) Surface modification of diamond powder: Take single crystal diamond powder with a particle size range of 1-50 μm, remove the non-diamond carbon layer on the surface with 30% nitric acid, and then use 10% dehydrated sorbet Alcohol monostearate carries out surface modification treatment to it;

[0034] (2) Preparation of resin emery blended materials: take 28wt% of resin binder, 25wt% of organic solvent, 30wt% of diamond micropowder after surface modification treatment in step (1), SiC ultrafine particle size range of 1-5μm Powder 17wt%, mix and stir the resin binder and organic solvent, after the resin dissolves, add the above-mentioned diamond micropowder and SiC ultrafine powder, mix evenly to form a paste, and obtain the resin emery blended material; wherein, the resin The binder is phenolic resin, and...

Embodiment 2

[0038] Example 2: The difference from Example 1 is that the non-diamond carbon layer on the surface is removed with a mixed acid with a concentration of 30% in step (1), and then 10% polyacrylic acid and 15% by mass fraction are used. % fatty alcohol polyoxyethylene ether successively carries out surface modification treatment to diamond micropowder; This mixed acid is the mixing of sulfuric acid and perchloric acid, wherein the ratio of sulfuric acid and perchloric acid is 3:1; In step (2), resin emery The weight percentages of each component in the blended material are: resin binder 25wt%, organic solvent 23wt%, diamond micropowder 30wt%, SiC ultrafine powder 22wt%, wherein the resin binder is epoxy resin and acrylic resin Mixture; in step (3), the wire feeding speed is 0.2m / s; in step (4), heat and solidify at a temperature of 1000°C for 15 minutes; in step (5), heat up to 450°C within 25h, and then keep warm for 8h. Then cool down to room temperature naturally.

Embodiment 3

[0039]Example 3: The difference from Example 1 is that in step (1), sulfonate and sodium dodecylsulfonate are used to carry out surface modification treatment on diamond micropowder successively; in step (2), the resin emery blended material The percentage by weight of each component in is: resin binder 17wt%, organic solvent 38wt%, diamond micropowder 20wt%, SiC superfine powder 25wt%; Wherein resin binder is epoxy resin; Step (3) sends The line speed is 0.1m / s; in step (4), heat and cure at 400°C for 30 minutes; in step (5), raise the temperature to 500°C within 40 hours, keep the temperature for 5 hours, and then cool down to room temperature naturally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com